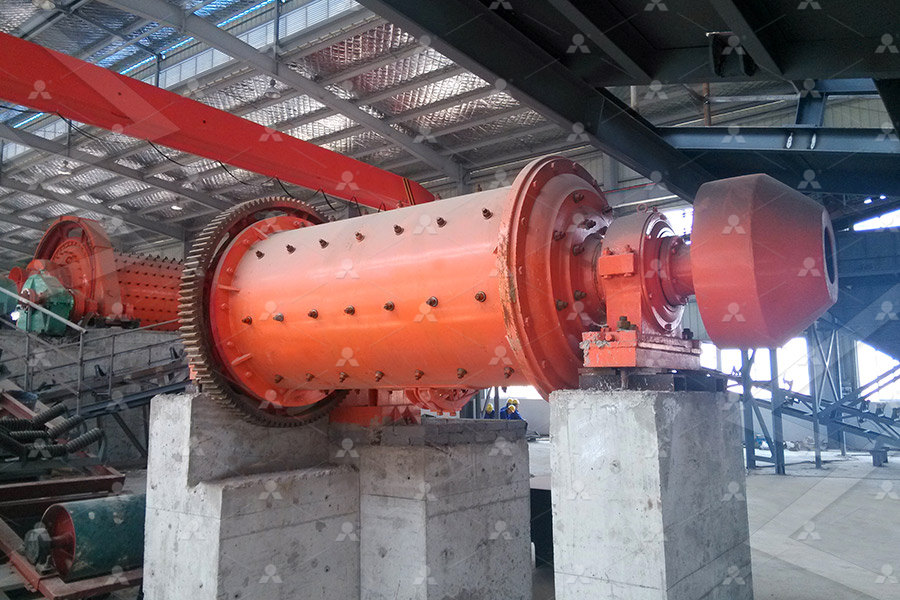

HOME→Concrete nickel slag pulverizing machinery factory site Concrete nickel slag pulverizing machinery factory site Concrete nickel slag pulverizing machinery factory site

Concrete nickel slag pulverizing machinery factory site Concrete nickel slag pulverizing machinery factory site Concrete nickel slag pulverizing machinery factory site

(PDF) AN INNOVATION OF HIGH PERFORMANCE CONCRETE BY

2019年9月20日 This paper investigates the characteristics of concrete made from blast furnace nickel slag powder (BFNSP) and fly ash (FA) to use an alternative binder to conventional 2022年9月13日 This research is an experimental study with the objectives of analyzing the physical and mechanical characteristics of nickel slag, analyzing the compressive strength of Use of Nickel Slag Waste as Coarse Aggregate in Concrete2015年11月23日 A study conducted on nickel slag and its use as a coarse aggregate in concrete mixtures found that it improved the mechanical properties of the concrete, including (PDF) MECHANICAL PROPERTIES OF CONCRETE USING NICKEL The paper describes a research to evaluate the performance of nickel slagaggregate high strength concrete (NSAHSC) Nickel slag, as a byproduct from nickel mines, was used as THE SHORTTERM PROPERTIES OF NICKEL SLAGAGGREGATE

.jpg)

Effect of nickel slag as a sand replacement in strength IOPscience

2019年10月1日 This research investigates the use of nickel slag as the replacement of sand in concrete Various concrete samples were produced with the increasing nickel slag content 2023年8月15日 In this study, a novel type of highquality mineral admixture, ultrafine ferronickel slag, is manufactured and designed, and the feasibility of its utilization in cement and concrete Recycling and comprehensive utilization of ferronickel slag in 2023年8月15日 This paper summarizes the research papers of FNS as supplementary cementitious materials (SCMs), aggregates and precursors and comprehensively analyses of Recycling and comprehensive utilization of ferronickel slag in 2021年2月17日 Ferronickel slag is widely used for production of concrete Appropriate addition of ferronickel slag can improve strength of concrete and delay the occurrence of chloride ion Utilization of Ferronickel Slag for Producing Concrete

Effect of slag nickel (FeNi3) as coarse aggregate on properties of

2021年10月1日 The results showed slag nickel (FeNi3) increase unit weight and compressive strength of nofine concrete For practical uses nofine concrete slag (NFCS) of 1:6 qualifies 2019年10月15日 This research investigates the use of nickel slag as the replacement of sand in concrete Various concrete samples were produced with the increasing nickel slag content (PDF) Effect of nickel slag as a sand replacement in strength and The nickel slag is recycled back into the process until its nickel concentration is low, and is then disposed of in stockpiles 72 In China alone, the 2005 generation of nickel slag was 800,000 tonnes, and just 8% of this was utilized for construction purposes, 72,73 with the remainder stockpiled or landfilled 72 In Greece 15 Mt of nickel slag were generated in 2000 74 Nickel Nickel Slag an overview ScienceDirect Topicsnickel slag as a substitute for coarse aggregates, can increase compressive strength by 1232% and reduce abrasion by 2417% and reduce shrinkage by 116% compared to normal concrete Potential utilization of nickel slag (nickel slag) as aggregate up to 100% in concrete (Wijaya Astutiningsih, 2021)Use of Nickel Slag Waste As Coarse Aggregate In Concrete

.jpg)

Use of Nickel Slag Waste As Coarse Aggregate in Concrete PDF

1 The document discusses a study on the use of nickel slag waste as a coarse aggregate in concrete Nickel slag is a waste product from nickel mining and smelting industries in Indonesia 2 The study aims to analyze the physical and mechanical properties of nickel slag, analyze the compressive strength of concrete with nickel slag substituting coarse aggregate at different First, it creates profits from waste and saves operating costs compared to the primary ores Nickel slag contains a notable amount of Co and Ni and is known to be mineralogically and physically Gradations of Nickel Slag Aggregate Download Table2021年2月22日 Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials (SCM) [23], that can enhance the strength and durability of concrete [2]The highly fine slag powder, with a surface area of 400–600 m 2 /kg and a bulk density of 1200 kg/m 3, can be mixed with free lime to replace 40% to 65% Slag uses in making an ecofriendly and sustainable concrete: A PENA TEKNIK: Jurnal Ilmiah IlmuIlmu Teknik Vol 7, No 2, September 2022 pISSN 26567288, eISSN 26567334 63 No Characteristics of coarse aggregatesUse of Nickel Slag Waste As Coarse Aggregate In Concrete

Recycling and comprehensive utilization of ferronickel slag in concrete

2023年8月15日 When “ferronickel slag” is input, 140 articles related to FNS (2012–2022) are reviewed, of which 93 articles are about the application of FNS in building materials The research status of the FNS is shown in Fig 1 The literature statistics are as follows: the research of nickel slag mainly focuses on metal recovery and material propertiesFirstly, nickel slag sand with a concentrated particle size distribution in the range of 236–060 mm was used to replace the mechanism sand in the ratio of 0%, 25%, 30%, 50%, 70% and 100%Mix composition of concrete with nickel slag (kg/m 3 )Founded in November 1988, SMAT MACHINERY is a largescale jointstock heavy machinery processing enterprise, integrated on the basis of the former Zhengzhou Machinery Group’s No 1 Machinery Factory and No 2 Machinery Factory Our main products are concrete batching plant, self loading concrete mixer truck, concrete pump, grinding machinery Concrete Batching Plant, Concrete Mixing Pump, Selfloading Concrete China Nickel Slag wholesale Select 2024 high quality Nickel Slag products in best price from certified Chinese Plating Nickel manufacturers, Jiangxi Province County Mining Machinery Factory Jiangxi Province County Mining Machinery Factory Diamond Member Audited Supplier Secured Trading Nickel Slag MadeinChina

.jpg)

An Innovation of High Performance Concrete by Replacing

LivaS: International Journal on Livable Space Bunga Yubi Nabiilah [80] Figure 1 Illustration of concrete mix composition RESULT AND DISCUSSION Physical Characterization of Nickel slag powder2022年12月1日 In contrast, concrete with a watercement ratio of 025 containing 50% nickel slag and the addition of class C fly ash up to 30% was declared suitable for application to concrete in the marine (PDF) Performance of Fly Ash Concrete with Nickel 2021年1月8日 Therefore, it is more suitable for application in mortar or concrete compared to other industrial byproducts [5][6][7] Recently, in addition to blast furnace slag (BS), which is a representative (PDF) Optimum combination of ferronickel slag 2021年10月1日 Pyrometallurgical nickel industry in New Caledonia produces several tons of slag per year, which is stocked on site There is no valorization today, except for a small transformation into sand(PDF) Prospective Life Cycle Assessment at Early Stage of Product

About Us – Pulverizing Machinery

Welcome To Pulverizing Machinery ; Talk To Expert : +9140, +9140; info@pulverizingmachinery Address We have positioned ourselves as one of the most prominent manufacturing of pulverisers spicer grinder machinery and Industrial Mixer manufacturers, in the global market2023年8月25日 Steel slag particles can potentially be used as aggregates in concrete production However, the volume stability of steel slag is poor, and the direct use of untreated steel slag aggregate (SSA (PDF) Application of Steel Slag as an Aggregate in Concrete 2017年7月20日 At 180 days, CPS15 and CPS30 concretes exhibited only 04% and 40% smaller compressive strength than PC0 concrete, respectively, while CPS45 concrete showed about 82% reduction in compressive Influence of highvolume electric furnace nickel slag and 2018年12月30日 Nickel slag is a granulated slag formed by natural cooling or water quenching of a melt formed during the smelting process of nickel metal, which contains FeO, SiO 2, Al 2 O 3 and MgO as the main components [1]For every ton of nickel produced, about 6–16 tons of nickel slag are generated and discharged in China [2]In recent years, nickel production in China is Utilization of nickel slag as raw material in the production of

.jpg)

Nickel Slag as A Partial Substitution of Fine Aggregate in Concrete

2024年3月23日 Title: Nickel Slag as A Partial Substitution of Fine Aggregate in Concrete Author(s): Gabriel Publication: Web Session Volume: wsS24Gabrielpdf Issue: Appears on pages(s): Keywords: DOI: Date: 3/23/2024 Abstract: The ferronickel processing process in Indonesia, as the largest nickel producing country in the world, produces large amounts of 2023年8月22日 Nickel slag (NS) is the solid slag produced by smelting nickel–iron alloy, usually spherical particles with a particle size of 0–5 mm Its main chemical composition is SiO 2, MgO, and Fe 2 O 3, which is China's fourth largest smelting industrial slag after iron slag, steel slag and red mud [4]There was an increase in the discharge of NS with industrial developmentEffects of incorporating large quantities of nickel slag with various 2022年9月2日 The results of this study indicate that the use of nickel slag as a substitute for coarse aggregate for 20 MPa concrete, and unable to achieve the planned average compressive strength of 20 MPa plus a margin of 12 MPa, resulted in a decrease in compressive strength and did not provide quality improvement concrete The application of nickel Use of Nickel Slag Waste as Coarse Aggregate in ConcreteGU + 40% Slag 53 040 800 766 510 GUL9% + 40% Slag 50 040 867 693 499 GUL9% + 50% Slag 41 040 625 553 419 GUL15% + 40% Slag 46 040 749 581 441 GUL15% + 50% Slag 38 040 525 438 347 GUL 5% + 6% Silica Fume + 25% Slag 53 040 357 296 300 CSA A231 limit is 1500 coulombs @ 91d for C1 ExposurePerformance of Slag Cement with Portland‐limestone Cement in Concrete

.jpg)

(PDF) Value Of Indirect Tensile Strength And

Table 5 shows the result of ITS (Indirect Tensile Strength) testing of concrete asphalt mixture with nickel slag as fine aggregate 152 IJSTR©2021 ijstr INTERNATIONAL JOURNAL OF SCIENTIFIC TECHNOLOGY RESEARCH 2020年11月25日 Sustainability in the construction industry refers to all resourceefficient and environmentally responsible processes throughout the life cycle of a structure Green buildings may incorporate reused, recycled, or recovered materials in their construction Concrete is as an important building material Due to the implementation of byproducts and waste from various Sustainability Potential Evaluation of Concrete with Steel Slag 2024年5月1日 Modern industrialization leads to an increasing demand for steel around the world, the production of one ton of crude steel generates a substantial amount of steel slag (SS 1), ranging from 130–200 kgThe accumulation of SS poses economic and environmental challenges, particularly in developing countries with low utilization ratesA review of the application of steel slag in concreteFigure 6 Splitting tensile strength of nickel slag concrete and control concrete 2619 1812 00 50 100 150 200 250 300 Nickel Slag Concrete Control Concrete a) 261 211 00 05 10 15 2 MECHANICAL PROPERTIES OF CONCRETE USING NICKEL SLAG

.jpg)

Performance of Fly Ash Concrete with Nickel Slag Fine Aggregate

2022年8月12日 In contrast, concrete with a watercement ratio of 025 containing 50% nickel slag and the addition of class C fly ash up to 30% was declared suitable for application to concrete in the marine environment zone C2 according to ACI 31819 Doi: 1028991/CEJ010 Full Text: PDF72,000 tons of nickel slag annually Nickel mining waste at this company is managed by PT Growth Java which has the authority to prevent it from being hazardous and toxic (B3) This research utilized nickel slag as a partial substitution of cement to produce high strength concrete The reuse of nickel slag powderAn Innovation of High Performance Concrete by Replacing Download scientific diagram Design of concrete using nickel slag as a substitute for sand in several compositions from publication: The behaviour of selfcompacting concrete (SCC) with nickel Design of concrete using nickel slag as a substitute for sand in Therefore, it is more suitable for application in mortar or concrete compared to other industrial byproducts [5][6][7] Recently, in addition to blast furnace slag (BS), which is a representative Compressive strength of the concrete based on the variation of slag

Nickel Slag an overview ScienceDirect Topics

The nickel slag is recycled back into the process until its nickel concentration is low, and is then disposed of in stockpiles 72 In China alone, the 2005 generation of nickel slag was 800,000 tonnes, and just 8% of this was utilized for construction purposes, 72,73 with the remainder stockpiled or landfilled 72 In Greece 15 Mt of nickel slag were generated in 2000 74 Nickel nickel slag as a substitute for coarse aggregates, can increase compressive strength by 1232% and reduce abrasion by 2417% and reduce shrinkage by 116% compared to normal concrete Potential utilization of nickel slag (nickel slag) as aggregate up to 100% in concrete (Wijaya Astutiningsih, 2021)Use of Nickel Slag Waste As Coarse Aggregate In Concrete1 The document discusses a study on the use of nickel slag waste as a coarse aggregate in concrete Nickel slag is a waste product from nickel mining and smelting industries in Indonesia 2 The study aims to analyze the physical and mechanical properties of nickel slag, analyze the compressive strength of concrete with nickel slag substituting coarse aggregate at different Use of Nickel Slag Waste As Coarse Aggregate in Concrete PDF First, it creates profits from waste and saves operating costs compared to the primary ores Nickel slag contains a notable amount of Co and Ni and is known to be mineralogically and physically Gradations of Nickel Slag Aggregate Download Table

Slag uses in making an ecofriendly and sustainable concrete: A

2021年2月22日 Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials (SCM) [23], that can enhance the strength and durability of concrete [2]The highly fine slag powder, with a surface area of 400–600 m 2 /kg and a bulk density of 1200 kg/m 3, can be mixed with free lime to replace 40% to 65% PENA TEKNIK: Jurnal Ilmiah IlmuIlmu Teknik Vol 7, No 2, September 2022 pISSN 26567288, eISSN 26567334 63 No Characteristics of coarse aggregatesUse of Nickel Slag Waste As Coarse Aggregate In Concrete2023年8月15日 When “ferronickel slag” is input, 140 articles related to FNS (2012–2022) are reviewed, of which 93 articles are about the application of FNS in building materials The research status of the FNS is shown in Fig 1 The literature statistics are as follows: the research of nickel slag mainly focuses on metal recovery and material propertiesRecycling and comprehensive utilization of ferronickel slag in concrete Firstly, nickel slag sand with a concentrated particle size distribution in the range of 236–060 mm was used to replace the mechanism sand in the ratio of 0%, 25%, 30%, 50%, 70% and 100%Mix composition of concrete with nickel slag (kg/m 3 )

.jpg)

Concrete Batching Plant, Concrete Mixing Pump, Selfloading Concrete

Founded in November 1988, SMAT MACHINERY is a largescale jointstock heavy machinery processing enterprise, integrated on the basis of the former Zhengzhou Machinery Group’s No 1 Machinery Factory and No 2 Machinery Factory Our main products are concrete batching plant, self loading concrete mixer truck, concrete pump, grinding machinery China Nickel Slag wholesale Select 2024 high quality Nickel Slag products in best price from certified Chinese Plating Nickel manufacturers, Jiangxi Province County Mining Machinery Factory Jiangxi Province County Mining Machinery Factory Diamond Member Audited Supplier Secured Trading Nickel Slag MadeinChina