Rotary kiln lime heat

.jpg)

LIME KILNS, HEAT TRANSFER, CONTROL AND COMBUSTION

Rotary kilns are large steel tubes that are lined on the inside with refractory bricks They are slightly inclined from the horizontal and are slowly rotated on a set of riding rings Feed is 2018年2月12日 (1) To develop a detailed heat transfer model of a lime rotary kiln integrated with the modeling of calcination reaction (2) To compare the Computer Simulation of Heat Transfer in a Rotary Lime 2016年4月15日 In this paper, thermal energy analysis of three zones of a lime production process, which are preheater, rotary kiln and cooler, is performed In order to perform a proper Thermal energy analysis of a lime production process: Rotary kiln 2016年4月1日 In this paper, thermal energy analysis of three zones of a lime production process, which are preheater, rotary kiln and cooler, is performed In order to perform a proper quantitativeThermal energy analysis of a lime production process:

Heat transfer processes in a rotary kiln ResearchGate

A 2D axisymmetric computational fluid dynamics (CFD) model, coupled to a 1D bed model, has been developed to capture the key processes that occur within rotary lime kilns2023年2月25日 Heat transfer plays a critical role in the preparation of clinker for a rotary kiln Often supplied with energy by means of a burner placed at its end, the rotary kiln is the site of Rotary kiln process: An overview of physical mechanisms, models Three types of rotary kiln flames are shown below: Longer flames are cooler, lazy and less well defined often washing on the kiln refractory and releasing heat well down the kiln26 Lime Kiln Combustion, Heat Transfer and Optimization 年3月28日 In the present work, a steadystate, finite differencebased computer model of heat transfer during production of lime in a rotary kiln has been developed The model Computer Simulation of Heat Transfer in a Rotary Lime Kiln

CFD Modelling of Calcination in a Rotary Lime Kiln

2022年8月1日 A 2D axisymmetric computational fluid dynamics (CFD) model, coupled to a 1D bed model, has been developed to capture the key processes that occur within rotary lime kilns The model simulates the calcination 2008年5月19日 A threedimensional steadystate model to predict the flow and heat transfer in a rotary lime kiln is presented All important phenomena are considered for the preheat and Modelling the Rotary Lime Kiln Semantic Scholar2022年8月1日 CFD Modelling of Calcination in a Rotary Lime Kiln Jarod Ryan 1, * , Markus Bussmann 1 and Nikolai DeMartini 2 1 Department of Mechanical Industrial Engineering, University of Tor onto, Toronto (PDF) CFD Modelling of Calcination in a Rotary Lime KilnAfter the limestone is calcined into lime inside the rotary kiln, it enters the vertical cooler, where it exchanges heat with secondary air blown into the cooler from the bottom Independent cooling facilities evenly distribute the cooling air ducts Rotary Lime Kiln Rotary Kiln Lime Production

.jpg)

Schematic diagram of a rotary lime kiln ResearchGate

Download scientific diagram Schematic diagram of a rotary lime kiln from publication: Computer Simulation of Heat Transfer in a Rotary Lime Kiln In the present work, a steadystate, finite AGRM Lime kiln types are classified by structure Lime Rotary kiln The Rotary kiln is a rotating horizontal cylindrical lime kiln It includes dry process kilns (including dry process kilns with waste heat boilers), dry suspension preheating kilns, precalcining kilns Rotary Lime Kiln Furnace and Refractory Materials Solution2022年11月16日 Rotary kiln is the thermal equipment for hightemperature heat treatment of solid raw materials in a rotary cylindrical kiln, also called rotary furnace, which is a continuous furnace The rotary kiln (see Fig 1 ) is mainly composed of kiln body, kiln lining, rolling ring, supporting device, transmission, discharge end hood, sealing device, dust collection chamber, Rotary Kiln SpringerLinkRotary Kiln Calciner A rotary kiln calciner is employed when high temperatures are needed to induce thermal decomposition or phase change in materials other than cement and lime Applications: Includes materials like alumina, catalyst support, or chemical byproducts Versatility: Suitable for a wide range of operational configurations and Rotary Kilns: Working Principles History Vaia

Modern, Efficient Preheater Rotary Kilns Greer Lime

As the hot lime cools the incoming ambient air, which becomes combustion air, is heated which increases the efficiency of the process The benefits of the preheater rotary kiln are in the high recovery of heat throughout the system Heat that would typically be wasted is used to preheat stone and combustion air to make a highly efficient process2002年8月1日 A threedimensional steadystate model to predict the flow and heat transfer in a rotary lime kiln is presented All important phenomena are included for the preheat and calcination zones(PDF) Mathematical Modelling of Lime Kilns ResearchGateCapacity: 501200 t/d (adjustable) Limestone Feeding Size: 2040mm Heat Consumption: approximate 1200 kcal/kg lime Fuel Type: natural gas, coke oven gas, coal powder, etc Features: fully automatic, continuous working 48 weeks per year End Product: the activity degree is 360400ml, 4N HCL method 10 minutes, CO 2 ≤15% SEND INQUIRY FOR QUOTATIONLime Rotary Kiln For Sale – Output: 2001200 T/D AGICODiagram rotary kiln) NOTE: During heating up the instructions of the refractory (brick) supplier are to be followed! Until the first feed of material, the pressure conditions in the kiln have to be adjusted in a way, that the fuel burns without formation of CO at the lowest amount of combustion air, and the heat is kept in the sintering zone1 HEATING UP THE KILN LINE International Cement Review

Oxyfuel combustion in rotary kiln lime production DiVA

raw material This will change the heat balances of the Lime cooler Flame Oxygen Fuel Recirculated gas Product Flue gas Limestone feed Rotary kiln Lime cooler Flame Air Fuel Product Flue gas Limestone feed Rotary kiln Figure 1 Simplified illustration of conventional and oxyfuel rotary kiln technology for lime production ª 2014 The AuthorsThe dynamic lime kiln object models the dynamics of mass and heat transfer phenomena in a rotary kiln Sass, A, "Simulation of the heattransfer phenomena in a rotary kiln", IEC Process Design and Development, vol 6, no 4, 1967, pp 532535MRAC Strategy for the Temperature Profile Control of a Lime Kiln2016年11月29日 Beginning in the ’20’s, efforts were directed toward lime recovery installations Today, a proper Rotary Lime Kiln Operation is an integral part of all modern pulp mills How a Rotary Lime Kiln Works Do not start Rotary Lime Kiln Operation 911Metallurgist2016年4月1日 A threedimensional steadystate model to predict the flow and heat transfer in a rotary lime kiln is presented All important phenomena are included for the preheat and calcination zonesThermal energy analysis of a lime production process: Rotary kiln

Thermal energy analysis of a lime production process: Rotary kiln

2016年4月15日 In this paper, a specific integrated model is developed for the lime production unit at Mobarakeh Steel Complex (MSC), Iran For this process, the heat transfer and calcination reaction phenomena have been simulated using 1D thermochemical equations in rotary kiln, preheater and cooler2008年5月19日 A threedimensional steadystate model to predict the flow and heat transfer in a rotary lime kiln is presented All important phenomena are considered for the preheat and calcination zones including turbulent gas flow, buoyancy, all modes of heat transfer, evolution and combustion of species and granular bed motion with calcination reactionModelling the Rotary Lime Kiln Georgallis 2005 The A lime kiln is a kiln used to produce quicklime by the calcination of limestone (calcium carbonate)The chemical equation for this reaction is: CaCO 3 + heat → CaO + CO 2 This reaction takes place at 900°C (at which temperature the partial pressure of CO 2 is 1 atmosphere), but a temperature around 1000°C (at which temperature the partial pressure of Lime kiln chemeurope2008年5月19日 A threedimensional steadystate model to predict the flow and heat transfer in a rotary lime kiln is presented All important phenomena are considered for the preheat and calcination zones including turbulent gas flow, buoyancy, all modes of heat transfer, evolution and combustion of species and granular bed motion with calcination reactionModelling the Rotary Lime Kiln Semantic Scholar

Lime Burning Operation Heat Energy Requirements

2020年11月3日 CaCO3 + Heat → CaO + CO2↑ After the lime has been cooled, it is then crushed and screened to various sizes depending upon market requirements Capital investment for a rotary kiln lime plant capable of producing in the range of 400 to 450 tons of quicklime per 24hour day is estimated to be high2024年6月15日 In this work, the production capacity of the lime rotary kiln is 800 t d −1, the length is 63 m, and the inner diameter is 45 mA burner with five channels, including an axial flow channel, a coke oven flow channel, a coal flow channel, a swirling flow channel, and a central flow channel, is installed at the kiln outlet, as shown in Fig 2Numerical simulation of flue gas recirculation in a lime rotary kiln2023年2月25日 In 1824, Joseph Aspdin successfully produced an eminently hydraulic lime by cooking at high temperature, in a bottle kiln, a mixture of limestone and clays; he referred to his output as “Portland Cement” [2] In their studies on particle motion and heat transfer in a rotary kiln, Liu et al Rotary kiln process: An overview of physical mechanisms, models The lime rotary kiln, also known as drum rotary kiln, is equipped with an advanced structure and combined flak seal on both ends It uses complex refractory materials to achieve an air leakage factor of less than 10%, which reduces Lime Rotary Kiln Roatry Kiln Manufacturer

Dynamic CFD Modelling of Calcination in a Rotary Lime Kiln with

a Rotary Lime Kiln with an External Dryer Abstract Midkiln ring formation is a problem in lime kilns, which may be related to the fluctuations of the position of the start of calcination Therefore, a dynamic 2D axisymmetric CFD gas model with a methane burner implemented in ANSYS Fluent, coupled by mass and heat balances to ause rotary kilns for pyroprocessing to calcinate ores, calcinate limestone to lime for cement, and to common types of kiln; wet process kilns, long dry kiln, travelling grate preheater kiln (lepol), cyclone preheater kiln, cyclone preheater kilns with riser duct firing and, precalciner kilns Heat for Clinker ProductionQuantitative Optimization of Cement Rotary Kiln for Heat This work deals with the energy analysis of a rotary kiln system working in a cement plant in Alburge Cement Plant (ACP), at Arab Union Cement Company (AUCC), Zliten city, Libya The kiln has a capability of producing 4200 tonclinker per day The main objective of this study is to examine heat loss of various components of the rotary kiln system(PDF) Optimizing Heat Balance in a Cement Rotary Kiln SystemAbstract (summary): Rotary lime kilns, extensively used in the pulp and paper industry, are industrial heat exchangers that use countercurrent combustion gases to provide heat to calcine granular lime mud Due to harsh conditions within the kiln, direct measurement during operation is difficult and operators may face issues in maintaining steady operation and controlling product CFD Modelling of Heat Transfer and Calcination in Rotary Lime

.jpg)

Rotary kiln process: An overview of physical mechanisms, models

2023年2月25日 As for the granular model, several models have been proposed to predict the thermal behavior of rotary kilns Heat transfer in the rotary kiln occurs between different components: the solids bed, Thermal energy analysis of a lime production process: Rotary kiln, preheater and cooler Energy Conversion and Management, Volume 114 Benefits of Rotary Kiln Versatility: Rotary kilns can handle a wide range of materials and processes, including calcination, sintering, thermal processing, and waste incineration Energy Efficiency: Modern rotary kilns are designed to be highly energyefficient They use advanced technology to ensure optimal heat transfer and minimal energy loss, resulting in significant Rotary Kiln Manufacturers Suppliers in Gujarat, IndiaRotary lime kiln (rustcolored horizontal tube at right) with preheater, Wyoming, 2010 Traditional lime kiln in Sri Lanka A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide)The chemical equation for this reaction is CaCO 3 + heat → CaO + CO 2 This reaction can take place at anywhere above Lime kiln Wikipedia2022年8月1日 CFD Modelling of Calcination in a Rotary Lime Kiln Jarod Ryan 1, * , Markus Bussmann 1 and Nikolai DeMartini 2 1 Department of Mechanical Industrial Engineering, University of Tor onto, Toronto (PDF) CFD Modelling of Calcination in a Rotary Lime Kiln

.jpg)

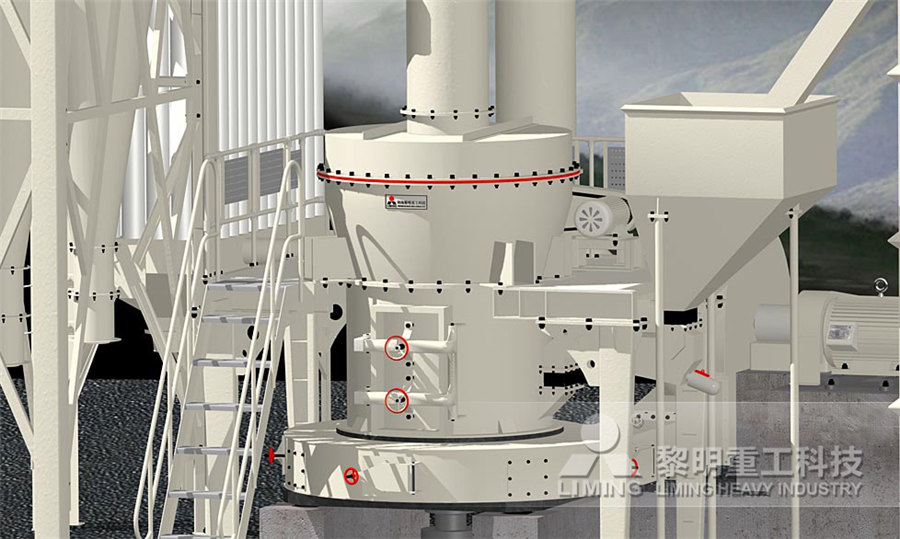

Rotary Lime Kiln Rotary Kiln Lime Production

After the limestone is calcined into lime inside the rotary kiln, it enters the vertical cooler, where it exchanges heat with secondary air blown into the cooler from the bottom Independent cooling facilities evenly distribute the cooling air ducts Download scientific diagram Schematic diagram of a rotary lime kiln from publication: Computer Simulation of Heat Transfer in a Rotary Lime Kiln In the present work, a steadystate, finite Schematic diagram of a rotary lime kiln ResearchGateAGRM Lime kiln types are classified by structure Lime Rotary kiln The Rotary kiln is a rotating horizontal cylindrical lime kiln It includes dry process kilns (including dry process kilns with waste heat boilers), dry suspension preheating kilns, precalcining kilns Rotary Lime Kiln Furnace and Refractory Materials Solution2022年11月16日 Rotary kiln is the thermal equipment for hightemperature heat treatment of solid raw materials in a rotary cylindrical kiln, also called rotary furnace, which is a continuous furnace The rotary kiln (see Fig 1 ) is mainly composed of kiln body, kiln lining, rolling ring, supporting device, transmission, discharge end hood, sealing device, dust collection chamber, Rotary Kiln SpringerLink

Rotary Kilns: Working Principles History Vaia

Rotary Kiln Calciner A rotary kiln calciner is employed when high temperatures are needed to induce thermal decomposition or phase change in materials other than cement and lime Applications: Includes materials like alumina, catalyst support, or chemical byproducts Versatility: Suitable for a wide range of operational configurations and As the hot lime cools the incoming ambient air, which becomes combustion air, is heated which increases the efficiency of the process The benefits of the preheater rotary kiln are in the high recovery of heat throughout the system Heat that would typically be wasted is used to preheat stone and combustion air to make a highly efficient processModern, Efficient Preheater Rotary Kilns Greer Lime2002年8月1日 A threedimensional steadystate model to predict the flow and heat transfer in a rotary lime kiln is presented All important phenomena are included for the preheat and calcination zones(PDF) Mathematical Modelling of Lime Kilns ResearchGateCapacity: 501200 t/d (adjustable) Limestone Feeding Size: 2040mm Heat Consumption: approximate 1200 kcal/kg lime Fuel Type: natural gas, coke oven gas, coal powder, etc Features: fully automatic, continuous working 48 weeks per year End Product: the activity degree is 360400ml, 4N HCL method 10 minutes, CO 2 ≤15% SEND INQUIRY FOR QUOTATIONLime Rotary Kiln For Sale – Output: 2001200 T/D AGICO

1 HEATING UP THE KILN LINE International Cement Review

Diagram rotary kiln) NOTE: During heating up the instructions of the refractory (brick) supplier are to be followed! Until the first feed of material, the pressure conditions in the kiln have to be adjusted in a way, that the fuel burns without formation of CO at the lowest amount of combustion air, and the heat is kept in the sintering zone