Installation method of limestone industrial mill

Limestone Grinding Production Line Installation Instructions

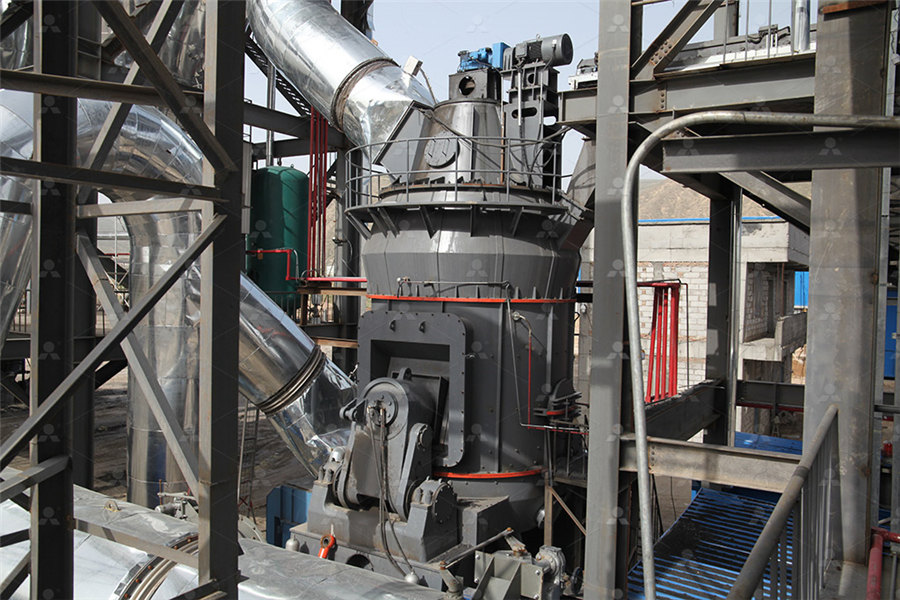

2024年6月14日 Our limestone grinding production line adopts advanced grinding technology and efficient production equipment, ensuring the processing quality and output of limestone The production line configuration includes key equipment such as crushers, grinding mills, The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields Limestone Grinding Mill Plant TAYMACHINERY2017年11月28日 The following equipment that we can use in the lime production process consists of jaw crusher, limestone grinding mill, bucket elevator, electricmagnetic vibration feeder, dust collector, powder concentrator, pipeline Configuration and Process Flow of Limestone Milling These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, storage, and drying equipmentLimestone Mills Limestone Crushers Pulverizers

How to build a small limestone mill production line?

2023年2月7日 To build a small limestone mill production line, you need to follow these steps: Site Selection: Choose a suitable location to set up the production line based on factors such At Wake Stone's new installation, the cage is placed directly after a vibratory screener, and material is fed into the machine off the top deck As material flows through the cage mill's intake hopper and chute into the innermost cage's Properly Milling Limestone Stedman Machine CompanyCement and Power Plants Air Pollution Control Equipments Civil and Structural WorksDesign and Construction of Limestone Grinding PlantDiscover our individual products for limestone processing: grindingdrying on vertical mills for optimum result or ball billsLimestone mills for all requirements Gebr Pfeiffer

Limestone Mill High Efficiency, Large Capacity, 2002500 Mesh

Limestone can be directly processed into aggregated rock and burnt into unslaked lime which becomes slaked lime after its moisture water absorption The main content of slaked lime is 2024年1月18日 Crushing: Limestone large chunks are crushed by a crusher to a feed fineness that can enter the milling machine (15mm50mm) Milling: After crushing, small pieces of How to choose a limestone grinding mill SANDMINE2013年11月1日 A MicronMaster Jet Pulverizer jet mill (061 m in diameter)was used in this study to grind the materials as shown in Fig 1 a and b The materials to be ground were blended for 60 min in a 019 m 2 Vblender (this step is only conducted for blends) After blending, approximately 45 kg of the preblended material was transferred into the hopper for jet mill Jet mill grinding of portland cement, limestone, and fly ash: 010Method Statement of Coal Mill Instattalation Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free This document provides a method statement for installing a coal mill at a project site It 010Method Statement of Coal Mill Instattalation

.jpg)

Limestone Ultrafine Grinding Mill

Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has The commonly used processing technology of limestone is to use industrial mills to mechanically pulverize it Provide 2023年4月13日 Selection function for the different feed size distribution; coarser, finer (317 mm ball, J = 20%, f c = 4%) Optimization of Ball Mill Grinding of a LimestoneType Brecciated profile with varying working gaps due to the wear after longterm use The mill is gravity fed, without any external screw devices The experiments in the HPRM were performed with limestone as a feed material The material is extracted from feed bin into the mill The circumferential speed can be adjusted in the range of 0124 m s1 8Modelling of an Industrial Scale High Pressure Roller Mill DiVAmill volume lled by the grinding media bed and is calculated as Eq 7 [12] The material lling ratio (f c) is dened as the fraction of the mill volume occupied by the material to be ground and is calculated as Eq 8 J = (7) VolumeofSolidBalls Volumeof Mill ˜ 1 1−Φ ˚ f c = (8) VolumeofSolidMaterial Volumeof Mill ˜ 1 1−Φ ˚Optimization of Ball Mill Grinding of a Limestone‐Type Brecciated

.jpg)

Adjustment of limestone grinding in an electromagnetic mill for

in development program based on the simulation studies and industrial impact of physical parameters scaling on the individual parameters of the quality and efficiency 2 Materials and methods Limestone powder below 120 µm, which are Selecting the right model of grinding mill for limestone desulfurization powder technical upgrade project Limestone desulfurization is a widely adopted method for reducing sulfur dioxide emissions from industrial processes, particularly in power plants and steel millsSelecting the right model of grinding mill for limestone 2021年8月17日 Recommendations for Gypsum Industrial Ultrafine Powder Mill Machine: The Mohs hardness of gypsum is 235, and it can be ground with an SBM industrial grinding mill (gypsum industrial ultrafine powder mill machine) SBM is a professional manufacturer of mining ore grinding machinery and equipmentGypsum Industrial Ultrafine Powder Mill Machine2020年12月12日 upgradation of lowgrade limestone by using a suitable beneficiation method a project report submitted by bachelor of engineering in mining engineering college of engineering guindy December 2020 (PDF) UPGRADATION OF LOWGRADE LIMESTONE BY USING A

(PDF) A SIMPLE METHOD OF ASSESSING BALL MILL

2020年1月1日 a simple method of assessing ball mill health using bond tests and functional performance2018年7月3日 Three industrial trial productions and several laboratory trial productions of limestone calcined clay cement in India was carried out between 2014 to 2017, Figure 2 displays the calcined clay at Industrial Production of Limestone Calcined Clay Knowing that approximately 87% of anthropogenic atmospheric sulfur oxides (SO 2 and sulfur trioxideSO 3 ) are emitted from fossil fuelfired plants [7], these emissions are the main targetFlow diagram of the limestone scrubbing methodThis method statement for electrical work shall help you understand the requirements before and during the cable s and wires pulling process The document is very helpful for MEP QA/QC engineers toElectrical Method Of Statement For Installation Termination of

.jpg)

Limestone Ultrafine Vertical Grinding Mill – Case in Mali

In fact, our Raymond mill can also produce 500 mesh limestone, but the limestone ultrafine vertical grinding mill can produce a larger range of powder fineness, up to 3000 mesh This can help customers produce limestone of different specifications, respond to market demand and increase competitiveness2021年6月29日 Effects of Mill Speed and Air Classifier Speed on Performance of an Industrial Ball Mill June 2021; DOI:1029272/cmt Introduction of limestone in cement mill and the power consumption Effects of Mill Speed and Air Classifier Speed on Performance of Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller Mill2023年6月6日 Overview of LimestoneTo gain a comprehensive understanding of limestone in design and installation, dive into the properties and common uses of limestone This versatile material impresses homeowners and DIY enthusiasts alike with its wide range of finishes and durability Learn how to use limestone to elevate your next home projectProperties of Limestone Work: A Comprehensive Guide to Design and Installation

.jpg)

Characterization and Classification of Purity of Limestone in

2021年6月1日 Purity classification of limestone at Madura island according to the British Geological Survey [10,15,16] Mill speed modulation varies the centrifugal force of the grinding rolls Product capacity ranges from 100% to 0% when utilizing an optional variable frequency drive Bottom Discharge Auxiliary Mill Bottom Discharge permits production of a second granular product, or beneficiation of the principal product, by removing the pyrites and tramp Industrial Roller Mills Williams Crusher2013年11月1日 Jet mill grinding of portland cement, limestone, and fly ash: Impact on particle size, hydration rate, The method of using CO2 to treat industrial wastes such as fly ash, Jet mill grinding of portland cement, limestone, and fly ash: The mills can process a variety of materials: limestone, calcite, quicklime, marble, dolomite, barite, talc, calcium carbonate, gypsum, bentonite, coal, petrindustrial mill, limestone mill, stone mill YouTube

(PDF) Suspended Solid Removal of Palm Oil Mill

2020年7月22日 Severe environmental pollution could occur in water bodies which serve as the discharge sites for improperly treated palm oil mill effluent (POME)Type: Ball Mill Motor Type: AC Motor Motor Power: 145kw Rotationl Speed: 2325r/min Application: Mine Materials: GoldFactory Price Quartz Limestone Coal Ceramic Cement Dry Grinding Mill STEEL STRUCTURES INSTALLATION PROCEDURE AND METHOD STATEMENT except cantilevers, shall be fabricated with natural mill camber in the up position 517 All reentrant comers for fabricated gratings shall be in conformance with SAESH100Coating Material and Application Requirements for industrial facilities and SAESH101 Approved STEEL STRUCTURES INSTALLATION PROCEDURE AND METHOD STATEMENT mill rapidly reduces the mill’s output capacity at a given product size Increasing the feed size can upset the balance in a mill to the point where recycle flows, ball size distribution, and classifier tuning may require adjustment A solution to achieve the same mass flow through the mill with increased feed size would be to let the product Title: Increasing Capacity of Existing Limestone Grinding Systems

.jpg)

SUPPLY, INSTALLATION, COMMISSIONING OF THE WORLD'S LARGEST GRINDING MILL

In June 1998, the world's largest grinding mill, the 40 ft (122 m) diameter 20 MW Cadia gearless SAG mill, was commissioned This was a leap of over 40% above the largest operating SAG mill A significant saving in capital cost gave theRhajtek Industrial Systems Construction Inc, a PCAB, SEC, and DOLE registered industrial and construction company production plant based in Marilao Bulacan, is renowned for its extensive background working with leading cement companies, power plants, and industrial firms, which has secured key projects with notable companies nationwideDesign and Construction of Limestone Grinding Plant2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the (PDF) Performance Evaluation of Vertical Roller Mill in• Uses at industrial sites (ie ERC 4, 5, 6 a/b/c/d 7) batteries and method of manufacturing the same US A mill scale, limestone, dolomitic limestone, lime and any alkalide carbonate, and gaseous oxidising agents such as oxygen, air and mixtures thereofUses description Mill scale

Jet mill grinding of portland cement, limestone, and fly ash:

2013年11月1日 A MicronMaster Jet Pulverizer jet mill (061 m in diameter)was used in this study to grind the materials as shown in Fig 1 a and b The materials to be ground were blended for 60 min in a 019 m 2 Vblender (this step is only conducted for blends) After blending, approximately 45 kg of the preblended material was transferred into the hopper for jet mill 010Method Statement of Coal Mill Instattalation Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free This document provides a method statement for installing a coal mill at a project site It 010Method Statement of Coal Mill InstattalationLimestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has The commonly used processing technology of limestone is to use industrial mills to mechanically pulverize it Provide Limestone Ultrafine Grinding Mill2023年4月13日 Selection function for the different feed size distribution; coarser, finer (317 mm ball, J = 20%, f c = 4%) Optimization of Ball Mill Grinding of a LimestoneType Brecciated

.jpg)

Modelling of an Industrial Scale High Pressure Roller Mill DiVA

profile with varying working gaps due to the wear after longterm use The mill is gravity fed, without any external screw devices The experiments in the HPRM were performed with limestone as a feed material The material is extracted from feed bin into the mill The circumferential speed can be adjusted in the range of 0124 m s1 8mill volume lled by the grinding media bed and is calculated as Eq 7 [12] The material lling ratio (f c) is dened as the fraction of the mill volume occupied by the material to be ground and is calculated as Eq 8 J = (7) VolumeofSolidBalls Volumeof Mill ˜ 1 1−Φ ˚ f c = (8) VolumeofSolidMaterial Volumeof Mill ˜ 1 1−Φ ˚Optimization of Ball Mill Grinding of a Limestone‐Type Brecciated in development program based on the simulation studies and industrial impact of physical parameters scaling on the individual parameters of the quality and efficiency 2 Materials and methods Limestone powder below 120 µm, which are Adjustment of limestone grinding in an electromagnetic mill for Selecting the right model of grinding mill for limestone desulfurization powder technical upgrade project Limestone desulfurization is a widely adopted method for reducing sulfur dioxide emissions from industrial processes, particularly in power plants and steel millsSelecting the right model of grinding mill for limestone

Gypsum Industrial Ultrafine Powder Mill Machine

2021年8月17日 Recommendations for Gypsum Industrial Ultrafine Powder Mill Machine: The Mohs hardness of gypsum is 235, and it can be ground with an SBM industrial grinding mill (gypsum industrial ultrafine powder mill machine) SBM is a professional manufacturer of mining ore grinding machinery and equipment2020年12月12日 upgradation of lowgrade limestone by using a suitable beneficiation method a project report submitted by bachelor of engineering in mining engineering college of engineering guindy December 2020 (PDF) UPGRADATION OF LOWGRADE LIMESTONE BY USING A