Calcium carbonate processing equipment model

.jpg)

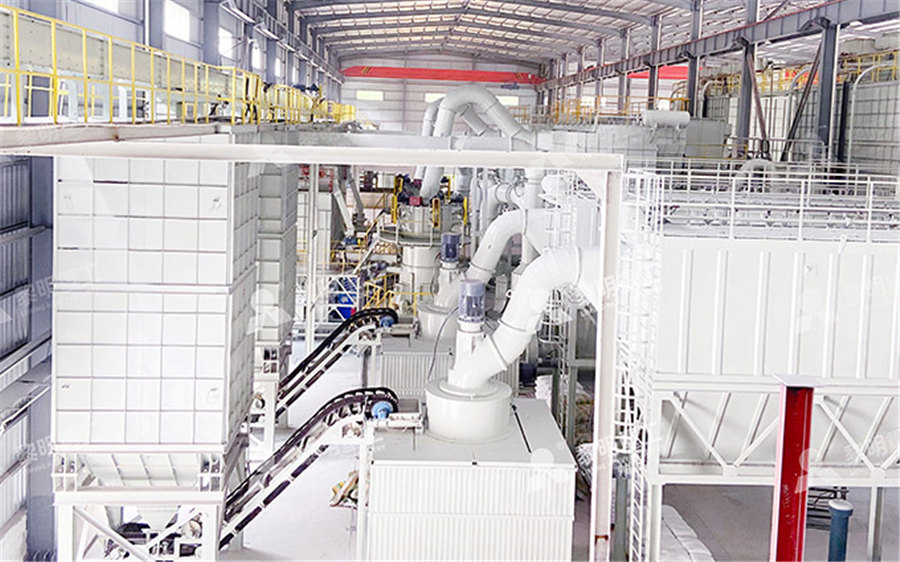

Calcium Carbonate Manufacturing Process and Equipment

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk occurs as a microcrystalline material and has 展开EPIC Powder supplies the complete set of equipment for the calcium carbonate plant, from a Calcium Carbonate Powder Production Line – Powder EquipmentCalcium Carbonate Processing Machine,Calcium Carbonate Powder Processing Machine Calcium Carbonate Powder Processing MachineThe calcium carbonate grinding production line is an efficient, stable, and reliable production Calcium Carbonate Grinding Production Line TAYMACHINERY

4 Steps To Build A Calcium Carbonate Processing Plant Zenith

2022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh2024年11月1日 Supersaturation causes dissolved salts to grow on the surface as crystal scaling (also known as precipitation fouling or scaling), which is one of the prevalent fouling mechanisms in process equipment such as heat exchangers, evaporators, crystallizers, membranes, etc [3]Calcium carbonate is a common salt that causes crystallization fouling and its solubility Calcium carbonate crystallization process analysis on a heat The introduction of advanced milling technology and equipment can not only process calcium carbonate efficiently, but also further improve the grinding efficiency, improve the added value of products, help enterprises improve the Calcium Carbonate Powder Processing27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM

Decarbonizing cement plants via a fully integrated calcium

2021年4月21日 A lumpedelement model was here used to evaluate the compositions of the gas running out from CaL process when modifying the quantity of CaO sorbent during the CO 2 capture in the carbonator reactor and therefore changing the extent of methane burned to sustain the regeneration of the calcium carbonate in the calciner (Fig 10) [17]The utility model discloses precipitated calcium carbonate process equipment, including body, the bottom of the body inner chamber is fixedly connected with the first motor, the inner chamber of the body and dividing plate is fixedly connected with above the first motor, the rotating shaft of first motor is through the top of dividing plate and extends to the outside of dividing plate, the CNU Precipitated calcium carbonate process equipment Shanghai Clirik machinery supply calcium carbonate mill for calcium carbonate powder process,If you are interested in calcium carbonate processing machine, we are welcoming to your Roller Mill is the specialized ultrafine grinding equipment for non Types of Calcium carbonate Stone Pulverizer —— five models: HGM80, HGM90 Calcium Carbonate Mill,Calcium Carbonate processing Machine Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores The equipment is independently developed and produced by SBM, sold directly by the factory, without middlemen, and is extremely costeffective It is a piece of ideal grinding equipment for processing 1503000 mesh Calcium Carbonate Ultrafine Grinding Mill

CNU Calcium carbonate processing is with classified

The utility model belongs to the technical field of calcium carbonate processing, and a calcium carbonate processing is with classified screening equipment is disclosed, including a box, the left surface fixed mounting of a box has No two boxes, No one box and No two positive bottom of box movable mounting have a chamber door and No two chamber doors respectively, the top 2024年11月29日 Calcium carbonate powder processing equipmentCalcium carbonate powder processing equipment 2017年10月20日 Download Citation Process Characteristics of Synthesis Calcium Carbonate using Desulfurization Gypsum in an Integrated Equipment of Reaction and Separation Desulfurization gypsum is a Process Characteristics of Synthesis Calcium Carbonate using EPIC Powder specializes in designing and engineering calcium carbonate processing lines A grinder or grinding mill is the core equipment for a calcium carbonate grinding plant, Parameter / Model 1530 1557 1850 1870 2250 2270 2450 2470 2660 2670 3070 3090 3280 3290; Cylinder diameter (m) 15: 15:Calcium Carbonate Powder Production Line – Powder Equipment

Calcium Carbonate Mill,Calcium Carbonate processing Machine

Shanghai Clirik machinery supply calcium carbonate mill for calcium carbonate powder process,If you are interested in calcium carbonate processing machine, we are welcoming to your Roller Mill is the specialized ultrafine grinding equipment for non Types of Calcium carbonate Stone Pulverizer —— five models: HGM80, HGM90 calcium carbonate (PCC) samples after PUS treatment presents the characteristic absorption peaks of vaterite at 1112 and 1134 cm1 (White, 1974; Zhou et al , 2004)EFFECT OF ULTRASONICS ON MORPHOLOGY OF PRECIPITATED CALCIUM CARBONATE The fineness of onetime finished product is D97=333μm, and the production capacity of a single machine is 058t/h depending on the model In the processing of calcium carbonate powder, due to the different application industries of the finished products, the production capacity of the production line and the fineness of the finished 4 Steps to Build a Calcium Carbonate Processing Plant Zenith 2024年8月23日 Vertical mill + secondary classification, tertiary classification dry process is one of the main advances in the fine processing technology of heavy calcium carbonate powder in recent years Using vertical mill, ordinary heavy calcium carbonate of 325800 mesh can be directly processed, and some 325800 mesh products can be graded twice or three times to Heavy calcium carbonate dry production process and equipment

Towards decarbonisation of sugar refineries by calcium looping: Process

2024年8月15日 This work will deliver a new proof of concept model for simultaneous sugar refining and carbon capture, thereby transforming sugar into the carbon negative commodity which relies on the utilisation of CO 2 and fresh lime in the sugar refineries carbonisation tanks and in return byproduction of calcium carbonate that can be converted in the calciner of a 2024年10月31日 Characteristics of the Dry Production Process for Calcium Carbonate The dry process eliminates the need for subsequent filtration, drying, and dewatering, resulting in simple operation, easy control, and lower operating costs Compared to wet production, the dry production process exhibits unparalleled advantages in processing calcium carbonateProduction Process and Equipment for Dry Calcium Carbonate Keywords: Nucleation; Induction period; Calcium carbonate; Scale 1 Introduction Calcium carbonate is, together with calcium sulphates, the main component of scales on process equipment surfaces Their presence is mostly unwanted in several industrial applications, since scales reduce heat and mass transfer coefficientsCalcium carbonate scales on process equipment: A measure of Explore our mining equipment to find the ideal wholesale calcium carbonate grinding processing plant model and mills for any mining challenge All categories Featured selections Trade Assurance Buyer Central Help Center Get the appCalcium carbonate grinding processing plant

.jpg)

Calcium Carbonate Processing Machine

Calcium Carbonate Processing Machine,Calcium Carbonate Powder Processing Machine made by Shanghai Clirik has the features of high Model HGM80 HGM90 HGM100L HGM125 HGM1 68 Ring Diameter(mm) 800 900 1000 1250 1 680 Ring Number(layer Calcium Carbonate Grinding Mill is the equipment specializing in producing fine and superfine 2020年5月1日 The calcium carbonate scale often grows extensively on equipment and parts such as pumps, screens, heat transfer surfaces, and piping system, causing major operational difficultiesCalcium carbonate scaling kinetics in oilfield gathering pipelines 2020年10月7日 The proposed model was verified using the thermal decomposition experiment on calcium carbonate The equation has been modified as f (α) = n(1 − α) 1− 1 n [−ln(1 − α)] − 1 m [1 − A Multifaceted Kinetic Model for the Thermal 2018年7月15日 A bottomup approach is adopted to calculate the overall unit cost for this study Detailed cost models for the CCL process including main equipment, design and installation are developed for the CCL integration A breakdown of economic results Integration of the calcium carbonate looping process into an

.jpg)

Frontiers CO2 Capture for Dry Reforming of Natural Gas:

2021年1月21日 The main finding of this work is the usage of Malaysian limestone as sorbent in calcium looping process and investigation of the CO 2 uptake capacity of this limestone Then, the kinetic information obtained was used for the sizing and design of the carbonator and calciner reactors in the CCL process Simulation of Calcium Carbonate Looping ProcessHighquality thermosensitive products like calcium carbonate require gamechanging solutions WaveMix's lowtemperature microwave drying under vacuum is smart redefined when it comes to processing this essential and highly versatile material Want more information on microwave heating and drying equipment? Visit our WaveMix™ Product PageCalcium Carbonate Drying Equipment Marion Process SolutionsThis model is used to calculate the calcium carbonate precipitation indices (LSI, CCPP, AI, and RI) for a specific water chemistry Disinfection CT Calculator This model is used to calculate the CT inactivation ratio for Giardia and viruses achieved across a disinfection contactor at a water treatment plant using chlorine, chloramine, ozone, or chlorine dioxide as a disinfectantOnline Models Water Quality Treatment Solutions, IncExecutive Summary: The SCARLET (Scaleup of Calcium Carbonate Looping Technology for Efficient CO2 Capture from Power and Industrial Plants) project is a large and ambitious project to investigate one of the most promising postcombustion CO2 capture technologies, Calcium Carbonate Looping (CCL) The CCL technology combines low CO2 avoidance costs and Scaleup of Calcium Carbonate Looping Technology for Efficient

Study on Prediction Model of Calcium Carbonate Scaling Based

2024年3月21日 Carbonate scale, especially CaCO 3 scale, is a common inorganic salt scale in the process of oil and gas exploitation The formation fluid migrates from the downhole to the surface, the pressure drops significantly, and the CO 2 in the water escapes, which makes the gasliquidsolid balance go in the direction conducive to the formation of CaCO 3, resulting in Keywords: Nucleation; Induction period; Calcium carbonate; Scale 1 Introduction Calcium carbonate is, together with calcium sulphates, the main component of scales on process equipment surfaces Their presence is mostly unwanted in several industrial applications, since scales reduce heat and mass transfer coefficientsCalcium carbonate scales on process equipment: A measure of 2022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh4 Steps To Build A Calcium Carbonate Processing Plant Zenith 2024年11月1日 Supersaturation causes dissolved salts to grow on the surface as crystal scaling (also known as precipitation fouling or scaling), which is one of the prevalent fouling mechanisms in process equipment such as heat exchangers, evaporators, crystallizers, membranes, etc [3]Calcium carbonate is a common salt that causes crystallization fouling and its solubility Calcium carbonate crystallization process analysis on a heat

.jpg)

Calcium Carbonate Powder Processing

The introduction of advanced milling technology and equipment can not only process calcium carbonate efficiently, but also further improve the grinding efficiency, improve the added value of products, help enterprises improve the 27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM 2021年4月21日 A lumpedelement model was here used to evaluate the compositions of the gas running out from CaL process when modifying the quantity of CaO sorbent during the CO 2 capture in the carbonator reactor and therefore changing the extent of methane burned to sustain the regeneration of the calcium carbonate in the calciner (Fig 10) [17]Decarbonizing cement plants via a fully integrated calcium The utility model discloses precipitated calcium carbonate process equipment, including body, the bottom of the body inner chamber is fixedly connected with the first motor, the inner chamber of the body and dividing plate is fixedly connected with above the first motor, the rotating shaft of first motor is through the top of dividing plate and extends to the outside of dividing plate, the CNU Precipitated calcium carbonate process equipment

Calcium Carbonate Mill,Calcium Carbonate processing Machine

Shanghai Clirik machinery supply calcium carbonate mill for calcium carbonate powder process,If you are interested in calcium carbonate processing machine, we are welcoming to your Roller Mill is the specialized ultrafine grinding equipment for non Types of Calcium carbonate Stone Pulverizer —— five models: HGM80, HGM90 Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores The equipment is independently developed and produced by SBM, sold directly by the factory, without middlemen, and is extremely costeffective It is a piece of ideal grinding equipment for processing 1503000 mesh Calcium Carbonate Ultrafine Grinding MillThe utility model belongs to the technical field of calcium carbonate processing, and a calcium carbonate processing is with classified screening equipment is disclosed, including a box, the left surface fixed mounting of a box has No two boxes, No one box and No two positive bottom of box movable mounting have a chamber door and No two chamber doors respectively, the top CNU Calcium carbonate processing is with classified 2024年11月29日 Calcium carbonate powder processing equipmentCalcium carbonate powder processing equipment