Lithium ore grinding mill graphite manufacturing conditions

Graphite Ore Mining Production Line TAYMACHINERY

A graphite ore mining production line is used to extract and process graphite ore to produce graphite concentrate, which has numerous applications across various industries due to its 2023年5月12日 Graphite ore grinding (1) Generally, multistage grinding and multistage flotation process are adopted, with 2~7 times of grinding and 2~10 times of flotation; (2) Equipment: Rod mill or grid type ball mill is mostly Graphite Ore Processing: Optimal Processes and In this study, we proposed a simple strategy for preparing Nano graphite as the anode of lithiumion batteries by the rapid mechanical grinding method Diamond particles have been selected Nano graphite produced by rapid grinding as an anode for lithium 2024年9月20日 Converting waste graphite into batterygrade graphite can effectively reduce manufacturing cost and environmental impact While recycled scrap graphite may not meet Practical application of graphite in lithiumion batteries

Processing of lithium ores: Industrial technologies and case studies

2021年5月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically 2024年5月27日 Graphite extraction and processing involve a series of steps to transform raw graphite ore into usable forms with desired properties The process typically includes mining, Graphite Processing: From Raw Material to HighValue Applications2023年5月17日 Milling bulk graphite material to ultrafine micron size provides more space for the storage of lithium ions and improves performance, but the process is not straightforward How milling graphite can enhance the performance of lithiumion 2023年5月27日 The role of ball milling in lithium ore processing is to break down the lithiumcontaining minerals and release the lithium ions into the solution This is achieved through the Ball Milling in Lithium Ore Processing: A Comprehensive Guide

.jpg)

A Shortened Process of Artificial Graphite Manufacturing for

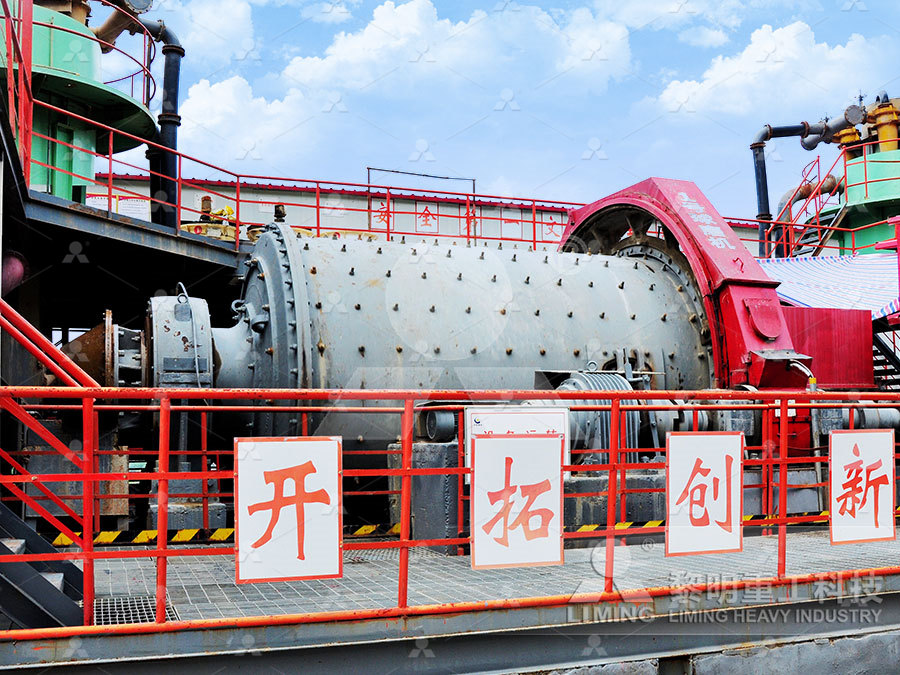

2024年12月1日 Recently, due to the rapid increase in the demand for artificial graphite, there has been a strong need to improve the productivity of artificial graphite In this study, we 2024年7月9日 SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill +17 [ protected]Lithium Ore Grinding Mills SBM Ultrafine Powder For spodumene with a relatively coarse crystal size, the heavymedia beneficiation method can be applied to make lithium ore a heavy mineral productMix the lithium ore after washing and desliming with heavymedia (there are two types of heavy medium: heavy liquid and heavy suspension, here mainly refer to heavy suspension), and feed it into the heavy medium Lithium Ore Production Line TAYMACHINERY2024年3月21日 The Significance of Grinding in Lithium Ore Processing: Grinding stands as an indispensable process in lithium ore processing, playing a pivotal role in liberating lithiumbearing minerals from the surrounding gangue materialBy reducing the ore particles to a finely ground state, grinding sets the stage for subsequent beneficiation processes, including flotation, Lithium Ore Grinding Mills

.jpg)

how to choose lithium mineral grinding mill

2022年5月26日 lithium mineral grinding mill case site, welcome to leave a message or consult [ protected] The application prospect of lithium ore after crushing, grinding and sorting will be To choose a good lithium mineral grinding mill, not only the output, fineness, and feeding conditions should be considered, but also the site Here are the primary uses of graphite and the overall utility of a graphite ore mining production line: Uses of Graphite Battery Manufacturing: LithiumIon Batteries: Graphite is a critical component of the anodes in lithiumion batteries, which are used in electric vehicles, portable electronics, and renewable energy storage systems Graphite Ore Mining Production Line TAYMACHINERY2023年7月31日 1 Large discharge port design, enabling a strong processing capacity for lithium ore, reaching up to 160t/h 2 Equipped with an automatic control system (PLC) that reduces labor costs and provides realtime transmission of equipment operating conditions for troubleshootingWhat ball mill for grinding lithium ore? What is the grinding 2024年12月1日 Recently, due to the rapid increase in the demand for artificial graphite, there has been a strong need to improve the productivity of artificial graphite In this study, we propose a new efficient process by eliminating the carbonation stage from the existing process The conventional graphite manufacturing process usually involves a series of stages: the A Shortened Process of Artificial Graphite Manufacturing for

Graphite Powder Grinding Mill Machines

2024年3月12日 Grinding Chamber: The HGM grinding mill features a grinding chamber where the graphite material is fed for processingThis chamber is equipped with grinding rollers or rings that rotate around a central axis Grinding Rollers/Rings: Inside the grinding chamber, there are multiple sets of grinding rollers or ringsThese rollers or rings apply pressure to the graphite For spodumene with a relatively coarse crystal size, the heavymedia beneficiation method can be applied to make lithium ore a heavy mineral productMix the lithium ore after washing and desliming with heavymedia (there are two types of heavy medium: heavy liquid and heavy suspension, here mainly refer to heavy suspension), and feed it into the heavy medium Lithium Ore Production Line TAYMACHINERY2022年10月31日 Introduction Lithium has gained great interest since its discovery in the early 1800s due to its application in glass, ceramic, rubber, grease manufacturing, air conditioning, aluminium industry 1, 2The recent application of lithium in lithiumion batteries has resulted in drastic increases in demand 3 – 6 Brine deposits have been the dominant source for lithium Lithium deportment by size of a calcined spodumene oreWhat is Spherical Graphite Grinding Mill Line for LithiumIon Battery, Ce Certificated Synthetic Graphite Spheroidization Grinding mill manufacturers suppliers on Video Channel of MadeinChinaWhat is Spherical Graphite Grinding Mill Line for LithiumIon

Spherical Graphite Grinding Mill Line for Lithium

2010年1月15日 Spherical Graphite Grinding Mill Line for LithiumIon Battery, Home Manufacturing Processing Machinery Agricultural Machinery Feed Processing Machinery; Spherical Graphite Grinding Mill Line for LithiumIon 2022年12月13日 Plus powder grinding lithium ore Xiaobian recommend LM large vertical mill, LM vertical mill using modern technology, has a national patent, set drying, grinding, powder selection, transportation in one; Single machine output, high efficiency, small metal pollution, stable operation, concentrated particle size distribution, skilled in the field of nonmetallic How to mine lithium ore, mineral processing, crushing, grindingFroth Flotation is one of the main methods for separating lithium ore Any lithium ore with an industrial value could apply the flotation method to form a closecircuit with ball mill for grinding, and control the mill’s output size Mixing tank / Agitating tank Equipment manufacturing OEM serviceLithium Ore Flotation Plant Pineer Mining MachineryGraphite Ball Mill 1Graphite ore ball mill investment is small 2The continuous operation of a graphite ball mill can achieve longterm operation and create high efficiency in the later period 3The graphite stone grinding mill adopts advanced technology, which has obvious energysaving and environmental protection effects, and low Graphite Powder Grinding Mill for Graphite Processing Fine Graphite

.jpg)

Flotation Machine for Lithium Ore: Efficient Separation and

2023年5月14日 The lithium ore flotation machine is highly selective, meaning it can selectively recover lithium from the ore while leaving other minerals behind This is important as it allows for the production of highpurity lithium products, which are essential for the manufacturing of lithiumion batteries 5) Scalability2024年4月26日 The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semiautogenous (SAG) mills are used for grinding These mills utilize the ore itself as the grinding media, reducing the need for additional Iron Ore Processing: From Extraction to Manufacturing2023年9月11日 The inside of the barrel can be set up in 2 or multiple chambers (generally at most four rooms) The length of each chamber is determined according to the grinding conditions This ball mill is used in lithium ore dressing It can be used in the factory for finegrinding operations 4 Lithium ore energysaving ball millBall Mills for Lithium Ore JXSC Machine2024年5月9日 01 Grinding and flotation process of graphite ore The important basis for measuring the value of flake graphite ore is the size of graphite flakes and the fixed carbon content The concentrate measurement index produced in the beneficiation process depends on the dissociation mode, dissociation degree and subsequent beneficiation process of the mineralsNew Grinding Floating Technology in Graphite Ore Dressing

Lithium (Li) Ore Minerals, Formation, Deposits Geology Science

2023年4月23日 Lithium (Li) ore is a type of rock or mineral that contains significant concentrations of lithium, a soft, silverwhite alkali metal with the atomic number 3 and symbol Li on the periodic table Lithium is known for its unique properties, such as being the lightest metal, having the highest electrochemical potential, and being highly reactive with water2023年3月1日 Guo et al [90] discovered that increasing grinding mill filling reduced the liberation of lithium ore Grinding media and material were centrifuging at 60% mill filling volume whilst this Study on the unequalprobability comminution of ResearchGateIncreasing the ore productivity of the grinding mill under the influence of external disturbances, preventing overloading of the mill in operating conditions close to overloading MethodsFlow diagram of the ball mill grinding processCrushing stage: The coarsely crushing of crystalline and aphanitic graphite ore can use a jaw crusherAnd medium and fine graphite crushing use cone crushers and hammer crushers Grinding stage: graphite grinding equipment can Graphite Ore Mining Process JXSC Mineral

.jpg)

Nano graphite produced by rapid grinding as an anode for lithium

Nano graphite produced by rapid grinding as an anode for lithiumion batteries Materials and Methods Fabrication of NanoGraphite Nanographite was prepared from natural flake graphite (1200 mesh, Shanghai Macklin Abstract Reducing the particle size of active materials is an effective solution to the performance degradation of lithiumion Spherical Graphite Grinding Mill Line for LithiumIon Battery, Industrial Equipment Components, Manufacturing Processing Machinery Management System Certification: ISO 9001, ISO 14001 Main Products: Pulverizer, Crusher, Grinding MillSpherical Graphite Grinding Mill Line for LithiumIon Battery2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car market, it is crucial to improve lithium recovery from its rich mineral deposits using the most effective extraction technique In recent years, both Aspects of Spodumene Lithium Extraction Techniques MDPI2021年11月1日 For example, a graphite ore sample from Shangrao, Jiangxi province, China requires seven stages of grinding, six stages of cleaner flotation, and two stages of scavenger flotation in addition to a rougher flotation stage to obtain a concentrate with 9215% grade and 8922% recovery [19]An innovative flake graphite upgrading process based on

Graphite Ore Mining Production Line TAYMACHINERY

Here are the primary uses of graphite and the overall utility of a graphite ore mining production line: Uses of Graphite Battery Manufacturing: LithiumIon Batteries: Graphite is a critical component of the anodes in lithiumion batteries, which are used in electric vehicles, portable electronics, and renewable energy storage systems 2024年7月9日 SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill +17 [ protected]Lithium Ore Grinding Mills SBM Ultrafine Powder For spodumene with a relatively coarse crystal size, the heavymedia beneficiation method can be applied to make lithium ore a heavy mineral productMix the lithium ore after washing and desliming with heavymedia (there are two types of heavy medium: heavy liquid and heavy suspension, here mainly refer to heavy suspension), and feed it into the heavy medium Lithium Ore Production Line TAYMACHINERY2024年3月21日 The Significance of Grinding in Lithium Ore Processing: Grinding stands as an indispensable process in lithium ore processing, playing a pivotal role in liberating lithiumbearing minerals from the surrounding gangue materialBy reducing the ore particles to a finely ground state, grinding sets the stage for subsequent beneficiation processes, including flotation, Lithium Ore Grinding Mills

how to choose lithium mineral grinding mill

2022年5月26日 lithium mineral grinding mill case site, welcome to leave a message or consult [ protected] The application prospect of lithium ore after crushing, grinding and sorting will be To choose a good lithium mineral grinding mill, not only the output, fineness, and feeding conditions should be considered, but also the site Here are the primary uses of graphite and the overall utility of a graphite ore mining production line: Uses of Graphite Battery Manufacturing: LithiumIon Batteries: Graphite is a critical component of the anodes in lithiumion batteries, which are used in electric vehicles, portable electronics, and renewable energy storage systems Graphite Ore Mining Production Line TAYMACHINERY2023年7月31日 1 Large discharge port design, enabling a strong processing capacity for lithium ore, reaching up to 160t/h 2 Equipped with an automatic control system (PLC) that reduces labor costs and provides realtime transmission of equipment operating conditions for troubleshootingWhat ball mill for grinding lithium ore? What is the grinding 2024年12月1日 Recently, due to the rapid increase in the demand for artificial graphite, there has been a strong need to improve the productivity of artificial graphite In this study, we propose a new efficient process by eliminating the carbonation stage from the existing process The conventional graphite manufacturing process usually involves a series of stages: the A Shortened Process of Artificial Graphite Manufacturing for

Graphite Powder Grinding Mill Machines

2024年3月12日 Grinding Chamber: The HGM grinding mill features a grinding chamber where the graphite material is fed for processingThis chamber is equipped with grinding rollers or rings that rotate around a central axis Grinding Rollers/Rings: Inside the grinding chamber, there are multiple sets of grinding rollers or ringsThese rollers or rings apply pressure to the graphite For spodumene with a relatively coarse crystal size, the heavymedia beneficiation method can be applied to make lithium ore a heavy mineral productMix the lithium ore after washing and desliming with heavymedia (there are two types of heavy medium: heavy liquid and heavy suspension, here mainly refer to heavy suspension), and feed it into the heavy medium Lithium Ore Production Line TAYMACHINERY2022年10月31日 Introduction Lithium has gained great interest since its discovery in the early 1800s due to its application in glass, ceramic, rubber, grease manufacturing, air conditioning, aluminium industry 1, 2The recent application of lithium in lithiumion batteries has resulted in drastic increases in demand 3 – 6 Brine deposits have been the dominant source for lithium Lithium deportment by size of a calcined spodumene ore