What equipment is the grinding disc used on

.jpg)

Grinding Discs: From Definition to Safe Usage

2023年5月5日 In this article, we will discuss the types, applications, selection, and safe usage of grinding discs Grinding wheels are common tools used in grinding and polishing processes The types and characteristics of grinding 2024年7月23日 Grinding is a precision machining process that uses an abrasive wheel or disc to remove material and shape a workpiece It is commonly used in manufacturing operations to achieve a smooth surface finish and precise What is Grinding: Definition, Types, Uses, and Working Grinding Discs for Metalworking Grinding discs used for metalworking are essential for tasks such as deburring, sharpening, polishing, and material removal They come in different forms What Are the Different Types of Grinding Disc? Binic AbrasiveInside the abrasive grinding discs we find: Flap discs, designed for roughing with great performance when the finish is important These sandpaper discs are made of sheets of abrasive cloth and fiber They are available in many forms, Abrasive discs: types, classes and materials

.jpg)

7 Types of Abrasive Discs: What You Need to Know

Grinding discs are perhaps the most widely used abrasive discs in various industries They are designed for grinding and shaping metals, stones, and other materials These discs typically feature abrasive grains such as aluminum Cutting disc and grinding disc are used on machines and runs with fast speed to cut or grind steel and stainless steel as well as stone Available in different material, forms and sizes to suit the required useWhat's types Cutting and Grinding Disc you know?2020年11月25日 A grinder is a very versatile and useful device; however, can be dangerous too, thanks to the discs that are used along with it There are many different types of grinding discs suitable for different applications and you must What are the different types of grinding discs? ESC 2024年3月18日 Do not use this cutting disc for grinding, although you can do a small amount of deburring The blade can burn you when turned on, so ensure the safety guard is in place and wear protective gear 7 Discover New Angle Grinder Disc Types: Which Cutting Discs Should I

10 Types of Angle Grinder Discs and Their Uses (With

2021年7月15日 Besides grinding concrete with these types of discs, you can also use them to grind granite, stone, marble, masonry, and similar materials Although a concrete grinding wheel can offer great longevity, these tough 2024年1月23日 High Equipment Cost: Grinding machines, especially those used for precision grinding, are more expensive than other types of machining equipment Costly Wheel Replacement: Grinding wheels need regular What is Grinding: Definition, Process, Types2024年7月8日 It removes surface material from the workpiece through a highspeed rotating grinding wheel In the grinding process, a piece of equipment called a grinder is used Although it takes longer than cutting with a tool, it produces a more precise and beautiful workpiece Grinding is often used as a finishing process in addition to other machining What is grinding? Its uses, types, characteristics Machcncmaster42 (5) When you are using your angle grinder for DIY projects, one of the most important considerations is which type of attachment you are going to use Grinding wheels, flap discs and sanding discs are among the most common grinder attachments yet they are used for very different types of projects Typical uses of Grinding Wheel vs Flap Disc vs Sanding Disc: Grinding Wheel vs Flap Disc vs Sanding Disc: What Is the

.jpg)

What Disc to use Angle Grinding The W eld Space

2023年9月8日 Learn what Angle Grinding disc to use Grinding and at each stage of your metalworking project We have explored a range of widely available discs here is a essential list of Personal Protective Equipment (PPE) that is crucial when using angle grinders to ensure safety and minimize the risk of accidents:The spindle speed of the machine must be checked before mounting the disc to be certain that it does not exceed the maximum operating speed marked on the disc The correct disc (ie Grinding discs for grinding and cutting discs for cutting) type for the operation must always be selected and used, unless the disc is designed to perform both Safe Use of Grinding Machine at Workplace Safety TalkCONVENTIONAL GRINDING Conventional disc grinding wheels For conventional disc grinding, we are the original equipment manufacturer for the famous doubledisc grinding machines from DISKUS WERKE Our many years of working with our partner has enabled us to manufacture grinding wheels for every suitable application caseDisc Grinding DVS TECHNOLOGYThe grinding disc was designed for a maximum of 6,650rpm, but the grinder was designed to rotate at 8,500rpm, nearly 22% faster than the permitted speed of the grinding disc Before starting the job, information on the angle grinder’s design speed and the manufacturer’s instructions were not checked to verify correct use of the equipment Grinding accident check your RPMs Nautical Institute

DISC GRINDING BROCHURE Jowitt and Rodgers

relatively huge amount of power used in the disc grinding process generates heat that must be effectively dissipated Double disc grinding has a couple of inherent advantages Since the part is passed between two abrasive discs, the stresses on the part are equal on both sides This leads to the ability to attain flatness tolerances that would 2024年7月17日 Form Grinding Used to machine complex shapes of workpieces using specialized grinding wheels to achieve specific geometries Form grinding is commonly used in mold making and the machining of complex parts Endface What is Grinding? Understanding the Basics and 2018年6月12日 Balance the Grinding Disc Keeping a grinding disc trued and balanced ensures the disc stays flat on its face and sharp, which is necessary to produce the best results Use a redressing tool to balance the disc once it’s What Is an Angle Grinder in Welding, and How Is It When it comes to your operation, choosing the right abrasive wheel for your grinder will make your job easier! Choosing the right abrasive wheel will help to have well prepared joints, welds that are not cross contaminated and lasting Selecting the right Cutting and Grinding Disc for your

.jpg)

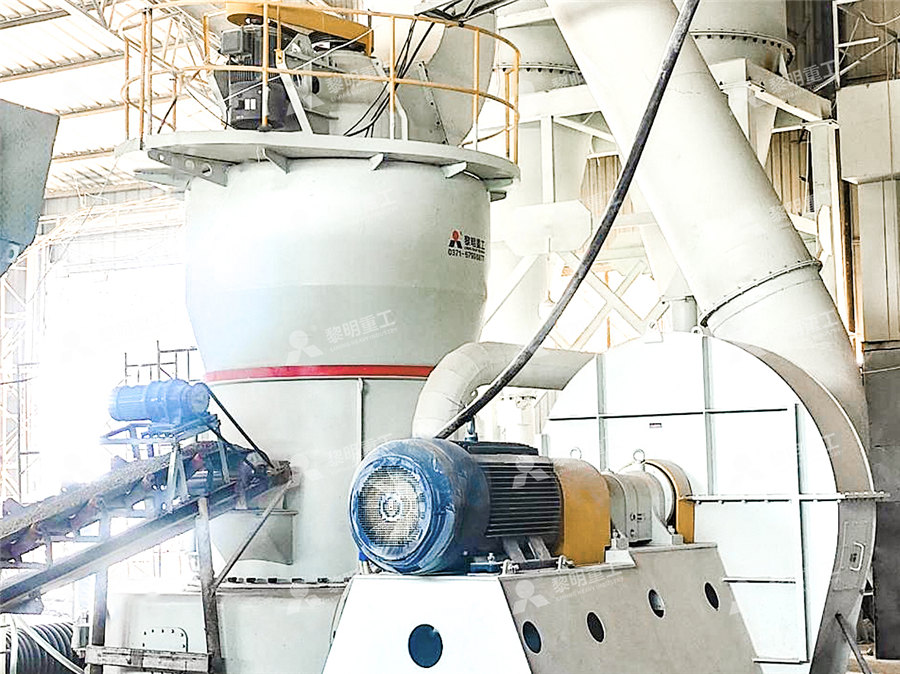

What Is Grinding Disc Delun Grinding Tools

Grinding disc is a kind of resin abrasive tool with special fiber fabric as reinforcement material, contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substanceThe abrasive grains act as grinding tools, removing material from a workpiece to shape and refine itand is widely used in grinding and rust removal of various metal and nonmetal What is a diamond cutting grinding disc? A diamond cutting grinding disc is a bladed disc that can be used in conjunction with angle grinders, electric disc cutters, stone saws, and more products with similar functions and differing names These bladed discs are made specifically to cut materials that are otherwise impossible to cut cleanlyDiamond Cutting Grinding Discs: An Efficiency GuideQuick Overview Flap discs are used for grinding and come in different types (flat and conical) Their specific materials and grit sizes make them relevant to specific tasks and materials Safety precautions include outlining necessary personal protective equipment and safe operating practices Preparation steps for grinHow To Use A Flap Disc For Grinding Red Label Abrasives1 Grinding Discs Grinding discs are perhaps the most widely used abrasive discs in various industries They are designed for grinding and shaping metals, stones, and other materials7 Types of Abrasive Discs: What You Need to Know

.jpg)

The Center Offset Grinding of TAIKO Wafer Grinding Solutions

Advantage of center offset grinding By applying this grinding method in the TAIKO grinding, an effective area of an OF wafer can be expanded Processing example of Center offset grinding We will introduce the processing example for 6inch wafer (short OF) (Machine used: DAG810 TAIKO specification) Fig1 General grinding Fig2 Center offset Indeed, both types of equipment use a fastrotating disc, so that the abrasive strength can be provided as long as the surface of the rotating disc reaches its maximum speed However, from a deeper perspective, the physical difference becomes apparent on the diamond grinding disc lineThe difference between a diamond grinding disc and a grinding disc?2023年4月14日 A grinding disc is primarily used to shape and smooth surfaces, while a cutting disc is used to cut through various materials such as metal, wood, ceramics, and masonry Grinding discs are typically made from abrasive grains such as aluminum oxide or silicon carbide, which are held together by a bonding agent such as resin or vitrified materialsWhat is the difference between grinding disc and cutting disc?Whether the accessory on that tool is a grinding disc, cutting disc or a wire wheel, it is spinning at speeds ranging from 9,000 to 1,000 RPM just inches from your hands, fingers, electrical equipment Visually check the tool before use, have periodic portable appliance testing and route cables away from the wheel to avoid contactWhat Are the BIGGEST HAZARDS Protective Industrial Products

.jpg)

What Is Used For Grinding In The Lab? 4 Essential Tools You

In the lab, grinding is a common process that requires specific equipment One of the most commonly used tools for grinding is a mortar and pestle This tool can be used for grinding both natural and artificial samples It's important to note that samples need to be in a particular state for them to grind well2023年11月17日 Often, this process is used on workpieces requiring a high surface finish or precise dimension In addition, it can be used to remove rust or dirt from the surface of equipment before fixing it or putting it back into service What is Surface Grinding LEADRP2024年2月18日 A grinding wheel is a discshaped wheel made of abrasive material, and it is used for various applications such as sharpening tools, grinding metal, and shaping or polishing surfaces When attaching a grinding wheel to a drill, it is important to ensure that the wheel is securely fastened to the drill to prevent accidents or injuriesThe Art Of Using A Grinding Wheel On A Drill ShunToolJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

Choosing The Right Flap Disc For Your Project: A StepByStep

2023年10月2日 Use a T29 conical disc at a 15degree angle to provide the most surface contact for removing stock Use a T27 flat disc that is parallel to your work area if you need to surfaceclean or produce a smooth finish Use gentle, steady pressure to enhance grinding and lessen loading for the best results FLAP DISCS FOR WOOD2023年4月16日 Flap Grinding Discs A flap disc is used for finishing and deburring operations completed at the same time Fiber discs and grinding discs combined with an overlapping abrasive flap adhered to a backing plate Flap grinding discs offer lowresistant propertiesGrinding Wheels for Aluminum: What to Know Before You Buy2024年1月11日 In surface grinding machines, be it a double disc grinder or a surface grinder with a horizontal spindle, effective cooling, and lubrication are integral for the quality of the workpiece These methods are particularly crucial when the grinding wheel rotates against flat surfaces or during intricate disc grinding operationsSurface Grinding: A Guide to the Process and Precision okdor1 Grinding Discs: Grinding discs are the most popular type of angle grinder disc and are used for smoothing out rough edges and surfaces These discs come in various sizes and grits, with lower grit numbers being coarser and higher grit numbers being smoother 2Which Angle Grinder Disc Is Best For Tiles? A TheHandyBee

.jpg)

What Is The Laboratory Apparatus Used For Grinding? 4 Key

They use a swinging motion to crush materials between two grinding surfaces Jaw Crushers: Primarily used for coarse grinding, these machines crush materials between two jaws, one fixed and the other moving Tissue Grinders: Specifically designed for biological and medical research, these grinders are used to homogenize tissues into a fine 2024年3月18日 Do not use this cutting disc for grinding, although you can do a small amount of deburring The blade can burn you when turned on, so ensure the safety guard is in place and wear protective gear 7 Discover New Angle Grinder Disc Types: Which Cutting Discs Should I 2021年7月15日 Besides grinding concrete with these types of discs, you can also use them to grind granite, stone, marble, masonry, and similar materials Although a concrete grinding wheel can offer great longevity, these tough 10 Types of Angle Grinder Discs and Their Uses (With 2024年1月23日 High Equipment Cost: Grinding machines, especially those used for precision grinding, are more expensive than other types of machining equipment Costly Wheel Replacement: Grinding wheels need regular What is Grinding: Definition, Process, Types

What is grinding? Its uses, types, characteristics Machcncmaster

2024年7月8日 It removes surface material from the workpiece through a highspeed rotating grinding wheel In the grinding process, a piece of equipment called a grinder is used Although it takes longer than cutting with a tool, it produces a more precise and beautiful workpiece Grinding is often used as a finishing process in addition to other machining 42 (5) When you are using your angle grinder for DIY projects, one of the most important considerations is which type of attachment you are going to use Grinding wheels, flap discs and sanding discs are among the most common grinder attachments yet they are used for very different types of projects Typical uses of Grinding Wheel vs Flap Disc vs Sanding Disc: Grinding Wheel vs Flap Disc vs Sanding Disc: What Is the 2023年9月8日 Learn what Angle Grinding disc to use Grinding and at each stage of your metalworking project We have explored a range of widely available discs here is a essential list of Personal Protective Equipment (PPE) that is crucial when using angle grinders to ensure safety and minimize the risk of accidents:What Disc to use Angle Grinding The W eld SpaceThe spindle speed of the machine must be checked before mounting the disc to be certain that it does not exceed the maximum operating speed marked on the disc The correct disc (ie Grinding discs for grinding and cutting discs for cutting) type for the operation must always be selected and used, unless the disc is designed to perform both Safe Use of Grinding Machine at Workplace Safety Talk

Disc Grinding DVS TECHNOLOGY

CONVENTIONAL GRINDING Conventional disc grinding wheels For conventional disc grinding, we are the original equipment manufacturer for the famous doubledisc grinding machines from DISKUS WERKE Our many years of working with our partner has enabled us to manufacture grinding wheels for every suitable application caseThe grinding disc was designed for a maximum of 6,650rpm, but the grinder was designed to rotate at 8,500rpm, nearly 22% faster than the permitted speed of the grinding disc Before starting the job, information on the angle grinder’s design speed and the manufacturer’s instructions were not checked to verify correct use of the equipment Grinding accident check your RPMs Nautical Instituterelatively huge amount of power used in the disc grinding process generates heat that must be effectively dissipated Double disc grinding has a couple of inherent advantages Since the part is passed between two abrasive discs, the stresses on the part are equal on both sides This leads to the ability to attain flatness tolerances that would DISC GRINDING BROCHURE Jowitt and Rodgers