Coal mill cylinder function

.jpg)

Coal Mill an overview ScienceDirect Topics

Coal mills or pulverizers play a very essential part in the coalfired power production system Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the Coal Pulveriser Mill Function and Operation details Pulverizer as shown in fig1 is used in power plant to reduce the size of the incoming raw coal to a fineness thatPulveriser Mill Performance Analysis Optimisation in Super2015年11月1日 Coal mills are one of the critical power plant components that influence the efficiency and reliability of a coal fired power plant The coal mill grinds the raw coal into fine A unified thermomechanical model for coal mill operation2023年9月8日 Hydraulic cylinders in coal mills are commonly used to regulate the pressure on grinding discs or wheels, aiding in controlling the coal pulverization process to achieve the desired fineness Besides pressure The hydraulic cylinder of the coal mill HOPETECH

.jpg)

Mathematical validation and comparison of ball tube and bowl

coal mill is an important component of a steam power plant which grinds precrushed raw coal particles of size 1020 mm to fine particles of size less than 150 μm using heated primary air te speed (30 to 60 rpm) about its axis It is recognized as the most advantageous design of the coal pulveriser because of its low initial cost, low ength is slightly more to its diameter The BHEL PRESENCE IN COAL MILLING EQUIPMENTThe BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in A Comparison of Three Types of Coal Pulverizers Babcock Power2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Coal mill pulverizer in thermal power plants PPT

(PDF) Modeling and Control of Coal Mill Academia

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control Using conventional methods, many results are reported in the form of transfer functions which are not derived from physical principles [2]Ball mill is a kind of grinding equipment for repulverizing primary crushed materials It is widely used in cement, construction, fertilizer, mineral processing, and other industries Ball mill grinder is used for dry or wet grinding of various 5 Mustknow Ball Mill Parts And Functions2021年5月20日 Operation Philosophy of Mill Reject Handling System (MRHS) The pneumatic cylinder operated plate valve at mill outlet (Pyrite Hopper inlet) is normally kept open Mill Rejects from coal mill will drop into the Pyrite Hopper through the MRHS Mill Reject Handling System in Thermal Power PlantDownload scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Technical specifications of vertical roller coal mill

.jpg)

Modeling and Control of Coal Mill

Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validation2022年8月10日 According to the running characteristics of vertical coal mill, KINGCERA has designed different wearresistant lining plates for coal mill barrel and coal mill shell The coal mill liner can be Mediumspeed coal mill wearresistant ceramic plate Composite Discover the efficient and versatile air swept coal mill for industrial applications Airswept coal mills produced by AGICO CEMENT have 13 models according to their cylinder sizes The diameter and length are between Φ1200×2400Φ2900×4700 which can realize functions such as remote monitoring, Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill2016年12月27日 Ball Mill Liner Function Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding Ball Mill Liner Function Wear Parts For Industry Qiming Casting

.jpg)

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

2021年8月5日 Pulveriser function is to crush/grinding the raw coal into a predetermined size in order to increase the surface area of the coal Hot air through the mill besides removing coal moisture, The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, Coal Mill Free download as PDF File (pdf), Text File (txt) or view presentation slides online This dissertation examines technologies to enhance the maintenance performance of coal pulverizers through new technologies It presents the results of testing modifications to rotating throat assemblies, spider and guide wear plates, ball loading cylinders, classifier cones, and Coal Mill PDF Mill (Grinding) IndustriesCoal Mill PPT Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document provides an overview of coal mill operation, protections, and interlocks It discusses Coal Mill PDF Combustion ChemistrySource every style of cylinders from Alibaba If you need a coal mill hydraulic cylinder search our wholesale cylinder range, with models for every industrial application All categories Featured selections Rolling Coal Mill Metal Hydraulic Cylinder $35000 Min Order: 1 pieceCoal mill hydraulic cylinder

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI The interior of the cement mill separator usually includes a conical cylinder, which is equipped with a set of rotating impellers When the cement clinker enters the separator from the cement mill, it will be forced to form in the cylinder through the action of the impellers swirling airflowCement Separator HighEfficiency Cement Mill Separator2015年11月1日 As presented by Andersen et al (2009) and Odgaard, Stoustrup, and Mataji (2007), coal moisture imposes limit on the maximum load at which a coal mill can be operated and the load gradient (how fast the mill may change its operating point), if it is desired that the pulverized coal entering the furnace has moisture content less than or equal to a certain value A unified thermomechanical model for coal mill operationCoal Pulveriser Mill Function and Operation details Pulverizer as shown in fig1 is used in power plant to reduce the size of the incoming raw coal to a fineness that will efficiently burn in a furnace [1] Fig 1 H P Pulveriser actual view and parts As in fig2 Pulveriser Mill Performance Analysis Optimisation in Super

.jpg)

Hydraulics OperationCoalMillpdf

Coal mill: A stop buffer on the rocker arm prevents the tires from coming into direct contact with the grinding plates Illustration Process and operation – LOESCHE Vertical Roller Mill Type Coal and Raw material 31Oct14 4 8,0 7,0 6,0 Cwf Spring stiffness of the roller 5,0 p1 Charging pressure of the hydraulic accumulator cwf Spring 2023年9月8日 The hydraulic cylinder of the coal mill Client: China Steel Corp Specification: CA220/125x200st Pressure Capabilities: 160 bar The coal mill is primarily used to grind coal or similar solid materials into smaller powder or granular states, commonly employed in industries such as steel mills, chemical plants, power plants, and paper mills that require the refinement The hydraulic cylinder of the coal mill HOPETECHLooking for coal mill cylinder factory direct sale? You can buy factory price coal mill cylinder from a great list of reliable China coal mill cylinder manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidence Supplier Discovery Sign In Join FreeCoal Mill Cylinder Factory, Custom Coal Mill Cylinder OEM/ODM unit The efficiency of the mill in providing the desired coal and air mixture to the furnace has increased cost consequences with the addition of NOx controls The repairs and modifications to the mills ensure that the mills operate reliably Keywords Pulverizer mill Exhauster Coal feeder Maintenance Reliability Troubleshooting Pulverizer Maintenance Guide, Volume 1 Raymond Bowl Mills

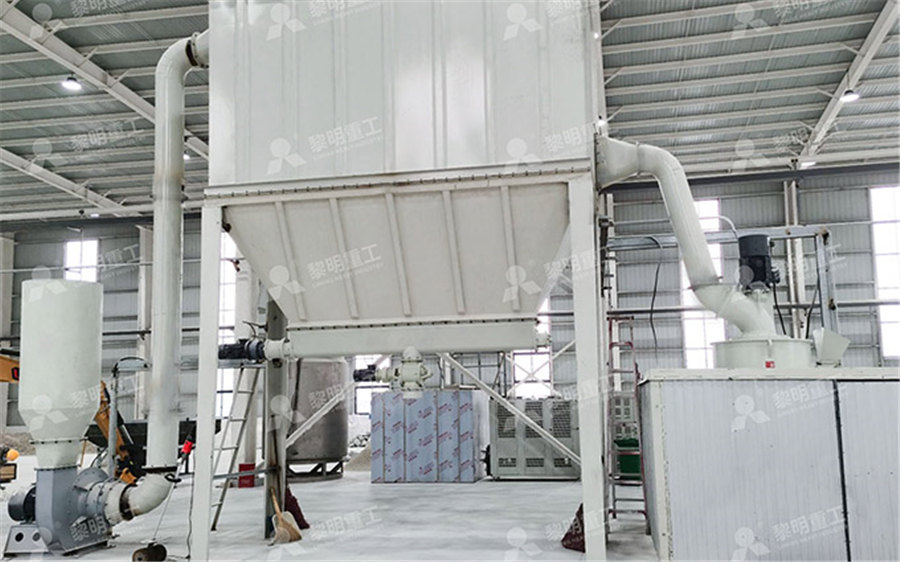

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying over range, low airtocoal ratio, ability to pulverise a wide range of coals, virtually unaffected by foreign material and the flexibility of available capacity Tube mills suitable for catering to coal throughput from 30 TPH to 110 TPH Bowl Mill is basically a vertical Mill rotating at Moderate speed (30 to 60BHEL PRESENCE IN COAL MILLING EQUIPMENTCoal is a vital source of energy in many industries worldwide From power generation to manufacturing, coal is used in various processes However, before it can be used, coal needs to be processed in a coal mill In this article, we will explore the basics of how a coal mill works Introduction Coal mills are []How does a Coal Mill Work? ball mills supplier2024年3月3日 coal mill Feedercoal mill Feeder1 (2) The document describes the components and functions of bowl mills and gravimetric feeders, and provides details on their control logic and IT IS USED FOR PROVIDING PATH FOR PA TO INDIVIDUAL MILL It consists OF – SOLENOID POWER CYLINDER LIMIT SWITCHES HOT AIR coal mill Feedercoal mill Feeder1 (2)ppt SlideShare

COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS

Since the first application using an MPS mill to process pulverized coal in Germany in the mid 1960s, there have been over 2,000 different MPS mill installations operating in coalfired power plants worldwide As one of the most popular coal pulverizers in the utility industry, the MPS mill was first introduced into the US in the early 1970s010Method Statement of Coal Mill Instattalation Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free This document provides a method statement for installing a coal mill at a project site It outlines the general components and purpose of the coal mill It then describes the responsibilities of personnel overseeing the installation010Method Statement of Coal Mill Instattalation PDF Scribdlonger service life and more convenient maintenance Hp1103 coal mill is a kind of HP coal mill Compared with similar coal mills, it has stronger adaptability to raw coal and is more suitable for large unit thermal power plants Taking hp1103 medium speed roller disc coal mill as the carrier, this paper mainly describes theSHPHGLXPVSHHGFRDOPLOO IOPscience2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required particle size and temperature at the outlet channel throughout with better classifier performance are crucial indicators that characterize the coal mill performanceAn investigation of performance characteristics and energetic

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control Using conventional methods, many results are reported in the form of transfer functions which are not derived from physical principles [2](PDF) Modeling and Control of Coal Mill AcademiaBall mill is a kind of grinding equipment for repulverizing primary crushed materials It is widely used in cement, construction, fertilizer, mineral processing, and other industries Ball mill grinder is used for dry or wet grinding of various 5 Mustknow Ball Mill Parts And Functions2021年5月20日 Operation Philosophy of Mill Reject Handling System (MRHS) The pneumatic cylinder operated plate valve at mill outlet (Pyrite Hopper inlet) is normally kept open Mill Rejects from coal mill will drop into the Pyrite Hopper through the MRHS Mill Reject Handling System in Thermal Power Plant

Technical specifications of vertical roller coal mill

Download scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal Mill2022年8月10日 According to the running characteristics of vertical coal mill, KINGCERA has designed different wearresistant lining plates for coal mill barrel and coal mill shell The coal mill liner can be Mediumspeed coal mill wearresistant ceramic plate Composite Discover the efficient and versatile air swept coal mill for industrial applications Airswept coal mills produced by AGICO CEMENT have 13 models according to their cylinder sizes The diameter and length are between Φ1200×2400Φ2900×4700 which can realize functions such as remote monitoring, Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill

.jpg)

Ball Mill Liner Function Wear Parts For Industry Qiming Casting

2016年12月27日 Ball Mill Liner Function Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding 2021年8月5日 Pulveriser function is to crush/grinding the raw coal into a predetermined size in order to increase the surface area of the coal Hot air through the mill besides removing coal moisture, The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, Pulveriser in Thermal Power Plant Bowl Mill Ball Mill