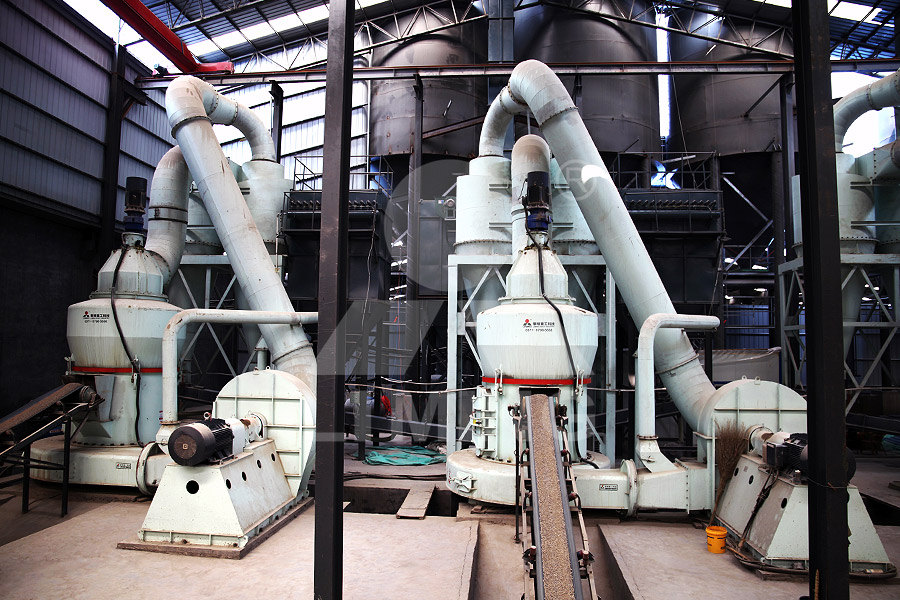

Coal raw coal grinding mill manufacturer

.jpg)

Coal grinding mill, Coal grinding grinding mill All industrial

Find your coal grinding mill easily amongst the 48 products from the leading brands (Fritsch GmbH, Retsch, NETZSCH, ) on DirectIndustry, the industry specialist for your professional purchasesVertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal materials in cement, power plants, iron and steel plants and other fields The GRMC coal vertical mill coal grinding machine CHAENGOur ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, ATOX® Coal Mill FLSmidth CementSBM has been focusing on developing automation for aggregates projects and successfully released the intelligent IoT service SBM operates spare parts warehouses to ensure swift Coal Grinding MillSBM Industrial Technology Group

.jpg)

Coal Mills (Coal Pulverisers, Coal Milling Plants, Coal Milling, Coal

8 companies for Coal Mills B2B manufacturers, distributors suppliers from 2 countries With special service for fast information and pricesUsing the high efficient coal mill of Zenith, can meet the strict requirements of the pulverized coal preparation of activated carbon The high quality coal is a strong propellant to help us Raymond MillLarge Pulverized Coal Preparation System, Coal Grinder Find out all of the information about the Xinxiang Great Wall Machinery Co, Ltd product: roller mill GMRC Series coal mill Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleRoller mill GMRC Series coal mill DirectIndustryIt is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

.jpg)

Pulverized Coal Preparation Pulverized Coal Grinding

Our Pulverized Coal Preparation Production Line is composed of Raw Coal Storage Transportation System, Grinding System, Dust Collecting System, Electrical Instrument Automation SystemProcess introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, LtdA compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between Roller mill ATOX® COAL FLSmidth DorrOliver Coal is a vital source of energy in many industries worldwide From power generation to manufacturing, coal is used in various processes However, before it can be used, coal needs to be processed in a coal mill In this article, we will explore the basics of how a coal mill works Introduction Coal mills are []How does a Coal Mill Work? ball mills supplier

.jpg)

quality Vertical Coal Mill Limestone Vertical Mill manufacturer

Name: Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type: Coal Grinding Capacity: 10~90 T/h Motor Power: 1101120kwGrinding storehouse is equipped with grinding balls so that raw coal can be crushed and ground into coal powder in this compartment, while, a dedicated induced draft fan carries over pulverized coal together with gas through discharging device, and coarse particles return back grinding storehouse for regrinding The airswept coal mill is used Air Swept Coal Mill Cement Plant MachineryThe introduction of hot air helps to improve the drying effect of coal powder and carries coal powder into the coal mill shell during the coal grinding process Coal Powder Conveying System The pulverized coal conveying system is used to transport pulverized coal from the pulverizer to the target location, such as a combustion furnace or a pulverized coal storage binAir Swept Coal Mill Cement Plant Equipment Coal Grinding MillName: Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type: Coal Grinding Capacity: 10~90 T/h Motor Power: 1101120kwquality Vertical Coal Mill Limestone Vertical Mill manufacturer

Fire and explosion protection of coal grinding systems Where are

You will be surprised about what has gone wrong with fire and explosion protection of your system(s) Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grindingRaw material, final products: soft coal, MTM160, 200mesh, D90;MTM130, 200mesh,D90 Customer Evaluation: Since 2003 cooperated with Zenith, we have purchased 16 sets grinding mill, from the high pressure grinding mill to the Trapezium grinding millLarge Pulverized Coal Preparation System, Coal Grinder Milling Mill The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal ball mills are widely used in the cement industry and thermal power generation industry, and are also suitable for metallurgical industry, chemical industry, sugar industry and other fieldsCoal Ball Mill Grinding for Different Kinds of Pulverized CoalCoal mill is an important part of the pulverizing system and an important auxiliary power equipment in power plant Its main task is to break and grind coal into pulverized coal to provide boiler equipment, its configuration will directly affect How to choose coal grinding equipment? What are the basis for coal mill

.jpg)

Coal Mill Manufacturers Powder Making Machine Price

Phrase one: raw material crushing Coal blocks will be crushed to 15mm50mm fineness by crusher Phrase two: drying and grinding 1Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding The hot air in the mill will dry the coal This will reduce drying cost 2For high Coal Vertical Roller Mill (VRM) for Grinding Stone, When it works, raw materials are fed in evenly by the feeder at the bottom of the hopper, China Limestone Grinding Ball Mill Manufacturer US$10,00000100,00000 / Piece Coal Vertical Roller Mill (VRM) for Grinding Stone2024年10月15日 The working principle of the vertical coal grinding mill is like that of mill, coal mill normal starting procedure can be summarized as Grinding mill motor start: The start working of vertical coal mill is driven by an electric motor At this state the following parameter are controlled: Mill inlet shutoff damper 30% open before feedingCashew Nutshell and Raw Coal Cogrinding for Sustainability The air swept ball mill is an ideal grinding machine that merges pulverizing and drying into a single It has the characteristics of high efficiency, energy saving, and environmental protection It is often used as the main equipment in the coal preparation system, which is capable to grind coal of various hardness (the fineness of pulverized coal can reach 85% and the moisture content Air Swept Coal Mill AGICO Ball Grinding Mill ball mill machines

Coal grinder mill, coal processing equipmentGrinding Mill,Grinding

Raw coal is fed through hopper at the top of the coal grinder mill and falls down to grinder ring t HOME; Ltd is a manufacturer of HGM series grinder mill, milling machinery, ultrafine powder mill, and powder ultra fine mill Grinding materials of our HGM Micro Powder Grinder mill include various stones and rocks, such as: Kaolin, Sourcing Guide for Coal Pulverizers: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: grinding mill, grinding machine, coal pulverizerCoal Pulverizers MadeinChinaOther Manufacturing Equipment > Vertical roller mill Vertical roller mills 7 coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type Vertical roller mill, Vertical roller grinding mill All industrial Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee

Limestone mill, Limestone grinding mill All industrial manufacturers

for coal grinding for limestone variable speed Suitable material: Raw material, clinker, slag, iron ore, limestone, coal powder, coke, coal gangue, fly ash, gypsum, calcite, pyrophylite SBM, a Chinese grinding mill manufacturer, has researched and developed the fifthgeneration pendulous hanging grinding mill – MB5X grinding mill Coal is crushed to desired fineness between spheres or cylindrical rollers After that, air from the boiler is heated to around 330°C (650°F) The raw coal is then fed into the pulverizer where it is ground into fine coal particles What are the Coal Crushers Coal Pulverizers Mills Williams 2021年7月26日 When the humidity of the raw coal is below 15%, the CLIRIK coal pulverizer is used to grind the raw coal into 200 meshes Fine powder, while eliminating the need for drying and saving energy The drying capacity of the Coal PulverizerRaymond MillNEWSClirikRaymond China Coal handling plant Suppliers, Coal handling Coal handling plant suppliers from China – view details and contact manufacturers, suppliers and Herbal extraction plant Drying plant Triple roller mill Shot » Free Online Chat High Grade CoalHigh Grade Coal Manufacturers, High Grade Coal Manufacturers High Grade Coal Suppliers coal drying machine 1Top coal drying plant manufacturers in china – Grinding Mill China

Coal Vertical Mill Grinding Machine From China Manufacturer

Type: Vertical Coal Mill Motor Type: AC Motor Motor Power: 22KW Rotationl Speed: 2123r/min Application: Power Plant, Cement Plant, Lime Plant and Other Co Materials: CoalBowl Mill, Coal Pulverizer Mill, Raymond Mill, Bowl, Bowl Hub, Vertical Shaft, Worm Shaft, Mill Base Plate, Insulation Cover plate Hub, Grinding Rolls, Tyre Roller for Power Plant, Raw Coal Pulverizer Spare parts, Dynamic Classifer, Coal Mill, Thermal Power Plant Grinding vane wheel, Power Plant Pulverizer, Power Plant Coal Grinding Mill, Hammer Mill, Pulverizer Disc Blade Vertical Mills Ring Roller Coal Pulverizer DuoCast Xwin Ductile It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen After the iron is removed by the electromagnetic iron separator, the belt conveyor sends the raw coal into the original coal bin for storage 2Roller mill GMRC Series coal mill Xinxiang Great Wall Leading manufacturer of Chinese cement machinery; China rotary kiln production champion enterprisePengfei Group,global export base of kiln and energysaving grinding mill equipment, is a model enterprise of jspfgroup@163 +86 0731 raw mill, mining mill and air swept coal mill are pengfei featured products Best grinding China Cement Machine Leading Manufacturer, Rotary Kiln, Grinding Mill

.jpg)

Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal During the operation of the ball mill, the raw coal first enters the drying chamber through the feed inlet for drying, and the dried raw coal enters the grinding chamber for grinding and second 2024年7月9日 Charcoal powder mixer (also known as wheel mill, charcoal mixer machine, charcoal powder grinding machine) is used for mixing and pressurizing charcoal powder, necessary in the coal processing plant It can handle charcoal powder with a capacity of 0310t/h You can choose suitable output to meet your charcoal making line demandsGreat Charcoal Powder Mixer For Grinding In Coal LineCoal water slurry ball mill manufacturer Ball mill grinding evenly, suitable for coal water slurry power plant The specifications of CWS ball mill are complete, welcome to inquire As the main equipment of the raw material grinding link in the coal water slurry production line, Coal Water Slurry Ball MillProcess introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

.jpg)

Roller mill ATOX® COAL FLSmidth DorrOliver

A compact coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between Coal is a vital source of energy in many industries worldwide From power generation to manufacturing, coal is used in various processes However, before it can be used, coal needs to be processed in a coal mill In this article, we will explore the basics of how a coal mill works Introduction Coal mills are []How does a Coal Mill Work? ball mills supplierName: Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type: Coal Grinding Capacity: 10~90 T/h Motor Power: 1101120kwquality Vertical Coal Mill Limestone Vertical Mill manufacturerGrinding storehouse is equipped with grinding balls so that raw coal can be crushed and ground into coal powder in this compartment, while, a dedicated induced draft fan carries over pulverized coal together with gas through discharging device, and coarse particles return back grinding storehouse for regrinding The airswept coal mill is used Air Swept Coal Mill Cement Plant Machinery

.jpg)

Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill

The introduction of hot air helps to improve the drying effect of coal powder and carries coal powder into the coal mill shell during the coal grinding process Coal Powder Conveying System The pulverized coal conveying system is used to transport pulverized coal from the pulverizer to the target location, such as a combustion furnace or a pulverized coal storage binName: Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type: Coal Grinding Capacity: 10~90 T/h Motor Power: 1101120kwquality Vertical Coal Mill Limestone Vertical Mill manufacturerYou will be surprised about what has gone wrong with fire and explosion protection of your system(s) Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grindingFire and explosion protection of coal grinding systems Where are Raw material, final products: soft coal, MTM160, 200mesh, D90;MTM130, 200mesh,D90 Customer Evaluation: Since 2003 cooperated with Zenith, we have purchased 16 sets grinding mill, from the high pressure grinding mill to the Trapezium grinding millLarge Pulverized Coal Preparation System, Coal Grinder Milling Mill

.jpg)

Coal Ball Mill Grinding for Different Kinds of Pulverized Coal

The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal ball mills are widely used in the cement industry and thermal power generation industry, and are also suitable for metallurgical industry, chemical industry, sugar industry and other fields