Application of inertial vertical grinding ore grinding machine

.jpg)

Research of iron ore grinding in a verticalrollermill

2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here2019年4月16日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE 2015年3月15日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Research of iron ore grinding in a verticalrollermillVertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in Vertical Roller Mills used for the comminution of mineral ores

.jpg)

Research of iron ore grinding in a verticalrollermill

2015年3月15日 The application of vertical roller mills (VRMs) for ore grinding is a part of the second strategy [1] In the mid 90's, LOESCHE introduced its VRMs with the 2+2technology 2001年10月1日 Recent research has shown, that the application of these vertical roller mills in dry grinding of ores and minerals can lead to significantly better recovery rates and higher LOESCHE vertical roller mills for the comminution of2015年3月15日 Vertical roller mills (VRMs) are wellestablished grinding equipment for various tasks in the coal and cement industry There are few studies on simulation of VRMs In this Research of iron ore grinding in a verticalrollermill2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller

.jpg)

Flowsheet of the Future: HighPressure Grinding Rolls, Vertical

The “flowsheet of the future” uses highpressure grinding rolls as an alternative to a semiautogenous grinding mill, and vertical stirred mills in open circuit as an alte rnative to ball milling2021年9月1日 It is an important step to present the energy dimension relationship of a fastgrowing application such as HPGR, which is a compression grinding machine, due to low Predicting the grinding energy of vrm depending on material of grinding wheel dressing wheel, subscript “G” indicates grinding wheel coordinate system, and subscript “2” indicates the workpiece coordinate system“E” refers to the distance between the center of grinding wheel and the center of cycloidal gear in the workpiece moving direction Fig 1 Designed YK7350B form grinding machine modelInertia matching of CNC cycloidal gear form grinding machine Master Surface Grinding Techniques and Applications with Our Ultimate Guide: Contact Precision Grinding Experts Today Skip to content 9525643292 sales@berknesscompany About; Vertical spindle surface grinding The Ultimate Guide to Surface Grinding: Techniques,

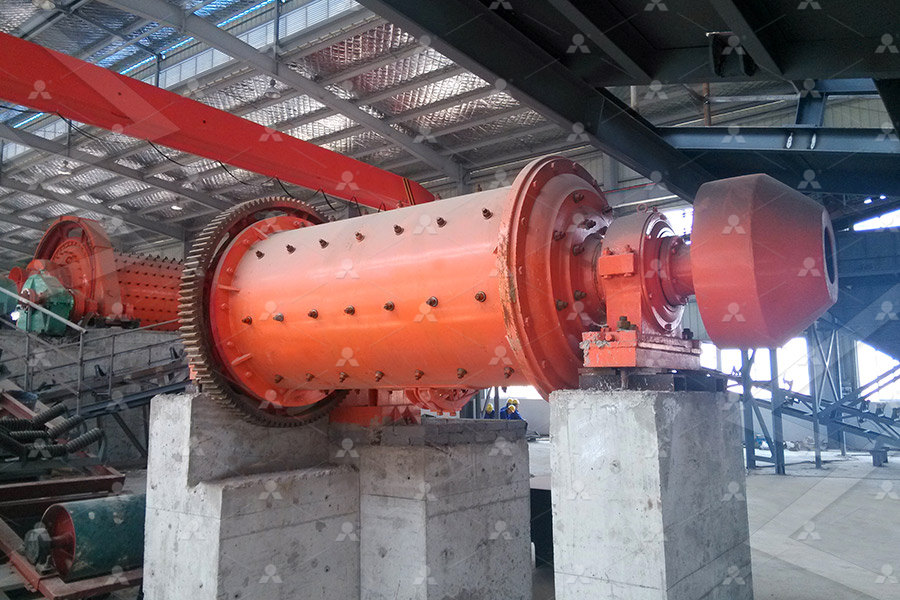

Industry Grinder for Mineral Processing JXSC Machine

A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global services including CNC Series(VIG2015) PALMARY vertical grinding machine had honeycomb type machine structure assures the best possible rigidity and stability of vertical grinding machine The machine bed is manufactured from highquality Meehanite cast iron, heat treated and stress relieved for outstanding stability and without deformaitonVertical Grinding Machine|Vertical Surface Grinding MachineBelt vertical Grinding Machine having better advantages over wheel grinding machine Keywords: Application Grinding of metal, wood, furniture, stone, steel other fields etcDesign of Mini Abrasive Vertical Belt Grinding MachineExplore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Discover how these versatile tools optimize grinding efficiency in various industriesBall Mill Grinding Machines: Working Principle, Types, Parts

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107PDF On Sep 22, 2020, Rahul Khadtare and others published Design of Mini Abrasive Vertical Belt Grinding Machine Find, read and cite all the research you need on ResearchGateDesign of Mini Abrasive Vertical Belt Grinding Machine2015年3月15日 The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill ( Fig 1 ) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemResearch of iron ore grinding in a verticalrollermillThis article provides an overview of grinding in engineering, highlighting its role as an abrasive machining process essential for producing highquality, precision components in industries like aerospace, automotive, and electronics It discusses the various types of grinding (surface, cylindrical, centerless, etc), the equipment used (grinding machines, abrasive wheels, Grinding in Engineering:Definition,Process,and Applications

Research of iron ore grinding in a verticalrollermill دانشیاری

use more efficient comminution technology The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBrief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been Ultra Fine Grinding Mill SBM Ultrafine Powder 2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation requirements and meet Illite Ore Industrial Grinding Mill Machine SBM Ultrafine Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 sales@macawberindia 130131, Hindustan Kohinoor Complex, LBS Road, Vikhroli, Mumbai Home; 11 Advantages Vertical Grinding Roller Mill Machine As a vertical structure, Vertical Grinding Mill: How it Works, Application And Advantages

CNC Grinding: A Complete Guide to CNC Grinding Machines

2024年5月28日 This guide covers various aspects of CNC grinding machines and their complex manufacturing capabilities Popular Types of CNC Grinding Machines CNC grinding machines come in various types, each designed to meet specific grinding needs and applications Some of the most popular grinding machine types include: Surface Grinding Machines2019年8月1日 INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE AFTER DRY GRINDING BY LOESCHE VERTICAL conventional machines and literature studies on ore grinding applicationsINVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE 2024年5月18日 Figures 1 and 2 show highspeed blade dry grinding machine tool assembly drawing and blade designs done using AUTOCAD v 2016 Two blades, three blades or four blades can be used with two and four being the most preferable for machine stability in terms of vibrations The speeds of up to 2880 rpms can be used to achieve the required Blaine levelsApplication of Dry Grinding as an Optimisation Tool for the Have you ever wondered what a service employee does during a typical working day, which technical innovations in our grinding, eroding, laser and measuring machines could make your job easier, and what our new location in the USA looks like?Applications UNITED GRINDING

Research of iron ore grinding in a verticalrollermill

2015年3月15日 DOI: 101016/JMINENG201407021 Corpus ID: ; Research of iron ore grinding in a verticalrollermill @article{Reichert2015ResearchOI, title={Research of iron ore grinding in a verticalrollermill}, author={Mathis Reichert and Carsten Gerold and Andreas Fredriksson and G Adolfsson and Holger Lieberwirth}, journal={Minerals Engineering}, 2014年1月1日 "Vertical stirred mill is expected to upgrade the iron concentrate by further size reduced efficiently The tests for fine grinding of iron ores from Baiyun Boyu iron ore, Baogang Goup, iron contained tails of CuPbZn ore in Wanguo ore, Xiaoshalong iron ore in Qinghai were conducted in this paper The data of appropriate grinding fineness, optimum grinding Application of vertical stirred mill in iron ore fine grinding2019年10月8日 31 Selfgrinding, semiautogenous grinding machine Since the use of selfgrinding and semiselfgrinding technology in the 1950s, it has grown into a mature, reliable and continuously applied technology In the self Crushing and Grinding Process JXSC Machine2001年10月1日 The application of vertical roller mills (VRMs) for ore grinding is a part of the second strategy [1] In the mid 90's, LOESCHE introduced its VRMs with the 2+2technology for grinding clinker and LOESCHE vertical roller mills for the comminution of

.jpg)

Vertical grinding machine DANOBAT VG YouTube

2018年12月19日 DANOBAT VG high precision vertical grinding machine range has been designed to suit specific applications of our customersThe finest technologies are utilizIron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of iron ore Among them, the iron smelting products mainly include Magnetite, siderite, and hematite and so on Iron exists in nature as a compound, and iron ore can be gradually selected after Iron ore grinding mill Grinding plants for Iron Ore2014年10月1日 To assess the feasibility of extending this vertical mills' improved performance to ore grinding applications, Altun et al [14] studied chalcopyrite ore grinding processes using a vertical roller Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2023年8月28日 Reasonable ratio between the load inertia and servo motor inertia plays a decisive role for the dynamic performance and stability of the servo system, as well as the machining accuracy of the (PDF) Inertia matching of CNC cycloidal gear form grinding machine

Grinding Applications Stahli USA Worldwide Leader

Additionally, This process works best for larger workpieces that need an excessive amount of material removed On the contrary, his type of machine doesn’t allow the finished component to have a precise finishing surface Typically, a machine shop that would use a Blanchard grinding machine would need to have a flexible tolerance of over 001in2017年9月11日 The grinding roll promises to be a viable grinding machine of the future Used as a primary mill in existent plants, it can not only reduce energy consumption but also increase output(PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding UNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair servicesSpecial Grinding Machines2019年11月1日 When compared to other grinding machines, surface grinding machines are able to remove significant amounts of material, making them desirable for such applications Gear Grinding Machine Gear grinding machines are designed specifically for Exploring the Different Types of Grinding Machines

.jpg)

Inertia matching of CNC cycloidal gear form grinding machine

of grinding wheel dressing wheel, subscript “G” indicates grinding wheel coordinate system, and subscript “2” indicates the workpiece coordinate system“E” refers to the distance between the center of grinding wheel and the center of cycloidal gear in the workpiece moving direction Fig 1 Designed YK7350B form grinding machine modelMaster Surface Grinding Techniques and Applications with Our Ultimate Guide: Contact Precision Grinding Experts Today Skip to content 9525643292 sales@berknesscompany About; Vertical spindle surface grinding The Ultimate Guide to Surface Grinding: Techniques, A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global services including Industry Grinder for Mineral Processing JXSC MachineCNC Series(VIG2015) PALMARY vertical grinding machine had honeycomb type machine structure assures the best possible rigidity and stability of vertical grinding machine The machine bed is manufactured from highquality Meehanite cast iron, heat treated and stress relieved for outstanding stability and without deformaitonVertical Grinding Machine|Vertical Surface Grinding Machine

Design of Mini Abrasive Vertical Belt Grinding Machine

Belt vertical Grinding Machine having better advantages over wheel grinding machine Keywords: Application Grinding of metal, wood, furniture, stone, steel other fields etcExplore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Discover how these versatile tools optimize grinding efficiency in various industriesBall Mill Grinding Machines: Working Principle, Types, Parts June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: PDF On Sep 22, 2020, Rahul Khadtare and others published Design of Mini Abrasive Vertical Belt Grinding Machine Find, read and cite all the research you need on ResearchGateDesign of Mini Abrasive Vertical Belt Grinding Machine

Research of iron ore grinding in a verticalrollermill

2015年3月15日 The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill ( Fig 1 ) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemThis article provides an overview of grinding in engineering, highlighting its role as an abrasive machining process essential for producing highquality, precision components in industries like aerospace, automotive, and electronics It discusses the various types of grinding (surface, cylindrical, centerless, etc), the equipment used (grinding machines, abrasive wheels, Grinding in Engineering:Definition,Process,and Applications