Spiral ore vertical mill threedimensional view drawing method

.jpg)

Solid Edge’s Application in Vertical Mill Design Springer

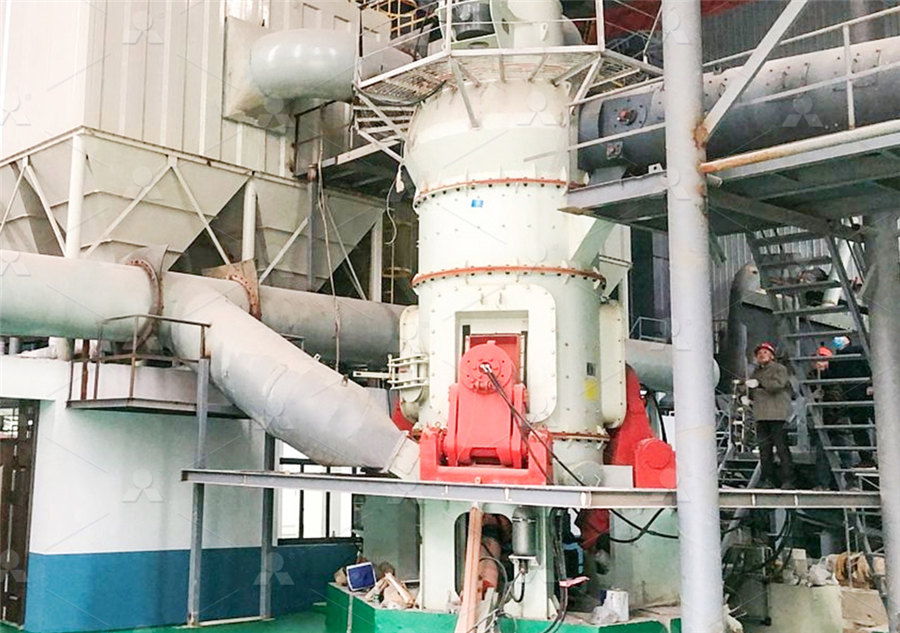

Threedimensional software can directly use threedimensional models to generate twodimensional engineering drawings, freeing designers from the dilemma of drawing various The invention relates to a method for manufacturing a spiral supporting plate of a large vertical mill, which can effectively solve the problems of inconvenient operation and incapabilityCNA Manufacturing method of spiral Google 2019年1月17日 The animation and pictures demonstrated by the threedimensional production plan of the vertical mill fully demonstrate the product’s structure and performance Solid Edge’s Application in Vertical Mill DesignIts classification efficiency and the pressure difference determine the entire producing capacity and power consumption, respectively, which makes them the two key indicators describing the The 3D geometry model of the vertical roller mill 1: separator

(PDF) Design and Optimization of Working Parts of Vertical Spiral

2022年6月28日 Using ANSYS preprocessor, the finite element model of cutting soil with spiral cutter is established, and the implicit functional relationship between milling force factor and 2023年12月4日 An industrialscale vertical roller mill has been developed and successfully simulated employing the discrete element method Analysis of the VRM to many operational Numerical Investigation of Vertical Roller Mill Operation Using Our experienced Product Development team utilise the latest 3D CAD/DEM modelling software and 3D laser equipment to ensure overall fit complies with the machine The software provides Vertical Mill 3D DEM Modelling Bradken2015年4月1日 Four different samples of iron ore were tested in a pilotscale grinding circuit with a vertical mill (Metso) and a high frequency screen (Derrick) The tests were performed using Vertical mill simulation applied to iron ores ScienceDirect

Research on the dynamics of grinding medium in vertical spiral

Firstly, threedimensional model of vertical mill and the fluid and medium ball model completing parameter calibration is set, the motion of medium ball in the grinding cylinder under wet 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and Spiralator is a free, easytouse, mobilefriendly, online geometric drawing tool inpired by the Spirograph toy Explore infinite fascinating geometries Create vector graphics SVG files Design your own complex rotational patterns Share your work in Spiralator Spirograph Drawing Tool Free Online Mobile PC SVG 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill single particle breakage method is allowing us to observe the data in a threedimensional (3D) view (PDF) Performance Evaluation of Vertical Roller Mill

(PDF) Industrial Vertical Stirred Mills Screw Liner Wear Profile

2021年4月10日 Data from a vertical stirred mill screw liner wear measurement obtained in a fullscale mill ar e used to correlate with simulation results The results indicate a relative agreement with industrialSurgery 1983; 94:159– 165 34 Vannier MW, Marsh JL, Warren JO Three dimensional CT reconstruction images for craniofacial surgical planning and evaluation Radiology 1984; 150: 179–184 35 Fishman EK, Magid D, Ney DR, Drebin RA, Kuhlman JE Threedimensional imaging and display of musculoskeletal anatomy J Comput Assist Tomogr 1988; 12: Threedimensional Volume Rendering of Spiral CT Data: Theory and Method2020年3月15日 Investigating grinding media dynamics inside a vertical stirred mill using the discrete element method: This assumption was proved by measuring the macroscopic temperature inside the mill chamber for the three impeller designs Driven by the same Aerodynamic classification in a spiral jet mill Powder Technol, 243 (2013), Investigating grinding media dynamics inside a vertical stirred mill 2020年8月1日 To understand the mechanism of hangup phenomena, ore flow simulations in long and vertical ore passes were carried out using the threedimensional discreteelement method, and the influences of Analysis of Ore Pass HangUps in Long Vertical Ore Passes by 3

Industrial Vertical Stirred Mills Screw Liner Wear Profile Compared

wear profile is commonly estimated in twodimensional methods, taking the assumption that wear has a uniform profile More recently, with the advent of new technologies, it is easier to perform threedimensional measurements, and there MM SCIENCE JOURNAL I 2018 I JUNE 2403 experiment is required The milling operation for gear cutting was carried out on a 3axis machining centre (Brigdeport VMC 2216, USA), as shown in Figure 5MANUFACTURING METHOD OF SPIRAL BEVEL GEARS BASED ON The first pitch length varies in the range of L = 40–160 mm, and spiral guide vane turns are 05–3 Threedimensional simulations are performed using ANSYS FLUENT software when the Reynolds Schematic drawing of a spiral separator [22] ResearchGateDownload scientific diagram VERTICAL ROLLER MILL TECHNICAL DETAILS from publication: Grinding process optimization — Featuring case studies and operating results of the modular vertical roller VERTICAL ROLLER MILL TECHNICAL DETAILS

Investigating the effect on power draw and grinding performance

DOI: 101016/jmineng2020 Corpus ID: ; Investigating the effect on power draw and grinding performance when adding a shell liner to a vertical fluidised stirred media millDownload scientific diagram Threedimensional model of spiral blade from publication: Design and Optimization of Working Parts of Vertical Spiral Ditching Machine Based on Milling Force and BP Threedimensional model of spiral blade2023年12月4日 21 Vertical Roller Mill The VRM shall have three or four rollers and a table The rollers were pressed against the ore and table using hydraulic cylinders during operation The table is rotated by an external drive train, and rollers are counterrotated due to the friction between the roller and materialNumerical Investigation of Vertical Roller Mill Operation Using Threedimensional (3D) medical images of computed tomographic (CT) data sets can be generated with a variety of computer algorithms The three most commonly used techniques are shaded surface display, maximum intensity projection, and, more recently, 3D volume rendering Implementation of 3D volume Threedimensional volume rendering of spiral CT data: theory and method

.jpg)

MANUFACTURING METHOD OF SPIRAL BEVEL GEARS BASED ON

machining spiral bevel gears on a 3axis CNC machine can be a suitable choice This paper describes a practical method based on CAD/CAM and 3axis CNC machining to manufacture spiral (PTC, USA) is used for three dimensional (3D) modelling and tool path planning to machine spiral bevel gears on a 3axis machining centre2018年11月14日 Vertical stirred mills have been widely used in the regrinding process in mining operations for its efficiency over other conventional mills Screw liner wear prediction in these regrinding QUALITATIVE ANALYSIS OF THE SCREW LINER WEAR PREDICTION IN VERTICAL Studies investigating these metrics have digitized the spiral exam through scanned paper drawings (13)(14)(15) or Wacom tablet applications, which capture pen strokes from a penandpaper drawing Example of the original drawing of Archimedes' spiral, 2016年2月2日 Request PDF Observation of Iron Ore Beneficiation within a Spiral Concentrator by Positron Emission Particle Tracking of Large (Ø≈1440μm) and Small (Ø≈58μm) Hematite and Quartz Tracers Observation of Iron Ore Beneficiation within a Spiral Concentrator

.jpg)

Engineering Working Drawings Basics

ThreeDimensional Views Working drawings usually include a threedimensional view (or views) of the part or assembly as needed (but it is not a must) Axonometric Views An axonometric view is a view in which an object appears to be rotated to show its all three dimensions Axonometric views are classified according to how the axesThe invention discloses a spiral ore feeding device of a ball mill, which comprises a pentagonal prism ore feeding box body, an ore feeding bent pipe and a left spiral ore feeding device which are sequentially connected; the left spiral feeding device is arranged in the hollow shaft of the ball mill, is connected with the barrel of the ball mill and rotates together with the barrel, and a CNA Spiral ore feeding device of ball mill and using method 2020年10月9日 In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the particles by controlling three Operation Analysis of a SAG Mill under Different finite duration from the event driven method Moreover, Two and three dimensional DEM simulations of ball mill were primary reported by [2] and [3] De Carvalho et al [4] proposed a mechanistic model to describe grinding iron ore pellet feed in pilot and industrial scale ball mills by simulations using DEMSimulations of Planetary Ball Mill Using Discrete Element Method

(PDF) Blockage Simulation of Vertical Shaft for Ore CarryOut

2014年1月1日 To understand the mechanism of hangup phenomena, ore flow simulations in long and vertical ore passes were carried out using the threedimensional discreteelement method, and the influences of Minerals 2022, 12, 133 3 of 12 22 Experimental Setup The device (Figure2) used in this investigation in China was a specially designed laboratoryscale VRM with a production capacity of 02 t/hRoller Mill Based on Experimental Method ResearchGate2021年6月23日 The isometric view (a) of the CAD geometry used for CFDDEM simulations of the jet mill [28,29] The red section in the top (b) and front (c) view of the geometry depicts the particle factory in Numerical Simulation of Particle Dynamics in a Spiral Jet Mill 2023年5月18日 The vertical stirred mill is vertically installed, and gravity works in the grinding process With the advantages of high grinding efficiency and less area occupation, it is widely used in the regrinding, fine grinding, and ultrafine grinding process of such metal mines as iron ore, copper ore, leadzinc, and such nonmetallic mineral industries as calcium carbonate, Stirred Mill SpringerLink

.jpg)

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2022年1月23日 Based on the Box–Behnken method, the experimental tests on three factors and three levels were carried out in the DesignExpert software (806, StatEase, Minneapolis, USA) As reported by Boehm [Analysis and Optimization of Grinding Performance of Vertical 2002年1月31日 The application of PEPT has allowed a detailed study of the motion of media in a stirred grinding mill Further analysis of this motion has identified the main differences between this media Measurement of the motion of grinding media in a vertically 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and

Spiralator Spirograph Drawing Tool Free Online Mobile PC SVG

Spiralator is a free, easytouse, mobilefriendly, online geometric drawing tool inpired by the Spirograph toy Explore infinite fascinating geometries Create vector graphics SVG files Design your own complex rotational patterns Share your work in 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill single particle breakage method is allowing us to observe the data in a threedimensional (3D) view (PDF) Performance Evaluation of Vertical Roller Mill 2021年4月10日 Data from a vertical stirred mill screw liner wear measurement obtained in a fullscale mill ar e used to correlate with simulation results The results indicate a relative agreement with industrial(PDF) Industrial Vertical Stirred Mills Screw Liner Wear Profile Surgery 1983; 94:159– 165 34 Vannier MW, Marsh JL, Warren JO Three dimensional CT reconstruction images for craniofacial surgical planning and evaluation Radiology 1984; 150: 179–184 35 Fishman EK, Magid D, Ney DR, Drebin RA, Kuhlman JE Threedimensional imaging and display of musculoskeletal anatomy J Comput Assist Tomogr 1988; 12: Threedimensional Volume Rendering of Spiral CT Data: Theory and Method

.jpg)

Investigating grinding media dynamics inside a vertical stirred mill

2020年3月15日 Investigating grinding media dynamics inside a vertical stirred mill using the discrete element method: This assumption was proved by measuring the macroscopic temperature inside the mill chamber for the three impeller designs Driven by the same Aerodynamic classification in a spiral jet mill Powder Technol, 243 (2013), 2020年8月1日 To understand the mechanism of hangup phenomena, ore flow simulations in long and vertical ore passes were carried out using the threedimensional discreteelement method, and the influences of Analysis of Ore Pass HangUps in Long Vertical Ore Passes by 3 wear profile is commonly estimated in twodimensional methods, taking the assumption that wear has a uniform profile More recently, with the advent of new technologies, it is easier to perform threedimensional measurements, and there Industrial Vertical Stirred Mills Screw Liner Wear Profile Compared MM SCIENCE JOURNAL I 2018 I JUNE 2403 experiment is required The milling operation for gear cutting was carried out on a 3axis machining centre (Brigdeport VMC 2216, USA), as shown in Figure 5MANUFACTURING METHOD OF SPIRAL BEVEL GEARS BASED ON

Schematic drawing of a spiral separator [22] ResearchGate

The first pitch length varies in the range of L = 40–160 mm, and spiral guide vane turns are 05–3 Threedimensional simulations are performed using ANSYS FLUENT software when the Reynolds