Specifications for the installation of foundation pads for large equipment

Essential Guide to Equipment Foundations RJ Potteiger

2022年11月28日 Equipment foundations are the concrete bases below machines during manufacturing projects These machine foundations are created to meet the needs of particular weights, sizes and loads The concrete pad for mechanical equipment must provide a durable June 2008: Jones commissions the design and installation of the video screen FOUNDATIONS OF BUILDINconstruction of static equipment foundations The term “static equipment” as used herein refers to industrial equipment that does not contain moving parts or whose operational characteristics 3512R94 Foundations for Static Equipment FreeMachinery with rotating, reciprocating, or impacting masses requires a foundation that can resist dynamic forces Precise machine alignment should be maintained, and foundation vibrations 3513R18: Report on Foundations for Dynamic Equipment

.jpg)

Your Machine Foundation Guide: From Concept to

Building a strong and stable machine foundation is crucial for the successful operation and longevity of any industrial equipment A welldesigned foundation not only provides structural support and stability but also helps to minimize This document provides guidance on foundations and equipment pads for traffic signals and lighting projects It discusses: 1) Standard plates, plans, and detail drawings that are included Chapter 10 Foundations and Equipment PadsIt presents various design criteria, methods and procedures of analysis, design, and construction applied to static equipment foundations by industry practitioners This document should, 3512R10(20): Report on Foundations for Static EquipmentThis document summarizes a research paper on the design and analysis of foundations for industrial equipment It discusses different types of equipment foundations, including for vertical vessels, horizontal vessels, package Mechanical Equipment Foundation Pads

Foundations for Dynamic Equipment

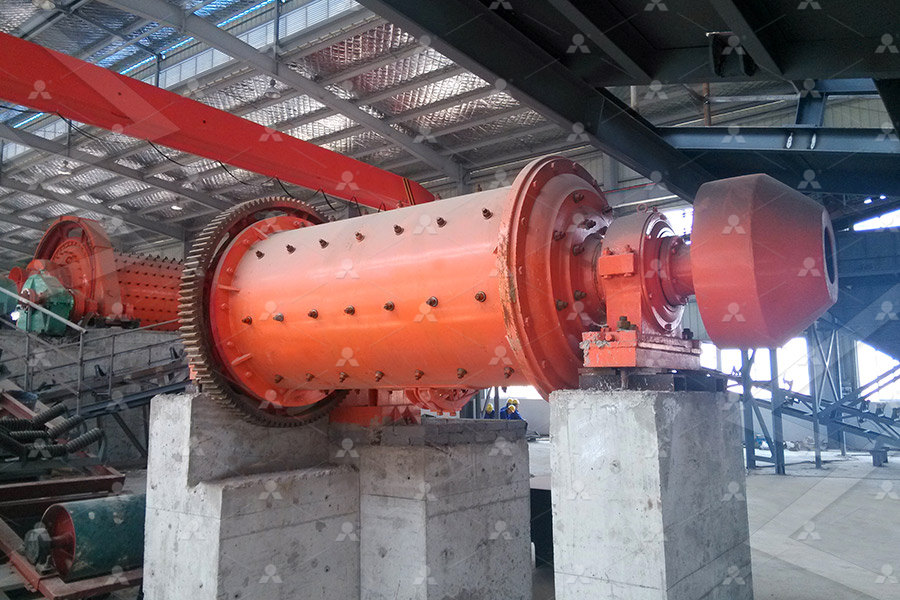

For the purposes of this document, dynamic equipment includes the following: Impact or impulsive machinery Recognition that certain machines, particularly large reciprocating compressors, 2019年2月6日 As a thumb rule, the foundation block should be 3 times of mass of equipment Usually pockets are left open for inserting the foundation bolts/Anchor bolts Pocket size should be sufficient to accommodate the Best practices for machinery installationThese foundations are suitable for equipment that spreads its load over a large area, such as HVAC units, large machinery, and assembly lines Slab type foundations offer the advantage of distributing loads evenly across the surface Equipment Foundations for Industrial Machinery Ace This includes assessing the installation site, reviewing equipment specifications, and identifying potential challenges Safety measures should be outlined at this stage to minimize risks during installation Step 2: Site Preparation Clear the installation site of any obstructions and ensure that the area is clean and wellorganizedKey steps for a successful machinery installation

Foundations for Dynamic Equipment ResearchGate

23—Foundation types Chapter 3—Design criteria, p 3513R7 31—Overview of design criteria 32—Foundation and equipment loads 33—Dynamic soil properties 34—Vibration performance ACI 351414: SPECIFICATION FOR INSTALLATION OF CEMENTITIOUS GROUTING BETWEEN FOUNDATIONS AND EQUIPMENT BASES Author: ACI Committee 351 Subject: This specification covers minimum requirements for cementitious grouting between foundations and equipment bases Included are requirements for materials and placing Created Date: Specification for Installation of Cementitious Grouting between 2019年2月6日 Over a period of time, hydrocarbon and water ingress and weakens the foundation INSTALLATION OF LEVELLING PAD: Mark the centerline of foundation and center line of equipment Check for the approximate position of equipment nozzles if applicable Install the leveling plate using grout on leveling jack screwBest practices for machinery installationChapter 2—Foundation and machine types, p 3513R4 21—General considerations 22—Machine types 23—Foundation types Chapter 3—Design criteria, p 3513R7 31—Overview of design criteria 32—Foundation and equipment loads 33—Dynamic soil properties 34—Vibration performance criteria 35—Concrete performance criteriaFoundations for Dynamic Equipment

Static Equipment: A Look Inside the How and Why of Specification

2018年12月18日 Selfreinforced forged nozzles are nozzle necks that have extra wall thickness which avoids the needs for a reinforcing pad, and hence reduces the number of welds to the shell The ones shown here are supplied by CHW Forge, India Self reinforced nozzles are advisable at high temperature (>370°C), high pressure (>70 bar), H 2 service, lowalloy steel (CrMo) 65—Equipment installation and setting 66—Grouting 67—Concrete materials 68—Quality control Chapter 7—References, clarifiers and largediameter storage tanks); • Buildings, concrete silos, chimneys, and structures that contain static equipment; or This document addresses static equipment foundation engineering and 3512R10(20): Report on Foundations for Static EquipmentACI 3513R 04 Foundations for Dynamic Equipment × Close Log In Log in with Facebook Log turbines, large electric motors, and generators, etc are subject to vibrations caused by unbalanced machine forces as well as In the case of block foundation, if changes in size and mass of the foundation do not lead to a satisfactory design, a ACI 3513R 04 Foundations for Dynamic EquipmentThe foundation design may entail the construction of an engineered gravel pad “Pads are normally cheap to install, but do not always provide good solid contact between the package skid and the gravel pad that is necessary to transmit vibration into the ground,” said Pak “It becomes a painstaking process to ensure properFOUNDATION ANALYSIS AND DESIGN FOR RECIPROCATING AND ROTATING EQUIPMENT

The Basics: Generator Concrete Pads Woodstock Power

Review: Concrete generator pads are the most commonly used foundation when installing a commercial generator, but involve careful planning and calculation give us a call 6106583242 ServicesBlock Type Machine Foundation: Following figure shows block type machine foundation This type of foundation consists of a pedestal resting on a footing have has large mass and a small natural frequency 2 Box or Caisson Type Different Types of Machine Foundations and their static equipment are discussed in ACI 3512R There are many technical areas that are common to both dynamic equipment and static equipment foundations Various aspects of the analysis design and construction of foundations for static equipment are addressed in ACI 3512R To simplify the presentation, this report is limited in3513R18: Report on Foundations for Dynamic EquipmentCWC 604 Machine Bond / Specifications for Installation Technical Bulletin # 1105B, Page 3 90 GROUT MIXING PROCEDURES 9 GROUT MIXING PROCEDURES 91 All material and equipment for mixing, placing, and cleanup shall be on hand before any mixing is started All mixing and placing equipment shall be clean and dryEQUIPMENT FOUNDATION SYSTEMS CWC 604 Machine Bond Specifications

Installation and Foundation of Machine Tools SpringerLink

2021年11月9日 For optimal dimensioning of the foundation block, the overall system (comprising the machine, securing elements for the machine on the foundation block (installation elements), foundation block and subsoil) must be factored in if possible Figure 410 shows a simplified, planar simulation model2018年10月26日 Be ready to install your new vibratory equipment with this installation preparation checklist from your friends at General Kinematics Skip to main content 8154553222 Top Menu Your new vibratory equipment, if not balanced, is going to need a foundation (a concrete pad or structure) that can support its weight, Installation Preparation Checklist General KinematicsWhen installing machinery or equipment on a support foundation that rests directly on soil as the means of providing isolation, the soil conditions must be taken into account Poorly designed and installed foundations may amplify vibration or worse, may settle unevenly and sink Interaction between the soil and the foundation is equally asVibration Isolation Theory of Foundations FabreekaThese foundations are suitable for equipment that spreads its load over a large area, such as HVAC units, large machinery, and assembly lines Slab type foundations offer the advantage of distributing loads evenly across the surface area, reducing stress on any single point and enhancing the overall stability of the equipmentEquipment Foundations for Industrial Machinery Ace Avant

.jpg)

The Comprehensive Guide to Pad Foundations: Definitions,

2024年4月3日 Brief Discover everything about pad foundations, from their importance, applications, and costs, to selecting the right type for your construction project, in this detailed guide Insight Pad foundations are a fundamental element of structural systems, providing stability and support to buildings by efficiently transferring structural loads to the groundPad Transformer Concrete Found Specs Free download as PDF File (pdf), Text File (txt) or read online for free Step 2 The document provides specifications for constructing concrete foundations for 3phase padmount transformers for Duke Energy It outlines responsibilities of both Duke Energy and customers Duke Energy will supply and install the ground rod and Pad Transformer Concrete Found Specs PDF ScribdMechanical Equipment Foundation Pads Free download as PDF File (pdf), Text File (txt) or read online for free This document summarizes a research paper on the design and analysis of foundations for industrial equipment It discusses Mechanical Equipment Foundation Pads Free download as PDF File (pdf), Text File (txt) or read online for free The document provides details on method statements for pad foundations: 1 The method statement should include details on excavation, soil testing, formwork installation, concrete pouring and curing, and inspection methods 2 Reinforcement, if required, should be adequately Method Statement For Pad Foundation PDF Deep Foundation

.jpg)

Installation of Static Machinery Procedure

2 Foundation Drawing 3 Equipment Details Tools and equipment Installation of Static Machinery Tools and equipment needed should be in good condition and must be checked by competent person and respective supervisor prior to use 2020年12月2日 Pad foundation is a category 2 structure, and this design is to be done using prescriptive methods: Let 10% of the service load account for the selfweight of the pad foundation Base area A = 11(800 + 425)/225 = 599 m 2 Minimum dimensions of footing = √599 = 2447m Adopt a square foundation of 2500 mm x 2500m x (600 mm) trial depth (Area Design of Pad Foundation Structville3 The combined centre of gravity of machine and foundation should, as far as possible, be in the same vertical line as the centre of gravity of the base plane 4 No resonance should occur, hence the natural frequency of the foundation–soil system should be either too large or too small compared to the operating frequency of the machineGeneral Requirements of Machine Foundations during Design Duke Energy 3Phase Padmount Transformer Concrete Foundation Specifications 3 Ma y 20 16 6 The top of the concrete pad must be steel troweled and completely smooth to prevent “gaps” between the transformer and the surface of the concrete pad Installing Conduit in Pit PadsPadmount Transformer Concrete Foundation studylib

.jpg)

54 in x 32 in x 3 in Precast Concrete Block Universal Equipment Pad

Increase the value of your residential or commercial property by installing this Unbranded Precast Concrete Block Universal Equipment 54 in x 32 in x 3 in Precast Concrete Block Universal Equipment Pad Large (5) Questions Answers (3) Hover Image Specifications Dimensions: H 3 in, W 32 in, D 54 in Dimensions Product Depth (in Achieve foundation isolation for your machinery with UNISORB®'s professionally engineered vibration isolation mounts, pads, and systems Learn ® vibrationplus is applied as a vibration isolating structural element in the installation of both source and sensitive equipment These installations provide a costeffective and simple approach Vibration Isolation Mounts Vibration Isolation Pads UNISORB®Installation Instructions Bulletin 37737C Foundation Specifications for 9Meter Earth Station Antennas Revision E 10 INTRODUCTION 11This document specifies typical foundation characteristics, designs, requirements and dimensional specifications for the Andrew 9Meter Earth Station Antenna 20 FOUNDATION LOADING CHARACTERISTICSInstallation Instructions Foundation Specifications Skybrokers2023年10月28日 Foundation Options: Depending on the site and its requirements, options such as a foundation stem wall or pole barn may be considered for added support and stability Determining the Thickness The thickness of the concrete slab is a critical factor in its ability to support heavy loads and dynamic forcesHeavy Equipment Concrete Slab Design Essentials

Key steps for a successful machinery installation

This includes assessing the installation site, reviewing equipment specifications, and identifying potential challenges Safety measures should be outlined at this stage to minimize risks during installation Step 2: Site Preparation Clear the installation site of any obstructions and ensure that the area is clean and wellorganized23—Foundation types Chapter 3—Design criteria, p 3513R7 31—Overview of design criteria 32—Foundation and equipment loads 33—Dynamic soil properties 34—Vibration performance Foundations for Dynamic Equipment ResearchGateACI 351414: SPECIFICATION FOR INSTALLATION OF CEMENTITIOUS GROUTING BETWEEN FOUNDATIONS AND EQUIPMENT BASES Author: ACI Committee 351 Subject: This specification covers minimum requirements for cementitious grouting between foundations and equipment bases Included are requirements for materials and placing Created Date: Specification for Installation of Cementitious Grouting between 2019年2月6日 Over a period of time, hydrocarbon and water ingress and weakens the foundation INSTALLATION OF LEVELLING PAD: Mark the centerline of foundation and center line of equipment Check for the approximate position of equipment nozzles if applicable Install the leveling plate using grout on leveling jack screwBest practices for machinery installation

Foundations for Dynamic Equipment

Chapter 2—Foundation and machine types, p 3513R4 21—General considerations 22—Machine types 23—Foundation types Chapter 3—Design criteria, p 3513R7 31—Overview of design criteria 32—Foundation and equipment loads 33—Dynamic soil properties 34—Vibration performance criteria 35—Concrete performance criteria2018年12月18日 Selfreinforced forged nozzles are nozzle necks that have extra wall thickness which avoids the needs for a reinforcing pad, and hence reduces the number of welds to the shell The ones shown here are supplied by CHW Forge, India Self reinforced nozzles are advisable at high temperature (>370°C), high pressure (>70 bar), H 2 service, lowalloy steel (CrMo) Static Equipment: A Look Inside the How and Why of Specification 65—Equipment installation and setting 66—Grouting 67—Concrete materials 68—Quality control Chapter 7—References, clarifiers and largediameter storage tanks); • Buildings, concrete silos, chimneys, and structures that contain static equipment; or This document addresses static equipment foundation engineering and 3512R10(20): Report on Foundations for Static EquipmentACI 3513R 04 Foundations for Dynamic Equipment × Close Log In Log in with Facebook Log turbines, large electric motors, and generators, etc are subject to vibrations caused by unbalanced machine forces as well as In the case of block foundation, if changes in size and mass of the foundation do not lead to a satisfactory design, a ACI 3513R 04 Foundations for Dynamic Equipment

FOUNDATION ANALYSIS AND DESIGN FOR RECIPROCATING AND ROTATING EQUIPMENT

The foundation design may entail the construction of an engineered gravel pad “Pads are normally cheap to install, but do not always provide good solid contact between the package skid and the gravel pad that is necessary to transmit vibration into the ground,” said Pak “It becomes a painstaking process to ensure proper