Changde fly ash processing

.jpg)

A critical review on mechanochemical processing of fly ash and fly

2023年2月20日 This paper is aimed at providing a comprehensive overview of advances in the mechanical processing of fly ash and fly ashderived materials, in addition to highlighting the 2024年3月1日 Gong et al (2023) proposed a novel process for the extraction of alumina from high alumina fly ash using an improved hydrochemical process, in which the low alkali Review A review on fly ash highvalue synthesis utilization and its fly ash depends not only on the coal types and sources (chemical composition), but also the power plant processing conditions and the collection system (physical composition) From Fly Ash Separation Technology and its Potential ApplicationsFly ash can undergo aging in the atmosphere through interactions with sulfuric acid and water These reactions could result in chemical and physical changes that could affect the cloud condensation or ice nucleation activity of fly ash Acidic processing of fly ash: chemical characterization,

An Investigation of Fly Ash and Slag Processing and

2024年6月1日 The purposes of this study were to process fly ash and slag (formed during the incineration of household waste) using a plasmabased chemical process, to investigate the influence of technological parameters on With the functionality to process both wet and dry fly ash, the MP618 technology can be installed at operating power plants, nonoperating power plants or offsite, regardless of whether the fly COSTEFFECTIVE ASH BENEFICIATION TECHNOLOGY Charah2020年12月17日 Treatment techniques of incineration fly ash were discussed to determine the effectiveness of obtaining environmentally stable material, and, finally, possible applications of incineration(PDF) Incineration Fly Ash and Its Treatment to Possible 2021年9月1日 Fly ash can be modified or transformed into new materials for heavy metal ions adsorption The high content of Al 2 O 3 and SiO 2 in class F fly ash make it suitable for Fly ash properties, characterization, and applications: A review

Operations: Operated Own Processing and Packing

Fly Ash Processing and Packing Plant at Sembcorp Energy India Limited (Owned and Operated by JAYCEE) 0 km from thermal power plant 35 km from Krishnapatnam Port 200 km from Chennai Airport 12 million MT per annum Fly ash can undergo aging in the atmosphere through interactions with sulfuric acid and water These reactions could result in chemical and physical changes that could affect the cloud condensation or ice nucleation activity of fly ash Acidic processing of fly ash: chemical characterization, 2013年4月1日 In the United States, coalfired power plants generated 119 billion kg of ash, roughly one half of this being classified as fly ash [9] While some coalderived ashes can be used for the manufacture of products (cements, structural fill, road base), much of it is destined for disposal because the heavy metals naturally occurring in coal are concentrated in the ash [9], Analysis of the fly ash from the processing of wood chips in a 2017年1月1日 Recent figures indicate that 780 Mt of coal combustion residues are produced globally on an annual basis (Heidrich, Feuerborne, Weir, 2013)Much of the fly ash from this is used beneficially; for example, utilization in the European Union was about 43% in 2010 (European Coal Combustion Products Association, 2016), which is comparable to levels in the Recovery, processing, and usage of wetstored fly ash

.jpg)

(PDF) Processing of incinerated municipal solid waste fly ash

2018年12月1日 Fly ash resulting from Municipal Incinerated Solid Wastes (MISW) can be potentially reused as cement replacement in concrete However, treatment of these fly ashes is found to be prerequisite for Our process experts are wellversed in fly ash processing and regularly conduct feasibility studies in the Innovation Center to test and evaluate the best pelletization solution for each unique sample MATERIAL PROCESSING Agglomeration We offer disc pelletizers, pug mills, Fly Ash Processing Equipment FEECO International Inc2020年12月17日 Treatment techniques of incineration fly ash were discussed to determine the effectiveness of obtaining environmentally stable material, and, finally, possible applications of incineration fly ash (PDF) Incineration Fly Ash and Its Treatment to Possible2018年11月14日 Fly ash can undergo aging in the atmosphere through interactions with sulfuric acid and water These reactions could result in chemical and physical changes that could affect the cloud condensation or ice nucleation activity of fly ash particles To explore this process, different water and acid tre Acidic processing of fly ash: chemical characterization,

The influence of selected grain size fractions of coal fly ash on

2024年9月14日 Fly ash processing and separation are commonly used to enhance ash properties and extract various grain fractions with the desired parameters 3,4 Concerning this study, the separation due to the 2020年2月17日 In order to meet the increasing energy demand and to decrease the dependency on coal, environmentally friendly methods for fly ash utilization are required In this respect, the priority is to identify the fly ash properties and to consider its potential as raw material in the obtaining of highvalue materials The physicochemical and structural characteristics of Fly Ash, from Recycling to Potential Raw Material for Mesoporous 2021年1月13日 In Switzerland, waste wood fly ash (WWFA) must be treated before deposition on landfills due to its high pollutant load (Cr(VI) and heavy metals) Acid fly ash leaching, the process used for heavy metal recovery from Waste Wood Fly Ash Treatment in Switzerland: Effects 2023年5月27日 Fly ash processing technology has transformed fly ash from waste into a popular construction material It can be used in cement, concrete, lightweight aggregate, grouting, siding, and soil stabilization To achieve the How to Process Fly Ash and What Is It Used for? Fote

data for fly ash processing limited to drying and stocking,

Download scientific diagram data for fly ash processing limited to drying and stocking, adapted from (Chen et al, 2010) from publication: A lifecycle approach to environmental, mechanical 2023年8月16日 Harvested fly ash, an indispensable ingredient for contemporary cement manufacturing, is a fine, powdery byproduct of coal combustion originating from power plantsRich in silica, alumina, iron, and calcium, fly ash’s composition and properties are influenced by the type of coal used and the specificities of the combustion processFly ash processing: Tailored solutions for reclaimed fly ash Atritor2019年6月1日 In this study, five fly ashes from China and Australia were selected for carbonation The experiments were first performed in a batch reactor at 40 and 140 °C, 20 bar initial CO 2 pressure, 200 g/L solid to liquid ratio, 450 rpm stirring rate to compare the carbonation characteristics of the five fly ashes and investigate the effects of fly ash properties on Effects of fly ash properties on carbonation efficiency in CO2 TECHNOLOGIES OF COAL FLY ASH PROCESSING INTO METALLURGICAL AND SILICATE CHEMICAL PRODUCTS Solomon Shcherhan, Int Assn of Science, Inc, 1 IO Bennett Ave, 3H New York, NY 10033; Victor Raizman TECHNOLOGIES OF COAL FLY ASH PROCESSING INTO

.jpg)

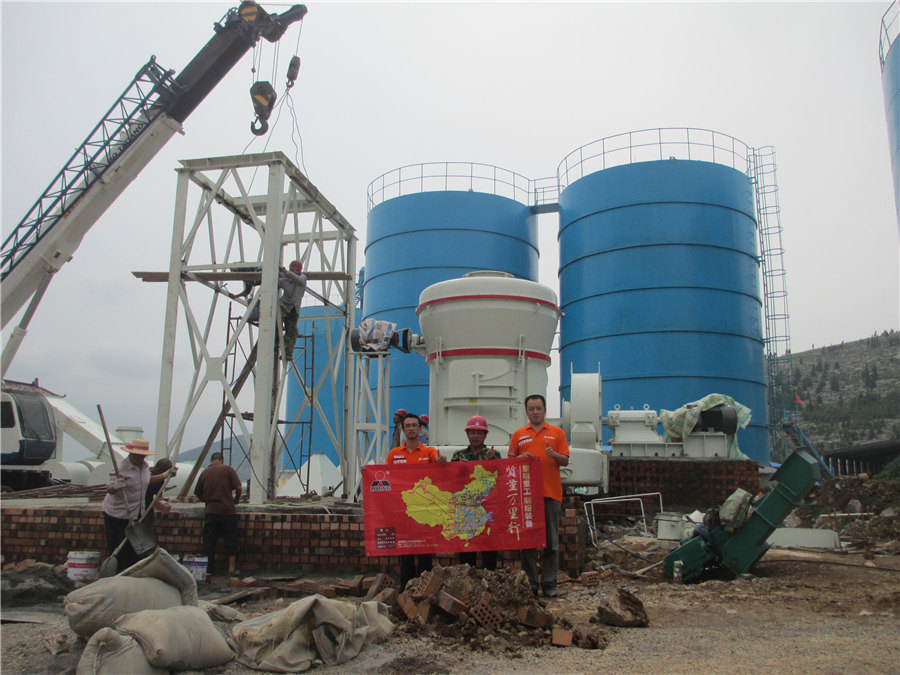

Fly Ash Processing Plant Cement Equipment Manufacturing

The fly ash processing plant constructed by AGICO Cement is highly automated and mechanized, with low investment, high profit, simple structure and easy operation, which helps each region realize reasonable waste recycling and utilization to ‘green up’ users’ supply chains Raw Material: Fly Ash / Volcanic Ash: Capacity(t/h) 811:2018年9月1日 1 Introduction Fly ash has found increasing use as an addition (cement component) in recent years, giving benefits to concrete's performance, including aspects of durability, and environmental impact [1, 2]With moves from coalfiring in electricity generation to alternative methods, the availability of fly ash for concrete is being affected [3]Dryprocessing of longterm wetstored fly ash for use as an 2018年4月1日 This work investigated the course of fly ash’s glassy phase crystallization in terms of structural and thermal changes On the basis of XRD studies the olivine and albite phases are formed after Effect of thermal processing on the structural characteristics of fly 2020年8月10日 Generally, the fly ash, metakaolin, fly ashmetakaolin based geopolymers all could be prepared at lower temperature by alkaline activation [16] While, when fly ashmetakaolin mixtures were alkaliactivated and followed by a hydrothermal processing at higher temperatures (90–210 ℃), the hydroceramics [17] and zeoceramics [18] could be synthesizedHydrothermal processing, characterization and leaching toxicity

.jpg)

Recent trends in mechanochemical processing of fly ash

2023年10月18日 For achieving sustainable development in terms of waste to wealth, low CO2 production, and recycling, geopolymers can be recognized as a practicable alternative The current review presented a brief study of the potential usage of class F fly ash as a raw material for geopolymer, the chemistry of geopolymerization, and recent development in the field A 2023年9月1日 The geopolymer foams were made using fly ash, which was sourced from Skawina Combined Heat and Power Plant (Skawina, Poland) The XRD oxide analysis of the fly ash is shown in Table 1Portland cement (Górażdże, Poland) was the hydraulic additive stabilizing the porous structures produced, while 5 g of Syringaldehyde powder (Merck, Germany) was Influence of the addition of phase change materials on thermal Remedial processing of oil shale fly ash (OSFA) and its valueadded conversion into glassceramics Waste Manag 2015 Dec;46:31621 doi: 101016/jwasman201509007 Epub 2015 Sep 19 Authors Zhikun Zhang 1 , Lei Zhang 1 , Aimin Li 2 Affiliations 1 Key Laboratory of Remedial processing of oil shale fly ash (OSFA) and its value 2019年9月13日 The fly ash collected from the combustion of Crdoped coal alone has a lower water solubility (ie, 587%) for its Cr(VI) species, due to the formation of Ba/Pb chromate and/or the incorporation Speciation and risk assessment of heavy metals in MSWI fly ash

SEFA Announces New Coal Ash Processing Milestone

2023年10月12日 The SEFA Group, LLC has announced a new milestone in processing over 5 million t of harvested coal ash for beneficial, encapsulated use since 2015 Coal ash is excavated from legacy ash ponds, beneficiated, and converted into highquality, specificationgrade fly ash for recycling into concrete highway and construction projects2015年12月1日 Remedial processing of oil shale fly ash (OSFA) and its valueadded conversion into glass–ceramics Author links open overlay panel Zhikun Zhang, Lei Zhang, Aimin Li Show more various solid wastes such as coal fly ash (Albertini et al, 2013), fly ash (Chen et al, 2013, Li et al, 2013) and industrial slag (Khater et al Remedial processing of oil shale fly ash (OSFA) and its value and 1 beneficiated stockpile) in concrete (III) Laboratory studies of wetstored fly ash and evaluation of various processing techniques (assessed by fly ash characterisation and use in concrete) (IV) A visit to a site carrying out beneficiation of wetstored fly ash and evaluation of material before and after recovery This was followed by a University of Dundee Innovative Processing of Stockpile Fly Ash 内容提示: Designation: E1266 − 20Standard Practice forProcessing Mixtures of Lime, Fly Ash, and Heavy MetalWastes in Structural Fills and Other ConstructionApplications 1This standard is issued under the f i xed designation E1266; the number immediately following the designation indicates the year oforiginal adoption or, in the case of revision, the year of last revisionASTM E12662020 Standard Practice for Processing Mixtures of Lime, Fly

Accelerated CO2 mineralization technology using fly ash as raw

2024年5月15日 Fly ash is composed of fine particles captured from flue gas generated during fuel combustion, Fitting and processing data for temperatures 20–80 °C, additive concentrations 0–15 mol/L, and gas flow rates 05–15 L/min yielded an R 2 value of 0996Coal fly ash (FA) valorization is of great significance and sustainable interests to addressing the current environmental challenges faced by coal power industry Herein, this work attempted a novel molten salt Na2CO3 treatment for processing FA into a robust matrix to support lauric acid (LA) toward construction of latent phase change compositeSurface RoughnessGoverned Shape Stability of the Coal Fly Ash Fly Ash Processing and Packing Plant at Sembcorp Energy India Limited (Owned and Operated by JAYCEE) 0 km from thermal power plant 35 km from Krishnapatnam Port 200 km from Chennai Airport 12 million MT per annum Operations: Operated Own Processing and PackingFly ash can undergo aging in the atmosphere through interactions with sulfuric acid and water These reactions could result in chemical and physical changes that could affect the cloud condensation or ice nucleation activity of fly ash Acidic processing of fly ash: chemical characterization,

Analysis of the fly ash from the processing of wood chips in a

2013年4月1日 In the United States, coalfired power plants generated 119 billion kg of ash, roughly one half of this being classified as fly ash [9] While some coalderived ashes can be used for the manufacture of products (cements, structural fill, road base), much of it is destined for disposal because the heavy metals naturally occurring in coal are concentrated in the ash [9], 2017年1月1日 Recent figures indicate that 780 Mt of coal combustion residues are produced globally on an annual basis (Heidrich, Feuerborne, Weir, 2013)Much of the fly ash from this is used beneficially; for example, utilization in the European Union was about 43% in 2010 (European Coal Combustion Products Association, 2016), which is comparable to levels in the Recovery, processing, and usage of wetstored fly ash2018年12月1日 Fly ash resulting from Municipal Incinerated Solid Wastes (MISW) can be potentially reused as cement replacement in concrete However, treatment of these fly ashes is found to be prerequisite for (PDF) Processing of incinerated municipal solid waste fly ash Our process experts are wellversed in fly ash processing and regularly conduct feasibility studies in the Innovation Center to test and evaluate the best pelletization solution for each unique sample MATERIAL PROCESSING Agglomeration We offer disc pelletizers, pug mills, Fly Ash Processing Equipment FEECO International Inc

(PDF) Incineration Fly Ash and Its Treatment to Possible

2020年12月17日 Treatment techniques of incineration fly ash were discussed to determine the effectiveness of obtaining environmentally stable material, and, finally, possible applications of incineration fly ash 2018年11月14日 Fly ash can undergo aging in the atmosphere through interactions with sulfuric acid and water These reactions could result in chemical and physical changes that could affect the cloud condensation or ice nucleation activity of fly ash particles To explore this process, different water and acid tre Acidic processing of fly ash: chemical characterization, 2024年9月14日 Fly ash processing and separation are commonly used to enhance ash properties and extract various grain fractions with the desired parameters 3,4 Concerning this study, the separation due to the The influence of selected grain size fractions of coal fly ash on 2020年2月17日 In order to meet the increasing energy demand and to decrease the dependency on coal, environmentally friendly methods for fly ash utilization are required In this respect, the priority is to identify the fly ash properties and to consider its potential as raw material in the obtaining of highvalue materials The physicochemical and structural characteristics of Fly Ash, from Recycling to Potential Raw Material for Mesoporous