Safety regulations for the use of ore grinding mill

Ball mill operation procedures and safety precautions

By following the recommended procedures and safety guidelines, operators can ensure safe and efficient operation, minimize equipment wear and tear, and prolong the lifespan of the ball mill Regular maintenance and adherence to safety protocols are essential for the continued Using grinding machines safely is not just a precaution; it is a critical aspect of workplace health, safety, and environmental (HSE) management Understanding the potential hazards, implementing robust safety measures, and adhering to Using grinding machines safely Safety Notes2023年10月11日 In this article, we will explain what grinding safety precautions are and how they can be identified and implemented using a grinding risk assessment and provide you with grinding safety tips to keep your workers Grinding Safety Precautions and Control MeasuresThis new ILO code of practice sets out principles concerning safety and health in the use of machinery and defines safety and health requirements and precautions applicable to Safety and health in the use of machinery

Essential Guidelines For Working With Grinding Mill

Here are some common safety guidelines for working with grinding mills: 1 Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses or goggles, face shields, gloves, and hearing protection, to protect By approving this American National Standard, the ANSI Board of Standards Review confirms that the requirements for due process, consensus, balance and openness have been met by American National Standard Safety Requirements for Grinding Prior to using a mill, you must receive basic shop safety training and equipment specific training before using this tool You must wear appropriate PPE and follow all shop rules Refer to the Mill Safety University of Michigan2023年4月25日 As with any powered machinery, it’s essential to safeguard your milling machine appropriately to prevent accidents and injuries This article will discuss how to safeguard a milling machine and the different types of safety Safety Guarding on Milling Machines

.jpg)

Safety in Grinding SpringerLink

2017年9月27日 Safety regulations for grinding prepared by a number of national and international bodies are reviewed, and factors affecting safety in grinding are presented, safety needs greater attention from OSH professionals and employers •This article presents 10 best practices for grinder use that are based on several years of practice as a safety profes PeerReviewed Working Safely With Grinders American Society Why should you have the fire and explosion safety of your solid fuel or coal grinding systems evaluated? The answer is clear and compelling Most coal mill system designs have been in use for approximately three decades or more, Evaluation of Existing Systems for Safety Coal Mill HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill

.jpg)

Safety considerations when purchasing a standalone coal mill grinding

grinding systems are purchased for existing lines, the situation is similarly complex Vincent Grosskopf of Coal Mill Safety asks some pertinent questions Vincent Grosskopf, Coal Mill Safety I n cases when a complete clinker line is purchased, 2023年10月11日 The use of abrasive wheels is regulated by the Provision and Use of Work Equipment Regulations act 1998 (PUWER) which legislates how machinery should be handled and operated to keep workers as healthy and safe as Grinding Safety Precautions Hazards Control Measures2024年6月26日 Flour mills are one of the workplaces with occupational health hazards due to irregular workplaces and environments where insufficient attention is paid to workers’ safetyOccupational health and safety in flour Mills: A research and risk Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

Flowsheet considerations for optimal use of high pressure grinding

2010年8月1日 Traditionally, for minerals, applications have included pregrinding or regrinding in iron ore pellet feed preparation circuits, or as secondary or recrushing devices in Kimberlite processing In the latter case, the unit was introduced in the recrushing of DMS product, but effectively operated as open circuit unit ( Maxton et al, 2002 )Rolling mills play a crucial role in the steel industry, enabling the shaping and processing of metal materials As businesses consider investing in rolling mill machinery or upgrading their existing infrastructure, it is imperative to prioritize the safety of employees and create a secure working environment This article presents comprehensive and practical general safety norms for rolling Rolling Mill Safety: Essential Guidelines for a Secure Workplace2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in Grinding Mills — Types, Working Principle ApplicationsUDC 621’922’025 : 6148 IS : 1991 (Part 7)1987 Indian Standard SAFETYREQUIREMENTS FORJHE USE,CARE AND PROJECTION OF ABRASIVE GRINDING WHEELS PART 7 STANDARD SPEEDS ( Second Revision ) 1 Scope This standard ( Part 7 ) covers the maximum operating speed of grinding wheels It also covers the responsibilities of the IS 19917 (1987): Safety requirements for the use, care and

Ensuring Safety in Coal Grinding Operations Coal Mill Safety

Coal grinding is a critical process in the production of energy and industrial products like cement It comes with inherent risks Ensuring the safety of workers and equipment in coal grinding operations is paramount This article outlines key safety measures and best practices to mitigate the hazards associated with coal grinding2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLinkThis guideline is specific to surveying and sampling of autogeneous grinding (AG), semiautogeneous grinding (SAG), and rod and ball mill circuits operating within the normal range of application This guideline does not directly address analysis of crushing plants and fine grinding circuits, but it is a useful reference for such endeavoursMethods to Survey and Sample Grinding Circuits for Determining 1 Grindability: The grindability of the ore affects the efficiency of the grinding mill Harder ores require more energy and longer grinding times, which can impact the mill's performance and operational costs 2 Media andliner Wear: The condition of the grinding media and liners affects the mill's efficiencyUnderstanding the operation of grinding mills in the mining and

.jpg)

Protecting Workers: The Importance Of A Grinder Machine Guard

2024年4月19日 Promotes compliance with safety regulations: Many countries and industries have specific safety regulations and standards in place that require the use of grinder machine guards By using these guards, individuals and organizations can ensure compliance with these regulations, avoiding legal penalties and potential liability in the event of an accident or injurySuccessful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015Mills for minerals and ores Loesche2023年1月16日 The objective of this research is to design and construct a hammer mill for grinding leonardite charcoal (Lignite, class J) The conditions for the design and construction of the grinder are Optimum Design of Hammer Mill for Grinding Leonarditethe mill speed allowing improved control of the product particle size (Viklund et al, 2006) The mill motor power draw serves as an indication of the energy required to lift the mill charge The ground ore in the mill mixes with the water to form a slurry and Throughput and product quality control for a grinding mill circuit

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

The Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for grinding materials, the Autogenous Mill relies on the material being ground to break itself into smaller pieces2024年4月19日 Bradken’s MillSafe Solutions are keeping personnel safer during mill relining A grinding mill is a critical asset to a mining operation Capable of breaking down ore, these incredibly powerful machines are built from equally robust materials It’s precisely this combination that makes them hazardous for workers during maintenanceGamechanger in mill relining safety Safe To Work2021年1月1日 Mill filling has a dominant effect on grinding mill performance (Apelt, Asprey and Thornhill, 2001), and therefore, its accurate measurement is vital for modelling grinding mill performanceMeasuring filling is also necessary to estimate the composition of the load for mill modelling: rock and slurry for AG mills; rock, balls and slurry for SAG mills; or balls and slurry An improved method for grinding mill filling measurement and 2021年1月1日 Mill filling has a dominant effect on grinding mill performance (Apelt, Asprey and Thornhill, 2001), and therefore, its accurate measurement is vital for modelling grinding mill performance Measuring filling is also necessary to estimate the composition of the load for mill modelling: rock and slurry for AG mills; rock, balls and slurry for SAG mills; or balls and slurry An improved method for grinding mill filling measurement and

Occupational Safety in Grain Elevators and Feed Mills CDC Stacks

"Prevention of Grain Elevator and Mill Explosions," NMAB 3672, which was jointly funded by the National Institute for Occupational Safety and Health (NIOSH), the Occupational Safety ana Health Administration (OSHA), and the US Department of Agriculture (USDA) The systems approach was used in the 1This mill accepts grinding set weights of up to 30 kg, the largest grinding jar has a volume of 2,000 ml chemical industry, etc, it has two ore grinding Compare this product Remove from comparison tool ball grinding mill horizontal for ore ball grinding mill Final grain size: 74 µm Ore mill, Ore grinding mill All industrial manufacturers5] However, the economic recovery of metals requi res the use of energyefficient and selective grinding, beneficiation, and metallurgical processes The efficiency of grinding, apart from economic benefits, results in the improvement of health and safety in mining areas [ 6, 7]Modeling of Bauxite Ore Wet Milling for the Improvement of 2024年6月17日 Hammer mill safety is crucial for your operations, preventing explosions, injuries and other emergencies Learn proper safety precautions here Request a Quote (844) 4860742 smoking or other open flame devices Prevent dust buildup in the grinding chamber, which will prevent heat from creating a source of ignition 6Ensure Workplace Safety: Hammer Mill Operation Maintenance

Grinding Machine Safety: Essential Tips for Operators

2024年7月21日 8) When grinding the end face of a workpiece, the feed amount and speed should be within the range that the grinding wheel strength can withstand to prevent the grinding wheel from breaking 9) When switching from external to internal grinding, the screw under the operating handle must be tightened after moving the grinding wheel carriage to the front endGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Grinding Mills 911Metallurgist2019年1月30日 Request PDF The Evolution of Grinding Mill Power Models Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of The Evolution of Grinding Mill Power Models Request PDFBasic Mill Linings Use rubber linings wherever possible due to lifetime, low weight, easy to install and noise dampening; When application is getting tougher use steelcapped rubber, still easier to handle than steel; When these both options are overruled (by temperature, feed size or chemicals) use steel; Orebed is a lining with rubber covered permanent magnets used for AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

.jpg)

Evaluation of Existing Systems for Safety Coal Mill

Why should you have the fire and explosion safety of your solid fuel or coal grinding systems evaluated? The answer is clear and compelling Most coal mill system designs have been in use for approximately three decades or more, HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Millgrinding systems are purchased for existing lines, the situation is similarly complex Vincent Grosskopf of Coal Mill Safety asks some pertinent questions Vincent Grosskopf, Coal Mill Safety I n cases when a complete clinker line is purchased, Safety considerations when purchasing a standalone coal mill grinding 2023年10月11日 The use of abrasive wheels is regulated by the Provision and Use of Work Equipment Regulations act 1998 (PUWER) which legislates how machinery should be handled and operated to keep workers as healthy and safe as Grinding Safety Precautions Hazards Control Measures

Occupational health and safety in flour Mills: A research and risk

2024年6月26日 Flour mills are one of the workplaces with occupational health hazards due to irregular workplaces and environments where insufficient attention is paid to workers’ safetyRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill2010年8月1日 Traditionally, for minerals, applications have included pregrinding or regrinding in iron ore pellet feed preparation circuits, or as secondary or recrushing devices in Kimberlite processing In the latter case, the unit was introduced in the recrushing of DMS product, but effectively operated as open circuit unit ( Maxton et al, 2002 )Flowsheet considerations for optimal use of high pressure grinding Rolling mills play a crucial role in the steel industry, enabling the shaping and processing of metal materials As businesses consider investing in rolling mill machinery or upgrading their existing infrastructure, it is imperative to prioritize the safety of employees and create a secure working environment This article presents comprehensive and practical general safety norms for rolling Rolling Mill Safety: Essential Guidelines for a Secure Workplace

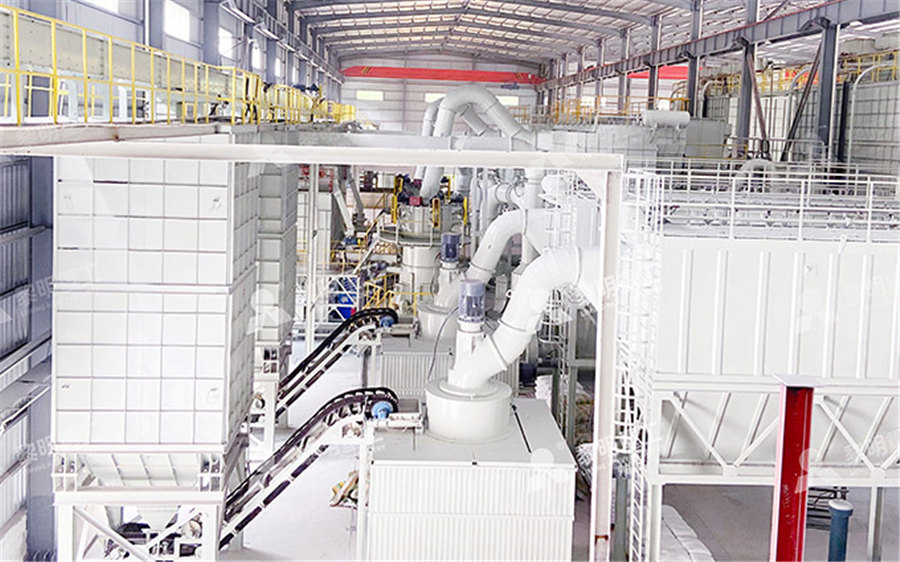

CFB石灰石脱硫剂制备64.jpg)

Grinding Mills — Types, Working Principle Applications

2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in UDC 621’922’025 : 6148 IS : 1991 (Part 7)1987 Indian Standard SAFETYREQUIREMENTS FORJHE USE,CARE AND PROJECTION OF ABRASIVE GRINDING WHEELS PART 7 STANDARD SPEEDS ( Second Revision ) 1 Scope This standard ( Part 7 ) covers the maximum operating speed of grinding wheels It also covers the responsibilities of the IS 19917 (1987): Safety requirements for the use, care and