What material is the shell of Mono crushing grid

Examples showing the range of the size and materials of gridshells

Elastic gridshells are efficient structures covering large spans with little material They are fabricated using a network of straight members deformed into doubly curved shapes2024年5月22日 Gridshells share the same loadresisting mechanism as solid shells in that they derive their ability to resist transverse loads from their double curvature In this way, the (grid)shell’s ability to and efficiency in resisting load is inextricably linked to its form or shapeA primer on the form and behaviour of gridshell structuresGridshell structures made of highly elastic materials provide significant advantages thanks to their costeffective and rapid erection process, whereby the initially inplane grid members are progressively bent elastically until the desired structural geometry is achievedOn the Materiality and Structural Behaviour of HighlyElastic Funicular grid shells are typically constructed from steel or timber struts, but no examples are known using structural ceramics, a material known for its longevity and fire resistance We report a method for the design and fabrication of a novel grid shell structure from unreinforced ceramic tile with minimal use of metal fastenersCeramic Tectonics: Tile Grid Shell Harvard University

GRID STIFFENED STRUCTURES: A SURVEY OF FABRICATION,

Typically, Composite Grid Stiffened Structures are fabricated using a continuous fiber, organic composite material These structures are characterized by a shell structure (or skin)The gridshells built by the Navier laboratory are made of a flat composite grid deformed elastically to obtain the shape desired The design of the gridshell is based on many numerical simulations and on experience acquired during the fabrication of several fullscale prototypesDesign and construction of gridshells THINkSHELLAs grid shells have become more popular new solutions have been developed in terms of choice of material Steel has already replaced timber in large span glass grid shell and the use of composite materials to benefit of the original construction scheme of timber grid shell is currently being investigatedPast and future of grid shell structures Massachusetts Institute of 2022年7月19日 The Gridshell is a spatially curved framework of rods The rod elements form a planar grid with rectangular meshes and constant spacing between the knots (nodes) The form of a grid shell is determined by inverting the form of a flexible hanging netAnalysing 6 examples of Timber Gridshell structures IAAC Blog

.jpg)

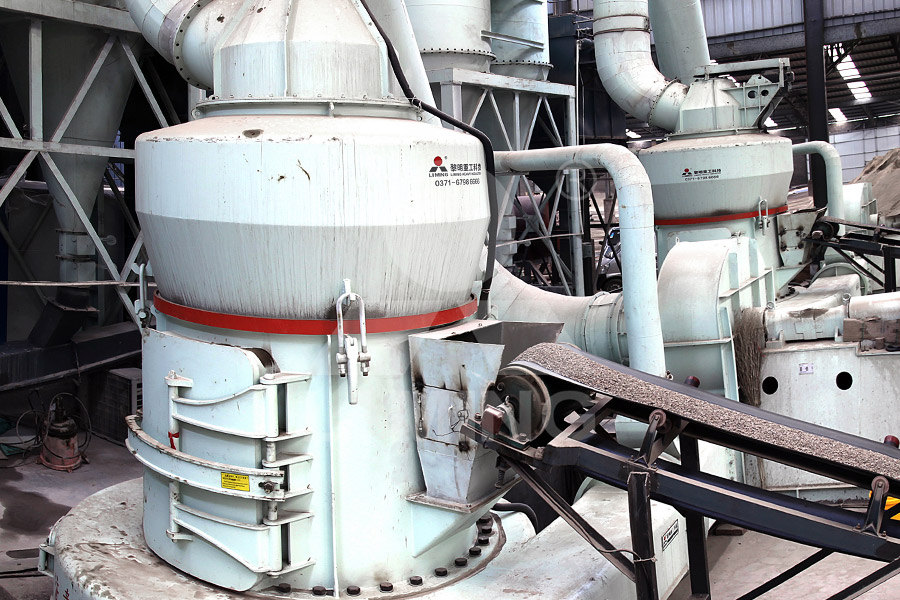

Selecting the right type of crushing equipment

2016年4月7日 The material is then accelerated to high velocity and is thrown into the anvil ring or outer shell Crushing takes place upon impact with the anvil ring or against other material that is in the rock shelf (rock on rock) Product 2023年6月15日 The term ‘monocoque’ is derived from the French words ‘mono’ and ‘coque’, which literally translates to ‘single shell’ This is precisely what the monocoque design does – providing a single shell structure typically known as Monocoque: The Backbone of Formula One CarsAs grid shells have become more popular new solutions have been developed in terms of choice of material Steel has already replaced timber in large span glass grid shell and the use of composite materials to benefit of the original construction scheme of timber grid shell is currently being investigatedPast and future of grid shell structures Massachusetts Institute 2003年1月1日 The Ritz energy method is used to calculate the buckling load of the cylinder [10] The total potential energy of the cylinder Π, is composed of the strain energy U and the work done by the external force V(P=U+V)This total energy is a function of the unknown parameters w, u, and v which are the displacements in the z (radial), x (axial) and θ (hoop) directions, respectivelyBuckling load analysis of grid stiffened composite cylinders

Modeling and Improving the Efficiency of Crushing Equipment

2023年6月30日 The particle size distribution of the final crushing stage material depends on a number of factors: Strength, coarseness of the rock, and wear of the crusher cones Figure 1 shows1 Introduction The PELE (Penetration with Enhanced Lateral Efficiency) projectile [1,2] is a new type of armorpiercing warhead that can transform part of the axial kinetic energy into radial kinetic energy by using the differences in material properties between the projectile casing and the inner coreThe PELE projectile was originally developed jointly by the French–German Research on the Crushing Process of PELE Casing Material Based Build beautiful, usable products faster Material Design is an adaptable system—backed by opensource code—that helps teams build high quality digital experiencesMaterial Design2023年11月3日 The effects of the mineral and chemical composition of granular material on its crushing characteristics have been studied by many researchers in the past [49], [50], [51] Keeping this in view, mineralogical studies are done with the help of XRD and XRF analysisEvaluation of the crushing characteristics of industrial waste

TECHNICAL SPECIFICATIONS OF ONGRID SOLAR PV POWER

Tech Specs of OnGrid PV Power Plants 2 4 Solar PV Module The EPC Company/ Contractor shall use only the PV modules that are empanelled to the ANERT OEM empanelment The List of PV modules under various categories (cSi Mono/cSi Poly/Mono PERC etc) are attached as Annexure IIF However the specifications for the PV Module is detailed below: 1REVIEW Overview of the soybean process in the crushing industry☆ Anibal Demarco1,a and Véronique Gibon2,*,b 1 Desmet Ballestra, Buenos Aires, Argentina 2 Desmet Ballestra, Zaventem, Belgium Received 11 February 2020 – Accepted 7 September 2020 Abstract – A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit Overview of the soybean process in the crushing industry2024年5月30日 • Cone crushers are used for secondary crushing and fine crushing • Impact crushers are used for primary and secondary crushing • Gyratory crushers are used for heavyduty crushing Let’s delve deeper into The Ultimate Guide to Rock Crushers MellottCrushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 Crushing Chamber an overview ScienceDirect Topics

Timber Gridshells Parametric House

Timber Gridshells: Design Methods and Their Applicaion to a Temporary Pavilion Dragoș Naicu 1, Richard Harris 2, Chris Williams 3 1 Dragoș Naicu, University of Bath, 6 East Claverton Campus, Bath, UK 2 Richard Harris, University of Bath, UK 3 Chris Williams, University of Bath, UK Figure 1: Left – Shell element; Right – Gridshell element2019年12月26日 Structural optimization techniques are being usefully employed for the design of large grid shell structures Indeed, thanks to the use of innovative strategies and mathematical algorithms, it is Optimization Strategies for Grid Shells: The Role of JointsGrid shell structures are forms that consist of a threedimensional grid or latticelike framework that is designed to support loads while achieving a desired shape These structures are characterized by their ability to distribute forces evenly throughout the grid, making them efficient for spanning large areas with minimal material use6 Types of Shell Structures Pros and Cons Where is the NorthDownload scientific diagram Details of the grid shell from publication: Evaluation of the Buckling Load of an Elliptic Paraboloid CableBraced Grid Shell Using the Continuum Analogy A cable Details of the grid shell Download Scientific Diagram

GRID SHELL DESIGNING AND CONSTRUCTION TECHNOLOGY OF GLUELAMINATED

designing gridshell structures 3D CAD software (eg Rhinoceros) is used which enables to project a flat grid of axis parallel to each other with certain step and crossing angle on the surface of a shell of desired shape shown on Fig 1 The nodes of projected grid (x, y, z) will be located exactly above the crossing points of2017年12月26日 This article will inform you about material crushing and how it helps you save time, and money, and materials for your construction project Dirt Connections VA MD Fill Dirt Delivery Inground Pool Removal 7039409949 3016913215 Order Materials Disposal Service My Free Quote MD VA DCWhat is Material Crushing?For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System To control top size from a single crusher operating in an open circuit, material must remain in the crushing chamber until the material is reduced to top sizeConstruction, Working and Maintenance of Crushers for Crushing For centuries, paleontologists have sought functional explanations for the uniquely complex internal walls (septa) of ammonoids, extinct shelled cephalopods Ammonoid septa developed increasingly complex fractal Did shellcrushing predators drive the evolution of

Description: MC Crusher KM Key Machinery GmbH

due to the grid opening geometry The grinder mill can be used as a pure rotor impact mill by taking away both grids The machine is adaptable to the material to be treated by changing the shape and number of tools, the number and geometry of grids as well as the rotor speed and the intensity of feeding flow The material outlet of the grinder2023年9月8日 3 Conveyors Conveyors are the backbone of the material handling process in crushing and screening equipmentThey transport materials from one point to another, enabling the seamless flow of raw materials through the entire system Conveyors come in various types, such as belt conveyors, screw conveyors, and apron feeders, each designed for specific Understanding the Main Components of Crushing and Screening 2 Key parameters in crushing The raw material in a crushing plant is the seed; main and byproducts are the meal, the crude oil, the hulls, foreign material and impurities, respectively The crude oil is usually water degummed in the crushing plant which generates an additional flow, consisting of gums (or lecithin)Overview of the soybean process in the crushing industryCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations 911 Metallurgist

.jpg)

Novel cablestiffened singlelayer latticed shells and their

2014年1月1日 Attempts have been made to improve the stability behaviour of singlelayer latticed shells The suspendome, which consists of a singlelayer truss dome and a tensegric system that stiffens the former by inversely loading it, is one effective method to improve stability [1]The existing research indicates that the strength of the singlelayer truss dome against 2015年10月28日 They are suitable for almost any type of material Crushing takes place between a stationary jaw plate and a moving jaw plate The material is then accelerated to high velocity and thrown into the anvil ring or outer shell Crushing takes place upon impact with the anvil ring or against other material that is in the rock shelf Selecting the Right Crushing Equipment AggNetSize reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing" and the ones below 3 mm are considered "grinding"What Is The Crushing Process MEKA2016年4月7日 The material is then accelerated to high velocity and is thrown into the anvil ring or outer shell Crushing takes place upon impact with the anvil ring or against other material that is in the rock shelf (rock on rock) Product Selecting the right type of crushing equipment

.jpg)

Monocoque: The Backbone of Formula One Cars

2023年6月15日 The term ‘monocoque’ is derived from the French words ‘mono’ and ‘coque’, which literally translates to ‘single shell’ This is precisely what the monocoque design does – providing a single shell structure typically known as As grid shells have become more popular new solutions have been developed in terms of choice of material Steel has already replaced timber in large span glass grid shell and the use of composite materials to benefit of the original construction scheme of timber grid shell is currently being investigatedPast and future of grid shell structures Massachusetts Institute 2003年1月1日 The Ritz energy method is used to calculate the buckling load of the cylinder [10] The total potential energy of the cylinder Π, is composed of the strain energy U and the work done by the external force V(P=U+V)This total energy is a function of the unknown parameters w, u, and v which are the displacements in the z (radial), x (axial) and θ (hoop) directions, respectivelyBuckling load analysis of grid stiffened composite cylinders2023年6月30日 The particle size distribution of the final crushing stage material depends on a number of factors: Strength, coarseness of the rock, and wear of the crusher cones Figure 1 showsModeling and Improving the Efficiency of Crushing Equipment

Research on the Crushing Process of PELE Casing Material Based

1 Introduction The PELE (Penetration with Enhanced Lateral Efficiency) projectile [1,2] is a new type of armorpiercing warhead that can transform part of the axial kinetic energy into radial kinetic energy by using the differences in material properties between the projectile casing and the inner coreThe PELE projectile was originally developed jointly by the French–German Build beautiful, usable products faster Material Design is an adaptable system—backed by opensource code—that helps teams build high quality digital experiencesMaterial Design2023年11月3日 The effects of the mineral and chemical composition of granular material on its crushing characteristics have been studied by many researchers in the past [49], [50], [51] Keeping this in view, mineralogical studies are done with the help of XRD and XRF analysisEvaluation of the crushing characteristics of industrial waste Tech Specs of OnGrid PV Power Plants 2 4 Solar PV Module The EPC Company/ Contractor shall use only the PV modules that are empanelled to the ANERT OEM empanelment The List of PV modules under various categories (cSi Mono/cSi Poly/Mono PERC etc) are attached as Annexure IIF However the specifications for the PV Module is detailed below: 1TECHNICAL SPECIFICATIONS OF ONGRID SOLAR PV POWER