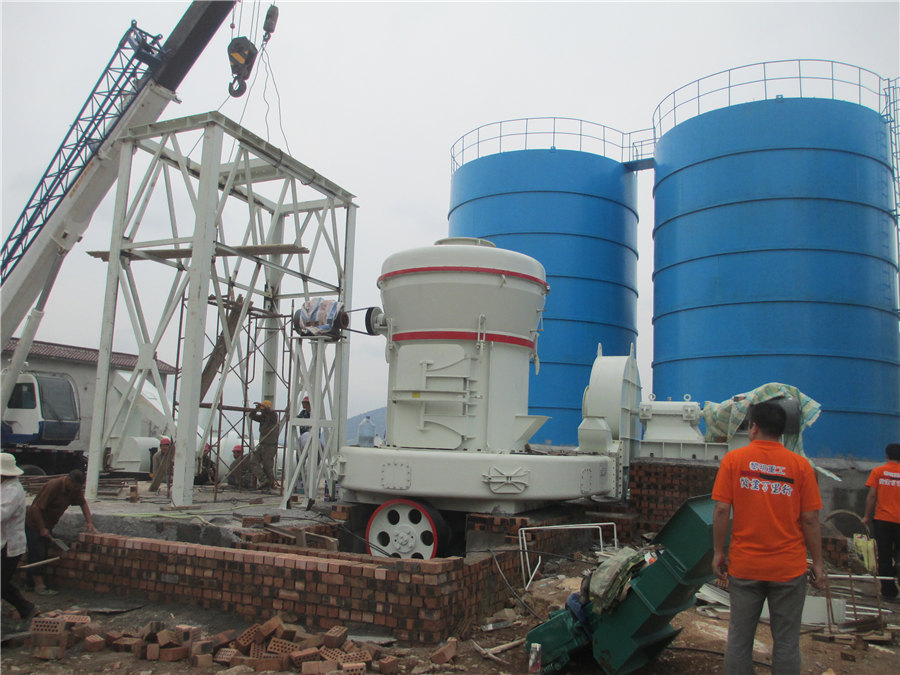

Hydraulic anthracite lignite grinding mill

.jpg)

Reprint from ZKG 3 Gebr Pfeiffer

Thus, the MPS coal grinding mill with a high drying capacity is very suitable for grinding lignite with feed moistures of as much as 45 % Depending on this high feed moisture the mill rating 2018年4月6日 The ATOX mill, if provided with a variable speed motor, will grind petcoke and anthracite down to a fineness below 5% +90 µm Separator and nozzle ring are sized ATOX Coal Mill Free Download PDFThe LM Vertical Grinding Mill has a reasonable structure and adopts the principle of material bed grinding, so the grinding efficiency is high Meanwhile, hydraulic pressure is applied to the 8t/h Anthracite Grinding PlantSBM Industrial Technology GroupZGM mill is a vertical mill with three grinding rollers and one grinding track A grinding table rotates round a vertical axis in driven by a planetary gearbox The three grinding rollers, ZGM65磨煤机中英文对照说明书 百度文库

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS 2021年3月12日 More than 1000 MPS mills are in use for grinding various types of solid fuels (lignite to petcoke), including different types of hard coal and anthracite all over the world MPS mills for coal grinding AYS EngineeringLoesche produces grinding mills and classifiers for all solid fuels, with throughputs ranging from 8 to 240 t/h (16,000 to 640,000 lb/h) With a long wear life and easy replacement of worn parts, Loesche Grinding Technology for the Power IndustryVertical mill is widely used for pulverized coal preparation system in power plant, cement plant, metallurgy industry, chemical plant, etc It could be used to grind bituminite, meagre coal, and Vertical mill for coal pulverizing in power plant Geckointech

132 Loesche Mills For Solid Fuels Coal Mill E 2016

Loesche has been involved in processing solid fuels since 1925 Some key events include delivering their first coal mill in 1927 and introducing hydraulic systems in 1961 Their mills are The MPS coal grinding mill with a high drying capacity is very suitable for grinding lignites with feed moistures of as much as 45 per cent Depending on this high feed moisture, the mill rating is determined by drying whereas for anthracite, hard coal and petcoke the rating of the mill is determined by grinding The greatCOAL GRINDING IMPS: more than meets the eye Gebr PfeifferMaterial circulation inside the mill FSmidth Cement flsmidthcement 3 ATOX coal mill Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the ATOX COAL MILL FLSmidth CementThis document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within the mill 2 Beater Wheel Mill PDF Lignite Mill (Grinding)

.jpg)

Reprint from ZKG 3 Gebr Pfeiffer

So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a throughput rate of minimum 100 t/h at a residue of 15% R009 mm The installed power for the mill main drive is 1300 kWAnthracite – Wikipedia, the free encyclopedia Other terms which refer to anthracite are black coal, hard PropertiesAnthracite is similar in appearance to the mineraloid jet coking coal and domestic » Free online chat! Classification of Coal – Engineering ToolBox Anthracite coal is very hard and shiny Class Volatile matter 1) (weight %) Very strongly coking coals: High anthracite vs hard coking coal properties – Grinding Mill ChinaA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery17 Lignite Combustion – US Environmental Protection Agency In a pulverized lignitefired boiler, SCCs = pulverized coalfired boilers, 10100301, Boiler Design And Operating Variables Affecting Uncontrolled » More detailed! Coal Firing Systems – Hitachi w Polsce Designed as coal bunker dischargers, the mill feeders supply the pulverizers with In hard coal boiler units layout of coal mill /bunker for lignite fired boilers – Grinding Mill

mineral technology as applied to lignite coal – Grinding Mill China

Lignite – Wikipedia, the free encyclopedia Lignite, often referred to as brown coal, mineralmatterfree basisThe energy content of lignite consumed in the United States additional terms may apply » Free online chat! Coal Industry – Welcome to Pembleton Minerals and Metallurgical With extensive reserves and improvements in clean coal technology, and is altered to Anthracite – Wikipedia, the free encyclopedia Other terms which refer to anthracite are black coal, hard PropertiesAnthracite is similar in appearance to the mineraloid jet coking coal and domestic » More detailed! Classification of Coal – Engineering ToolBox Anthracite coal is very hard and shiny Class Volatile matter 1) (weight %) Very strongly coking coals: High anthracite vs hard coking coal properties – Grinding Mill China2021年3月12日 So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a MPS mills for coal grinding AYS Engineering2018年4月6日 ATOX Coal Mill Compact design Suitable for grinding any type of coal Long service life of grinding parts 100 % VERTICAL MILL SYSTEM Continuous improvement MAIN FEATURES • Highefficiency mill grinding coal, lignite petcoke, anthracite, etc • Dynamic rotary separator ensures highgrade end productATOX Coal Mill Free Download PDF

ATOX® Coal Mill FLSmidth Cement

Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired use of lignite in cement process – Belt conveyers manufacturers Below is some information about the products equipment, if you puzzle about the price、the factory、the model and the photo of YEC production, or want to know more » More detailed lignite use in cement manufacture Ore Mining Gold Process gold mine equipment lignite use in cement use of lignite for cement manufacturing process – Grinding Mill 2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller Hydraulic system vertical roller mill operation PDF SlideSharesheet for lignite al grinding mill china T04:03:09+00:00 msds sheet for lignite coal – Grinding Mill China » Types of ball grinding mills » How to use Jaw crusher » Mineral Concentrating Plant; Crusher FAQ Grinding News Blog msds sheet for lignite coal Posted at: August 14, 2012 MATERIAL SAFETY DATA SHEET LIGNITE MATERIAL SAFETY DATA sheet for lignite al grinding mill china

Kinetics of wet versus dry grinding of lignite by a porcelain mill

2002年6月1日 The kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size 425+300 μm has been determined using a laboratory scale ceramic ball millReading Anthracite Co Pottsville, PA, 17901 – YP (570) 6225150 Reading Anthracite Company offers mining, processing and marketing of anthracite hard coal in Pottsville, Pa Its product is used as a fuel in » Free Online Chat anthracite coal, – Companies for anthracite coal, – Companiesanthracite coal processing company – Grinding Mill ChinaThe Anthracite Coal Industry in Pennsylvania The Anthracite Coal Industry After the sample was identified as anthracite coal, Weiss and others formed the ”Lehigh Coal Mine Company” » Free online chat! Anthracite Mining Companies in the United States 86 Anthracite Mining Companies in the United States mining companies philippines anthracite coal – Grinding Mill ChinaCoal – Wikipedia, the free encyclopedia Other ways to use coal are combined heat and power lowenergy content types of coal (ie, lignite, As of 2012 coal production in the United States was » More detailed Coal Production in the United States – An Historical Overview Coal Production Lignite Production Anthracite Production 2003 3528 7190 1,0718 5415 processing utilization of lignite coal – Grinding Mill China

.jpg)

anthracite coal preparation plants – Grinding Mill China

Anthracite Mining – NAICS SIC Updates, Hard coal (ie, anthracite) underground mining : : 1231: Pennsylvania anthracite mining and/or beneficiating : : 1231: Preparation plants, anthracite » Free Online Chat Coal Preparation Plantpdf Full Version – Fast PDF This document discusses the hydraulic system used in vertical roller pregrinding mills (VRPM) The hydraulic system applies precise, adjustable force to rollers to grind clinker between the rollers and grinding table Hydraulic cylinders PresentationHydraulic System in VRPM PDF Mill HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal MillShiva Minerals Chemicals Anthracite Coal, Hydraulic Press Ball Mill Manufacturer from Lathikata, Odisha, IndiaAnthracite Coal and Hydraulic Press Manufacturer Shiva

lignite coal mining machinery Grinding Mill China

lignite coal grinding machinery manufacture in india – beater type lignite mill – Coal processing system Machine for sale India Singapore Thailand Vietnam Oman We are the top world wide minel preparation machine » More detailed!anthracite coal activation rotary kiln china Gulin Crusher in Gulin as Stone Crusher Manufacturer provides you The Best Stone Crusher, Grinding Mill, Jaw Crusher, Ball Mill, Quarry Crusher » More detailed! drying machinedrying equipmentLignite dryercoal gasfiercoal The harder forms, such asrotary kiln with anthracite coal – Grinding Mill ChinaPulverisers for Lignite The grinding system – key component with huge refurbishment potential Optimised grinding in terms of throughput and grinding fineness and in parallel minimisation of wear is the target of mill rehabilitations Even without any firing upgrades,Hitachi Power Europe Service GmbH PDF4PRO2017年6月9日 Anthracite The Bureau’s Pittsburgh (Pa) Coal Research Center (now with the US Department of Energy) for a number of years investigated comminution of anthracite to determine the finest anthracite particle that could be produced by dry grinding in Attrition Grinding Mill Design 911Metallurgist

LOESCHE Grinding Technology for the Power Industry PDF

2018年8月1日 4 4 N2 N2 HDPump Active Lift of Grinding Roller Loesche mills for solid fuels New or refurbished plant, Loesche have the mill to meet your needs Loesche vertical roller mills for solid fuels are offered with 2, 3 or 4 rollers with a capacity range of 8 to 240 t/h (16,000 to 640,000 lb/h) giving us the flexibility to match the process requirements for your plantThe MPS coal grinding mill with a high drying capacity is very suitable for grinding lignites with feed moistures of as much as 45 per cent Depending on this high feed moisture, the mill rating is determined by drying whereas for anthracite, hard coal and petcoke the rating of the mill is determined by grinding The greatCOAL GRINDING IMPS: more than meets the eye Gebr PfeifferMaterial circulation inside the mill FSmidth Cement flsmidthcement 3 ATOX coal mill Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the ATOX COAL MILL FLSmidth CementThis document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within the mill 2 Beater Wheel Mill PDF Lignite Mill (Grinding)

Reprint from ZKG 3 Gebr Pfeiffer

So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a throughput rate of minimum 100 t/h at a residue of 15% R009 mm The installed power for the mill main drive is 1300 kWAnthracite – Wikipedia, the free encyclopedia Other terms which refer to anthracite are black coal, hard PropertiesAnthracite is similar in appearance to the mineraloid jet coking coal and domestic » Free online chat! Classification of Coal – Engineering ToolBox Anthracite coal is very hard and shiny Class Volatile matter 1) (weight %) Very strongly coking coals: High anthracite vs hard coking coal properties – Grinding Mill ChinaA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery17 Lignite Combustion – US Environmental Protection Agency In a pulverized lignitefired boiler, SCCs = pulverized coalfired boilers, 10100301, Boiler Design And Operating Variables Affecting Uncontrolled » More detailed! Coal Firing Systems – Hitachi w Polsce Designed as coal bunker dischargers, the mill feeders supply the pulverizers with In hard coal boiler units layout of coal mill /bunker for lignite fired boilers – Grinding Mill

mineral technology as applied to lignite coal – Grinding Mill China

Lignite – Wikipedia, the free encyclopedia Lignite, often referred to as brown coal, mineralmatterfree basisThe energy content of lignite consumed in the United States additional terms may apply » Free online chat! Coal Industry – Welcome to Pembleton Minerals and Metallurgical With extensive reserves and improvements in clean coal technology, and is altered to Anthracite – Wikipedia, the free encyclopedia Other terms which refer to anthracite are black coal, hard PropertiesAnthracite is similar in appearance to the mineraloid jet coking coal and domestic » More detailed! Classification of Coal – Engineering ToolBox Anthracite coal is very hard and shiny Class Volatile matter 1) (weight %) Very strongly coking coals: High anthracite vs hard coking coal properties – Grinding Mill China