Working principle of Namibia ore powder machine

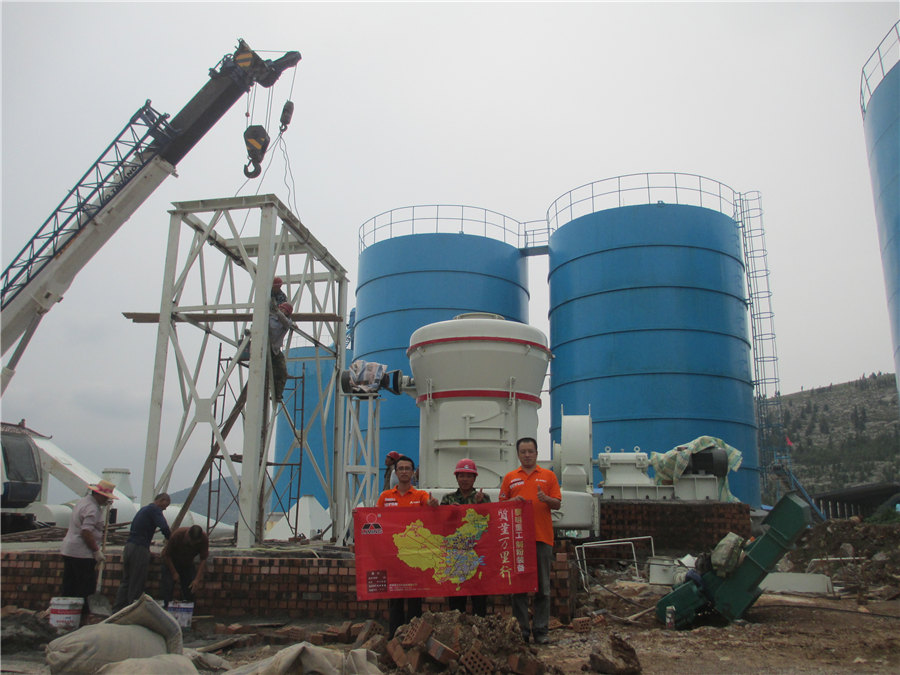

Grinding mill for sale in Africa SANDMINE

2024年1月31日 Working Principle: The working principle of mining powder mills is essentially to grind ore particles through mechanical force and friction These machines typically consist of a rotating grinding stone or disc where ore particles are placed and then ground through rotation 2023年3月2日 Working principle: After the compressed air is cooled, filtered and dried, it forms a supersonic airflow through the nozzle and injects it into the rotary crushing chamber to make How to choose a grinding equipment? ALPA PowderThe Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation SBM has launched three upgrade series of Raymond Raymond Mill History, Working Principle ApplicationsSBM 2021年11月1日 The main purpose of the video is to demonstrate the working principle of the jig, in other words, you could understand how the jig improves the ore grade The video is divided WORKING PRINCIPLE OF JIG MACHINE

.jpg)

Roller Mill Springer

Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the air lock feeder, and the 2020年10月30日 The Otjikoto Gold Mine in the Republic of Namibia is located approximately 300 kilometers north of the capital city of Windhoek The project features surface mining with a Design of the Otjikoto Gold Mill, Namibia Mining, Metallurgy Working Principle of Ore Powder Dryer Ore powder drying machine adopts hightemperature and rapid drying technology, which is a successful combination of hotair slot rotaryplate drying Ore Powder Dryer Zoneding MachineWe support providing complete powder grinding plant equipment, including cyclone powder collector, dust collector, bucket elevator, vibrating feeder, jaw crusher, blower and main Raymond Mill JXSC Machinery

Advanced Ore Powder Dryer Fote Machinery (FTM)

Working Principle of Ore Powder Dryer Ore powder drying machine adopts hightemperature and rapid drying technology, which is a successful combination of hotair slot rotaryplate drying 2018年8月17日 Widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and non Grinding Mills — Types, Working Principle Applications2023年11月17日 Working principle of iron powder briquetting machine Feeding: Iron powder is fed into the machine through a hopper Pressing: The iron powder is compressed using a highpressure press The press can be a mechanical or hydraulic press The pressure applied causes the iron powder to form into a compacted and densified briquetteWorking principle of iron powder briquetting machine LSmojv2023年11月14日 Automatic feeding machine: it is the equipment responsible for material conveying It is different from an automatic powder packing machine The automatic powder granule packaging machine packages materials like salt, Working Principle Of Automatic Powder Granule

.jpg)

The Filling Machine Working Principle Explained

2023年8月15日 Application examples for this machine principle include filling large bags with powders or granules, large pails with all sorts of products, and so on Vacuum Filling Machine This filling machine working principle is called so 2021年4月29日 The bottom of the packaging bag is sealed by the heating part The last is blanking When the packaging materials enter the powder packaging machine, they are sealed and cut, so that a complete packaging bag comes out This is the working principle of our common small powder automatic packaging machine The powder packaging machine needs The working principle and use method of the packaging machine2024年4月17日 The principle of Tablet Compression Machine: The basic principle behind the tablet compression machine is hydraulic pressure This pressure is transmitted unreduced through the static fluid Any externally applied pressure is transmitted via static fluid to all the directions in the same proportionWorking and Principle of Tablet Compression Machine2023年7月26日 This video shows you the powder filling machine working principle and powder filling process The whole line include filling, capping, labeling, etc If you Powder Filling Machine Working Principle YouTube

Working principle of LPBF During LPBF, a powder layer is

Download scientific diagram Working principle of LPBF During LPBF, a powder layer is deposited (a), and a focused laserbeam locally melts a specific volume according to a predetermined geometry2024年6月17日 The powder filling and packaging line is an automated production line equipment dedicated to packaging powder products Its working principle mainly includes key steps such as powder metering, filling, sealing and packaging The powder filling and packaging line relies on the synergy of a series of automated equipment to ensure the efficient production processWorking principle of powder filling packaging lineIn the food processing industry, selecting the appropriate powder packaging machine is crucial for efficient and accurate packaging This article focuses on introducing several common powder packaging machines, explaining their working principles, advantages, and applications, so that buyers can choose suitable products based on their actual situationAn Overview of Powder Packaging Machine ModelsThe Vibro Sifter Machine works on the principle of vibration and centrifugal force The sieving powder is fed into the sifter through a hopper or conveyor, and it is distributed evenly across the mesh screen The screen vibrates rapidly, and the centrifugal force moves the particles towards the screen edges, where the fine particles pass through the mesh while the oversize particles Powder Sieving Vibro Sifter Machine Working Principle

.jpg)

Working Principle of Rapid Mixer Granulator NU

Working Principle of RMG The fast mixing granulator utilizes the mixing (compression) force and compression force exerted by the impeller on the powder material to provide the composition, density, and aggregation degree RMG Dry powder filling machines often incorporate dust containment systems, such as dust extraction and filtration, to ensure a clean and safe working environment Benefits of Dry Powder Filling Machines Precision: These machines can What Is The Principle of Dry Powder Filling Machine?2021年7月27日 The working principle and main purpose of jet mill 27/07/2021 In Company News By ALPA Powder With the rapid development of superfine powder related industries, fluidized bed jet mills, Turn on the machine, The working principle and main purpose of jet millTitle: Industrial Filling Packing Machine Powder Packing Machine: Working Principle Operation Steps Description: Introduction: Welcome to our comprehensive video guide on the Industrial Filling Packing Machine and Powder Packing Machine In this video, we will delve into the working principle and operation steps of these machines, providing youDive into the Working Principle of Powder Packing Machine

Powder Mixer Machine: Types,Production Steps,Working Principle

2024年9月18日 Mixing machines: features, working principle, production steps, and types of mixers, everything you need to know Mixing machines: features, working principle, Powder Mixing Machine; Soft Gel Capsule Making Machine; Pharmaceutical Packaging Machine Blister Packaging Machine; PillsDrugs Packing Machine;This article introduces the powder packing machine working principle and its application in daily life powder packing machine working principle To explain the powder packing machine working principle, it is necessary to first understand the metering methods used powder packing machine working principle and precautions for 2024年9月25日 These machines are widely used in many fields such as pharmaceuticals, food, and chemicals Understanding the working principle of powder filling machines is essential for optimizing the production process This article will explore in detail the working principle, main components, and applications of powder filling machines in different fieldsIndustrial Powder Filling Machine Working PrincipleDownload scientific diagram Schematic of the working principle of the powder atomization process from publication: Manufacturing Methods, Microstructural and Mechanical Properties Evolutions of Schematic of the working principle of the powder atomization process

Powder Packing Machine Working Principle

2021年12月20日 To figure out the working principle of the powder packaging machine, we must first figure out the measuring method of the machine Then, for different measurement methods, the working principle is explained in detail2020年4月22日 Tablet Compression Machine Hopper : Hopper The tablet compression process starts from here and blend or powder has to put in hopper which are compress into tablets Depending on the design of a tablet compression machine, we can fill the powder manually or using other automated systems Feeder System : Feeder SystemWorking Principle of Tablet Compression machine2023年11月17日 Working principle of iron powder briquetting machine Feeding: Iron powder is fed into the machine through a hopper Pressing: The iron powder is compressed using a highpressure press The press can be a mechanical or hydraulic press The pressure applied causes the iron powder to form into a compacted and densified briquetteWorking principle of iron powder briquetting machineZYminingA manual powder filling machine is worth buying for such entrepreneurs Laboratories A manual powder filling machine fits best within a small laboratory setup where testing or assessing biological samples is carried out routinely Different Types Of Powder Filling Machines And

.jpg)

Working principle of iron ore dryer

2023年12月26日 The heat source of Jiutian iron ore dryer is generally hot air, hightemperature flue gas, coal, etc The heat source can also be specifically designed according to customer needs We provide complete iron ore processing plants, if you are interested in our equipment, please contact us2021年11月23日 Working principle: The compressed air or superheated steam is transformed into highspeed air flow through the nozzle When the material is sent into the crushing chamber through the feeder, it is sheared by the highspeed air flow The strong impact and intense friction make the material grind into ultrafine productsClassification and working principle of jet mill ALPA Powder 2024年10月15日 Powder Packing Machine Granule Packing Machine Liquid Packing Machine Paste Packing Machine Sauce Packing Machine Elevator Conveyor Belt Packing Machine Linear Automation Machine Accessories News Industry News JOYV packing machine Blog Case overseas Factory Show office and factory Factory and warehouse Product Working principle of powder packaging machine2023年11月17日 Working principle of iron powder briquetting machine Feeding: Iron powder is fed into the machine through a hopper Pressing: The iron powder is compressed using a highpressure press The press can be a mechanical or hydraulic press The pressure applied causes the iron powder to form into a compacted and densified briquetteWorking principle of iron powder briquetting machineHongtai

.jpg)

Stone Powder Making Machine

① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costs2024年7月30日 Iron ore is the core raw material for steel production, and its processing is crucial to the sustainable development of the steel industry In the processing of iron ore, crushing is the first step, which is directly related to the efficiency of subsequent processes and product quality Among them, jaw crusher, as a commonly used crushing equipment, plays an irreplaceable Working Principle and Production Process of Iron Ore Jaw Crusher2022年10月13日 Powder filling machine working principle powder filling machine, from the perspective of quantitative principle, there are two main ways: weighing type, volumetric type two kinds of 1, weighing type weighing type quantitative filling is to ensure the accuracy of filling by controlling the weight of the filled material, compared with the previously mentioned volumetric Working principle of powder screw filling machine2023年11月17日 Working principle of iron powder briquetting machine Feeding: Iron powder is fed into the machine through a hopper Pressing: The iron powder is compressed using a highpressure press The press can be a mechanical or hydraulic press The pressure applied causes the iron powder to form into a compacted and densified briquetteWorking principle of iron powder briquetting machine LSmojv

.jpg)

Working Principle Of Automatic Powder Granule

2023年11月14日 Automatic feeding machine: it is the equipment responsible for material conveying It is different from an automatic powder packing machine The automatic powder granule packaging machine packages materials like salt, 2023年8月15日 Application examples for this machine principle include filling large bags with powders or granules, large pails with all sorts of products, and so on Vacuum Filling Machine This filling machine working principle is called so The Filling Machine Working Principle Explained2021年4月29日 The bottom of the packaging bag is sealed by the heating part The last is blanking When the packaging materials enter the powder packaging machine, they are sealed and cut, so that a complete packaging bag comes out This is the working principle of our common small powder automatic packaging machine The powder packaging machine needs The working principle and use method of the packaging machine2024年4月17日 The principle of Tablet Compression Machine: The basic principle behind the tablet compression machine is hydraulic pressure This pressure is transmitted unreduced through the static fluid Any externally applied pressure is transmitted via static fluid to all the directions in the same proportionWorking and Principle of Tablet Compression Machine

Powder Filling Machine Working Principle YouTube

2023年7月26日 This video shows you the powder filling machine working principle and powder filling process The whole line include filling, capping, labeling, etc If you Download scientific diagram Working principle of LPBF During LPBF, a powder layer is deposited (a), and a focused laserbeam locally melts a specific volume according to a predetermined geometryWorking principle of LPBF During LPBF, a powder layer is 2024年6月17日 The powder filling and packaging line is an automated production line equipment dedicated to packaging powder products Its working principle mainly includes key steps such as powder metering, filling, sealing and packaging The powder filling and packaging line relies on the synergy of a series of automated equipment to ensure the efficient production processWorking principle of powder filling packaging lineIn the food processing industry, selecting the appropriate powder packaging machine is crucial for efficient and accurate packaging This article focuses on introducing several common powder packaging machines, explaining their working principles, advantages, and applications, so that buyers can choose suitable products based on their actual situationAn Overview of Powder Packaging Machine Models

.jpg)

Powder Sieving Vibro Sifter Machine Working Principle

The Vibro Sifter Machine works on the principle of vibration and centrifugal force The sieving powder is fed into the sifter through a hopper or conveyor, and it is distributed evenly across the mesh screen The screen vibrates rapidly, and the centrifugal force moves the particles towards the screen edges, where the fine particles pass through the mesh while the oversize particles