How is garnet abrasive processed

Garnet How to Process Use It as Industrial Abrasives

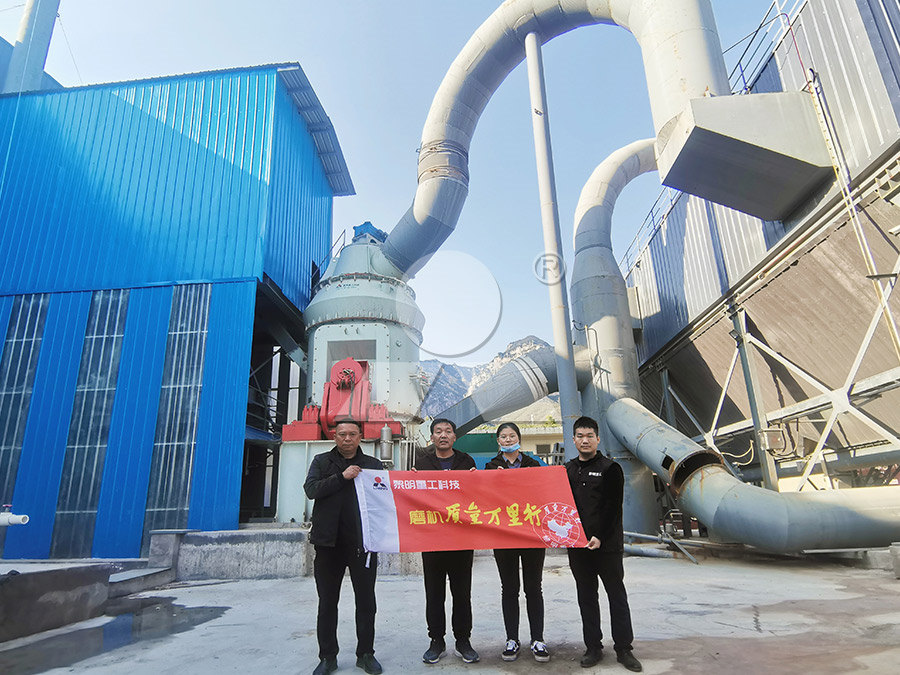

Garnets are relatively durable minerals They are often concentrated in soils and sediments that form when garnetcontaining rocks are weathered and eroded These alluvial garnets are the mining target as they are easy to mine by mechanical processing For example, at the Emerald Creek mine in Idaho, the 展开2024年2月13日 How is garnet processed for abrasive applications? Garnet is mined and then crushed and screened to obtain the desired particle size and shape It undergoes further Unveiling The Abrasive Properties Of Garnet: Why It's A Gem In 2020年5月2日 Garnet abrasive is mined from almandite and andradite mineral deposits in Australia, and India In its natural state, garnet is a semiprecious Garnet Abrasive – Production , Uses and its Benefits2019年8月23日 Today, the vast majority of garnet is used as an abrasive blasting material, for water filtration, in a process called water jet cutting, and to make abrasive powders If you have some questions about our products, Garnet Processing Equipment, Process Flow, Cases

Garnet Abrasive What Is It What Are The Uses Key

Garnet abrasive is a highperformance blast media that is commonly used for the cleaning of aluminium and fibreglass structures It also has uses in waterjetting and can be used on sites where contamination is a concern such as 2023年8月26日 Garnet’s moderate yet efficient abrasive action helps smooth wooden surfaces, adding to the stone’s allure in the woodworking industry The rhythm of the garnet abrasive brings life to the woodworker’s studio It’s a The Beauty Of Garnet Abrasive In Material Processing2024年11月7日 Garnet abrasive is an efficient grinding material widely used in metal processing, surface treatment and cleaning It is processed from natural garnet ore and has excellent Introduction of garnet abrasive Nice AbrasiveTo cut through metal or stone in waterjet applications, or to remove surface contaminants using abrasive blasting, the media used must be extremely hard And that’s what you get with What are Garnet Abrasives BARTON

.jpg)

Tech Sheet: Galaxy Garnet Abrasive

Garnet, derived from mined Almandite and Andradite mineral deposits, is a semiprecious stone Once extracted, it is processed and then screened to the desired grade The combination of 2020年4月24日 As an abrasive, Garnet can be broadly separated into two classes, blasting grade and water jet grade The garnet is crushed to finer grains as it is mined and collected; all pieces which are higher than 60 mesh (250 What is Garnet Abrasive? SICHENG Garnet SandGalaxy Garnet Abrasive Manufactured by: Garnet, derived from mined Almandite and Andradite mineral deposits, is a semiprecious stone Once extracted, it is processed and then screened to the desired grade The combination of the high density and physical properties make Garnet nature’s most highly efficient, effective and safe abrasive forTech Sheet: Galaxy Garnet Abrasive2020年6月2日 Garnet abrasive sand is a naturally occurring silicate mineral deposit The harder species of abrasive garnet like almandine are used for abrasive Skip to content Once extracted, it is washed, processed, and What is Garnet Sand? SICHENG Garnet Sand

Garnet Processing Equipment, Process Flow, Cases

2019年8月23日 Garnet processing description from its geology mineral property to how to extract mineral from rock and placer Garnets are extracted and processed more easily from alluvial deposits For example, Garnet is The harder the abrasive, the better it cuts GMA’s garnet is of the almandine variety — the hardest form of garnet Our garnet grains are up to 30% harder than other garnets and nearly 300% harder than coal slag, giving it a higher relative resistance for abrading a surface, and resulting in faster blast rates and higher cutting speedsOur Garnet: The GMA Advantage GMA Garnet Group2023年10月16日 The waterjet, when combined with abrasive grains like garnet, can become an extremely effective cutting tool The abrasive particles enhance the cutting ability, transferring the energy of the highpressure water to the workpiece in the form of a concentrated jet, which then erodes the material and performs the cutting actionWhat is Abrasive Machining: Definition, Types Abrasives UsedThe largest source of abrasive garnet today is garnetrich beach sand which is quite abundant on Indian and Australian coasts and the main producers today are Australia and India Since the material has been naturally crushed and ground, the material is normally available in fine sizes only: 80 mesh with ranges from 56 mesh to 100 mesh sizeHow to Choose the Right Garnet Abrasive for Your Waterjet Cutting

Choosing the Right Garnet for Blasting and Waterjet Cutting:

2024年9月29日 Garnet is a highly versatile abrasive, widely used in industries for blasting and waterjet cutting Its hardness, durability, and ecofriendly properties make it a preferred choice for many applications However, for endusers, Garnet, the typical waterjet abrasive, is an inert, naturally occurring, semiprecious mineral It is either natural garnet grains from our mine in Western Australia (alluvial garnet) and are very resistant to further breakdown compared to any other garnet from China or India or mined out of the mountains in Montana (crushed rock garnet)Garnet reprocessing and waste handling solutions2024年3月4日 Garnet abrasive is fed to the waterjet from a pressure pot to the abrasive regulator, which controls the abrasive feed to the cutting head Standard pressure pots have capacities from 110 to 600 lbs Larger pressure pots with 2,200 or 4,400lb capacity can be purchased for longer uninterrupted cutsBest practices for managing waterjet abrasive The FabricatorGMA NewSteel™ is the fastest cleaning mineral abrasive on the market for removing mill scale Exceptional surface cleanliness with minimal abrasive embedment, for better corrosion resistance and substrate integrity; High blasting and cleaning efficiency, leading to low abrasive consumption, minimizing usage and maximizing recyclingBlast Abrasives for Fabrication Manufacturing GMA Garnet

Technical Tip: Choosing the Right Garnet Abrasive

2018年11月27日 Types of Garnet Abrasive Alluvial Garnet (River Garnet) Alluvial garnet is particularly abundant in Australia This alluvial garnet is typically found in deposits in river beds or natural hollows and has been smoothed by a Our abrasives are made of solid almandine garnet particles, featuring four distinct characteristics — hardness, toughness, density, and angularity Almandine garnet’s toughness makes GMA Garnet™ very resistant to further breakdown during blasting, producing less dust than alternatives It is also a cleaner abrasiveDiscover Safer, Cleaner Abrasive Blasting GMA Garnet GroupBARTON garnet abrasive is the best abrasive for waterjet cutting BARTON garnet is processed to meet our highquality and purity standards Unlike lowpurity products, which may contain other materials that don’t cut well, Best Abrasive for Waterjet Cutting Garnet Abrasives2023年1月1日 Alluvial garnet is naturally eroded and transported by water, typically from a source of rock or mineral deposit Alluvial garnet deposits are often found in riverbeds or on beaches, where the movement of water has concentrated the heavy mineral grains Alluvial garnet is a popular abrasive material for various applications, including AWJ cuttingOptimization of Abrasive Water Jet (AWJ) cutting process accuracy

.jpg)

GMA GARNET BLAST ABRASIVES

GMA Garnet™ has a higher relative resistance to abrade a surface compared to other abrasives 1 Density GMA’s heavier, denser abrasive grain outperforms a less dense abrasive GMA Garnet™ grains create a deeper, consistent anchor profile when blasted at the same pressure Toughness To remove surface coatings effectively,Garnets are extracted and processed more easily from alluvial deposits For example, Garnet is ground to a variety of sizes to be used as an abrasive Garnet sandpaper was the original application of this mineral It is also used to make a number of similar products, including sanding belts, discs, and stripsGarnet Mining Processing Equipment Flow Chart Cases JXSCDisposing of used abrasive can be expensive through traditional waste management methods GMA is committed to offering a costeffective alternative, providing additional value to our abrasive customers Through advances in GMA's processing capabilities, we can now reprocess used garnet into a highquality abrasiveGarnet Disposal and Reprocessing GMA Garnet GroupAnd remember, garnet is a naturally occurring mineral and maybe repurposed Your used garnet abrasive may still be useable as a sand blasting medium, or added to concrete/block mixtures as an added hardener and filler, or used in similar applications as you might use sand in Can Spent Water Jet Abrasive be Recycled?Can Spent Garnet Be Recycled? How to Dispose of Waste Garnet

.jpg)

Garnet: Mineral, January birthstone, abrasive, filter media

Garnet abrasive: This photo shows garnet granules that have been crushed and sizegraded for use as abrasive, cutting, and filter media They are used in waterjet cutting, "sand" blasting, sandpaper, water filtration, and a number of other uses Almandine is the hardest garnet and also the most abundant2023年11月22日 Natural abrasive materials, such as emery, flint, garnet, and pumice, are derived from the earth They have been used for millennia for their hardness and ability to grind, cut, and polish However, they often have irregularities in shape and hardness due to their natural origin, which can lead to inconsistent performanceUnderstanding Abrasive Materials: Types, Applications, and Useful tips on garnet storage First and foremost, train your employees on the proper handling of garnet abrasive sand best work practices Managing your abrasives well not only maximises your resources but also ensures a troublefree and interrupted cutting operation Store GMA Garnet™ abrasives indoors and in a dry placeJetTalk: Keep your garnet abrasive safe and dryGarnet is proven to be the best abrasive mineral for waterjet cutting Barton is the world’s leading supplier of highquality garnet abrasive Garnet also has the toughness to be processed into a wide variety of particle sizes, even the Advantages of Garnet Abrasives Barton International

BARTON Garnet Waterjet abrasives Barton International

It is essential to match the type and grade of garnet abrasive to your specific waterjet cutting application Whether your application demands the premium cutting power of our ADIRONDACK HPX or the workhorse performance of What is Garnet Abrasive? The garnet abrasive is mined from highquality mineral deposits, particularly andradite and almandite, in India and Australia It is a naturally occurring semiprecious stone It is entrecote, cleaned and processed to the needed grade to be used as an abrasive The garnet manufacturers in India source thisWhat Is Garnet Abrasive? Benefits of Garnet AbrasiveYour abrasive is costing you more than its price Find out how much you can save on your next project with the GMA TruCost Calculator It estimates the amount of GMA Garnet™ required for a project compared to other abrasives, and itemizes the costs of material, labor, equipment, cleanup, and removalHigh Productivity Abrasive Blasting GMA Garnet GroupWe supply garnet abrasive media and deliver it to your project site Back in the 1980’s, garnet was used as an abrasive blasting media as well It used to be called gemstone and was used by the founders of Garnet Millers Australia (GMA Garnet now) Garnet abrasive is now one of the most popular blast media’s in the worldBlasting with Garnet Abrasive Media Blast Booths Spray Paint

.jpg)

Garnet Abrasive Corrosionpedia

2024年7月19日 A garnet abrasive is an abrasive blasting material consisting of minerals from the garnet family, which includes almandite, andradite, grossularite, pyrope and spessartite It is used as a nontoxic alternative to slags and silica sand While expensive, garnet abrasives are costeffective because garnet has a Mohs hardness value between 7 and 8 2024年10月12日 Although often associated with gemstones and jewelry, garnet's abrasive properties make it an indispensable tool in industrial applications In this article, we explore the unique characteristics that make garnet a favored choice for abrasive applications and the specific advantages it offers over other materials 1Why is Garnet Used as an Abrasive?GMA GARNET™ BLAST ABRASIVE PRODUCT LINE Reduce Overall Project Costs GMA Garnet™ results in higher productivity and lower abrasive consumption, despite the higher initial product cost compared to slags With GMA Garnet™, you can save 15% to 30% on a typical project due to lower cleanup and equipment costs, andGMA GARNET BLAST ABRASIVE PRODUCT LINE2022年6月9日 Garnet has been used for decades as an abrasive in water jet cutting and sand blasting because of its superior physical properties When added to high pressure streams of water, garnet abrasive is How to select right garnet abrasive LinkedIn

.jpg)

Tech Sheet: Galaxy Garnet Abrasive

Galaxy Garnet Abrasive Manufactured by: Garnet, derived from mined Almandite and Andradite mineral deposits, is a semiprecious stone Once extracted, it is processed and then screened to the desired grade The combination of the high density and physical properties make Garnet nature’s most highly efficient, effective and safe abrasive for2020年6月2日 Garnet abrasive sand is a naturally occurring silicate mineral deposit The harder species of abrasive garnet like almandine are used for abrasive Skip to content Once extracted, it is washed, processed, and What is Garnet Sand? SICHENG Garnet Sand2019年8月23日 Garnet processing description from its geology mineral property to how to extract mineral from rock and placer Garnets are extracted and processed more easily from alluvial deposits For example, Garnet is Garnet Processing Equipment, Process Flow, CasesThe harder the abrasive, the better it cuts GMA’s garnet is of the almandine variety — the hardest form of garnet Our garnet grains are up to 30% harder than other garnets and nearly 300% harder than coal slag, giving it a higher relative resistance for abrading a surface, and resulting in faster blast rates and higher cutting speedsOur Garnet: The GMA Advantage GMA Garnet Group

.jpg)

What is Abrasive Machining: Definition, Types Abrasives Used

2023年10月16日 The waterjet, when combined with abrasive grains like garnet, can become an extremely effective cutting tool The abrasive particles enhance the cutting ability, transferring the energy of the highpressure water to the workpiece in the form of a concentrated jet, which then erodes the material and performs the cutting actionThe largest source of abrasive garnet today is garnetrich beach sand which is quite abundant on Indian and Australian coasts and the main producers today are Australia and India Since the material has been naturally crushed and ground, the material is normally available in fine sizes only: 80 mesh with ranges from 56 mesh to 100 mesh sizeHow to Choose the Right Garnet Abrasive for Your Waterjet Cutting2024年9月29日 Garnet is a highly versatile abrasive, widely used in industries for blasting and waterjet cutting Its hardness, durability, and ecofriendly properties make it a preferred choice for many applications However, for endusers, Choosing the Right Garnet for Blasting and Waterjet Cutting: Garnet, the typical waterjet abrasive, is an inert, naturally occurring, semiprecious mineral It is either natural garnet grains from our mine in Western Australia (alluvial garnet) and are very resistant to further breakdown compared to any other garnet from China or India or mined out of the mountains in Montana (crushed rock garnet)Garnet reprocessing and waste handling solutions

.jpg)

Best practices for managing waterjet abrasive The Fabricator

2024年3月4日 Garnet abrasive is fed to the waterjet from a pressure pot to the abrasive regulator, which controls the abrasive feed to the cutting head Standard pressure pots have capacities from 110 to 600 lbs Larger pressure pots with 2,200 or 4,400lb capacity can be purchased for longer uninterrupted cutsGMA NewSteel™ is the fastest cleaning mineral abrasive on the market for removing mill scale Exceptional surface cleanliness with minimal abrasive embedment, for better corrosion resistance and substrate integrity; High blasting and cleaning efficiency, leading to low abrasive consumption, minimizing usage and maximizing recyclingBlast Abrasives for Fabrication Manufacturing GMA Garnet