What to make money by processing fly ash

How To Make Money With Fly Ash? Turn Waste Into

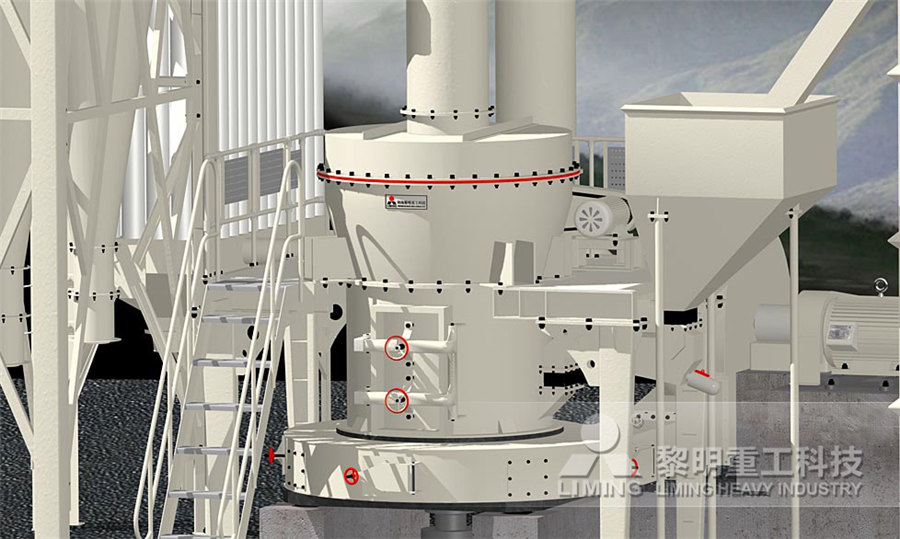

2023年10月13日 How to turn fly ash into wealth? Now we must mention fly ash processing plant, which is an effective solution for fly ash recycling The whole fly ash processing plant can be divided into seven sections, including crushing, 2020年12月10日 The key market drivers of fly ash are the growing construction sector, infrastructure, road development, rules for handling fly ash, and rising focus on the use of Value in Waste: Fly Ash Utilization and Money Making OpportunitiesBelow are some common and notsocommon fly ash products The use of coal fly ash has both environmental and economic benefits First, it contains minerals we would typically get from mining the Earth’s virgin resources Reusing this What Products are Made from Fly Ash?By embracing sustainable practices and investing in advanced processing systems, your business can thrive It can generate more revenue while minimizing its ecological footprint Heyl Patterson technology has proven to be a leader in Fly Ash Production Process and Industry Trends Heyl

Value in Waste: Fly Ash Reuse and Recovery

For example, although not a reuse application, many companies have taken to conditioning fly ash prior to deposit into landfill; processing fly ash in a pugmill mixer with water or a binder can dedust the material so it does not become 2023年6月2日 Fly ash can partially substitute cement in the production of concrete, reducing the carbon footprint of construction projects 1 Building supplies This is essential since the Fly ash can partially substitute cement in the production of Fly ash is the fine ash collected from the flue gas after coal combustion Fly ash is the main solid waste discharged from coalfired power plants If a large amount of fly ash is not treated, it will produce dust and pollute the atmosphere How to Process Fly Ash and What Is It Used forCommercial uses can make fly ash recovery a profitable venture For example, fly ash is used as a direct substitute for Portland cement in concrete production or can replace mined gypsum in wallboard The site of its first documented use in What is Fly Ash? SLY, LLC

Converting Waste Fly Ash into Valuable Products: An Insight into

2024年5月25日 When used as a cement substitute, fly ash can save money and the earth by reducing the need for cement Adding more fly ash to concrete could make it more usable and 2022年2月5日 In this study, aluminumbased metal matrix composites containing 5, 10, 15, 20, and 25% fly ash particles by weight have been fabricated using a stir casting route(PDF) Fly Ash Composites: A Review ResearchGate2022年1月1日 Fly Ash Cenospheres (FACs) are among the most valuable byproducts obtained from the burning of coal They are lightweight (density 400 kg/m3 – 800 kg/m3), hollow, and spherical in nature, and Fly Ash Cenosphere: Characterization, processing, and properties2023年4月3日 It's commonly used as structural fill for road construction and fly ash can be used to make bricks, ceramic tiles, plaster, Portland cement, and readymix cement Other building materials that may contain fly ash include What Is Fly Ash and How Is It Used in Concrete? The

(PDF) Incineration Fly Ash and Its Treatment to Possible

2020年12月17日 Treatment techniques of incineration fly ash were discussed to determine the effectiveness of obtaining environmentally stable material, and, finally, possible applications of incineration fly ash The increased workability and longterm strength benefits of fly ash make it the ideal cement replacement product for this low moisture form of concrete From heavy haul shipping yards, to cattle feedlot pens, to full sized hydroelectric dams, Ashcor What Is Fly AshThe only materials worth buying off the mp are Acacia, Fir and Tin ore If you are checking in every few hours then processing any timber is fine (aka you can just buy any timber and process it for decent money Avoid Ash if you can its easily the worst) Timber processing is strictly more money then ore Its faster and more profitableTips for making money with processing? : r/blackdesertonline2024年5月25日 Fly ash is the main component of fly ash bricks; Other ingredients include stone or sand dust as fine aggregate, lime as a source of calcium carbonate, which gives the bricks their label of “Selfcementing bricks,” gypsum to improve the fineness of the shape of the bricks (Nayak et al, 2022), and cement to strengthen the bond and bonding (Botchway et al, 2020)Converting Waste Fly Ash into Valuable Products: An Insight into

What is Fly Ash? SLY, LLC

Commercial uses can make fly ash recovery a profitable venture For example, fly ash is used as a direct substitute for Portland cement in concrete production or can replace mined gypsum in wallboard The site of its first documented use in cement production was in the 1940s when fly ash concrete was used for a tunnel spillway at the Hoover DamTECHNOLOGIES OF COAL FLY ASH PROCESSING INTO METALLURGICAL AND SILICATE CHEMICAL PRODUCTS Solomon Shcherhan, Int Assn of Science, Inc, 1 IO Bennett Ave, 3H New York, NY 10033; Victor Raizman TECHNOLOGIES OF COAL FLY ASH PROCESSING INTOWhen used in concrete mixes, fly ash improves the strength and segregation of the concrete and makes it easier to pump Why Use Fly Ash? Fly ash's properties improve the performance of concrete Concrete made with fly ash tends to be harder, has Fly Ash Concrete Alberta2023年8月16日 Harvested fly ash, an indispensable ingredient for contemporary cement manufacturing, is a fine, powdery byproduct of coal combustion originating from power plantsRich in silica, alumina, iron, and calcium, fly Fly ash processing: Tailored solutions for reclaimed fly

.jpg)

Fly Ash What a Replacement Structural Guide

Fly ash also has the potential to save money on building projects Because fly ash can be used to replace Portland cement, it can reduce the overall cost of construction projects In addition, because fly ash can improve the strength After processing, fly ash is transported to its final destination using trucks, trains, or barges The transportation method depends on the distance between the processing facility and the final destination Benefits of Fly Ash Fly ash has several benefits that make it an attractive alternative to traditional materialsHow do You Process Fly Ash?The fly ash processing plant constructed by AGICO Cement is highly automated and mechanized, with low investment, high profit, simple structure and easy operation, which helps each region realize reasonable waste recycling and utilization to ‘green up’ users’ supply chains Raw Material: Fly Ash / Volcanic Ash: Capacity(t/h) 811:Fly Ash Processing Plant Cement Equipment Manufacturing2019年9月12日 It involves the conversion of fly ash into an amorphous material By doing so, it rids the fly ash of 999% of its hazardous organic constituents and fixes the heavy metals in the final glasslike product [7, 8] Its composition largely comprises SiO 2, Al 2 O 3, and CaO In fact, MSW fly ash typically falls within the margins of the CaOAl 2 O HIGH TEMPERATURE PROCESSING OF FLY ASH FOR THE

Fly Ash Processing and Equipment to Collect Fly Ash Heyl

Cyclone furnaces: These produce the least amount of coal fly ash, composition of which is between 70 to 80 percent fly ash and 20 to 30 percent molten bottom ash Wetbottom boilers: Also known as a slagtap furnace, these produce less fly ash, with only about half leaving the plant along with the flue gas, while the rest remains in the furnace2024年9月27日 Freecash offers multiple ways to earn money, including game app testing, earning cashback on inapp purchases, and unlocking payouts by reaching specific game levels During my testing, I earned between $10 and $50 a month, which is typical for moderately active users On one particularly active month, I pulled in over $100 by completing highvalue offers 21 Best Games That Pay Real Money DollarSproutRaw Materials Used in Fly Ash Brick Manufacturing The manufacturing process of fly ash bricks involves using several raw materials mixed together in specific proportions The primary raw materials used in fly ash brick manufacturing are as follows: 1 Fly Ash Fly ash is a fine powder produced as a byproduct of coalfired power plantsHow Are Bricks Made Fly Ash Bricks Manufacturing Process2024年5月6日 The following guides and resources can help you learn more about these real ways to make money from home for free 46 Sign up for a food delivery service While this isn’t technically a way to make money from home, delivering food or packages is an easy way to earn extra income outside of a day job56 Legit Ways to Make Money Online DollarSprout

-2.jpg)

Fly Ash Processing Equipment FEECO International Inc

Our process experts are wellversed in fly ash processing and regularly conduct feasibility studies in the Innovation Center to test and evaluate the best pelletization solution for each unique sample MATERIAL PROCESSING Agglomeration We offer disc pelletizers, pug mills, form of fly ash When treated, this fly ash can have industrial applications This is mainly due to its pozzolanic properties that can make it a suitable replacement for ordinary portland cement Fly ash characteristics Fly ash characteristics differ due to the coal grade, chemistry, method of firing and any flue gas scrubbing processesMetso centrifugal classifier for fly ash processing2023年5月25日 Adding fly ash to concrete can also save homeowners money Because it is often more costeffective than cement alone, incorporating fly ash can be economical for extensive hardscaping projects In addition, since the What Is Fly Ash And How Is It Used? House Digest2023年9月25日 perspective; Fly ash processing must also be carried out with attention to occupational safety and health aspects, so as not to endanger employees involved in the Utilization of Fly Ash Waste in the Cement Industry

.jpg)

Mechanical processing of wet stored fly ash for use as a cement

2024年10月10日 Wet storage effects on fly ash mean that processing may be necessary to achieve the physical properties required for use in concrete This paper considers drying, deagglomeration and milling of various wet stored fly ashes at laboratory and pilot/benchtop scales, towards meeting these2012年2月1日 However, there are several technologies and fly ash processing methods that can reduce the environmental impact of cement industry production activities, The processing, characterization, and properties of fly ash 2024年4月25日 So far we’ve covered ways to make extra money online, using your phone, and with little to no effort at all But sometimes it’s nice to take a break from technology, especially if you’re on a computer all day for work Here are some ways to make extra money that don’t involve staying glued to a screen 99 Bet on your own weight loss189 Side Hustle Ideas to Make Extra Money (2024) DollarSproutHi Armand, there is a easier way to do this with millis() you can get the number of milliseconds that passed since the programm started in the draw loop you can then calculate the number of milliseconds that passed since the last time draw was called with this information you could set the fill color to red for just the next frame (see first ellipse) or fill it with red according to the How to make a shape flash colour every X amount a second?

An Investigation of Fly Ash and Slag Processing and Fiber MDPI

2024年6月1日 As the world’s population grows and resource consumption rises, there will be an increase in household waste and, consequently, the fly ash and slag from after the incineration of this waste need to be properly recycled or used as secondary raw materials in other industries The authors of this work propose an innovative technology that has not yet been studied much 2023年3月20日 Cenosphere processing from fly ash has been gaining traction in recent years due to its numerous applications across a wide range of industries The cenosphere market is expected to see a compound annual growth rate of around 12% between 2020 and 2030, according to a report by Future Market InsightsManufacturing Business of Cenosphere Processing from Fly Ash2020年12月10日 The key market drivers of fly ash are the growing construction sector, infrastructure, road development, rules for handling fly ash, and rising focus on the use of environmentally compatible products As illustrated below, class F Fly ash type exhibits market monopoly and is estimated to grow at a compounded annual growth rate of 67 percentValue in Waste: Fly Ash Utilization and Money Making 2022年2月5日 In this study, aluminumbased metal matrix composites containing 5, 10, 15, 20, and 25% fly ash particles by weight have been fabricated using a stir casting route(PDF) Fly Ash Composites: A Review ResearchGate

Fly Ash Cenosphere: Characterization, processing, and properties

2022年1月1日 Fly Ash Cenospheres (FACs) are among the most valuable byproducts obtained from the burning of coal They are lightweight (density 400 kg/m3 – 800 kg/m3), hollow, and spherical in nature, and 2023年4月3日 It's commonly used as structural fill for road construction and fly ash can be used to make bricks, ceramic tiles, plaster, Portland cement, and readymix cement Other building materials that may contain fly ash include What Is Fly Ash and How Is It Used in Concrete? The 2020年12月17日 Treatment techniques of incineration fly ash were discussed to determine the effectiveness of obtaining environmentally stable material, and, finally, possible applications of incineration fly ash (PDF) Incineration Fly Ash and Its Treatment to PossibleThe increased workability and longterm strength benefits of fly ash make it the ideal cement replacement product for this low moisture form of concrete From heavy haul shipping yards, to cattle feedlot pens, to full sized hydroelectric dams, Ashcor What Is Fly Ash

Tips for making money with processing? : r/blackdesertonline

The only materials worth buying off the mp are Acacia, Fir and Tin ore If you are checking in every few hours then processing any timber is fine (aka you can just buy any timber and process it for decent money Avoid Ash if you can its easily the worst) Timber processing is strictly more money then ore Its faster and more profitable2024年5月25日 Fly ash is the main component of fly ash bricks; Other ingredients include stone or sand dust as fine aggregate, lime as a source of calcium carbonate, which gives the bricks their label of “Selfcementing bricks,” gypsum to improve the fineness of the shape of the bricks (Nayak et al, 2022), and cement to strengthen the bond and bonding (Botchway et al, 2020)Converting Waste Fly Ash into Valuable Products: An Insight into Commercial uses can make fly ash recovery a profitable venture For example, fly ash is used as a direct substitute for Portland cement in concrete production or can replace mined gypsum in wallboard The site of its first documented use in cement production was in the 1940s when fly ash concrete was used for a tunnel spillway at the Hoover DamWhat is Fly Ash? SLY, LLCTECHNOLOGIES OF COAL FLY ASH PROCESSING INTO METALLURGICAL AND SILICATE CHEMICAL PRODUCTS Solomon Shcherhan, Int Assn of Science, Inc, 1 IO Bennett Ave, 3H New York, NY 10033; Victor Raizman TECHNOLOGIES OF COAL FLY ASH PROCESSING INTO

Fly Ash Concrete Alberta

When used in concrete mixes, fly ash improves the strength and segregation of the concrete and makes it easier to pump Why Use Fly Ash? Fly ash's properties improve the performance of concrete Concrete made with fly ash tends to be harder, has