Jining Coal Gangue Crushing

.jpg)

Compressive deformation and energy dissipation of crushed coal

2016年9月1日 This paper studied gangue backfill in the goaf of Jining No3 Coal Mine and proposed fundamentals of energy dissipation calculations for crushed gangue according to 2023年8月4日 In this study, based on the geological and mining conditions of Workface 822 of the Yuandian No 1 Mine, we used theoretical analysis and numerical simulation to analyze (PDF) Near crushing mechanism of ganguecontaining coal seams 2021年2月23日 Cemented coal gangue paste backfill (CCGPB) containing coal gangue and fly ash is a backfilling technique newly developed in coal mines in China that allows Monitoring and Assessment of Cemented Paste Backfill In Jining, Shandong Province, China, a coal mine crushing plant provided the coal gangue for this study Some studies suggest that a specic proportion of ne particles in the mixMulticriteria comparative analysis of the pressure drop on coal

Characterizations of macroscopic deformation and particle

2019年2月1日 In solid backfilling coal mining (SBCM), the deformation resistance of crushed gangue particle material (CGPM) is critical for controlling overburden strata movement and 2016年5月4日 Crushing characteristics of coal and gangue under impact load were expressed by crushing ratio and crushing probability Experimental results showed that crushing ratios of Experimental Study on Crushing Characteristic of Coal and Gangue The coal gangue used in this study was collected from a coal mine crushing plant located in Jining, Shandong Province, China According to some researches, a particularMulticriteria comparative analysis of the pressure drop on coal 2020年3月9日 To accurately estimate the separation effects and breakage characteristics of coal and gangue particles (CGPs), it is of great significance to understand the mesomorphologies Morphological characterization of crushed coal gangue by micro X

Near crushing mechanism of ganguecontaining coal seams and

2023年7月20日 Based on the geological and mining conditions of Workface 822 of the Yuandian No 1 Mine, this paper analyzes the crushing mechanism of gangue coal seams from a In Jining, Shandong Province, China, a coal mine crushing plant provided the coal gangue for this study Some studies suggest that a specic proportion of ne particles in jining coal crushingIn Jining, Shandong Province, China, a coal mine crushing plant provided the coal gangue for this study Some studies suggest that a specic proportion of ne particles in a 3D numerical extraction model was built based on the geologic and mining conditions of Jining coal mine to jining coal crushing2024年1月12日 The experimental materials are coal gangue, cement, fly ash, desulfurization gypsum and water Coal gangue comes from Xinhe Coal Mine in Jining, Shandong Province The cement is PO 325 cement, The stress and strain and crushing mode of the numerical simulation model are in good agreement with the laboratory test resultsEvolution law study of pore and fracture of coal gangue cemented

Using Chinese Coal Gangue as an Ecological

2022年6月26日 Coal gangue is a kind of industrial solid waste with serious ecological and environmental implications Producing concrete with coal gangue aggregate is one of the green sustainable development requirements This 2019年2月1日 In solid backfilling coal mining (SBCM), the deformation resistance of crushed gangue particle material (CGPM) is critical for controlling overburden strata movement and ground surface subsidenceIn engineering practice, CGPM is generally circularly compacted first by the compaction machine to reduce its compressibilityHowever, a systematic approach to guide Characterizations of macroscopic deformation and particle crushing 2019年2月1日 The change rules of crushing ratio and newly added fine particle content with the cyclic loading times were similar This is due to that the crushing forms of the gangue block in CGPM samples are mainly edges fracture and corners fracture In this two crushing forms, gangue blocks in CGPM are mostly crushed into fine particles (0–10 mm)Characterizations of macroscopic deformation and particle crushing Near crushing mechanism of ganguecontaining coal seams and parameter optimization for combined fully mechanized caving Xiaobo Hao1*, Pengcheng Liu1, Yanhui Deng1, Xiaolou Chi2 and Zhihua Li2 Near crushing mechanism of ganguecontaining coal seams

Design and application of coal gangue sorting system based on

5 Yankuang Energy Group Co, Ltd, Jizou Road, Jining No 2 Coal Mine, Jining, Shandong China Find articles by Tijun Liu 5, The coal gangue image capture section comprises a cubic darkroom equipped with an industrialgrade digital camera array and a highly uniform strip light source2024年12月1日 Coal gangue (CG) was sourced from a mining area in Yanzhou, Jining, Shandong, and processed into powder through crushing, grinding, and sieving with a 200mesh size The chemical compositions and CG contents are shown in Table 1 Performance study of foam concrete prepared by the synergistic Download scientific diagram Integrated system and photo of underground backfill mining: (A) coal mining, (B) coalgangue dressing, and (C) goaf backfilling from publication: Risk assessment and Integrated system and photo of underground backfill mining: (A) coal distribution following crushing and more than 70% of the coal gangue particles are less than 5 mm The y ash used in this investigation came from a coalred power station in Jining, China, and Fig 2 shows the particle size distribution Xray diraction analysis of the coal gangue and y ash's chemical composition resulted in a summary in Table 1Multicriteria comparative analysis of the pressure drop on coal gangue

.jpg)

Spontaneous combustion coal ganguebased composite cement:

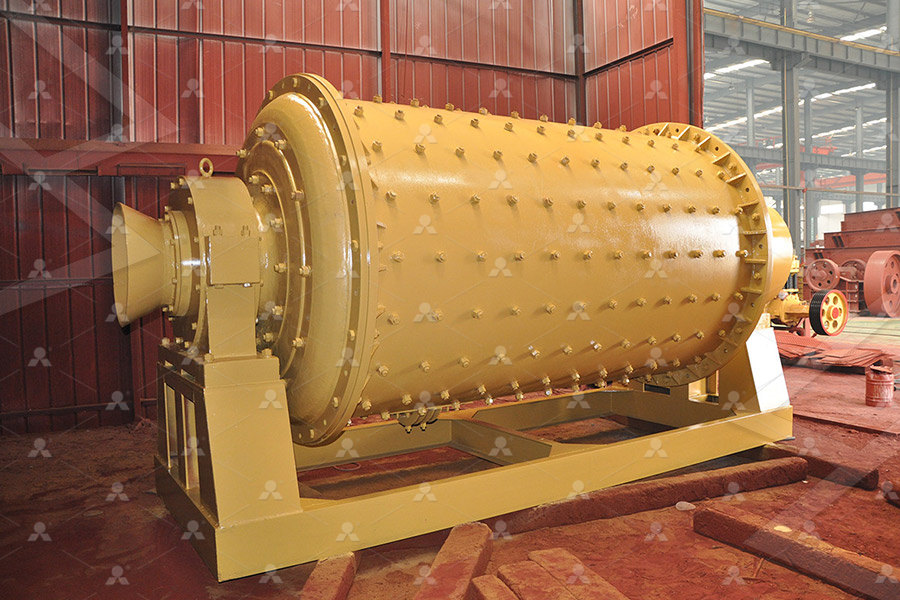

To enhance its reactivity, the coal gangue was ground The preparation steps for the spontaneous combustion coal gangue powder involved crushing the material, passing it through a 20mesh sieve (denoted as grinding for 0 min), and then grinding it in a planetary ball mill for 5, 15, 25, 35, 45, and 55 min at a speed of 350 rpmDownload scientific diagram Coal gangue crushing from publication: An Experimental Study of the Road Performance of Cement Stabilized Coal Gangue The research into the road performance of Coal gangue crushing Download Scientific Diagram2022年12月28日 The compaction and recrushing characteristics of crushed gangue are important factors which affect the quality and effectiveness of the filling of the quarry(PDF) Experimental Investigation of the CompactionCrushing 2022年11月1日 The mechanical properties and strength formation mechanism of cement–flyashstabilized slag–coal gangue mixture were examined using an unconfined compressive strength test, splitting strength test, triaxial test, and scanning electron microscopy to solve the limitations of land occupation and environmental pollution that is caused by fly ash from the Mechanical Properties of Furnace Slag and Coal Gangue Mixtures

Study on recognition of coal and gangue based on multimode

with the coalgangue falling state detection as the target, increasing the ability to extract the weight information of coalgangue Zhang Jinwang et al [11] proposed a new concept of coal gangue recognition of "liquid intervention + infrared detection," and a recognition test of liquid intervention under different mixing degrees was conductedCoal Gangue Crushing And Grinding Plant Machine 1 Coal gangue crusher Because coal gangue is a brittle material, we can adopt a singlestage crusher machine or multistage crushing with over two crushers Multistage crushing mainly uses a combination of jaw crusher and impact crusher to process large coal gangue into small particlesCustom Coal Gangue Crushing And Grinding Plant Machine2021年3月11日 Coal gangue is the main pollution source of mining areas When coal gangue is stacked and recycled, the heavy metal elements contained in it are released by natural weathering and leaching, which Characteristics of leaching of heavy metals from lowsulfur coal gangue Abstract In solid backfilling coal mining (SBCM), the deformation resistance of crushed gangue particle material (CGPM) is critical for controlling overburden strata movement and ground surface subsidence In engineering practice, CGPM is generally circularly compacted first by the compaction machine to reduce its compressibility However, a systematic approach to guide Characterizations of macroscopic deformation and particle crushing

.jpg)

Effect of coal gangue grading characteristics on cemented paste

This research categorises the particle size grading for the coal gangue into three types: single grade (G1), gap grade (G2), and continuous grade (G3) Upon screening and refining of coal gangue, the predetermined gradation was obtained Each coal gangue particle type was assigned a specific proportion based on sizeDownload scientific diagram Physical properties of coal gangue aggregate from different origins in China from publication: Application of Coal Gangue as a Coarse Aggregate in Green Concrete Physical properties of coal gangue aggregate from different 2023年10月8日 After crushing, coal will produce a large amount of waste of coal gangue and dust The coal gangue can be recycled The coal ash can be collected by a dust collector, or it can be used for making Portland cement or 6 Types of Coal Crusher: Which Is Best for Crushing Minerals 2023, 13, 329 3 of 19 identification methods have shifted their focus onto coal gangue image recognition Wang, Li, and Yang [12] investigated coal gangue response characteristics under Coal Gangue Recognition during Coal Preparation Using an

.jpg)

Enhancing coal gangue aggregates with fly ashcement slurry

2024年8月23日 Enhancing coal gangue aggregates with fly ashcement slurry: [36], the gangue used should belong to sandstone gangue It underwent a crushing process using a jaw crusher (PE125X150) The larger aggregates were subjected to multiple crushing cycles and subsequent screening using a vibrating sieve, 2024年2月1日 Coal is not only the most abundant fossil fuel on earth, but also an indispensable energy source in the industrial age According to the data of “2021 National Mineral Resources Reserve Statistics Table”, the cities with the most coal reserves in China's energy minerals are Inner Mongolia, Xinjiang, Shanxi, Hebei, Chongqing, Gansu, Shaanxi and other regionsRepresentative coal gangue in China: Physical and chemical Design and application of coal gangue sorting system based on deep learning Kun Zhang1,2,3, Zhen Wang1, Jining No 2 Coal Mine, Jining , Shandong, China *: yinzhuangsdust@163 2Design and application of coal gangue sorting system based on2023年8月4日 Fully mechanized caving is the most popular method for safe and efficient coal mining in China In this study, based on the geological and mining conditions of Workface 822 of the Yuandian No 1 (PDF) Near crushing mechanism of ganguecontaining coal

.jpg)

Characterization of heavy metals in coal gangue

2018年3月1日 Coal gangue filling reclamation is an important means to restore coal mining subsided cultivated land However, coal gangue can release heavy metals, threatening the overlying soil environmentSustainability 2022, 14, 12395 2 of 15 raw material in a onestep pyrolysis method Numerous studies have shown that coal ganguemodified biochar composites can be used not only for phosphorus Experimental Investigation of Particle Size Alteration and the In Jining, Shandong Province, China, a coal mine crushing plant provided the coal gangue for this study Some studies suggest that a specic proportion of ne particles in a 3D numerical extraction model was built based on the geologic and mining conditions of Jining coal mine to jining coal crushing2024年1月12日 The experimental materials are coal gangue, cement, fly ash, desulfurization gypsum and water Coal gangue comes from Xinhe Coal Mine in Jining, Shandong Province The cement is PO 325 cement, The stress and strain and crushing mode of the numerical simulation model are in good agreement with the laboratory test resultsEvolution law study of pore and fracture of coal gangue cemented

Using Chinese Coal Gangue as an Ecological

2022年6月26日 Coal gangue is a kind of industrial solid waste with serious ecological and environmental implications Producing concrete with coal gangue aggregate is one of the green sustainable development requirements This 2019年2月1日 In solid backfilling coal mining (SBCM), the deformation resistance of crushed gangue particle material (CGPM) is critical for controlling overburden strata movement and ground surface subsidenceIn engineering practice, CGPM is generally circularly compacted first by the compaction machine to reduce its compressibilityHowever, a systematic approach to guide Characterizations of macroscopic deformation and particle crushing 2019年2月1日 The change rules of crushing ratio and newly added fine particle content with the cyclic loading times were similar This is due to that the crushing forms of the gangue block in CGPM samples are mainly edges fracture and corners fracture In this two crushing forms, gangue blocks in CGPM are mostly crushed into fine particles (0–10 mm)Characterizations of macroscopic deformation and particle crushing Near crushing mechanism of ganguecontaining coal seams and parameter optimization for combined fully mechanized caving Xiaobo Hao1*, Pengcheng Liu1, Yanhui Deng1, Xiaolou Chi2 and Zhihua Li2 Near crushing mechanism of ganguecontaining coal seams

Design and application of coal gangue sorting system based on

5 Yankuang Energy Group Co, Ltd, Jizou Road, Jining No 2 Coal Mine, Jining, Shandong China Find articles by Tijun Liu 5, The coal gangue image capture section comprises a cubic darkroom equipped with an industrialgrade digital camera array and a highly uniform strip light source2024年12月1日 Coal gangue (CG) was sourced from a mining area in Yanzhou, Jining, Shandong, and processed into powder through crushing, grinding, and sieving with a 200mesh size The chemical compositions and CG contents are shown in Table 1 Performance study of foam concrete prepared by the synergistic Download scientific diagram Integrated system and photo of underground backfill mining: (A) coal mining, (B) coalgangue dressing, and (C) goaf backfilling from publication: Risk assessment and Integrated system and photo of underground backfill mining: (A) coal