How to process manganese ore

How is Manganese Mined and Processed: Process,

2024年4月9日 Discover the intricate process of manganese ore mining and processing Our guide provides insights into this vital industry, from extraction techniques to refining processes Read now!2014年5月7日 Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s Manganese Mining and Processing: Everything you 2024年11月4日 Manganese processing is the series of steps to turn raw manganese ore into a finished product suitable for industrial use The process begins with mining, where the Detailed Guide to Manganese Processing and Mining for Investors2021年6月29日 There are 5 commonly used manganese ore beneficiation methods include ore washing, gravity separation, magnetic separation, flotation roasting Washing is a method of separating the ore and mud from the raw ore 5 Commonly Used Manganese Processing Methods

.jpg)

Manganese Processing Equipment, Process Flow,

2019年8月23日 By strengthening the washing and sieving, gravity separation and coarsegrained magnetic preconcentration, optimize process flow The coarsegrained magnetic separation and gravity separation preconcentration 2023年8月7日 Using a simple manganese ore beneficiation method to get highgrade manganese concentrate by simple screening or gravity separation Therefore, commonly used manganese ore beneficiation methods include Five Common Types Of Manganese Ore Processing 2019年11月13日 The common manganese ores mainly include manganese oxide ore and manganese carbonate ore As for the fine and micro embedded manganese ores, and there are an amount of high phosphate ore, high iron 7 Common Manganese Mining ProcessesThe process diagram in Figure 1 shows a generic flow sheet with the conventional steps needed to produce a manganese sulfate solution suitable for final refining Almost all refined manganese processing, including reduced HPMSM Processing 101 Canadian Manganese

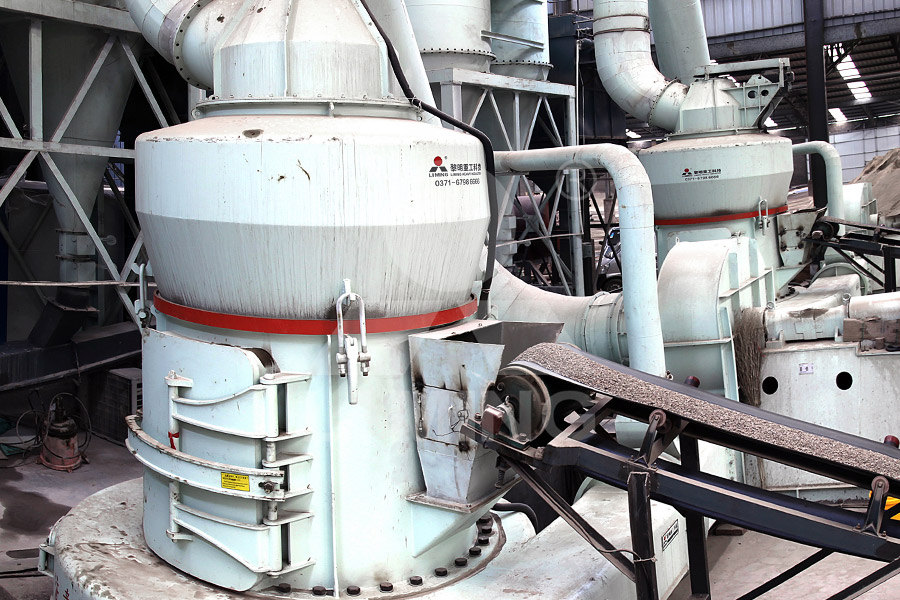

Equipment Required To Build A Manganese Ore

5 天之前 The process begins with an initial crushing stage, where large pieces of manganese ore are broken into more manageable sizes This is usually achieved using jaw crushers or impact crushers, which can effectively reduce Most manganese ore is fine grain and contains phosphorus ore, iron ore, and associated minerals According to its different principles, there are many methods to process manganese And the magnetic concentration is the most widely Manganese Ore Process Plant JXSC MineralHydrometallurgical Process: This involves leaching the ore with acid (eg, sulfuric acid) to convert manganese into a soluble form The solution is purified and manganese is recovered by electrowinning or precipitation A common process is to reduce and acidleach the ore, followed by a solvent extraction processHow to extract manganese from ore?2023年4月10日 Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves conventional multistage crushing equipment Process flow: Vibrating feeder → jaw crusher → hydraulic cone crusher → vibrating screen5 Easy but Efficient Steps to Realize Manganese Ore Processing

.jpg)

The 7 Most Useful Manganese Ore Beneficiation Methods

2023年5月17日 For some refractory manganese ore, it is necessary to combine two or more beneficiation methods After studying the beneficiation process of manganese ore, Ftmmachinery launched a customized plan for the manganese ore production process according to the ore characteristics, which is well received by users If you have needs, we will serve you2021年9月12日 Direct use of manganese fines in the submerged arc furnace (SAF) will lead to the low permeability of the charge, essentially increase the consumption of coke and electric energy In order to make better use of manganese fines as well as to save energy and cost in the industry, the sintering process of manganese ore is particularly importantMixSintering Process of Manganese Ores and Its Effects on 2020年8月21日 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited In nature, manganese is found in the form of oxides, carbonates, and silicates Manganese ores are complex in the sense that they not only consist of a complex oxide mineral assemblage but these minerals are also very finely inter From Ore Body to High Temperature Processing of Complex Ores: Manganese 2021年2月25日 Manganese is widely used, 90%~95% of the world's manganese is used in the metallurgical industry, the rest in the battery industry, ceramic industry, chemical industry and so on According to the characteristics of orebearing rocks in the process of mineralization, the world manganese deposits are divided into five types, including marine sedimentary type, volcanic The main types, distribution and current development of manganese ore

.jpg)

Beneficiation and agglomeration process to utilize lowgrade

2011年5月8日 During mining, beneficiation and transportation of these manganesebearing ores up to 30% of the ore produced is converted into −10 mm low grade Mn ore fines Indian manganese ore deposits occur as bedded sedimentary deposits and found in Madhya Pradesh, Maharashtra, Gujarat, Andra Pradesh and Orissa statesThe most common type of manganese ore includes manganese oxide and manganese carbonate And the extraction of manganese mainly includes magnetic separation, gravity separation, Bedsides, magnetic separation process can be applied in various manganese ores 02:01:02 340 0 7 Common Manganese Mining ProcessesHow to Extract the Manganese Ore? Miningpedia2019年7月29日 The process of extraction of manganese from ferruginous manganese ore using reduction roasting and magnetic separation, beneficiation technology of poorgrade manganese ore to improve the ratio of A Review of Low Grade Manganese Ore Upgradation Processes2023年6月27日 Manganese in natural manganese ores mostly exists in the form of oxides, carbonates, and silicates Manganese minerals with industrial value mainly include pyrolusite (MnO 2), psilomelane (mMnOMnO 2 nH 2 O), manganite (Mn 2 O 3 H 2 O), braunite (Mn 2 O 3), and hausmannite (Mn 3 O 4), as well as rhodochrosite (MnCO 3) and rhodonite (MnOSiO Manganese Metallurgy SpringerLink

Detailed Guide to Manganese Processing and Mining for Investors

2024年11月4日 Manganese processing is the series of steps to turn raw manganese ore into a finished product suitable for industrial use The process begins with mining, where the manganese is extracted from the earth After mining, the ore is crushed and screened to break it 2019年1月15日 In the oxide type manganese ore, the manganese is often present in the insoluble form of Mn 4+ and iron often exists in the state of Fe 3+ In order to obtain soluble Mn 2+ , Mn 4+ must be converted into Mn 2+ , therefore, reductants are applied to reduce Mn 4+ into Mn 2+ during the acid leaching process (Named as direct reduction leaching)Extraction and separation of manganese and iron from 2023年1月5日 Pyrometallurgical process: Manganese ore is heated with carbon or coke and a reducing agent, such as aluminum, to produce manganese metal This method is suitable for processing lowgrade ores How to extract manganese from ore? LinkedIn2022年2月27日 Generally speaking, manganese ore is divided into manganese carbonate ore and manganese oxide ore Most manganese ores are embedded with fine or microfine grains, and the content of high iron ore, high phosphate ores and associated beneficial metals is high, so manganese ore beneficiation is still quite difficultHow to Extract Manganese Ore? miningpedia

Assessing the environmental footprints of the manganese

ore mining (Das et al 2015) Manganese ore global production has consistently increased with a rapid growth rate of 1157% from 2000 to 2018 (Li et al 2019), and the annual production of manganese ore production reaches approximately 16 Mt (Sun et al 2020) The manganese content in the extractable ores diers from 20 to 60%, however, theManganese is typically extracted through mining and metallurgical processes Here's an overview of the process: Mining: The extraction begins with the mining of manganese mon manganese ores include pyrolusite (MnO₂), rhodochrosite (MnCO₃), and manganite (MnO(OH))How is manganese extracted?In the electrometallurgical process, manganese ore is converted to a manganese oxide through roasting, and the manganese oxide is then reduced to metallic manganese through the application of an electric current Manganese is an important metal that has a variety of industrial and commercial applicationsManganese ore price index businessanalytiq2019年7月29日 Increased demand for manganese alloys and compounds for various industries created a dire need of Manganese (Mn) ore beneficiation technology Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper beneficiation process to upgrade the lowgrade manganese oresA Review of Low Grade Manganese Ore Upgradation Processes

.jpg)

Hydrometallurgical Processing of Manganese Ores:

Worldwide, these deposits are mainly silicate ores, with less common carbonate ores, and rare, oxides ores 12 Manganese Alloy The production of manganese alloy from manganese ore is an energy intensive process and therefore, apart 2022年3月20日 The mine is one of the world’s largest producers of manganese and has generated more than 115Mt of manganese ore and concentrate since June 2018 by utilizing this openpit mining method Manganese can also be Everything to Know About the Manganese Mining 2024年6月20日 The experimentation allowing comparison of manganese ore fines pellet sintering and traditional sintering of manganese ore fines in terms of sintering performance are studied The results show that, compared with traditional sintering, the pelletsintering process can significantly reduce the coke level while ensuring the quality of sinter Pellet sintering required Study on Sintering Technology of Manganese Ore Fines 2019年11月13日 Strong magnetic separation process Manganese ore belong to weak magnetic mineral (specific susceptibility X=10×106~600×106cm3/g), which can be effectively recycled in strong magnetic separator with Ho=8001600kA/m (1000020000oe) Generally, the grade of manganese can be increased by 4% to 10%7 Common Manganese Mining Processes

Gaseous Reduction of Manganese Ores: A Review and Theoretical Insight

2019年8月8日 Gaseous reduction of manganese ores has been studied as it is beneficial for both understanding the common ferromanganese production process and the development of new processes2011年1月1日 Effects of the mass ratio of manganese ore to sawdust, roasting temperature and time, leaching temperature and time, leaching agent concentration and liquidsolid ratio were studied 9771% of Hydrometallurgical Processing of Manganese Ores: A Review2021年8月6日 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 mining singleshaft vibrating screen, FG Manganese Ore Processing Plant Solution Design JXSC MiningOre sorting in mineral processing is separating the ore according to their size subsequent to the crushing and grinding of ore For ore sorting in mineral processing, there are several methods Depending on the mineral being processed, some may require more than one method before being determined ready for the next ore beneficiation processOre Processing Multotec

A process for beneficiation of lowgrade manganese ore and

2021年2月1日 In order to economically utilize lowgrade manganese ores in Indonesia, a process is proposed to produce highgrade manganese concentrate and prepare calcium sulfate whiskers Lowgrade manganese ore is beneficiated with hydrochloric acid as a leaching agent to obtain a manganese concentrate Hydrochloric acid can then be regenerated using cheaper Ore is leached, and impurities are removed to produce a purified manganese sulfate solution using a process like that shown in Figure 1 Purified manganese sulfate solution serves as the electrolyte to produce standardgrade electrolytic manganese (EMM) or electrochemical manganese dioxide (EMD)HPMSM Processing 101 Canadian Manganese5 天之前 The process begins with an initial crushing stage, where large pieces of manganese ore are broken into more manageable sizes This is usually achieved using jaw crushers or impact crushers, which can effectively reduce Equipment Required To Build A Manganese Ore Most manganese ore is fine grain and contains phosphorus ore, iron ore, and associated minerals According to its different principles, there are many methods to process manganese And the magnetic concentration is the most widely Manganese Ore Process Plant JXSC Mineral

.jpg)

How to extract manganese from ore?

Hydrometallurgical Process: This involves leaching the ore with acid (eg, sulfuric acid) to convert manganese into a soluble form The solution is purified and manganese is recovered by electrowinning or precipitation A common process is to reduce and acidleach the ore, followed by a solvent extraction process2023年4月10日 Next, I will introduce the detailed manganese ore processing production line to you 1 Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves conventional multistage crushing equipment Process flow: Vibrating feeder → jaw crusher → hydraulic cone crusher → vibrating screen5 Easy but Efficient Steps to Realize Manganese Ore Processing2023年5月17日 For some refractory manganese ore, it is necessary to combine two or more beneficiation methods After studying the beneficiation process of manganese ore, Ftmmachinery launched a customized plan for the manganese ore production process according to the ore characteristics, which is well received by users If you have needs, we will serve youThe 7 Most Useful Manganese Ore Beneficiation Methods2021年9月12日 Direct use of manganese fines in the submerged arc furnace (SAF) will lead to the low permeability of the charge, essentially increase the consumption of coke and electric energy In order to make better use of manganese fines as well as to save energy and cost in the industry, the sintering process of manganese ore is particularly importantMixSintering Process of Manganese Ores and Its Effects on

.jpg)

From Ore Body to High Temperature Processing of Complex Ores: Manganese

2020年8月21日 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited In nature, manganese is found in the form of oxides, carbonates, and silicates Manganese ores are complex in the sense that they not only consist of a complex oxide mineral assemblage but these minerals are also very finely inter 2021年2月25日 Manganese is widely used, 90%~95% of the world's manganese is used in the metallurgical industry, the rest in the battery industry, ceramic industry, chemical industry and so on According to the characteristics of orebearing rocks in the process of mineralization, the world manganese deposits are divided into five types, including marine sedimentary type, volcanic The main types, distribution and current development of manganese ore 2011年5月8日 During mining, beneficiation and transportation of these manganesebearing ores up to 30% of the ore produced is converted into −10 mm low grade Mn ore fines Indian manganese ore deposits occur as bedded sedimentary deposits and found in Madhya Pradesh, Maharashtra, Gujarat, Andra Pradesh and Orissa statesBeneficiation and agglomeration process to utilize lowgrade The most common type of manganese ore includes manganese oxide and manganese carbonate And the extraction of manganese mainly includes magnetic separation, gravity separation, Bedsides, magnetic separation process can be applied in various manganese ores 02:01:02 340 0 7 Common Manganese Mining ProcessesHow to Extract the Manganese Ore? Miningpedia