Ultrafine grinding mill for thermal power plants

HIGmill high intensity grinding mill Metso

The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that Coal plays a vital role in electricity generation worldwide Thermal power plants generate a significant portion of the electricity consumed globally, and coalfired power plants are still a predominant source of this electricity A key component of these plants is the coal mill pulverizerCoal Mill Pulverizer in Thermal Power Plants2021年6月11日 Raymond grinding mill: etc), solid fuel production Powder (blast furnace coal injection, petroleum coke, carbon block, carbon, etc); power plant environmental protection desulfurization limestone powder; slag powder Types of grinding mills for petcoke grindingNews The Raymond Ultrafine Mill System is designed to produce extremely fine powders for use in various applications including coatings, fillers, and pigments The mill system will generate products as fine as 50% passing 2 microns or as coarse as 50% passing 10 micronsRaymond Ultrafine Mill Qlar

PolarFit® UltraFine Grinding Mill

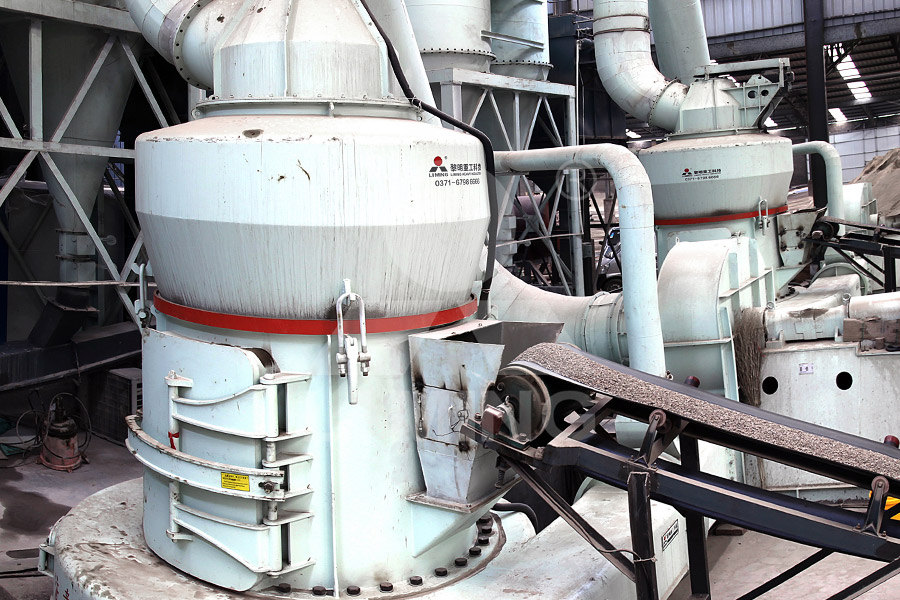

It uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsIt uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsPolarFit® UltraFine Grinding Mill2020年4月13日 Ultrafine Grinding Mill Production Line For nonmetallic mines, thermal power plants, cement plants and coal mines These mills are wellknown in the industry, widely creating value for nonmetallic mines, thermal power Ultrafine Grinding Mill Production Line For nonmetallic mines, thermal It uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsPolarFit® UltraFine Grinding Mill Air Products

.jpg)

HGM Ultrafine Grinding Mill Is Applied To The CCM Powder

2024年9月26日 HGM Series Grinding Mill for CCM Powder Making The HGM Series Ultrafine Grinding Mill is specifically designed for producing ultrafine powders of noninflammable nonexplosive and brittle materials with Moh’s hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, etc, totally more than 100 kinds of materialsCoal Mill in Thermal Power Plant Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document discusses coal pulverizers/mills which are critical components that convert the stored energy in coal into electricity There are various types of pulverizers that primarily utilize grinding, drying, classification and circulation processesCoal Mill in Thermal Power Plant PDF Mill (Grinding) ScribdIt uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsPolarFit® UltraFine Grinding Mill Air Products ChemicalsThe Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian

.jpg)

Ultra Fine Grinding A Practical Alternative to Oxidative

Table 1 Typical Mill Grinds and Power Intensities Type of Mill Typical Lower Grind Size P80 µm Power Intensity kW/m3 Ball Mill 75 20 Tower Mill 20 40 UFG Mill 5 280 Two basic types of UFG mills are available, the vertical stirred mill and the horizontal stirred mill Both use rotating stirrers within a stationary mill shell to impart kinetic2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Coal mill pulverizer in thermal power plants PPTProcess introduction Vertical coal mill, also known as vertical roller coal mill or vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal powerMainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plantcoal grinding machine CHAENGLUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment For limestone, calcite, dolomite Mohs hardness of 6 or less nonflammable, Power plant desulfurization grinding process Grinding Mill ultrafine grinding mill, vertical ultrafine mill

Thermal Power Plant PDF Boiler Mill (Grinding)

Thermal Power Plant Free download as PDF File (pdf), Text File (txt) or view presentation slides online This document provides information about coal analysis, coal handling and storage, and coal firing systems used in thermal power plants It discusses the key components of coal analysis including proximate analysis, ultimate analysis, ash analysis, and calorific valueHuatong Machinery is committed to the celllevel ultrafine crushing of traditional Chinese medicine and is widely used in major pharmaceutical factories, hospitals, veterinary drugs, pesticides, cosmetics, health care, food, beverage and other industries; Degree is an international leader, deeply cultivating the global market, integrating production, sales, research and exportZhengzhou Huatong Machinery Co,LtdAdvances in the Cyanidation of Gold G Deschênes, in Gold Ore Processing (Second Edition), 2016 44 Ultrafine Pyrrhotite Concentrate Ultrafine grinding is used to liberate gold finely disseminated in metallic sulfides KCGM is the first gold mine using ultrafine grinding followed by cyanidation (Ellis and Gao, 2002)The gold sulfide concentrate is grind with an IsaMill to a P Ultrafine Grinding an overview ScienceDirect TopicsA bead mill is a type of equipment used for ultrafine grinding and dispersing of particles It operates on the principle of impact and attrition: grinding media (beads) made of glass, ceramic, or steel are agitated inside a vessel or a chamber by a rotating shaft with impellers, causing the particles to break into smaller sizes due to collision and shear forcesBead Mills for ultrafine grinding RETSCH

Ultra Fine Grinding A Practical Alternative to Oxidative

Table 1 Typical Mill Grinds and Power Intensities Type of Mill Typical Lower Grind Size P80 µm Power Intensity kW/m3 Ball Mill 75 20 Tower Mill 20 40 UFG Mill 5 280 Two basic types of UFG mills are available, the vertical stirred mill and the horizontal stirred mill Both use rotating stirrers within a stationary mill shell to impart kineticafter ultrafine grinding with the IsaMill Figure 3 Improvement in the zinc grade/recovery curve after ultrafine grinding Of specific interest in the Mount Isa operations is the wide choice of grinding media available for use in the IsaMills Mt Isa has variously used heavy media plant reject and lead or copper smelter slag for grinding mediaIsaMill Ultrafine Grinding for a Sulphide Leach ProcessThere is a large gap between the tip speed and power intensity of the lowspeed vertical mills and the highspeed horizontal mills The VXP mill bridges the gap between highspeed and lowspeed mills The VXPmills are designed for fine and ultra fine grinding applications In practice, the mill performs best when the feed has a normal distributionVXPmill for fine ultra fine grinding FLSmidthThe super fine mill is an advanced grinding machine designed to produce extremely fine powders from various materials and that goes for everything from laboratoryscale machines to production plants The customer has been using imported dualpower pin mills for the modification of calHome Super Fine Mill

XZM Series Ultrafine Mill,Ultrafine Grinding Mill

XZM Series Ultrafine Mill XZM Series Ultrafine mills are designed for pulverizing minerals, material can be pulverized into 3252500Mesh It is a new superfine powder production equipment developed through accumulating years of experience, it symbolizes the new development and new science in the grinding world2013年4月25日 Best Practice for Thermal Power Plants » silicon carbide grinding media » power house building construction ppt Hot Products Used for best practices in thermal power plant vibrating screen scm ultrafine mill belt conveyor vsi best practices in thermal power plant Grinding Mill ChinaIsaMills have similar ultrafine grinding efficiencies to SMDs given and thermal cracking The irradiated PTFE becomes very brittle, and can be further refers to any substance which results in increased grinding efficiency and reduction in power consumption when added to the mill charge (amounts not exceeding 025 wt Ultrafine Grinding an overview ScienceDirect TopicsHIGmill high intensity grinding mill is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The HIGmill is the only ultrafine grinding technology having operating references with installed power greater than 3,000 kW Stirred mill plants unitsHIGmill high intensity grinding mill Metso

.jpg)

Ultrafine Grinding Mill Turbine Classifier Vsunny

Our powder mill equipment is suitable for grinding raw materials including dolomite, marble, calcite, kaolinite, etc We can provide solution according to raw materials in customer needs, to provide fine powder grinding equipment for use in heavy industry like cement production plant, thermal power plant, steelmaking plant, and so onLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller MillCoal plays a vital role in electricity generation worldwide Thermal power plants generate a significant portion of the electricity consumed globally, and coalfired power plants are still a predominant source of this electricity A key component of these plants is the coal mill pulverizerCoal Mill Pulverizer in Thermal Power Plants2021年6月11日 Raymond grinding mill: etc), solid fuel production Powder (blast furnace coal injection, petroleum coke, carbon block, carbon, etc); power plant environmental protection desulfurization limestone powder; slag powder Types of grinding mills for petcoke grindingNews

Raymond Ultrafine Mill Qlar

The Raymond Ultrafine Mill System is designed to produce extremely fine powders for use in various applications including coatings, fillers, and pigments The mill system will generate products as fine as 50% passing 2 microns or as coarse as 50% passing 10 micronsIt uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsPolarFit® UltraFine Grinding MillIt uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsPolarFit® UltraFine Grinding Mill2020年4月13日 Ultrafine Grinding Mill Production Line For nonmetallic mines, thermal power plants, cement plants and coal mines These mills are wellknown in the industry, widely creating value for nonmetallic mines, thermal power Ultrafine Grinding Mill Production Line For nonmetallic mines, thermal

.jpg)

PolarFit® UltraFine Grinding Mill Air Products

It uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 microns2024年9月26日 HGM Series Grinding Mill for CCM Powder Making The HGM Series Ultrafine Grinding Mill is specifically designed for producing ultrafine powders of noninflammable nonexplosive and brittle materials with Moh’s hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, etc, totally more than 100 kinds of materialsHGM Ultrafine Grinding Mill Is Applied To The CCM Powder Coal Mill in Thermal Power Plant Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document discusses coal pulverizers/mills which are critical components that convert the stored energy in coal into electricity There are various types of pulverizers that primarily utilize grinding, drying, classification and circulation processesCoal Mill in Thermal Power Plant PDF Mill (Grinding) ScribdIt uses the power of liquid nitrogen to remove heat produced in the grinding process by controlling the temperature of your product or the mill The mill generates consistent yields of particles at the required mesh In some cases, it can produce particles as small as 10 micronsPolarFit® UltraFine Grinding Mill Air Products Chemicals