Porcelain grinding machinery process flow

Porcelain—Raw Materials, Processing, Phase Evolution,

2005年1月21日 Composed primarily of clay, feldspar, and quartz, porcelains are heattreated to form a mixture of glass and crystalline phases This review The main manufacturing process used for porcelain tile production is the wet route, shown in Figure 1 [4] It consists of six principal unit operations: wet milling, spray dry‐Microsoft Word machines Copydocx TUHHThe DRYTECH Porcelain process of Manfredini Schianchi is already the most worldwide spread alternative system in raw materials processing stage with more than 850000000 Dry grinding plants for ceramics and plants for the production of Composed primarily of clay, feldspar, and quartz, porcelains are heat‐treated to form a mixture of glass and crystalline phases This review focuses on raw materials, processing, heat (PDF) Porcelain—Raw Materials, Processing, Phase Evolution, and

.jpg)

Semiautomatic machines for grinding and polishing porcelain

The data were used to design and build a prototype of a universal semiautomatic for grinding and polishing the edges and feet of saucers and cups and also the feet of plates The output of the 2021年5月1日 An integrated flowsheet process model for porcelain stoneware manufacturing process has been developed and applied for simulation of an entire plant Semiempirical Integrated process simulation of porcelain stoneware Ceramic grinding is an essential process in achieving tight tolerances in otherwise impossibletocut materials Machining them requires superior tooling—such as special diamond Ceramic Grinding Machining Pillar Page Quartzite ProcessingThe batched raw materials go into ball mills for grinding, mixing and transforming the ingredients into liquidlike refined granules technically known as "body slip" To complete this process Our Production Capability Porcellan

.jpg)

(PDF) Application of Flowsheet Simulation Methodology to

2023年1月19日 Flowsheet simulations in the Dyssol framework were used to study the impact of the milling and firing process parameters on the electrical and thermal energy consumption, With the aim of mechanizing the grinding of domestic porcelain wares the Dovbysh porcelain plant in the Kiev economic area has designed two semiautomatic lines: one for grinding the edges Continuous lines for grinding and polishing porcelain goods2021年4月14日 The groove profile of ballbearing raceway is of vital importance to ensure the bearing transmission accuracy It is an attempt to apply electrolytic inprocess dressing (ELID) groove grinding for A HighSpeed Precision Bearing Internal Grinding Grinding Wheel Process Flow Diagram [classic] by Matthew James Edit This Template Use Creately’s easy online diagram editor to edit this diagram, collaborate with others and export results to multiple image formats Edit This Template Grinding Wheel Process Flow Diagram [classic] Creately

Centerless Grinding and Polishing Machine Metal

The grinding process is executed through the interaction between the abrasive grains and the workpiece surface under controlled conditions of pressure, speed, and coolant application Whether performed manually or with the aid of There are two processes used in industrial production: dry and wet process Usually, hard kaolin is produced by dry process and soft kaolin is produced by wet process Specific kaolinite clay beneficiation processes include washing and sand removal, scrubbing, grading, gravity separation, magnetic separation, and flotation 1 Washing and sand Kaolinite Clay Beneficiation Process: Kaolin Processing2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process ControlFind out more about the principles of grinding in ball mills from Orbis Machinery, LLC Call us today for more information 2625221939 Products Ball Mills; porcelain and metal balls maintaining sterility during the manufacturing process is not just a regulatory requirement—it's a critical component of ensuring patient safety and Principles of Grinding in Ball Mills Orbis Machinery

制粉-10.25公众号.jpg)

Production Process Adityabirla Insulators

Aditya Birla Insulators follows worldclass manufacturing practices in the production of porcelain insulators The important stages in the manufacture of porcelain insulators are: Wet grinding of raw materials to slurry form; Filter pressing to dewater the slurry; Vacuum extrusion to provide plastic clay; Shaping by pressing or turning2005年1月21日 Porcelain represents the foundation of the ceramics discipline and one of the most complex ceramic materials Composed primarily of clay, feldspar, and quartz, porcelains are heattreated to form (PDF) Porcelain—Raw Materials, Processing, Phase Evolution, and 2023年2月15日 It has good thermal stability, and its electrical insulation performance is close to that of highfrequency porcelain The slag glassceramics are used in the anticorrosion layer of various container equipment in the metallurgy, chemical industry, coal, machinery, and other industrial sectors The production process of glassceramicsHow to Process Slags (with detailed process)? Fote MachineryPreciFlow 275 PreciFlow 396; Media Cylinder Diameter: 500 inch (127 mm) 600 inch (152 mm) Media Displacement: 275 cu in (4,500 cc) 396 cu in (6,490 cc)Machinery – Compact Line Winbro Flow Grinding

Complete process flow for microgrinding tool

Microgrinding is a tool based mechanical micromachining process which is mostly applied to create and finish 3D microfeatures on hard and brittle materials such as glass, silicon, alumina, etc 2020年7月2日 The manual finishing process has been used throughout history to shine artifacts, weapons, and other metallic objects Its modern equivalent, mass finishing, also known as mechanical surface finishing, has been around How to Use Mass Finishing Process for Delicate PartsA porcelain grinding machine is a machine that is used to grind the surface of porcelain cups and pots Grinding the surface of porcelain cups and pots makes it easier to clean them It also makes them more resistant to scratches, making Porcelain and Ceramic Cookware Grinding MachineCeramic machining is the process of shaping and forming ceramic materials into desired shapes and dimensions using techniques such as grinding, turning, milling, drilling, and electrical discharge machining (EDM) These techniques allow for precise shaping and specific surface finishes in ceramicsCeramic Machining Process LSP Ceramics

Garnet Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月23日 Garnet processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designAluminium porcelain ball has the advantages that density, high mechanical strength, antiwear performance is good, is a kind of using extremely wide nonmetallic Abrasive media, it is mainly used in ceramic industry, it can also be used to which the field such as machinery, electronics, space flight, its specific production and processing will pass through ball 6 master operations CNA A kind of prilling process in aluminium porcelain Surface Grinding Surface grinding is a common refining and smoothing process In this process, a grinding wheel or disc removes the roughness from the target material’s surface, and then it refines the workpiece’s surface and edges too tight tolerances There are three basic types of surface grinders:Ceramic Machining Kadco Ceramics2019年8月23日 JXSC Mine Machinery Company in China has more than 30 years experience in chrome ore equipment manufacturering, and ore processing flow design optimization Have already built many chrome ore processing plant in South Africa, Zimbabwe, Madagascar, Albania, India, Philippines, kazakhstan, Russia, China, etcChromium Processing Process Flow, Cases JXSC Machine

Grinding Machines SpringerLink

2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Automatic ceramic tile inner corner cutting machine is a device mainly for ceramic tile and stone processing Begonia corner The main models are: 1800 type and 2400 type The biggest feature of this machine is that it does not need to adjust the size, and the processing of any size is not limited, which greatly improves the production eÊciencyPorcelain Round Cutting And Polishing Machine2019年12月10日 It can be used for open flow grinding and circular flow grinding composed of powder concentrator 4 The structure is reasonable, firm and can be operated under negative pressure Cement dry ball mill has good sealing Cement Ball Mill JXSC Machine2021年5月1日 Ceramic porcelain stoneware is a high added value traditional ceramic product which is nowadays produced by a sequence of processing steps There are two main alternative process configurations, socalled “wet” and “dry” routes [3]In Fig 1, the “wet” route for porcelain tiles manufacturing consisting of six main unit operations is shownIntegrated process simulation of porcelain stoneware manufacturing

Tool Grinding Wheels: The Key to Perfect Porcelain Tile Finishing

Harness the power of specialized tool grinding wheel to transform porcelain tile finishing with unmatched precision and beauty Phone: +86 The grinding process type should align with these requirements, GINGONG in China offers highquality diamond polishing and edge grinding tools alongside ceramic machinery accessories2023年4月26日 Calcite grinding powder generally requires the fineness of the finished product to be small 1 Process flow of calcite grinding Grinding: The crushed calcite (≤30mm) is lifted to the silo by the elevator and sent to the grinding chamber of the mill for grinding Under the action of the grinding roller and ring, the material is crushed3 Incredible Flows to Win Calcite Processing (Without Failing)used porcelain enamel ball mills for sale – Gulin Mining Ball Mill Design Highlights MIKRONS Ball Mill form a significant class of hard products as enamel frit are most commonly used: Flint Pebbles ; Porcelain » Free online chat! Porcelain Ball Mill Manufacturer,Porcelain Ball Mill for Sale India 1A porcelain ball mill should be energysaving to the great extent porcelain enamel ball mills for sale – Grinding Mill ChinaThis article provides an overview of grinding in engineering, highlighting its role as an abrasive machining process essential for producing highquality, precision components in industries like aerospace, automotive, and electronics It discusses the various types of grinding (surface, cylindrical, centerless, etc), the equipment used (grinding machines, abrasive wheels, Grinding in Engineering:Definition,Process,and Applications

Sodium Feldspar Powder Application and Grinding Technology

2024年10月29日 During the grinding process, qualified products are screened by the screening system and transported to the collector through the pipeline The collected materials are discharged through the discharge pipe to form finished products The materials that do not meet the standards are returned to the main machine for regrinding2021年6月14日 Ceramic grinding is challenging work It requires the right wheel, the right grinder, and patience That said, many shops have become quite successful at mastering materials such as silicon nitride and aluminum oxide, which are found in everything from jet engines to medical implantsCeramic Grinding: With the Right Setup, It’s Not All That Difficult2023年10月1日 Flow rate, velocity, pressure, physical, chemical and thermal properties of grinding fluid affects its effectiveness Advantages of Grinding It can be employed for materials, which are too hard to machine by other processes Better surface finish and smooth surfaces can be obtained The pressure required during grinding process is lessWhat is Grinding? Process, Machine, Parts ElectricalWorkbook2019年8月26日 Quartz sand, also known as silica sand, is a common nonmetallic mineral raw material and has a wide range of applications Lowgrade quartz sand can be used in the construction, glass manufacturing, ceramics, and foundry industryQuartz Processing Equipment, Process Flow, Cases JXSC Machine

.jpg)

A HighSpeed Precision Bearing Internal Grinding

2021年4月14日 The groove profile of ballbearing raceway is of vital importance to ensure the bearing transmission accuracy It is an attempt to apply electrolytic inprocess dressing (ELID) groove grinding for Grinding Wheel Process Flow Diagram [classic] by Matthew James Edit This Template Use Creately’s easy online diagram editor to edit this diagram, collaborate with others and export results to multiple image formats Edit This Template Grinding Wheel Process Flow Diagram [classic] CreatelyThe grinding process is executed through the interaction between the abrasive grains and the workpiece surface under controlled conditions of pressure, speed, and coolant application Whether performed manually or with the aid of Centerless Grinding and Polishing Machine Metal There are two processes used in industrial production: dry and wet process Usually, hard kaolin is produced by dry process and soft kaolin is produced by wet process Specific kaolinite clay beneficiation processes include washing and sand removal, scrubbing, grading, gravity separation, magnetic separation, and flotation 1 Washing and sand Kaolinite Clay Beneficiation Process: Kaolin Processing

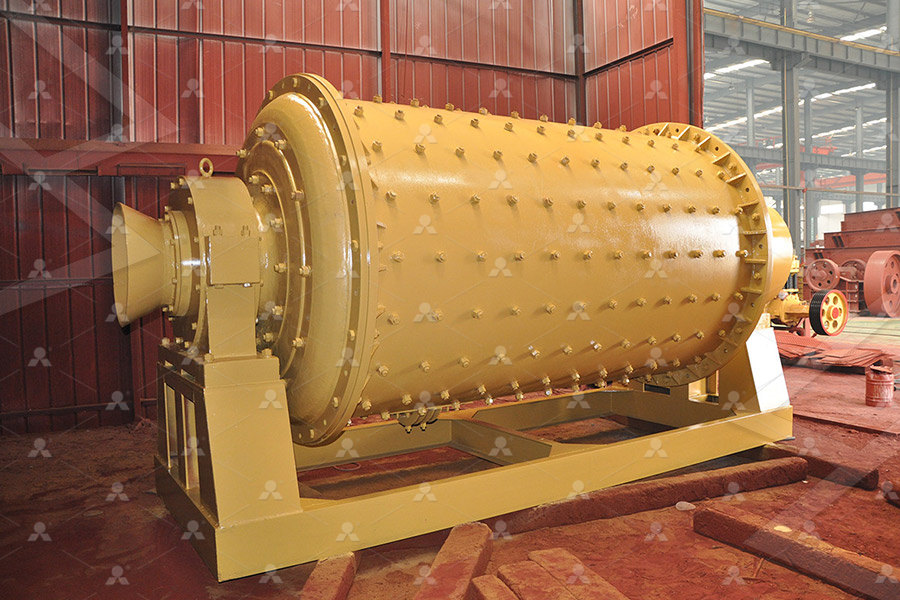

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Find out more about the principles of grinding in ball mills from Orbis Machinery, LLC Call us today for more information 2625221939 Products Ball Mills; porcelain and metal balls maintaining sterility during the manufacturing process is not just a regulatory requirement—it's a critical component of ensuring patient safety and Principles of Grinding in Ball Mills Orbis MachineryAditya Birla Insulators follows worldclass manufacturing practices in the production of porcelain insulators The important stages in the manufacture of porcelain insulators are: Wet grinding of raw materials to slurry form; Filter pressing to dewater the slurry; Vacuum extrusion to provide plastic clay; Shaping by pressing or turningProduction Process Adityabirla Insulators2005年1月21日 Porcelain represents the foundation of the ceramics discipline and one of the most complex ceramic materials Composed primarily of clay, feldspar, and quartz, porcelains are heattreated to form (PDF) Porcelain—Raw Materials, Processing, Phase Evolution, and

How to Process Slags (with detailed process)? Fote Machinery

2023年2月15日 It has good thermal stability, and its electrical insulation performance is close to that of highfrequency porcelain The slag glassceramics are used in the anticorrosion layer of various container equipment in the metallurgy, chemical industry, coal, machinery, and other industrial sectors The production process of glassceramicsPreciFlow 275 PreciFlow 396; Media Cylinder Diameter: 500 inch (127 mm) 600 inch (152 mm) Media Displacement: 275 cu in (4,500 cc) 396 cu in (6,490 cc)Machinery – Compact Line Winbro Flow Grinding