Mill Particle Size Analysis

A GUIDEBOOK TO PARTICLE SIZE ANALYSIS University of Iowa

Microscopy or automated image analysis are the only techniques that can describe particle size using multiple values for particles with larger aspect ratios WHICH SIZE TO MEASURE? A Microscopy or automated image analysis are the only techniques that can describe particle size using multiple values for particles with larger aspect ratios WHICH SIZE TO MEASURE? A A GUIDEBOOK TO PARTICLE SIZE ANALYSIS HoribaImpact mills use revolving hammers to strike incoming particles and to break or fling them against the machine case In jet mills, particles strike each other as they are transported in a stream of Particle size reduction, screening and size analysisParticle size reduction of solids or bulk materials is required when the particles are too coarse or the sample is too inhomogeneous for subsequent processes such as analysis, division, mixing Retsch: The art of Milling

.jpg)

Lab 3 – Particle Size Reduction, Screening and Size Analysis

Particles size reduction and analysis is necessary in obtaining the best particle sizes for various practical works In practice, powders with narrow range of size distribution can increase the Particle size analysis, particle size measurement, or simply particle sizing, is the collective name of the technical procedures, or laboratory techniques which determines the size range, and/or Particle size analysis WikipediaParticle size influences many properties of particulate materials and is a valuable indicator of quality and performance This is true for powders, suspensions, emulsions, and aerosols The A GUIDEBOOK TO PARTICLE SIZE ANALYSIS Moodle USP: e Explain the importance of particle size analysis and its application Differentiate between the different models used for predicting particle size Explain the different convention followed in measuring particle size Particles within a AMIT 135: Lesson 3 Particle Size Distribution – Mining

.jpg)

MODELING OF SIZE REDUCTION, PARTICLE SIZE ANALYSIS AND

Comparative study using RosinRammlerSperlingBennet (RRSB) and RosinRammler model parameters, including particle size analysis and flow characterization helps in identifying (DOI: 101016/JPOWTEC201909062) This article is published in Powder Technology The article was published on 01 Jan 2020 The article focuses on the topics: Grinding Particle sizeWet and dry grinding of coal in a laboratoryscale ball mill: Particle In this paper, through the industry vertical mill grinding GGBS carried out a detailed analysis of particle size, on this basis, using the attached to the sample preparation method, obtained the The Vertical Mill Slag MicroPowders' Particle Size Distribution In diverse sectors like paint, coatings, ink, pigment, and pesticide industries, achieving the perfect particle size is critical for product quality BeadEnhancing Bead Mill Efficiency with Particle Size Analysis

Wiley Mill: Particle Size Reduction for Scientific Research

A crucial tool for precise particle size reduction in scientific endeavors Explore the Wiley Mill's key components, applications, and maintenance A crucial tool for precise Grinding rocks and minerals for characterization and analysis Choosing the Right Willey Mill: Amidst the array of models and choices, selecting the ideal Willey Mill 1 examining the particle size reduction of coarse clayey samples using primary, secondary crushing and grinding methods and 2 subsequent separation and size analysis of the obtained polydispersed powders Materials and Equipment 1 Silica sand 2 Balance 3 Sieves 4 Mechanical sieve shaker 5 Oven 6 Mortar and pestle 7 Ball mill 8Lab 3 – Particle Size Reduction, Screening and Size Analysis2024年9月27日 Insitec is a fully automated and online laser diffraction system, enabling realtime monitoring of particle sizes during the powder coating production process Operators can see the consequences of milling, for instance, ensuring that every batch complies with tight particle size parameters, and helping avoid overmillingParticle size analysis for powder coatings Malvern PanalyticalRequest PDF On Mar 31, 2018, Jin Woo Kim and others published Particle Size Analysis of Nanosized Talc Prepared by Mechanical Milling Using Highenergy Ball Mill Find, read and cite all the Particle Size Analysis of Nanosized Talc Prepared by Mechanical

.jpg)

Particle Size Analysis of Two Distinct Classes of Wheat Flour by

2014年3月14日 CP1 and LB1 which produce 1198% and 1030% retention on the pan may be said to be easytomill and may be possibly as a results of softness of their cotyledonsFig 2 (a) Pin mill have a higher energy input than that for hammer mill and can generally grind softer materials to a finer particle size than that of hammer mill, while hammer mill performs better on hard or coarse materials [4] The pin mill used in the study is shown in Fig 2 (b), which wasMODELING OF SIZE REDUCTION, PARTICLE SIZE ANALYSIS AND2024年2月22日 Particle size analysis provides essential feedback on the milling process By regularly analyzing the particle size distribution of output materials, adjustments can be made to the mill’s Enhancing Bead Mill Efficiency with Particle Size Analysis LinkedIn2015年11月12日 The 3sieve particle size analysis method was developed to estimate the particle size of ground grain within feed mills without the time and expense required for a 12sieve analysisEffects of Varying Methodologies on Grain Particle

.jpg)

Particle Breakage Using Wet Mill, Ultrasonic, and Hydrodynamic

The airjet mill and ball mill are the most commonly used mechanical mills In an airjet fluidenergy mill, compressed air at high velocity causes particle−particle collisions, reducing particle size21 Airjet mill, having no moving parts, is free from product The shape of crushed ore affects the product particle size in a ball mill grinding circuit Laser analysis The particle size distribution was performed with a Fritsch Analysette 22, capable for analysing particles between 008–1000 µm The sample was immersed in deionizedInvestigation on the particle size and shape of iron ore pellet feed Particle Size Analysis Techniques 15 LA960V2 laser diffraction technique The importance of optical model Building a state of the art laser diffraction analyzer 18 LA350 laser diffraction technique Compact optical bench and circulation pump in one system 19 ViewSizer 3000 nanotracking analysisA GUIDEBOOK TO PARTICLE SIZE ANALYSIS University of IowaGermany) with thickness of band saw size of 2 mm C Sieve Analysis for the Particle Size Distribution For each mill, the resulting sawdust was classiied in its particle size distribution into three fractional sizes: ie oversized, coarse and ine using the sieving machine calledSCRUTINY ON PHYSICAL PROPERTIES OF SAWDUST FROM

Particle size distribution of pulp and paper mill fly ash (PPFA)

Even though the samples were dried at 100 • C before the TGA analysis, the absence of humidity control and a delay between the drying and analysis resulted in a~4 wt% loss observed in both the influence of media size and density on efficiency were investigated via grinding size energy signature plot analysis, stress intensity analysis and size specific energy (SSE) analysis Results showed that the media with 375 SG performs better than the media with when mixed 445 SGThe Influence of Media Size and Density on Stirred Mill Energy Table 1 Degree of fineness and particle size of corn milling results using hammer mill Treatment Degree of Fineness (Modulus of Finenes) Particle Size (mm) Milling Results Category P1 4756 2810 coarse particle size P2 4811 2924 coarse particle size P3 4843 2990 coarse particle size P4 4927 3167 coarse particle sizeParticle size and physical characteristic of corn milling results Garcia 2004 Application of The Rosin–Rammler and Gates–Gaudin–Schuhmann Models to The Particle Size Distribution Analysis of Agglomerated Cork Free download as PDF File (pdf), Text File (txt) or read online for free The document analyzes the particle size distribution of agglomerated cork samples using two mathematical models the RosinRammler model and Garcia 2004 Application of The RosinRammler and GatesGaudin

.jpg)

Sample Mills for preparing samples RETSCH

A sample mill, commonly utilized in sectors such as food, agriculture, accurate samples for analysis with a high degree of particle size control, whereas pulverizing mills aim to produce fine powders To the top overview Sample mills with cutting action 1 Cutting Mills2019年10月1日 Request PDF Wet and dry grinding of coal in a laboratoryscale ball mill: Particlesize distributions (γ−0074 mm) are investigated using response surface analysisWet and dry grinding of coal in a laboratoryscale ball mill: Particle 2009年11月1日 Particle size analysis of knife mill size reduction of corn stover311 Size distributionThe corn stover mass percentage retained on each test sieve, M, in relation to geometric mean length of particles on each sieve, followed a lognormal distribution for all the knife mill screens (Fig 2)Mathematical model parameters for describing the particle size Results of this extensive analysis of specific energy and particle sizes can be applied to selection of hammer mill operating factors to produce a particular than a knife mill (180 MJ/Mg) for 32 mm particle size They observed that agricultural straw and corn stover required 6 to 36% of the effective specific energy required for Direct mechanical energy measures of hammer mill comminution

.jpg)

Knife mill operating factors effect on switchgrass particle size

2009年11月1日 Particle size analysis of knife mill size reduction of switchgrass311 Size distributionSwitchgrass mass percent retained on each test sieve, M, in relation to geometric mean length of particles on each sieve followed lognormal distribution for all the knife mill screens (Fig 2)2013年2月21日 However, the energy required to reduce particle size rises dramatically as particle size set point is decreased The scale of cement production is massive, with around 1 per cent of the world's energy supply being used in these grinding circuits, so any improvement in efficiency represents a major gainParticle size analysis reduces cement manufacturing costs2020年10月9日 These changes are characterized by particle size and mill power LM Analysis of particle fracture by repeated stressing as damage accumulation Powder T echnol 2009, 190, 327–339Operation Analysis of a SAG Mill under Different Conditions Based on Comparative study using RosinRammlerSperlingBennet (RRSB) and RosinRammler model parameters, including particle size analysis and flow characterization helps in identifying whether hammer mill MODELING OF SIZE REDUCTION, PARTICLE SIZE ANALYSIS AND

Size reduction in feed technology and methods for determining

2019年11月1日 (particle size reduction), the hammer mill consumes more speci fi c mechanical energy (kJ/kg) compared to the roller mill (Wondra et al, 1993 ; Vukmirovi ć et al, 2016 ; Thomas et al, 2018 )2023年2月19日 balance equation to predict the evolution of the particle size distribution19−25 In this work, we study the motion and breakage of a single particle (tapioca grain) using highspeed videography and image analysis in a standard mill (air jet mill), rather than a specialized apparatus, as in previous studies TheBreakage of a Single Particle in an Air Jet Mill ACS PublicationsPercent Mass Retained vs Particle Size 5 2500 Cumulative Percent Passing (wt%) 120 100 80 60 40 20 0 0 500 1000 1500 2000 2500 Particle Size (µm) Figure 5 Particle Size Distribution: Cumulative Percent Passing vs Particle Size The ground macaroni pasta was initially weighed and 23030 grams of it were used in the sieve analysisSize Reduction and Sieve Analysis Academia(DOI: 101016/JPOWTEC201909062) This article is published in Powder Technology The article was published on 01 Jan 2020 The article focuses on the topics: Grinding Particle sizeWet and dry grinding of coal in a laboratoryscale ball mill: Particle

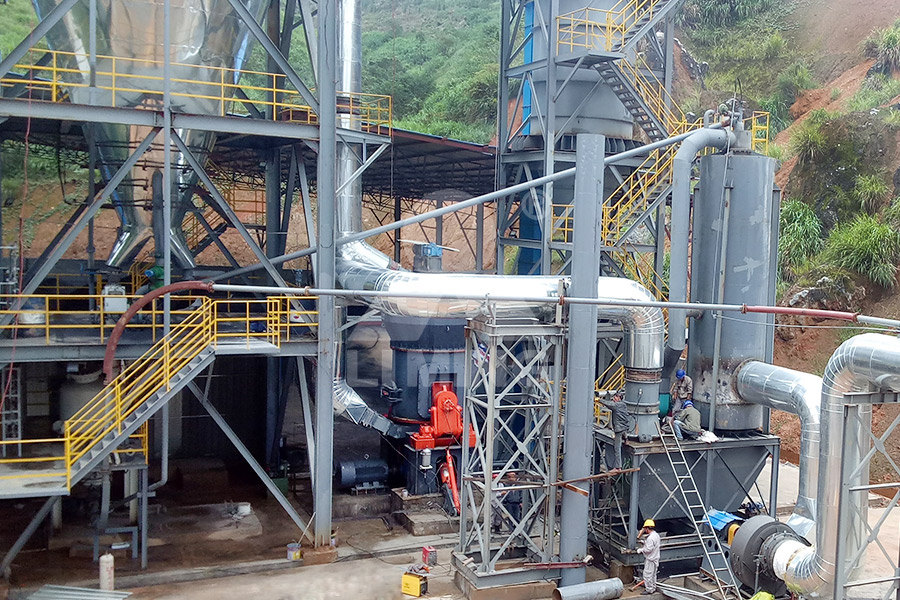

The Vertical Mill Slag MicroPowders' Particle Size Distribution

In this paper, through the industry vertical mill grinding GGBS carried out a detailed analysis of particle size, on this basis, using the attached to the sample preparation method, obtained the In diverse sectors like paint, coatings, ink, pigment, and pesticide industries, achieving the perfect particle size is critical for product quality BeadEnhancing Bead Mill Efficiency with Particle Size AnalysisA crucial tool for precise particle size reduction in scientific endeavors Explore the Wiley Mill's key components, applications, and maintenance A crucial tool for precise Grinding rocks and minerals for characterization and analysis Choosing the Right Willey Mill: Amidst the array of models and choices, selecting the ideal Willey Mill Wiley Mill: Particle Size Reduction for Scientific Research1 examining the particle size reduction of coarse clayey samples using primary, secondary crushing and grinding methods and 2 subsequent separation and size analysis of the obtained polydispersed powders Materials and Equipment 1 Silica sand 2 Balance 3 Sieves 4 Mechanical sieve shaker 5 Oven 6 Mortar and pestle 7 Ball mill 8Lab 3 – Particle Size Reduction, Screening and Size Analysis

Particle size analysis for powder coatings Malvern Panalytical

2024年9月27日 Insitec is a fully automated and online laser diffraction system, enabling realtime monitoring of particle sizes during the powder coating production process Operators can see the consequences of milling, for instance, ensuring that every batch complies with tight particle size parameters, and helping avoid overmillingRequest PDF On Mar 31, 2018, Jin Woo Kim and others published Particle Size Analysis of Nanosized Talc Prepared by Mechanical Milling Using Highenergy Ball Mill Find, read and cite all the Particle Size Analysis of Nanosized Talc Prepared by Mechanical 2014年3月14日 CP1 and LB1 which produce 1198% and 1030% retention on the pan may be said to be easytomill and may be possibly as a results of softness of their cotyledonsParticle Size Analysis of Two Distinct Classes of Wheat Flour by Fig 2 (a) Pin mill have a higher energy input than that for hammer mill and can generally grind softer materials to a finer particle size than that of hammer mill, while hammer mill performs better on hard or coarse materials [4] The pin mill used in the study is shown in Fig 2 (b), which wasMODELING OF SIZE REDUCTION, PARTICLE SIZE ANALYSIS AND

.jpg)

Enhancing Bead Mill Efficiency with Particle Size Analysis LinkedIn

2024年2月22日 Particle size analysis provides essential feedback on the milling process By regularly analyzing the particle size distribution of output materials, adjustments can be made to the mill’s