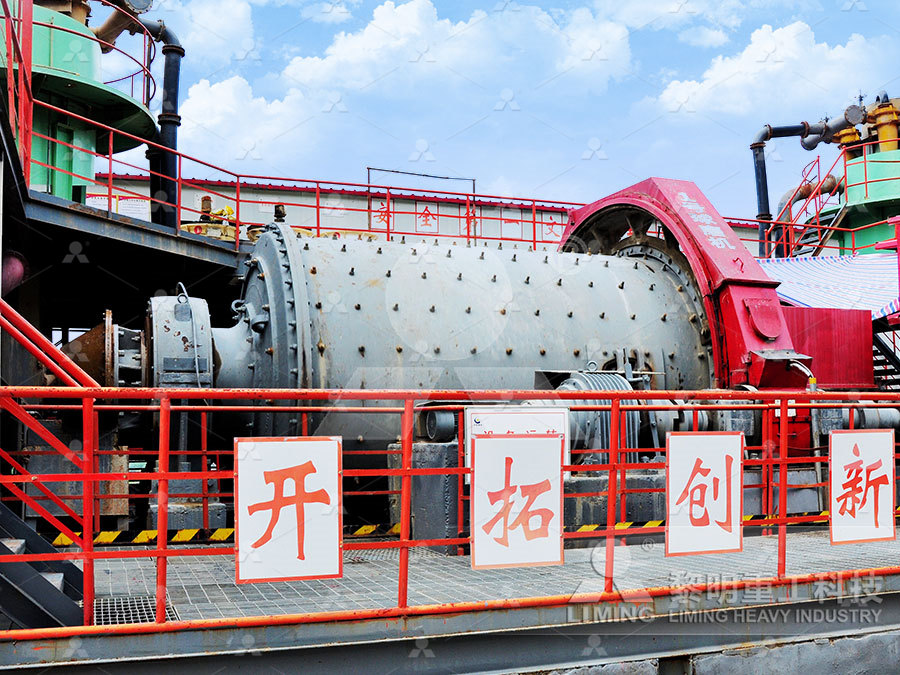

Various types of cement quick white ash quick lime grinding machine blast furnace slag

.jpg)

Slag Cement Production Line Blast Furnace Slag

Slag cement is also called blast furnace cement, pbfc cement(Portland blast furnace cement) It is composed of Portland cement clinker, 20%70% granulated blast furnace slag, and appropriate gypsum AGICO CEMENT helps you get Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, 2 µm 5 µm Loesche2023年6月1日 Granulated blast furnace slag (GBFS) has different types according to the different cooling methods for the molten slag When the molten slag is rapidly cooled by water Synergistic utilization of blast furnace slag with other industrial 2024年6月1日 This study explored potential pretreatment methods to enhance slag's performance as a cement raw material and the research on utilizing steelmaking slag, Utilization of steelmaking slag in cement clinker production: A

.jpg)

Blast Furnace Slag an overview ScienceDirect Topics

Liquid blast furnace slag cooling regimes traditionally include aircooling, granulating (wet), expanding, and pelletizing, and result in four distinct types of blast furnace slag: aircooled Ground granulated blast furnace slag is a latent hydraulic binder forming calcium silicate hydrates (CSH) after contact with water It is a strengthenhancing compound improving the durability Ground granulated blastfurnace slag WikipediaGround granulated blastfurnace slag (GGBFS), sometimes simply referred to as “slag”, is a glassy granular material formed when molten blastfurnace slag is rapidly chilled, as by Ground Granulated BlastFurnace Slag: Its Chemistry and Use with Portland Pozzolana Cement (PPC) is produced by grinding ordinary clinker with pozzolanic materials, such as fly ash, alongside of addition of gypsum It can also be prepared by Varieties of Cement CMA India

13 Types of Cement [PDF]: Properties, and Applications in

Blast furnace slag cement is obtained by grinding the clinkers with about 60% slag and resembles more or less in properties of Portland cement It can be used for works where economic 2020年8月25日 The basic objective of this investigation is to examine the characteristics of concrete using Ground granulated blastfurnace slag (GGBS) as binding material in (PDF) Ground Granulated BlastFurnace Slag (GGBS) as a2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of What is Blast Furnace Slag and How to Process It?2019年4月1日 This paper presents a study on the stabilization of contaminated soil deposits using fly ash (FA), quick lime (QL) and blast furnace slag (BFS)Remediation of heavy metal contaminated soils by

.jpg)

The Influence of FA Content on the Mechanical and Hydration

2024年9月20日 This study primarily investigates the effect of fly ash (FA) content on the mechanical properties and hydration performance of alkaliactivated ground granulated blast furnace slag cement (AAGC) and compares the related properties with ordinary Portland cement (OPC) Additionally, we examined the hydration products; performed thermal analysis, MIP, 15 Different Types of Cement In India 1) Ordinary Portland cement (OPC) 2) Portland Pozzolana Cement (PPC) 3) Rapid Hardening Cement 4) Extra Rapid Hardening Cement 5) Low Heat Portland Cement 6) Quick Setting Cement 7) Sulphate resisting Portland cement 8) High Alumina Cement 9) Blast Furnace Slag Cement 10) White Cement 11) Coloured Cement 15 Different Types of Cement in India and Their Uses OkCivil2017年5月29日 7 Blast Furnace Slag Cement: Definition: It is a modified type of Portland cement which contains 2565 percent (by weight) of blast furnace slag It is manufactured by grinding clinker and specific amounts of blast furnace slag together A small percent of gypsum is also added for controlling its setting time15+ Different Types of Cement Their Definition CivilSeek2024年7月22日 Blast furnace slag cement is a type of cement made by mixing blast furnace slag with Portland cement in a clinker This combination helps achieve a lower heat of hydration and a finely powdered mixture that provides better workability and durability High Alumina Cement; Highalumina cement is a type of cement made by melting and grinding lime Types of Cement and Their Common Uses in Construction

How to Make Cement From BlastFurnace Slag 911Metallurgist

2017年4月23日 The most important method of regulation used with the lowpercentage Al2O3 slag cements in the USA is the Whiting process This process includes the use of caustic soda, caustic potash, sodium chloride, c, added either as aqueous solution or in a dry state at some stage of the process of cement manufacture15 Slag cement types: The slag cement is prepared from blast furnace slag and hydrated lime The blast furnace slag consists of a combination of calcium and aluminum silicate which is granulated by pouring into a stream of cold water, then dried and blended with hydrated lime and then the powder is finely powderedTypes of Cement Used in Construction (18 Different Types)2023年7月5日 Finely grinding cement clinkers create QSC to raise cement alumina and lower gypsum, used in grouting and underwater concreting 9 Blast Furnace Cement Blast furnace slag cement is a blend of regular Portland cement and finely ground blast furnace slag produced as a byproduct of making steel and has a solid content of less than 70%Different Types of Cement in India for Construction MagicBricksDownload scientific diagram Chemical composition of ground granulated blast furnace slag (GGBFS) from publication: Activation of slag through a combination of NaOH/NaS alkali for transforming Chemical composition of ground granulated blast furnace slag

TYPES OF CEMENT ⋆ ArchiMonarch

In conclusion, Blast Furnace Slag Cement is a type of hydraulic cement made by grinding granulated blast furnace slag with Ordinary Portland Cement or other types of hydraulic cement It offers high durability, lower heat of hydration, and Portland Slag Cement (PSC) Portland Slag Cement incorporates granulated blast furnace slag into Portland cement, imparting unique properties to the concrete This type of cement is known for its low heat of hydration, making it A look at the various types of cement that are used Cement types include ordinary Portland cement, white cement, Portland pozzolan cement, oil well cement, quick setting cement, etc Skip to content Blog Contact About it refers to the cement used in general civil construction engineering, Cement Application – Cement Types AGICO 2023年6月1日 After further drying and grinding, the granulated blast furnace slag becomes a fine With the increase in fly ash in cement, the workability of the slurry increases, and the compressive strength declines The there are significant synergistic effects between GBFS and various types of solid waste (especially red mud, steel Synergistic utilization of blast furnace slag with other industrial

Types of Cement (Cement Types Uses) Tag Vault

2023年10月30日 Cement is a fundamental building material used in construction projects With various types of cement available, it’s crucial to understand their unique properties and uses to choose the right one for your specific project In this article, we will explore the different types of cement used in construction and their applications Key Takeaways:81 *Corresponding author, DOI 101179/Y International Journal of Geotechnical Engineering 2016VOL 10 NO 1 TECHNICAL NOTE Use of Use of granulated blast furnace slag and lime in cement Ground granulated blastfurnace slag (GGBFS), in Portland cement concrete GGBFS was first used in lime mortar production as early as the 1700’s In Germany, Type I Cement Type C Fly Ash Type F Fly Ash GGBFS SiO2 211 335 434 400 Ground Granulated BlastFurnace Slag: Its Chemistry and Use 2015年6月1日 Scientific interest in slag has been increasing steadily since the early 1990s The number of slag studies that are referenced in this paper by publication date is shown in Fig 1 (see Appendix A Summary of slag characterization references and type of data from each that was used in this paper, Appendix B Summary of slag application and reuse references for this Characteristics and environmental aspects of slag: A review

Cement Types of Cement Classification, Uses Dream Civil

2023年9月20日 iii Blast Furnace Slag Cement It is made by intergrinding portland cement clinker and granulated blastfurnace slag, the proportion of the latter not exceeding 65% of the weight of the mixture It has lower evolution of heat It is more resistant to attacks by weathering agencies It is cheaper than ordinary portland Cement Its color is 2021年11月1日 Ground granulated blast furnace slag (GGBFS) is one of green construction materials that held benefits in producing sustainable and highquality concreteAn Overview of Behaviour of Concrete with Granulated Blast Furnace Slag 2023年7月16日 Cement is replaced by slag from different steel mills, both blast furnace and ladle furnace slag The percentages of slag substitution by cement are 30%, 40% and 50% by weightVarious Uses of Blast Furnace Slag and Steel Slag in 2024年6月1日 Hence, it has become imperative to prioritize the development of carbonneutral construction and to investigate alternative approaches for substituting raw materials to mitigate CO 2 emissions within the cement manufacturing process Fig 1 illustrates the steelmaking process and the various types of steelmaking slag generated at each step The blast furnace Utilization of steelmaking slag in cement clinker production: A

Types Of Cement And Their Uses In Construction

9 Blast Furnace Slag Cement: Blast Furnace slag cement is made up of the Ordinary Portland Cement clinkers, gypsum and Ground Granulated Blast Furnace Slag (GGBS) added in certain proportions The GGBS is a waste 2024年4月5日 Concrete is the most widely used construction material due to its wide range of applications, and the current global concrete consumption has reached approximately 15 billion tonnes (Serres et al, 2016; Valipour et al, 2014)Concrete production has a significant environmental impact due to high energy consumption and greenhouse gas (GHG) emissions, Environmental impact of concrete containing high volume fly ash 2020年4月1日 During the steel making process, CO 2 is generated as a byproduct in either one of the following two processes: (i) reduction of iron ore with coke in a blast furnace (BF) to produce pig iron, or (ii) from the decarbonisation of limestone (CaCO 3) and dolomite (MgCO 3) which are added together with coke as fluxing materials to strip oxygen and other impurities Basic oxygen furnace slag: Review of current and potential usesSlag processing George C Wang, in The Utilization of Slag in Civil Infrastructure Construction, 2016 53 Blast furnace slag processing Iron blast furnace slag results from the fusion of iron ore, fluxing materials, and coke; the reduction reactions; and the separation of iron from the ore As indicated in Chapter 2, the term blast furnace slag is used often to refer to iron blast furnace Blast Furnace Slag an overview ScienceDirect Topics

.jpg)

Evaluation of Pozzolanic activity and lime reactivity of fly ash,

214 GGBS (Ground granulated blast slag): Ground granulated blast furnace slag This is bye product generated during iron extraction in blast furnace It is non metallic It consists mainly of silicates, alumina and calcium oxide GGBFS – Granulated blast furnace slag is obtained when molten blast furnace slag is rapidly chilled in cold waterSteel slags in cementbased composites: An ultimate review on characterization, applications and performance Ana Carolina Pereira Martins, Ricardo André Fiorotti Peixoto, in Construction and Building Materials, 2021 21 Blast furnace slag (BFS) The steel industry involves the production of different slags throughout the processes [23,39]Blast Furnace Slag (BFS) is a byproduct of Blast Furnace Cement an overview ScienceDirect Topics2022年7月18日 Building manufacturing has played a significant part in the urbanization and industrialization that has occurred in recent decades Approximately 5–10% of global employment is provided by the construction industry, which also accounts for 5–15% of national GDP []About 40% of overall energy use and 30% of total natural resource depletion are attributed to the A Comprehensive Review on the Ground Granulated Blast Furnace Slag 2018年10月11日 This paper presents a study on the stabilization of contaminated soil deposits using Fly Ash (FA), Quick Lime (QL) and Blast Furnace Slag (BFS)Remediation of Heavy Metal Contaminated Soils by Solidification

.jpg)

What is Blast Furnace Slag and How to Process It?

2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of 2019年4月1日 This paper presents a study on the stabilization of contaminated soil deposits using fly ash (FA), quick lime (QL) and blast furnace slag (BFS)Remediation of heavy metal contaminated soils by 2024年9月20日 This study primarily investigates the effect of fly ash (FA) content on the mechanical properties and hydration performance of alkaliactivated ground granulated blast furnace slag cement (AAGC) and compares the related properties with ordinary Portland cement (OPC) Additionally, we examined the hydration products; performed thermal analysis, MIP, The Influence of FA Content on the Mechanical and Hydration15 Different Types of Cement In India 1) Ordinary Portland cement (OPC) 2) Portland Pozzolana Cement (PPC) 3) Rapid Hardening Cement 4) Extra Rapid Hardening Cement 5) Low Heat Portland Cement 6) Quick Setting Cement 7) Sulphate resisting Portland cement 8) High Alumina Cement 9) Blast Furnace Slag Cement 10) White Cement 11) Coloured Cement 15 Different Types of Cement in India and Their Uses OkCivil

15+ Different Types of Cement Their Definition CivilSeek

2017年5月29日 7 Blast Furnace Slag Cement: Definition: It is a modified type of Portland cement which contains 2565 percent (by weight) of blast furnace slag It is manufactured by grinding clinker and specific amounts of blast furnace slag together A small percent of gypsum is also added for controlling its setting time2024年7月22日 Blast furnace slag cement is a type of cement made by mixing blast furnace slag with Portland cement in a clinker This combination helps achieve a lower heat of hydration and a finely powdered mixture that provides better workability and durability High Alumina Cement; Highalumina cement is a type of cement made by melting and grinding lime Types of Cement and Their Common Uses in Construction2017年4月23日 The most important method of regulation used with the lowpercentage Al2O3 slag cements in the USA is the Whiting process This process includes the use of caustic soda, caustic potash, sodium chloride, c, added either as aqueous solution or in a dry state at some stage of the process of cement manufactureHow to Make Cement From BlastFurnace Slag 911Metallurgist15 Slag cement types: The slag cement is prepared from blast furnace slag and hydrated lime The blast furnace slag consists of a combination of calcium and aluminum silicate which is granulated by pouring into a stream of cold water, then dried and blended with hydrated lime and then the powder is finely powderedTypes of Cement Used in Construction (18 Different Types)

Different Types of Cement in India for Construction MagicBricks

2023年7月5日 Finely grinding cement clinkers create QSC to raise cement alumina and lower gypsum, used in grouting and underwater concreting 9 Blast Furnace Cement Blast furnace slag cement is a blend of regular Portland cement and finely ground blast furnace slag produced as a byproduct of making steel and has a solid content of less than 70%Download scientific diagram Chemical composition of ground granulated blast furnace slag (GGBFS) from publication: Activation of slag through a combination of NaOH/NaS alkali for transforming Chemical composition of ground granulated blast furnace slag