Heavy calcium crushing feed volume is 36 mechanical equipment

Heavy calcium carbonate grinding, surface modification

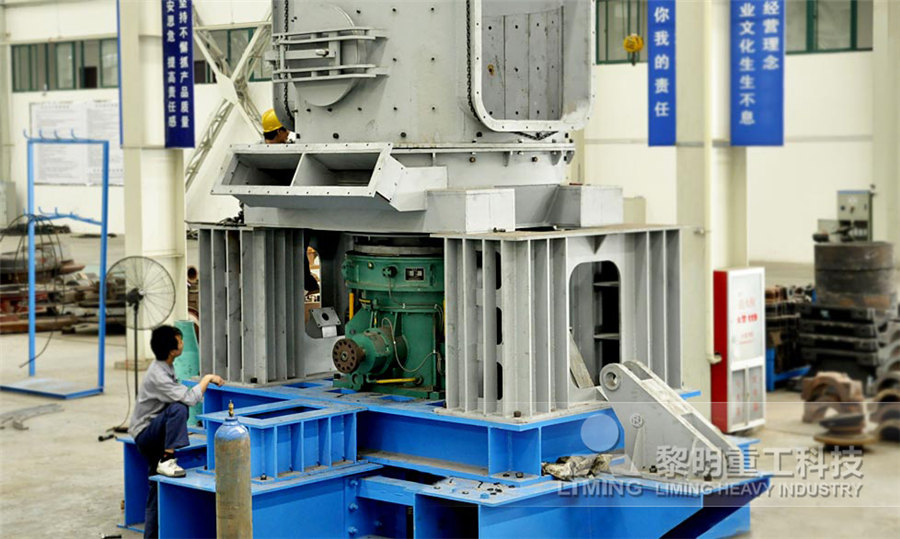

2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has the characteristics of wide raw material sources, high whiteness, low oil absorption value, good Heavy calcium carbonate (heavy calcium) is produced by directly crushing natural limestone, Heavy calcium carbonate millLarge unobstructed feed opening, heavyduty breaker plates and heavy rotor are designed to MEKA CRUSHING SCREENING AND CONCRETE BATCHING Production and processing equipment for ultrafine heavy calcium powder mainly include Production and processing equipment for ultrafine heavy calcium

Comparative analysis of heavy calcium powder production

If the primary focus is on highvolume, highquality production of heavy calcium powder, MEKA range of feeders are engineered for continuous use under harsh conditions providing Feeders MEKADetailed explanation of calcium powder processing machinery and equipment: Ordinary heavy News Calcium powder processing machinery and equipment 2022年2月21日 Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization It is a commonly used powdery inorganic filler with high chemical purity, high How to do the grinding of heavy calcium industry?

The difference between heavy calcium and light calcium in

2024年8月13日 Light calcium typically has a sedimentation volume above 25 mL/g, while heavy calcium ranges from 12 to 19 mL/g, depending on its crystal form and chemical composition Light calcium carbonate particles are usually date pitshaped, with a long diameter of 5–12 μm, a short diameter of 1–3 μm, and an average size of 2–3 μmCustomized Crushing: The equipment for sale is designed specifically for the crushing of heavy calcium carbonate It can handle a variety of feed sizes and is capable of producing fine to ultrafine calcium carbonate powdersFor Sale: Heavy Calcium Carbonate Crushing Process Equipment2023年6月30日 Research the modelling and automation of crushing equipment Develop a mathematical model of a cone crusher Identify the effect of plant capacity on the crusher’s current and drive powerModeling and Improving the Efficiency of Crushing Equipmentthe material towards the vibratory feeder The plant at this stage deals with heavy rocks and hence a rugged vibrating feeder is preferred automation to carry forward the rocks to the first stage of crushing at the jaw crusher1 The jaw crusheris one of the vital equipment capable of onefifth size reductionDesign of Dolomite Crushing and Grinding Plant JETIR

.jpg)

News The role of heavy calcium in the rubber industry and its

Heavy calcium carbonate is one of the nonmetallic mineral materials with high production and application scale in the world today It is widely used in plastics, papermaking, rubber, coatings, adhesives, inks, toothpaste, feed, food additives, etc In order to distinguish it from light calcium 2023年10月16日 The settling volume of light calcium is 2428mL/g, and the settling volume of nanolight calcium is 3040mL/g 10 Specific surface area The specific surface area of ordinary heavy calcium is generally about 1m2/g, and the specific surface area of heavy fine calcium carbonate is 145~21m2/g;Learn the 17 differences between light calcium and heavy calcium!2024年7月10日 2 Heavy calcium carbonate grinding technology and equipment At present, heavy calcium carbonate with d97≥5μm is mainly produced by dry method, and the equipment includes improved Raymond mill (suspension roller mill or pendulum mill), roller mill (including pressure roller mill/vertical mill, ring roller mill, etc) and ball mill, etcHeavy calcium carbonate grinding, surface modification 2022年7月18日 Heavy calcium carbonate also named ground calcium carbonate or GCC for short Heavy calcium carbonate is obtained by directly crushing natural calcite, limestone, marble, chalk, shells, etc by mechanical methodsBecause its sedimentation volume (1119mL/g/g) is smaller than that of chemically produced light calcium carbonate (2428mL/g), it is called 400 Mesh Heavy Calcium Carbonate Application Processing Equipment

.jpg)

Cooperative stabilization of calcium carbonate powder, blast

2024年11月8日 The longterm service quality of white concrete is determined from property, and volume stability was one of the momentous properties of white concrete [11], [12]Concretely, the volume stability of white concrete mainly refers to its ability to maintain a constant volume when subjected to external forces [13], [14], [15]The structure and function of the building were Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the Detailed explanation of calcium powder processing News Calcium powder processing machinery and Feed Opening Size The feed opening size is about 80% of the feed opening Automation Crusher technology keeps evolving in terms of automation and safety Some of today’s crushers are equipped with systems that will adjust Buyer's Guide: Crushers Equipment ContractingManager Crushing Chamber and Materials Development Product Development Center Crushing (RD) Master of Science in Mechanics, specialized in mechatronics PhD 2007, Chalmers University Partly funded by Sandvik Modeling, simulation and optimization of crushing plants TechnicalEconomic Optimization Sandvik employee since 2004Crushing Principles of Mechanical Crushing 911 Metallurgist

The difference between heavy calcium carbonate and light calcium

2023年11月12日 The sedimentation volume of heavy calcium carbonate is 1114mL/g; the sedimentation volume of light calcium carbonate is 2428mL/g, and the sedimentation volume of nanolight calcium carbonate is 3040mL/g The difference between heavy calcium carbonate and light calcium carbonate 4 Specific surface area2024年5月30日 • Cone crushers are used for secondary crushing and fine crushing • Impact crushers are used for primary and secondary crushing • Gyratory crushers are used for heavyduty crushing Let’s delve deeper into each type Jaw Crushers Jaw crushers are perhaps the most common type of crusher They work by using two jaws to crush materialsThe Ultimate Guide to Rock Crushers MellottGoogle's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle TranslateIS 3612 : 1994 Indian Standard CRUSHING AND GRINDING EQUIPMENT CLASSIFICATION AND METHODSFOR b MEASURINGCAPACITY ( First Revision ) UDC 621*925/*926 : 66012~4IS 3612 (1994): Crushing and grinding equipment Classification

Selecting the right type of crushing equipment Quarry

2016年4月7日 Most aggregate producers are well acquainted with the selection of crushing equipment, and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations However, theoretical conclusions must always be weighed against practical experience of the material at hand and of the operation, maintenance and economical 2016年2月28日 For heavyduty quarry or openpit mining operations the heavyduty steel apron feeder is the most practical type It can be made in any length to fit in with any type and size of transportation equipment and crusher house arrangement It hasCrushing Equipment Selection 911Metallurgist2015年8月31日 3 CONE CRUSHER • Designated in size either by the gape and mantle diameter • Primary or secondary crushing • The vertical spindle is free to rotate around its own axis HXJQ • Processing capacity: 12 1000t/h • Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum • PRICE:$88000Aggregate Crushing Equipment PPT SlideShare2015年6月11日 Mechanical screening is much more complicated than taking a single feed stream and making two piles Read on to learn more about mechanical screening and how material and operating characteristics impact A Guide to Mechanical Screening Aggregates

.jpg)

What is the difference between light and heavy Calcium carbonate?

2019年10月13日 The larger the sedimentation volume, the smaller the product particle size, the lighter the density, and the higher the product grade The settling volume of heavy Calcium carbonate is 11~14mL/g; the settling volume of light Calcium carbonate is 24~28mL/g, and the settling volume of nanolight Calcium carbonate is 30~40mL/g 4Heavy calcium carbonate is a commonly used powdery inorganic filler with high chemical purity, high inertia, not easy to occur chemical reaction, good thermal stability, no decomposition below 400 ° C, high whiteness, low oil absorption, low refractive index, soft and dry , Without crystal water, low hardness, low wear value, nontoxic, tasteless, odorless, good dispersibility and Heavy calcium carbonate millCNU CN67U CN6U CNU CN U CN U CN U CN 6 U CN6 U CN 6U CN U CN U CN U Authority CN China Prior art keywords plate heavy calcium crushing calcium powder processing Prior art date 202112 CNU Reducing mechanism is used in processing of heavy There are many kinds of grinding and processing equipment for heavy calcium in China Generally, they can achieve the effect of ultrafine production by combining with ultrafine classifier to form an ultrafine processing system However, which production process and equipment is more reasonable needs to objectively evaluate various processes and equipment How To Select The Dry Process Production Line For Heavy Calcium

.jpg)

17 Types of Heavy Equipment Commonly Used in Construction

2020年4月8日 Construction projects typically rely on several types of heavy equipment to get the job done in a timely, safe, and costeffective manner Depending on the size and scope of the construction project, you’ll probably need to use at least one of these pieces of heavy construction equipment 17 Types of Heavy Equipment and Their Uses2020年10月11日 Production classification of calcium carbonate拾拾 Heavy calcium carbonate (commonly known as heavy calcium)邏邏 It can be made by directly crushing natural Production classification of ALPA Powder EquipmentProduction classification of ALPA Powder Equipment FacebookFind the best crushing equipment for sale at Ritchie Bros today! Browse by category Auctions • Oil Cooler Package • Tramp Iron Relief System • 7 ft 8 in x 5 ft Double Deck Screen • Spray/Wash System • 36 in Wide Feed Conveyor • 32 in Crusher to Screen Conveyor • 54 in Wide Under Screen Conveyor • 19 in Wide Left Used Crushing Equipment For Sale Ritchie Bros Auctioneers2015年12月30日 The crushing and grinding equipment (Table 46) is classified here according to the scheme proposed by Rumpf , in which grinding of the material is done by two tools (eg, two surfaces), by only one tool, or by attrition of moving particles (eg, attrition between particles or between particles and the surrounding fluid)Mechanical Processing Equipment SpringerLink

.jpg)

Synergizing Portland Cement, highvolume fly ash and calcined calcium

2024年12月1日 SCC is among the many solutions for sustainable and highperformance construction materials It was invented in Japan in 1988 owing to many attributes such as workability, mechanical properties, and durability [1], [2], [3], [4]SCC is workable at the site without any form of mechanical compaction or vibration; hence, it flows under its own weight to 2022年2月21日 Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization It is a commonly used powdery inorganic filler with high chemical purity, high How to do the grinding of heavy calcium industry?2024年8月13日 Light calcium typically has a sedimentation volume above 25 mL/g, while heavy calcium ranges from 12 to 19 mL/g, depending on its crystal form and chemical composition Light calcium carbonate particles are usually date pitshaped, with a long diameter of 5–12 μm, a short diameter of 1–3 μm, and an average size of 2–3 μmThe difference between heavy calcium and light calcium in Customized Crushing: The equipment for sale is designed specifically for the crushing of heavy calcium carbonate It can handle a variety of feed sizes and is capable of producing fine to ultrafine calcium carbonate powdersFor Sale: Heavy Calcium Carbonate Crushing Process Equipment

Modeling and Improving the Efficiency of Crushing Equipment

2023年6月30日 Research the modelling and automation of crushing equipment Develop a mathematical model of a cone crusher Identify the effect of plant capacity on the crusher’s current and drive powerthe material towards the vibratory feeder The plant at this stage deals with heavy rocks and hence a rugged vibrating feeder is preferred automation to carry forward the rocks to the first stage of crushing at the jaw crusher1 The jaw crusheris one of the vital equipment capable of onefifth size reductionDesign of Dolomite Crushing and Grinding Plant JETIRHeavy calcium carbonate is one of the nonmetallic mineral materials with high production and application scale in the world today It is widely used in plastics, papermaking, rubber, coatings, adhesives, inks, toothpaste, feed, food additives, etc In order to distinguish it from light calcium News The role of heavy calcium in the rubber industry and its 2023年10月16日 The settling volume of light calcium is 2428mL/g, and the settling volume of nanolight calcium is 3040mL/g 10 Specific surface area The specific surface area of ordinary heavy calcium is generally about 1m2/g, and the specific surface area of heavy fine calcium carbonate is 145~21m2/g;Learn the 17 differences between light calcium and heavy calcium!

.jpg)

Heavy calcium carbonate grinding, surface modification

2024年7月10日 2 Heavy calcium carbonate grinding technology and equipment At present, heavy calcium carbonate with d97≥5μm is mainly produced by dry method, and the equipment includes improved Raymond mill (suspension roller mill or pendulum mill), roller mill (including pressure roller mill/vertical mill, ring roller mill, etc) and ball mill, etc2022年7月18日 Heavy calcium carbonate also named ground calcium carbonate or GCC for short Heavy calcium carbonate is obtained by directly crushing natural calcite, limestone, marble, chalk, shells, etc by mechanical methodsBecause its sedimentation volume (1119mL/g/g) is smaller than that of chemically produced light calcium carbonate (2428mL/g), it is called 400 Mesh Heavy Calcium Carbonate Application Processing Equipment2024年11月8日 The longterm service quality of white concrete is determined from property, and volume stability was one of the momentous properties of white concrete [11], [12]Concretely, the volume stability of white concrete mainly refers to its ability to maintain a constant volume when subjected to external forces [13], [14], [15]The structure and function of the building were Cooperative stabilization of calcium carbonate powder, blast