Gypsum powder frying equipment

.jpg)

Gypsum Dryer Henan Jiechang Machinery

1 Using chemical gypsum (flue gas desulfurization gypsum etc ) to stirfry into βhemihydrate gypsum powder; 2 The process guarantees the precision control of stirfrying time and temperature requirements of calcined gypsum powder; 3 This machine is specialized developed for frying β semihydrated gypsum powder and architectural gypsum podwer on the base of the technology of rotary dryer and food work machinegypsum rotary dryerEcofriendly Gypsum Plaster Powder Frying Boiler Machine For Sale , Find Complete Details Ecofriendly Gypsum Plaster Powder Frying Boiler Machine for Sale1 Using chemical gypsum (flue gas desulfurization gypsum, ardealit, etc) to stirfry into βhemihydrate gypsum powder; 2 The process guarantees the precision control of stirfrying time and temperature requirements of calcined gypsum Desulfurization Gypsum DryerGypsum Powder

.jpg)

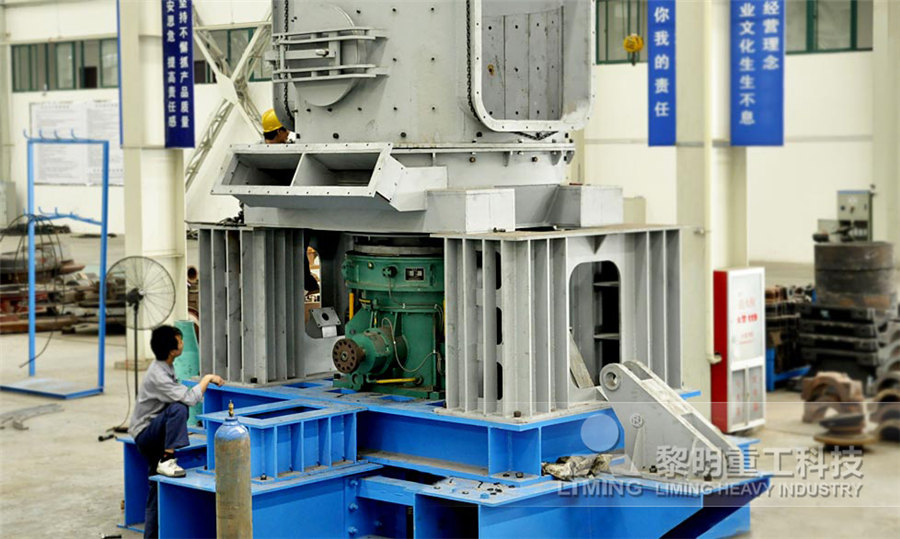

Gypsum Powder Production Line Gypsum Powder Making

2013年11月19日 Gypsum Powder Production Line, Find Details and Price about Gypsum New Type Fluidized Bed Furnace Frying Boiler / Gypsum Plaster Powder Production Line Manufacturing Plant, Find Details and Price about Gypsum Powder Machinery Gypsum Powder Equipment from New Type Fluidized Bed New Type Fluidized Bed Furnace Frying Boiler / We offer all devices that are required in a architectural plaster or gypsum plant We over 80 equip advanced modern manufacturing devices, including 2 double housing planing machines, 1 gantry milling machine, 2 boring machines, 3 50 Home Gypsum Processing Equipment ManufacturerWe are Gypsum Board Production Equipment Heat Transfer Oil Radiation Drying Type ManufacturersSuppliers,welcome to contact us here for what you are looking for: Industrial Gypsum Powder Equipment +35 +56 jrjx888@163 contact us EMail:jrjx888@163 Mobile:+35Gypsum Board Production Equipment Heat Transfer Oil Radiation

Gypsum board manufacturing machine, Gypsum Board Production Equipment

We produce Gypsum board manufacturing machine and Gypsum Board Production Equipment,if you need our products,pls contact us here for what you are looking for: Industrial Gypsum Powder Equipment +35 +56 jrjx888@163 contact us EMail:jrjx888@163 Mobile:+35We are Hot Air Drying Type of Gypsum Board Production Equipment ManufacturersSuppliers,welcome to contact us here for what you are looking for: Industrial Gypsum Powder Equipment +35 +56 jrjx888@163 contact us EMail:jrjx888@163 Mobile:+35Hot Air Drying Type of Gypsum Board Production Equipmentlntroduction Gypsum rotary dryer is manufactured to dry FGD gypsum, phosphogypsum, titanium gypsum, fluorogypsum, gypsum powder, gypsum plaster and other materials Dongding desulfurization (phosphogypsum) gypsum drying equipment process is advanced The gypsum rotary dryer is of high thermal efficiency, low energy consumption, small occupation area, Gypsum Rotary DryerIndustrial DryerProductdryerequipmentGypsum calcining method and equipment thereof The present invention is low in order to overcome in the existing gypsum production technology productivity, the shortcoming that labor condition difference or facility investment are big, change traditional " Po Sui Fen Sui oven dry " technical process, provide a kind of method (its technical process is: " Po Sui Hong Gan Ypsum Calcining Equipment

Synthetic Gypsum Processing Equipment FEECO International Inc

EQUIPMENT FEECO provides a variety of equipment and services for all types of synthetic gypsum From initial feasibility testing, to process scaleup and the manufacture of custom synthetic gypsum processing equipment, we can design and build a complete processing solution tailored to your distinctive requirements Bucket Elevator: Transports the crushed gypsum ore to the next processing stage 2 Grinding Mill The grinding mill is a crucial part of the gypsum powder production line It grinds the crushed gypsum ore into a fine powder with a specific fineness The following equipment is commonly used in this stage: Raymond Mill: A popular choice for An overview of equipment used for producing 300,000 tons of gypsum Cover walls, ceilings, plasters, fertilizers, cosmetics and some foods: gypsum’s vast applications granted it the recognition of “wonder mineral” Gypsum making equipment helps in making gypsum powder or board for industrial useGypsum making equipment MakingHighgrade gypsum is mostly used as raw material for the production of special gypsum products, such as food, medical, artwork, models and chemical fillers; gypsum mines with calcium sulfate dihydrate content of less than 60% are rarely used; more than 60% The gypsum ore, depending on its content, is used in various fields such as building materials and constructionGypsum Powder Production Line

Gypsum Rotary Dryer Drying equipment for sale

Gypsum Dryer Application The rotary dryer is suitable for drying powder and granular materials with special requirements, like gypsum, desulfurization gypsum, titanium gypsum, phosphogypsum, fluorgypsum, ore, blast furnace slag, coal, metal powder, phosphate fertilizer, ammonium sulfate, etcThe Chinese company is located in Linyi city, Shandong ProvinceWe are a largescale professional factory with independent research and design, production and sales of building materials machinery, accumulating richly experience in equipment designmanufacturing,installation and commissioningFactory in China,the main products are Yuanteng Machinery Equipmentgypsum boardgypsum powderBauxite Gypsum Bauxite, gypsum, Enjoy a generous 50% discount on select used equipment such as Gencor Burners, Clay Feeder, and Quench Tower This fantastic offer is valid from November 24, 2024 through November 30, 2024 Calcining Vulcan® Drying SystemsGypsum is a monoclinic mineral and is a hydrate of calcium sulfate (CaSO4) Natural dihydrate gypsum (CaSO42H2O) is also called raw gypsum After calcination and grinding, βtype hemihydrate gypsum (2CaSO4H2O) can be obtained, which is architectural gypsum, also known as plaster of paris and plaster Gypsum is a widely used industrial material and building Gypsum Drying and Calcination Technology Jinan, Shandong,

.jpg)

FGD Gypsum Rotary Dryer, Industrial Gypsum Drying Machine

The gypsum rotary dryer is suitable for drying powder and granular materials with special requirements With strong overload resistance, large capacity, low fuel consumption and low drying cost The FGD gypsum dryer is a drying equipment used to remove water from desulfurized gypsum2019年4月1日 The temperature at which gypsum transforms to hemihydrate and anhydrite, however, depends on a number of parameters such as the gypsum's pore water pressure, vapor pressure (for unsaturated conditions), chemicals in the pore water as well as whether the gypsum is natural or synthetic (Ramsdell and Partridge, 1929, HudsonLamb et al, 1996, Gysel, 2002, Analysis of drying and saturating natural gypsum samples for mechanical Other Popular Powder Drying Methods In addition to spray drying, other methods of drying, such as evaporation and granulation are commonly used in industrial settings Here are some of the most popular methods for drying powders: Drum Drying: In this method, a thin layer of slurry is spread onto the surface of a rotating drum The hot drum surface causes the water in the Powder Drying Making2024年8月12日 Crushing and Grinding: The raw gypsum is crushed and ground into a fine powder to prepare it for further processing Calcination: You then heat the ground gypsum in a process called calcination, which removes water from the gypsum’s crystal structure, producing hemihydrate gypsum (CaSO₄05H₂O), also known as plaster of ParisGypsum: Applications, Manufacturing and Optimal Drying Solutions

.jpg)

Drying Systems for Powders Bulk Solids Hosokawa Micron

We provide skids for heating or cooling the drying equipment and for cooling ancillaries A process air heater can be selected depending on utilities, such as steam, electricity or gas Condenser / vacuum skid One way to eliminate large vacuum pump systems or to reduce solvent emissions is to install a condenser in combination with a receptacleBuy Gypsum board/plasterboard drying microwave dehydrating equipment from Shandong Industrial Microwave Oven,Microwave equipment Distributor such as talcum powder, gypsum, gypsum board, copper carbonate etc This machine also fits for drying and sterilizing powders, granular, sheet frying machine; Core Filling Snacks Processing Line;Gypsum board/plasterboard drying microwave dehydrating equipmentZZ Group is a professional gypsum processing equipment manufacturer and gypsum plant solution provider, STATEOFTHEART TECHNOLOGY TO PROVIDE GYPSUM WALLBOARD AND GYPSUM POWDER PLANT Established in 1998; 45 plant projects (20112018) Production power up to 50 million m2/year;Home Gypsum Processing Equipment Manufacturer Gypsum 2011年8月10日 This equipment is specialized developed for frying βsemihydrated gypsum powder and architectural gypsum powder on the base of the technology of rotary dryer equipment and food wok equipment Main characteristics: Can make use of the chemical gypsum (desulfurization gypsum, phospho gypsum, and others) to fry to βsemiwater gypsum powder High drying capacity Gypsum dryer equipment

.jpg)

Desulfurization Gypsum Drying And Calcination

Equipment features: The Sid calciner, which is developed by Dongda Powder Company, is an integrated high efficiency equipment to drying, calcining, and dispersing the material, also known as onestep process equipment It is 2011年8月3日 This machine is specialized developed for frying βsemihydrated gypsum powder and architectural gypsum powder on the base of the technology of dryer machinery and food wok machine Main characteristics: Can make use of the chemical gypsum (desulfurization gypsum, phospho gypsum, and others) to fry to βsemiwater gypsum powder directlyDrying Equipment: Highefficiency Gypsum dryer machinery2018年10月10日 The bulk powder test may offer a simpler option, although it has some limitations Bulk powder test 4 A bulk powder test is used to evaluate selfheating properties of powder in quantities not exceeding 1 ton in situations when it is heated in bulk form Examples include powder accumulations in bulk in some dryers, hoppers, silos or packagingWays to achieve safe powder drying Processing Magazine2011年9月3日 Gypsum dryer Main characteristics: Can make use of the chemical gypsum (desulfurization gypsum, phospho gypsum, and more) to fry to βsemiwater gypsum powder directly Ensure the requirements of burning gypsum powder precise control frying time and temperature in the process Exit design of wok machine is reasonable, operation without dust Drying Equipment: Gypsum dryer

.jpg)

Gypsum Board Making Machine Manufacturer, Light Mineral

Shijiazhuang Wuxing Mechanical Co, Ltd Was founded in 2004, the former stateowned enterprises We are a focus on gypsum board production line, gypsum powder production line, calcium silicate board production line, mineral wool board production line and cellulose equipments, RD, manufacturing, sales, installation, debugging and training in the integration Rotary Packing Machines Rotary packing machines allows faster production, have 4, 6, 8, 10 or 12 spouts, filling with rotor or air High PrecisionProduction equipment for gypsum, gypsum plaster, 2013年11月19日 Gypsum Powder Production Line, Find Details and Price about Gypsum Powder Making Equipment from Gypsum Powder Production Line Henan Dafu Mechanical Import and Export Co, Ltd Home Product Directory Manufacturing Processing Machinery Building Material Making Machinery Gypsum Powder MachineGypsum Powder Production Line Gypsum Powder Making EquipmentEstablished in 1998, LVJOE is dedicated to developing and manufacturing gypsum and plaster processing equipment, we offer complete gypsum, gypsum board, gypsum block, etc plant solutions and services Home; About Us; Products Solution Natural Gypsum Powder Plant Chemical gypsum usually contains 10% of free water, Gypsum and plaster processing equipment Gypsum Plant

Gypsum Board Production Equipment Heat Transfer Oil Radiation

We are Gypsum Board Production Equipment Heat Transfer Oil Radiation Drying Type ManufacturersSuppliers,welcome to contact us here for what you are looking for: Industrial Gypsum Powder Equipment +35 +56 jrjx888@163 contact us EMail:jrjx888@163 Mobile:+35We produce Gypsum board manufacturing machine and Gypsum Board Production Equipment,if you need our products,pls contact us here for what you are looking for: Industrial Gypsum Powder Equipment +35 +56 jrjx888@163 contact us EMail:jrjx888@163 Mobile:+35Gypsum board manufacturing machine, Gypsum Board Production Equipment We are Hot Air Drying Type of Gypsum Board Production Equipment ManufacturersSuppliers,welcome to contact us here for what you are looking for: Industrial Gypsum Powder Equipment +35 +56 jrjx888@163 contact us EMail:jrjx888@163 Mobile:+35Hot Air Drying Type of Gypsum Board Production Equipmentlntroduction Gypsum rotary dryer is manufactured to dry FGD gypsum, phosphogypsum, titanium gypsum, fluorogypsum, gypsum powder, gypsum plaster and other materials Dongding desulfurization (phosphogypsum) gypsum drying equipment process is advanced The gypsum rotary dryer is of high thermal efficiency, low energy consumption, small occupation area, Gypsum Rotary DryerIndustrial DryerProductdryerequipment

.jpg)

Ypsum Calcining Equipment

Gypsum calcining method and equipment thereof The present invention is low in order to overcome in the existing gypsum production technology productivity, the shortcoming that labor condition difference or facility investment are big, change traditional " Po Sui Fen Sui oven dry " technical process, provide a kind of method (its technical process is: " Po Sui Hong Gan EQUIPMENT FEECO provides a variety of equipment and services for all types of synthetic gypsum From initial feasibility testing, to process scaleup and the manufacture of custom synthetic gypsum processing equipment, we can design and build a complete processing solution tailored to your distinctive requirementsSynthetic Gypsum Processing Equipment FEECO International Inc Bucket Elevator: Transports the crushed gypsum ore to the next processing stage 2 Grinding Mill The grinding mill is a crucial part of the gypsum powder production line It grinds the crushed gypsum ore into a fine powder with a specific fineness The following equipment is commonly used in this stage: Raymond Mill: A popular choice for An overview of equipment used for producing 300,000 tons of gypsum Cover walls, ceilings, plasters, fertilizers, cosmetics and some foods: gypsum’s vast applications granted it the recognition of “wonder mineral” Gypsum making equipment helps in making gypsum powder or board for industrial useGypsum making equipment Making

.jpg)

Gypsum Powder Production Line

Highgrade gypsum is mostly used as raw material for the production of special gypsum products, such as food, medical, artwork, models and chemical fillers; gypsum mines with calcium sulfate dihydrate content of less than 60% are rarely used; more than 60% The gypsum ore, depending on its content, is used in various fields such as building materials and constructionGypsum Dryer Application The rotary dryer is suitable for drying powder and granular materials with special requirements, like gypsum, desulfurization gypsum, titanium gypsum, phosphogypsum, fluorgypsum, ore, blast furnace slag, coal, metal powder, phosphate fertilizer, ammonium sulfate, etcGypsum Rotary Dryer Drying equipment for sale