Quicklime ball mill

.jpg)

Ball mills for various applications Gebr Pfeiffer

Hundreds of ball mills made by Pfeiffer to suit the customers’ particular requirements operating all over the world In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive In Pfeiffer lime hydrators, quicklime lumps are converted into lime hydrate by adding water In downstream Pfeiffer separators, highpurity lime hydrate is separated from the grits These are ground to target fineness in ball mills Quicklime preparation Gebr Pfeiffer2016年10月19日 Vibrated ball mill can be selected as grinding mill for quickl ime to obtain finer powders in less grinding time Keywords: grinding optimization, quicklime, particle size, Optimization of Grinding Parameters of Quicklime CaO at Slaking occurs when quicklime is reacted with water to form Ca(OH) 2, most commonly called hydrated lime in its dry form or lime slurry or milk of lime in its wet form The slaking process is exothermic, releasing heat as the quicklime Lime Slaking Systems Carmeuse

Ball Mills Lime Systems

We offer a range of ball mills in various sizes and configurations to cater to different grinding requirements Whether you need a small labscale ball mill for testing or a large industrial ball mill for highcapacity grinding, we can MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materialsCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsIn fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds as coarse Vertimill® Metsoslakers, or the ball mill media in a ball mill slaker In the case of paste slakers, proper mixing is also needed to mitigate against the risk that localized hotspots (ie, above boiling point) will develop in the slurry The final factor to impact lime slaking is steam control The slaking reactionLIME SLAKING 101 Carmeuse

Limestone Mill for Limestone Powder Grinding ball

Quicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be obtained, As a ball mills supplier with 22 years of Standard Horizontal Ball Mills are sometimes used for lime slaking Considering that Ball Mills are designed for grinding, and the slaking process is simply a chemical process, it is obvious that the use of a Ball Mill for slaking is not the best choice of equipment in most cases However, there are a few cases where the use of a Ball Mill A REVIEW OF LIME SLAKERS 911 MetallurgistIn Pfeiffer lime hydrators, quicklime lumps are converted into lime hydrate by adding water In downstream Pfeiffer separators, highpurity lime hydrate is separated from the grits These are ground to target fineness in ball mills which operate in closed circuit with separators, thus producing building limeQuicklime preparation Gebr Pfeiffermounted ball mills suitable for quicklime slaking and regrind applications The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime SystemsCOMPLETE PLANT CAPABILITY LIME SYSTEMS LTD

.jpg)

Lime Slaking Systems Carmeuse

Quicklime as CaO is not the most useful chemical form for many applications For applications such as water treatment, flue gas treatment, and when used as a raw ingredient to some chemical applications, batch type / mix tanks, vertical ball mill, Ball Mill The ball mill has two primary functions within the quicklime slaking system; firstly the reduction of quicklime / hydrated lime into smaller particles critical to the correct reaction with process, and secondly provide a rotating vessel to allow majority for the chemical reaction to LIME SLAKING SYSTEMS Bulk Handling Technologies AustraliaQuicklime, also known as calcium oxide (CaO) or simply lime, is produced by heating limestone or calcium carbonate in big furnaces During this heating process, CO2 is released from the stone, resulting in the formation of CaO along with some other small mineral components This CaO byproduct is what’s commonly recognised as high calcium Lime Slaking Systems Quicklime Slakers Lime SystemsTongli Heavy Machinery It was first established in 1958 After working hard for more than 65 years, Tongli has owned the firstclass science and technology development centers and craftsmen team with much experience and skilled technology, especially in manufacturing series of cement production equipment such as rotary kiln, ball mill, vertical roller mill, etcABOUTTongli Machinery

Crusher; Grinding Mill; Rotary Dryer Manufacturer, Cone Crusher,

Lab Ball Grinding Mill Ball Mill Machine Grinder Copper Ore Cement Gypsum Coal Limestone Grinding Ball Mill Factory Price FOB Price: US $5,50010,000 / Piece Min Order: 1 PieceBall Mill MATERIALS MORE Calcite Bentonite Bauxite Barite CASES MORE 500,000 TPY Heavy Calcium Carbonate Grinding Plant VIEW MORE Quicklime Grinding Plant VIEW MORE 5TPH Clay Grinding Plant VIEW MORE 30TPH Coal Grinding Plant VIEW MORE BLOGS MORE 7 Key Differences Between Raymond Mill And Vertical Roller Mill Bauma Grinding Mill, China Grinding Mill, Grinding PlantCarmeuse Systems provides the ZMI Portec Detention Slaker The ZMI Portec Detention Slaker slakes quicklime (particle size up to ¾”) and produces slurry with up to 30% solids Vertical Ball Mill Slakers When lime or water quality is poor and/or when lime consumption rates are high, we design slaking systems utilizing a vertical ball millLime Slaking Equipment Carmeuse2017年1月11日 Limestone Grindability Determination by the Laboratory Ball Mill Method 13 Settling Rate of Hydrated Lime 14 Particle Size Analysis Residue and Sieve Analysis 15 Sieve Analysis of Dry Limestone, Quicklime, and Hydrated Lime 16 Fineness of Pulverized Quicklime and Hydrated Lime by Air Permeabiity 17C110 Standard Test Methods for Physical Testing of Quicklime,

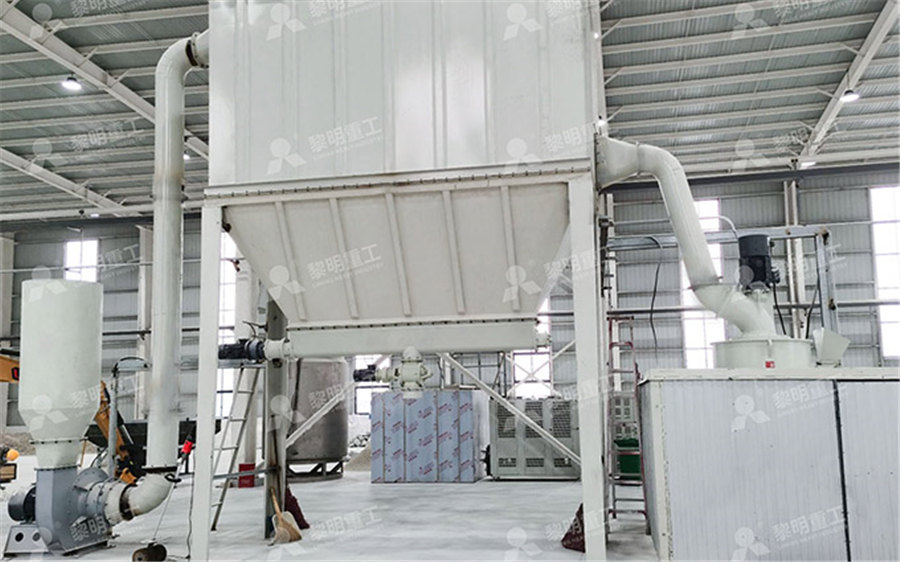

Quicklime vertical roller mill

A quicklime vertical roller mill is a specialized equipment used for grinding and processing quicklime Quicklime, also known as burnt lime, is mainly composed of calcium oxide (CaO) It is usually prDownload Table Comparison of ball mills according to experimental results from publication: Optimization of Grinding Parameters of Quicklime CaO at Different Mills Grinding, Milling and Comparison of ball mills according to experimental resultsBall mills normally operate with an approximate ball charge of 30% Ball mills are characterized by Stirred mills are also common for mixing quicklime (CaO) into a lime slurry There are several advantages to the tower mill: low noise, efficient energy usage, and low operating costs Table top hammer mill Vertical shaft impactor Mill (grinding) Wikipedia2024年5月17日 A ball mill is a type of grinder used to grind and blend materials for use in various industrial applications It operates on the principle of impact and attrition, where the grinding media (usually steel balls) are used to break down the materialUnderstanding Ball Mill Parts: Essential Components for Effective

Type Selection of Quicklime Deep Processing EquipmentNewsultramill

2022年12月22日 The vertical mills, highpressure mills, and micropowder mills developed and produced by CLIRIK have won high praise from users in quicklime processing CLIRIK has been committed to the research and development of energysaving and environmentally friendly grinding equipmentAn apparatus for grinding quicklime comprising a ball mill, means for continuously supplying quicklime to said ball mill, means for continuously exhausting ground quicklime having a predetermined fineness from said ball mill, and means associated with said supplying means for adding a predetermined small proportion of water to said quicklime to be ground, the weight USA Method of grinding quicklime Google PatentsVertical Mill Slaker No matter the quality of lime or water, Westpro’s Vertical Mill Slaker provides excellent slaking of lime Additionally, our Vertical Mill’s high efficiency will ensure the complete use of the quicklime regardless of the LIME SLAKING AND LIME MIXING SYSTEMS Westpro In detention and ball mill slakers, we would typically expect a slaking temperature between 175°F and 185°F (794°C and 850°C); in paste slakers, ball mill and paste) As quicklime constantly moves through these types of slaker, it is important to ensure the quicklime spends enough time in the slaker to complete the slaking reactionTHE SIX FUNDAMENTAL FACTORS OF LIME SLAKING Carmeuse

Advancements in Lime Slaking Technology: What's New and Next

A rotating chamber contains metal grinding balls that pulverize quicklime fed in with water The violent tumbling action provides efficient particle size reduction and intimate mixing for fast, complete slaking Ball mills produce a dry, fine hydrate powder preferred for applications like mine dust suppression and Portland cement manufacturingThe ZMI Portec detention slaker from Carmeuse Systems slakes quicklime and produces a highly reactive lime slurry with up to 30% solids Skip to main content Language LanguageDetention Slaker Carmeuse SystemsAerated Brick Calcium Hydroxide Plant Use 22X65 Meter Quicklime Ball Mill, Find Details and Price about Quicklime Ball Mill Ball Mill from Aerated Brick Calcium Hydroxide Plant Use 22X65 Meter Quicklime Ball Mill ZHENGZHOU ZHENGJIA HEAVY INDUSTRY CO,LTDAerated Brick Calcium Hydroxide Plant Use 22X65 Meter Quicklime Ball MillIn detention and ball mill slakers, we would typically expect a slaking temperature between 175°F and 185°F (794°C and 850°C); in paste slakers, ball mill and paste) As quicklime constantly moves through these types of slaker, it is important to ensure the quicklime spends enough time in the slaker to complete the slaking reactionTHE SIX FUNDAMENTAL FACTORS OF LIME SLAKING Carmeuse

What is the difference between a SAG mill and ball mill?

Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%China Manufacturer Quicklime Grinding Cement Ball Mill for Sale US$3,2000011,20000: 1 Piece (MOQ)China Manufacturer Quicklime Grinding Cement Ball Mill for SaleThe standard quicklime feed system from Carmeuse Systems is designed as a compact ”slakerina box” system This modular chemical feed system provides an integrated solution for receiving, storing, feeding, slaking and delivering up to 2,500 lb/h of quicklime from truck to the point of applicationStandard Quicklime Feed System in a Box Carmeuse SystemsIn fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds as coarse Vertimill® Metso

.jpg)

LIME SLAKING 101 Carmeuse

slakers, or the ball mill media in a ball mill slaker In the case of paste slakers, proper mixing is also needed to mitigate against the risk that localized hotspots (ie, above boiling point) will develop in the slurry The final factor to impact lime slaking is steam control The slaking reactionQuicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be obtained, As a ball mills supplier with 22 years of Limestone Mill for Limestone Powder Grinding ball Standard Horizontal Ball Mills are sometimes used for lime slaking Considering that Ball Mills are designed for grinding, and the slaking process is simply a chemical process, it is obvious that the use of a Ball Mill for slaking is not the best choice of equipment in most cases However, there are a few cases where the use of a Ball Mill A REVIEW OF LIME SLAKERS 911 MetallurgistIn Pfeiffer lime hydrators, quicklime lumps are converted into lime hydrate by adding water In downstream Pfeiffer separators, highpurity lime hydrate is separated from the grits These are ground to target fineness in ball mills which operate in closed circuit with separators, thus producing building limeQuicklime preparation Gebr Pfeiffer

.jpg)

COMPLETE PLANT CAPABILITY LIME SYSTEMS LTD

mounted ball mills suitable for quicklime slaking and regrind applications The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime SystemsQuicklime as CaO is not the most useful chemical form for many applications For applications such as water treatment, flue gas treatment, and when used as a raw ingredient to some chemical applications, batch type / mix tanks, vertical ball mill, Lime Slaking Systems CarmeuseBall Mill The ball mill has two primary functions within the quicklime slaking system; firstly the reduction of quicklime / hydrated lime into smaller particles critical to the correct reaction with process, and secondly provide a rotating vessel to allow majority for the chemical reaction to LIME SLAKING SYSTEMS Bulk Handling Technologies AustraliaQuicklime, also known as calcium oxide (CaO) or simply lime, is produced by heating limestone or calcium carbonate in big furnaces During this heating process, CO2 is released from the stone, resulting in the formation of CaO along with some other small mineral components This CaO byproduct is what’s commonly recognised as high calcium Lime Slaking Systems Quicklime Slakers Lime Systems