HOME→The relationship between mining license processing and industrial grinding mill factory mining land

The relationship between mining license processing and industrial grinding mill factory mining land

Predictive maintenance in mining industry: grinding

2022年10月19日 The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding2024年9月26日 The case study demonstrates a significant loss in equipment operating hours and highlights the potential cost savings from process optimization The research showcases Sustainable Mining and Processing of Mineral Resources• Amend the MPRDA to include linkages milestones in mining concession (license) • Make local content commitments a bid variable with significant weighting (30%?) for all new competitive The Interface Between Mining and Manufacturing: Beneficiation?2023年12月1日 This paper has provided an estimate of the historical final energy consumption of the mining industry globally, as well as an exploratory analysis of future possible pathways Global energy consumption of the mineral mining industry:

Stirred media mills in the mining industry: Material grindability

2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional 2017年1月17日 This paper reports the results of an investigation targeting two objectives: (1) characterising energy outputs in industrial grinding mill circuits, and (2) identifying the potential Breaking down energy consumption in industrial grinding mills2022年6月25日 In order to enhance the energy efficiency of the mining industry, artificial intelligence technology is being integrated to manage, predict, and optimize the energy Predicting energy consumption of grinding mills in mining Most efforts todate have centred on modifying and controlling the runofmine (ROM) size distribution to maximise grinding mill throughput The complexity of the interaction between Increased Profits Through MineandMill Integration AusIMM

The Essence of Regulating Mining Business Licenses

terms of obtaining Licenses and the management of mining as well as the distribution of its results on the communities surrounding mining and its impact on the environment As for the results When choosing your equipment we not only keep in mind mill performance, but also considering how your Premier™ or Select™ mill will optimize your minerals processing circuit Performance Metso Premier™ mills and Select™ mills are Grinding mills for mining and minerals processing2022年1月1日 The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding mills However, many approaches have been developed by the growth of the mining industry in order to reduce the cost and optimize the timePredictive maintenance in mining industry: grinding mill case studybasics of mining and mineral processing Free ebook download as PDF File (pdf), Text File (txt) or view presentation slides online mineral processing methods: crushing and grinding sulfide flotation smelting and refining Basics of Mining and Mineral Processing PDF Mill

Spatial response relationship between mining and industrial

2023年6月28日 Mining and industrial activities in mineral resourcebased areas are important sources of potentially toxic elements (PTEs) in the soil, which lead to spatial heterogeneity in regional ecoenvironmental risks In this study, we analysed the spatial response relationship between mining and industrial activities and ecoenvironmental risks using Anselin local Grinding plays an important role in mining, construction, metallurgy, chemical, coal and other basic industries In terms of beneficiation, grinding is the most energy consuming operation So, reasonable grinding conditions according to the properties of ores is the key to obtain good grinding results and reduce energy consumption and resource Minerals Special Issue : Grinding Modeling and Energy MDPI2023年10月17日 The global mining industry is at a critical juncture in its engagement with First Nations communities, with progress on economic participation and employment being tempered by ongoing challenges IMARC 2023: Exploring the relationship between Mining 2021年8月26日 The metals, machinery, and mining equipment industries have been at the heart of South Africa’s industrial ecosystem Their central position is associated with the longterm importance of mining (PDF) Metals, Machinery, and Mining Equipment Industries in

.jpg)

Optimization of the SAG Grinding Process Using Statistical

2023年4月19日 2 Background The SAG grinding process has been modeled by various authors, either generating explanatory models of the grinding process, with the aim of modeling, simulating, and optimizing the individual process, as well as integrating it into aggregate processes, such as the minetomill (M2M) paradigm, a practice that has generated the 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral Processing2017年3月2日 The results show that: (1) because the pertinence of standards for mining waste water and waste gas emissions are not strong and because the maximum permissible discharge pollutant concentrations The Empirical Relationship between Mining Industry Development 2021年9月1日 Recently there has also been discussion around the issue of individual responsibility in mining; notably professionals’ capacity to navigate different individual, professional and corporate codes of conduct (eg Di Capua et al, 2017; Smith et al, 2017)In the last decade the concept of geoethics was introduced as professional ethics in geosciencesOne concept fits it all? On the relationship between geoethics and

.jpg)

The Interface Between Mining and Manufacturing: Beneficiation

• Reestablish a national mining tech RD capacity (exCOMRO) as a PPP • Establish a Mining inputs industrial cluster of national private sector (cap goods, consumables, services) state (DTI, DMR, EDD and DST), HRD/RD (HEIs, SciCouncils) to jointly develop comprehensive industrial subsectoral strategies to grow the mineral inputs sectors2014年2月1日 In mining operations, crushing and grinding of coarse rock into smaller particles (ie, comminution) in the material processing stage is notably energyintensive, accounting for between around 30 Mine operating costs and the potential impacts of energy and grinding2017年3月2日 The results show that: (1) because the pertinence of standards for mining waste water and waste gas emissions are not strong and because the maximum permissible discharge pollutant concentrations in these standards are too high, ammonia nitrogen and industrial sulfur dioxide discharges increased in most mining industries; (2) chemical oxygen demand was The Empirical Relationship between Mining Industry Development 55 known as the distribution function [45, 46]) describes the distribution of fragment sizes obtained after a breakage of particles of size xjThus, b1j, b2j, , bnj are the mass fractions of particles in size classes 1, 2, , n after a breakage of particles in size class j The mechanism of breakage is illustrated in [23] by a diagram shown in Fig 3Grinding in Ball Mills: Modeling and Process Control Sciendo

.jpg)

Advancements in Mining Mill Technology: Efficiency,

2024年2月16日 Processing; Advancements in Mining Mill Technology: Efficiency, Sustainability, Innovation AllMinings 10 months ago 3 months ago 0 54 mins Subscribe to continue reading Subscribe to get access to the rest of this post and other subscriberonly 2020年7月23日 Innovation plays a critical role in the mining industry as a tool to improve the efficiency of its processes, to reduce costs, but also to meet the increasing social and environmental concerns among communities and authorities Technological progress has also been crucial to allow the exploitation of new deposits in more complex scenarios: lower ore Innovation in the Mining Industry: Technological Trends and a 2014年2月1日 The study looks at patterns in mining type, mill processing type, mineral type, and the differences between costs expressed in feasibility studies vs operating mines The paper explores the reasons for the relationships observed and Mine operating costs and the potential impacts of energy and grinding 2021年4月19日 PDF Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher Find, read and cite all the research you (PDF) Feasibility and necessity of mine to mill optimization in mining

(PDF) Optimization of the SAG Grinding Process Using Statistical

2023年4月19日 Optimization of the SAG Grinding Process Using Statistical Analysis and Machine Learning: A Case Study of the Chilean Copper Mining Industry April 2023 Materials 16(3220)2020年6月1日 It has been estimated that approximately 2% of the world's energy usage is applied to mineral comminution, and around a quarter of this is used specifically in metalliferous ore grinding [1] where it is typically the most energy intensive set of operations [2]The purpose of comminution in ore processing is to reduce particle size in order to improve liberation of Stirred media mills in the mining industry: Material grindability 2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen concurrently This necessitates Future of Mining, Mineral Processing and Metal Extraction Industry2019年9月10日 One of the most challenging relationships in the mining industry is the one that exists between mining companies and communities It is indisputable that mining can leave a devastating footprint if not managed The relationship between the mining industry and

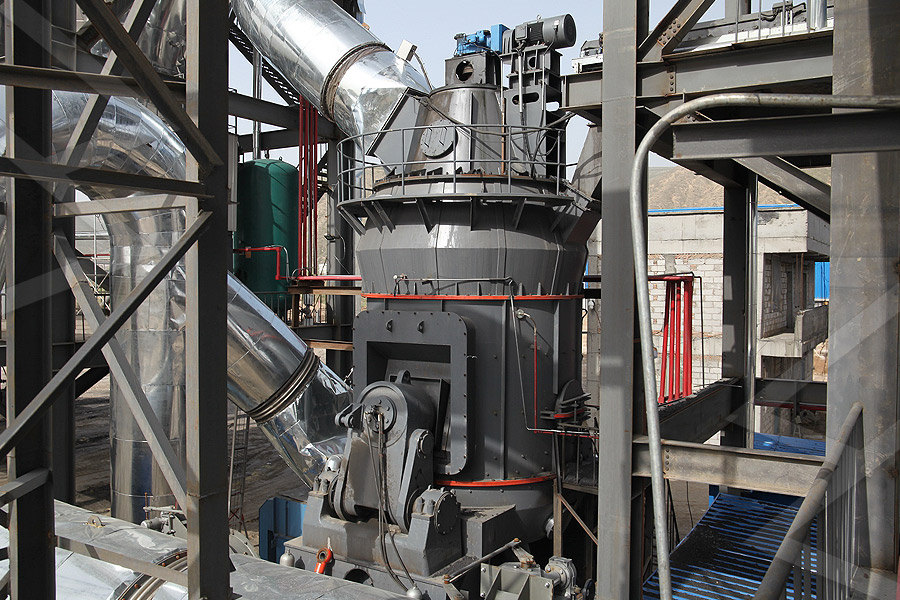

Mining Crushers, Breakers Grinding Mills for the Mining industry

Mill liners and feed chutes; Spare parts for crushers and mills, including jaw plates, side plates and blow bars; Belt conveyors; Wire ropes; Selecting mining crushing and grinding equipment Mine operators need to choose the correct mining machinery and processing equipment based on factors such as geological conditions and ore typeGrinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mill an overview ScienceDirect Topics2021年7月15日 From the life cycle assessments study of the mining and mineral processing of iron ore, bauxite, and copper concentrate carried out by Norgate and Haqueit , it was observed that loading and hauling made the largest contributions (approximately 50%) to the total greenhouse gas emissions from the mining and processing of iron ore and bauxite (119 and Limestone Mining, Industry, and Society SpringerLinkDownload scientific diagram Relationship between SAG mill power draw, bearing pressure and feed rate from publication: Supervisory Fuzzy Expert Controller for SAG Mill Grinding Circuits: Sungun Relationship between SAG mill power draw, bearing pressure

.jpg)

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and 2023年1月24日 Although companies recognize the importance of social responsibility and community engagement, conflicts between companies and communities have been noticeably increasingConflicts between mining companies and communities: When choosing your equipment we not only keep in mind mill performance, but also considering how your Premier™ or Select™ mill will optimize your minerals processing circuit Performance Metso Premier™ mills and Select™ mills are Grinding mills for mining and minerals processing2022年1月1日 The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding mills However, many approaches have been developed by the growth of the mining industry in order to reduce the cost and optimize the timePredictive maintenance in mining industry: grinding mill case study

Basics of Mining and Mineral Processing PDF Mill

basics of mining and mineral processing Free ebook download as PDF File (pdf), Text File (txt) or view presentation slides online mineral processing methods: crushing and grinding sulfide flotation smelting and refining 2023年6月28日 Mining and industrial activities in mineral resourcebased areas are important sources of potentially toxic elements (PTEs) in the soil, which lead to spatial heterogeneity in regional ecoenvironmental risks In this study, we analysed the spatial response relationship between mining and industrial activities and ecoenvironmental risks using Anselin local Spatial response relationship between mining and industrial Grinding plays an important role in mining, construction, metallurgy, chemical, coal and other basic industries In terms of beneficiation, grinding is the most energy consuming operation So, reasonable grinding conditions according to the properties of ores is the key to obtain good grinding results and reduce energy consumption and resource Minerals Special Issue : Grinding Modeling and Energy MDPI2023年10月17日 The global mining industry is at a critical juncture in its engagement with First Nations communities, with progress on economic participation and employment being tempered by ongoing challenges IMARC 2023: Exploring the relationship between Mining

(PDF) Metals, Machinery, and Mining Equipment Industries in

2021年8月26日 The metals, machinery, and mining equipment industries have been at the heart of South Africa’s industrial ecosystem Their central position is associated with the longterm importance of mining 2023年4月19日 2 Background The SAG grinding process has been modeled by various authors, either generating explanatory models of the grinding process, with the aim of modeling, simulating, and optimizing the individual process, as well as integrating it into aggregate processes, such as the minetomill (M2M) paradigm, a practice that has generated the Optimization of the SAG Grinding Process Using Statistical 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral Processing2017年3月2日 The results show that: (1) because the pertinence of standards for mining waste water and waste gas emissions are not strong and because the maximum permissible discharge pollutant concentrations The Empirical Relationship between Mining Industry Development