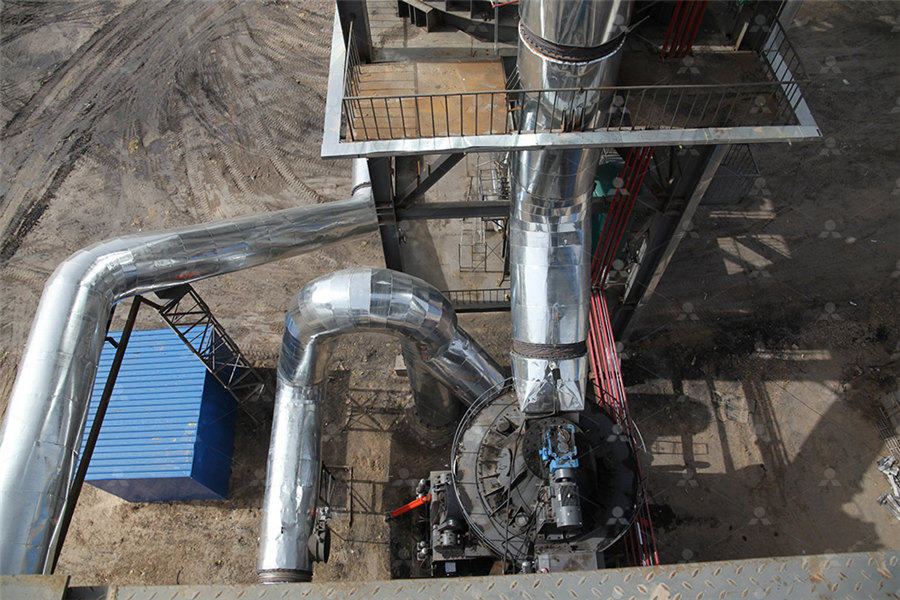

Rotary grinding cracking carbon black processing equipment

.jpg)

Carbon Black Processing Equipment FEECO

Whether looking to produce carbon black from biomass, transform it into biochar or activated carbon, or recover it from waste tires, FEECO custom rotary kilns provide an ideal thermal processing environmentUltra fine grinding: The mechanical ultrafine crushing and grading machine grinds the coarse CAMC Horizontal Cracking Carbon Black Deep Processing Special 2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill Tire pyrolysis carbon black deep processing grinding 2024年6月14日 This article will delve into its processing, covering grinding, granulation, drying, and the necessary equipment What is carbon black? Carbon black is typically produced from coal tar, petroleum, or natural gas, heated at Carbon Black Processing: Turning Soot into Industrial

.jpg)

China Cracking Carbon Black Grinder Manufacturer, Supplier

The Cracking Carbon Black Grinder by Weifang Jinghua Powder Engineering Equipment Co, Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, Carbon Black Processing Plant Process Carbon Black 2015年1月27日 Beston carbon black processing machine is aimed at processing the coarse carbon black(about 5060 mesh) into 325 mesh or more, to reach a N grade carbon black quality For example, N330 carbon black can be used in Carbon Black Processing Machine Carbon Black The carbon black powder grinder machine produced by Beston Group is suitable for the grinding process of metallurgy, building materials, chemicals, mining and other minerals materialsCarbon Black Grinding Machine Beston Pyrolysis Plant

.jpg)

Process Technology for recovered Carbon Black (rCB)

Especially the rCB can be used to replace the virgin Carbon Black in various applications Most important is the fineness of the rCB, which determines the final use To reach the fineness required, NETZSCH offers machines which meet ENERGYEFFICIENT RECOVERED CARBON BLACK FINISHING PRECISE CONTROL OF RECOVERED CARBON BLACK Hosokawa Alpine2024年6月14日 Carbon black is dubbed "industrial gold" for its extensive use in rubber, plastic, ink, coating, and more This article will delve into its processing, covering grinding, granulation, drying, and the necessary equipmentCarbon Black Processing: Turning Soot into Industrial Carbon black processing production line, the main processing equipment is mw micro powder grinding mill Through visits and research from all parties, the company purchased our MW micro powder mill production line for processing carbon black after tire cracking Hourly output : 152t/h Annual output : Carbon black powder grinding mill LIMING HEAVY INDUSTRY

.jpg)

Recovered Carbon Black Hosokawa Alpine

After pyrolysis, an intermediate process step is required The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine grinding, Hosokawa Alpine primarily uses Trommel screen or rotary screen, rotary drum screening machine is a screening device that classifies materials based on their particle size It is also known as a rotary drum screener Due to its simple process layout, it is widely used in the classification of products in industries such as activated carbon, coal, mining, building materials, transportation, energy, and chemicalTrommel Screen Rotary Trommel Screen Activated Carbon Equipment2016年11月23日 The carbon black grinding machine is an ideal energysaving micropowder production equipment with excellent performance and efficiency Carbon Black Grinding Equipment The fine powder grinding machine is suitable for the crushing of materials with low to medium hardness in chemical, pharmaceutical, dyestuff, paint, pesticide, metallurgy, food, Introduction, Usage, and Characteristics of Carbon Black Grinding Equipment2023年8月18日 After the reaction, the remaining solid material was cooled using a slagging system and transported to the carbon black deep processing line The production of CBp involved a wet method process consisting of grinding and pelletizing The liquid product was stored in an oil tank, and the gas was utilized as an energy source for the reactionInfluence of Pyrolytic Carbon Black Derived from Waste Tires at

.jpg)

CNA Method for deep processing and modifying cracking carbon

The invention relates to a cracking carbon black deep processing method and equipment applied to the method, which can realize the upgrading of lowaddedvalue cracking carbon slag into highquality cracking carbon black for rubber The method for further processing the pyrolysis carbon black comprises the following steps: (1) carrying out superfine grinding on the cracking carbon Cracking: Using continuous cracking equipment under high temperature and catalyst action, crude carbon black is cracked in negative pressure and some corresponding ash is neutralized 2 Iron removal: The automatic high magnetic iron remover further separates the CAMC Horizontal Cracking Carbon Black Deep Processing Special EquipmentCarbon black air conveying system Product Introduction of Carbon black air conveying system: Carbon black air conveying system is one auxiliary equipment of carbon black production line, which takes Roots blower as the air source, is designed specifical for close distance and continuous transportingTransporting distances is generally horizontal distance≤ 300m, vertical Carbon black air conveying systemSpecially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black grinding, carbon black refining equipment, carbon black grinding mill, carbon black pellet making machine, carbon black briquetting machine, oil distillation machine, etccarbon black processing machine, tyre pyrolysis carbon black grinding

China Cracking Carbon Black Grinder Manufacturer, Supplier

HighQuality Cracking Carbon Black Grinder for Precision Grinding The Cracking Carbon Black Grinder by Weifang Jinghua Powder Engineering Equipment Co, Ltd is a highperformance grinding device designed specifically for the processing of carbon black2022年3月9日 Number of publications on the subjectselected from Web of Science, with the keywords: "pyrolysis" and "endoflife tires", "waste tires", or "used tires"(PDF) Production and Upgrading of Recovered Carbon The invention belongs to the technical field of wet grinding processing equipment, and particularly relates to wet grinding processing equipment for crude carbon black after cracking waste rubber, which comprises a primary grinding box, wherein two first grinding rollers and two second grinding rollers are movably connected inside the primary grinding box from top to bottom, a first sieve CNA Wet crushing processing equipment for crude carbon black ROTARY DRUM DRYERS COOLERS As a wet process, pelletizing typically requires a drying step This is frequently carried out in a rotary dryer, a highcapacity dryer that utilizes a cascading motion to dry pellets, while also rounding and polishing them as they tumble through the drumIn some cases, a rotary cooler may follow the dryer to cool material prior to packaging or storagePelletizing Plant Equipment Process Development

5 kinds of carbon black production processes

At present, lamp smoke carbon black is mainly used as paint colorant, drum method and mixed gas method carbon black is mainly used for pigment carbon black for paint and ink, acetylene carbon black is mainly used for dry battery production, and other production processes are in the production of rubber Use carbon black in the applicationIn addition to tire oil, that is, fuel oil, the products of waste tire refining include steel wire, carbon black, and combustible gas The black face of the tire is due to the addition of carbon black to the rubber Carbon black has excellent reinforcement to rubber and can give tires excellent wear resistance By processing carbon black through a pulverizer, the byproducts of waste tires can News What Are The Uses Of Carbon Black From Tire Refining The invention belongs to the technical field of wet grinding processing equipment, and particularly relates to wet grinding processing equipment for crude carbon black after cracking waste rubber, which comprises a primary grinding box, wherein two first grinding rollers and two second grinding rollers are movably connected inside the primary grinding box from top to bottom, a first sieve CNA Wet crushing processing equipment for crude carbon black Waste Tyre Pyrolysis Plant for Carbon black Application field:Waste Tyre Pyrolysis Plant to make pyrolysis carbon black, oil, fuel, etc Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon black light charactercarbon black processing machine, tyre pyrolysis carbon black grinding

Carbon Activation Kilns Process Development

As a leader in advanced thermal processing, FEECO can assist in every step of processing raw biomass into activated carbon: DRYING Before it can be fed into the rotary kiln, raw feedstock must first be dried This can be carried out in a 2024年10月12日 It has been proved by thousands of customers that our machine has outstanding features and stable quality 5 micron carbon black grinding machine can upgrade its production and the additional value which is suitable for our customer to use It is the ideal equipment for fine millingWhat is an additional 5 micron carbon black grinding machine?Carbon black is a kind of amorphous carbon Light, loose and very fine black powder, with a very large surface area, ranging from 103000 ㎡/g, is the product of incomplete combustion or thermal decomposition of carbon containing Superfine grinding material Carbon blackAccording to the method, the waste tires are processed by the horizontal rotary cracking processor, and by controlling parameters of temperature, pressure and the like in the processor, 810 tons of the waste tires can generate 100200 jins of light oil, 5060 jins of heavy oil and 4555t of coarse carbon black, thereby reducing the consumption of resources; moreover, by CNA Method for preparing carbon black by processing

.jpg)

Carbon Black: Successful Handling and Transportation

2019年5月9日 Ensure a smooth flow of carbon black into the processing stream Use the appropriate screws we can help you with valves, storage equipment, transportation and more previous Classes of Butterfly Valves next Valve Basics Recent Posts May 10, 2019 Rotary Airlock FAQs May 10, 2019 Combustible Dust Particles: How to Reduce Risk The comprehensive utilization of waste rubber tires includes the cracking of giant old tires and the application of waste rubber pyrolysis regenerated carbon blackIn response to these difficulties, CLIRIK company based on many years of experience, developed a new process of refurbishing used tires and producing rubber oil and carbon black through pyrolysis process, making tyre Tyre pyrolysis carbon black grinding technology breakthroughSmall lumps of Carbon Black are produced Further grinding and processing can make these products equivalent to N330 grade of commercial carbon blackCarbon black has got several usages in industries like rubber, plastic, pigment, paint, and printing Carbon Black Equipment Supplies Environmental XPRT2023年9月19日 Refined carbon black after cracking of waste tires 1 Equipment list used in carbon black production line Production line: HGM80 ultrafine grinding mill production line: Processing materials: carbon black: Finished product particle size: 200600 mesh: Annual production capacity:HGM80 Ultra Fine Grinding Mill Used in Waste Tire Powder Processing

.jpg)

Screening Machines For Activated Carbon Activated Carbon Equipment

Compared with the linear vibrating screen, the rotary vibrating screen in the processing of activated carbon particles will be relatively small, but the accuracy is higher, suitable for small particles of activated carbon and the screening situation with lower production requirements (up to 3300kg/h) Powder activated carbon – swing round screenstep 2: pyrolysis carbon black grinding mill production linecarbon black grinding mill Shanghai Clirik Machinery has been in this field over 8 years, designed and produced HGM carbon black grinding mill, which are best for carbon black micro powder processing 1carbon black processing machine, tyre pyrolysis carbon black grinding 2024年6月14日 Carbon black is dubbed "industrial gold" for its extensive use in rubber, plastic, ink, coating, and more This article will delve into its processing, covering grinding, granulation, drying, and the necessary equipmentCarbon Black Processing: Turning Soot into Industrial Carbon black processing production line, the main processing equipment is mw micro powder grinding mill Through visits and research from all parties, the company purchased our MW micro powder mill production line for processing carbon black after tire cracking Hourly output : 152t/h Annual output : Carbon black powder grinding mill LIMING HEAVY INDUSTRY

Recovered Carbon Black Hosokawa Alpine

After pyrolysis, an intermediate process step is required The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine grinding, Hosokawa Alpine primarily uses Trommel screen or rotary screen, rotary drum screening machine is a screening device that classifies materials based on their particle size It is also known as a rotary drum screener Due to its simple process layout, it is widely used in the classification of products in industries such as activated carbon, coal, mining, building materials, transportation, energy, and chemicalTrommel Screen Rotary Trommel Screen Activated Carbon Equipment2016年11月23日 The carbon black grinding machine is an ideal energysaving micropowder production equipment with excellent performance and efficiency Carbon Black Grinding Equipment The fine powder grinding machine is suitable for the crushing of materials with low to medium hardness in chemical, pharmaceutical, dyestuff, paint, pesticide, metallurgy, food, Introduction, Usage, and Characteristics of Carbon Black Grinding Equipment2023年8月18日 After the reaction, the remaining solid material was cooled using a slagging system and transported to the carbon black deep processing line The production of CBp involved a wet method process consisting of grinding and pelletizing The liquid product was stored in an oil tank, and the gas was utilized as an energy source for the reactionInfluence of Pyrolytic Carbon Black Derived from Waste Tires at

.jpg)

CNA Method for deep processing and modifying cracking carbon

The invention relates to a cracking carbon black deep processing method and equipment applied to the method, which can realize the upgrading of lowaddedvalue cracking carbon slag into highquality cracking carbon black for rubber The method for further processing the pyrolysis carbon black comprises the following steps: (1) carrying out superfine grinding on the cracking carbon Cracking: Using continuous cracking equipment under high temperature and catalyst action, crude carbon black is cracked in negative pressure and some corresponding ash is neutralized 2 Iron removal: The automatic high magnetic iron remover further separates the CAMC Horizontal Cracking Carbon Black Deep Processing Special EquipmentCarbon black air conveying system Product Introduction of Carbon black air conveying system: Carbon black air conveying system is one auxiliary equipment of carbon black production line, which takes Roots blower as the air source, is designed specifical for close distance and continuous transportingTransporting distances is generally horizontal distance≤ 300m, vertical Carbon black air conveying system