Coal mill export coal powder fine

.jpg)

Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal

Coal mills, also known as pulverizers, play a critical role in power plants by grinding coal into fine powder, which is then used in various pyroprocesses These mills pose significant safety risks Ensuring the safe operation of coal mills is crucial for preventing accidents, maintaining plant Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives Coal Mill an overview ScienceDirect TopicsClean coal powder preparation refers to the process of converting raw coal into a fine powder Clean coal powder preparation: A comprehensive solutionCoal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thBest Practices and Precautions Coal Mill Safety, Explosion and

.jpg)

Decision Support System for Coal Mill Fault Diagnosis in Coal

Decision Support System for Coal Mill Fault Diagnosis in CoalFired Steam Power Plant Joga Dharma Setiawan1, *, Ronny Cahyadi Utomo1, 2, equipment that processes coal raw materials into fine coal powder to perfect combustion in the furnace In the operation of 4 coal mill units, delay and selfcombustion often occurred due to using LowRank2020年8月12日 Batubara yang siap digunakan ini dinamakan fine coal yang digunakan menjadi bahan bakar burner dan calciner yang terdapat pada rotary kiln, dan udara bersih akan dihisap oleh fan coal mill dan An investigation of performance characteristics and 2024年1月11日 With a ball mill 1 To pulverize crushed coals in a ball mill, you start by feeding the mill with crushed coal Then the grinding media crushes and grinds the coal in the rotating chamber 2 Airflow carries the pulverized coal out of the ball mill 3 Next, you'll need to use the mill classifier to separate the fine coal particles from the airflowHow to Process Coal into Pulverized Coal in 5 Steps?2022年9月13日 Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill Coal gangue powder is widely used in the construction field +17 [ protected] language the vibrating feeder evenly sends small pieces of coal gangue into the ultrafine grinding millCoal gangue ultrafine powder mill

Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill

The introduction of hot air helps to improve the drying effect of coal powder and carries coal powder into the coal mill shell during the coal grinding process Coal Powder Conveying System The pulverized coal conveying system is used to transport pulverized coal from the pulverizer to the target location, such as a combustion furnace or a pulverized coal storage binCoal Mill: The heart of the system, where raw coal is pulverized into a fine powder Various types of mills, such as ball mills, vertical roller mills, and hammer mills, can be used depending on the specific requirements of the application Storage Bin/Silo: Pulverized coal is temporarily stored in a bin or silo before being fed into the furnaceIndirect Firing Coal Grinding Systems: Enhancing Efficiency and Coal dust explosions are among the severe hazards in industries using coal, posing significant risks to personnel and infrastructure These explosions occur when fine coal particles become airborne and come into contact with a heat source in an enclosed environment, leading to a rapid combustion event Given the catastrophic potential of such incidents, robust measures for coal Coal Dust Explosion Protection: Ensuring Safety in industries using Raw Coal Inlet: Raw coal from the coal storage area is fed into the coal mill through a conveyor system Grinding: The raw coal is crushed by rollers or balls against a rotating horizontal grinding table The grinding process reduces the coal to a fine powder, which is necessary for efficient combustion in the furnaceHow does a coal mill work?

.jpg)

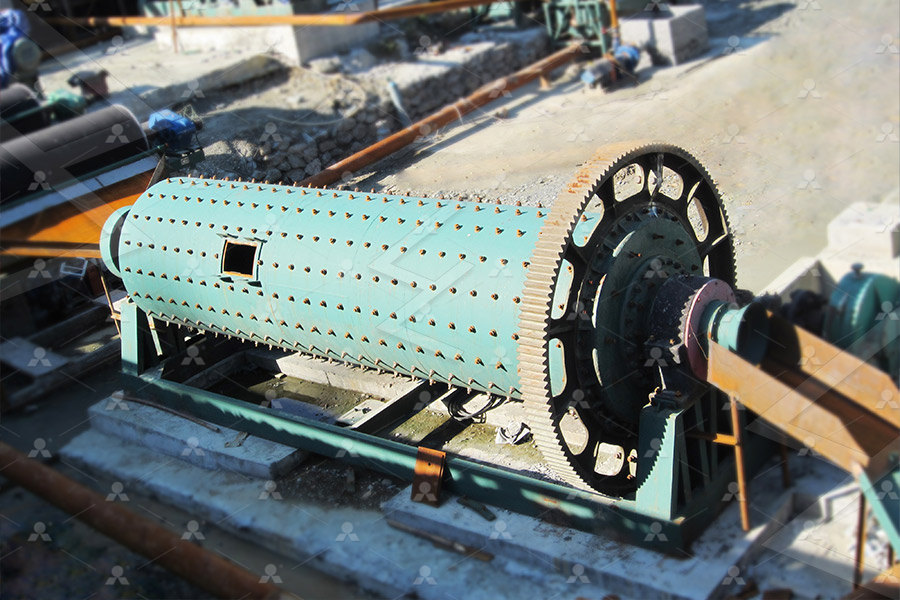

Application of ball mills in the coal industry

1 Coal Grinding for Combustion: Ball mills are commonly used in the coal industry for the grinding of coal prior to combustion in power plants and other industrial applications The fine grinding process increases the surface area of coal, enhancing its reactivity and burn rateTo convert raw coal into fine coal powder, coal grinding mills are essential Coal grinding mills are specialized equipment designed to break down coal into fine particles suitable for combustion The coal grinding process involves crushing and grinding coal into small particles, which are then heated to high temperatures in a furnace, producing steam that drives a turbine to generate What is a Coal Grinding MillSection of coal bowl mill Table 1 Guaranteed coal conditions for mill performance evaluation Coal Moisture % 20 Coal HGI 55 Mill Outlet Temperarure °C 80 Mill Air Flow T/hr 102 Coal Fineness (% passing trough 200 mesh) 70% passing through 200 mesh and 90% passing through 50 mesh Differental Pressure 300 mmwc Coal Output from Mill 609 t/hrA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill The raw coal is pulverized in the vertical cylindrical mill, and the pulverized coal is lifted to a powder separator by another bucket elevator The powder separator consists of a centrifugal rotor, 6 cyclones and a selfrecycling pneumatic system Large size particles return to the mill, and fine powder is collected by cyclones and thenCoal Pulverization System: Explosion Prevention and Process

How does a Coal Mill Work? ball mills supplier

A pulverizer coal mill works by grinding coal into a fine powder and then drying it in a hot air fan The coal powder is then blown into a combustion chamber where it is burned to generate heat The hot gases and heat energy produced from burning the coal powder then pass through a series of heat exchangers where the heat is transferred to water to produce steam2024年11月1日 Some analysts predict a decline in US thermal coal exports in 2024, Central Appalachia and Illinois Basin coal price indications show mixed sentiment for 2024, while Powder River Basin prices are likely to a comprehensive manufacturer and supplier in the coke and fine chemical industries, is extending its global reach Coal News Price Data – January 3, 2024 – US Thermal Exports HSN Code Product Description; 8474: Machinery for sorting, screening, separating, washing, crushing, grinding, mixing or kneading earth, stone, ores or other mineral substances, in solid (including powder or paste) form; machinery for agglomerating, shaping or moulding solid mineral fuels, ceramic paste, unhardened cements, plastering materials or other mineral products in Search HSN code for Coal Mill Machinery Parts in India Export coal raw materials into fine coal powder to get perfect combustion in the furnace In the operation of 4 coal mill units, signal of the outlet coal powder flow of the coal mill was constructed as a new output control target of the pulverizing system [1] To obtain massive fault sample data effectively, basedCoal IJSER

.jpg)

Sustainability of coal mines: Separation of clean coal from the fine

2021年1月31日 Experiments were conducted with alkali concentration of 10%20% with a step of 5%, reaction temperature of 140 o C160 • C with a step of 10 • C, and reaction time of 30 min60 min with a step The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40% Therefore, the ball mill should have a drying function besides grindingCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill3 天之前 Find Coal Powder manufacturers, Made from fine quality cooking coal, the Coal Powder is brownish black in color Henan Zhongyi Import And Export Co, Ltd Get Best Price FragranceFree Black Coal Powder Used As A Cooking Fuel 150 INR By: Purushottam Traders Coal Powder Manufacturers, Suppliers, Dealers Prices TradeIndiaVertical pulverized coal mill integrates grinding, homogenization, drying, powder selection and conveying functions Due to its simple structure Petroleum Coke Vertical Roller Mill, Powder Paint Grinding Mill From China Supplier, Mill What is the process flow of vertical mill to produce

Improving Coal Pulverizer Performance and Reliability Pall

Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more efficient combustion Combustion Engineering 783RP BowlMill Coal Pulverizer enclosed chamber with wear resistant plates The hammers impact Coal Milling • 43t/hr processing –coal is ground to fine powder (75% thro’ 75micron) • Coal CV ~24MJ/kg • Brittle material • Mill inlet temp ~ 260300°C • Outlet temp target 90°C Biomass Milling • 50t/hr target throughput (giving similar heat input to coal) • Wood pellets are broken back to constituent particlesCoal to Biomass Conversion Institution of Mechanical EngineersTherefore, coal powder preparation has become an important part of cement production, and coal mill has also become a crucial machine in cement plants 62 Airswept coal mill in thermal power plants Coal powder combustion is often used in modern AirSwept Coal Mill of High Quality Fote MachineryBatubara yang siap digunakan ini dinamakan fine coal yang digunakan menjadi bahan bakar burner dan calciner yang terdapat pada rotary kiln, dan udara bersih akan dihisap oleh fan coal mill dan Technical specifications of vertical roller coal mill

.jpg)

HighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresBy pulverizing coal to a fine powder, the ball mill ensures that all particles are uniformly sized, making it easier to transport, store, and combust Furthermore, coal pulverization increases combustion efficiency, reduces emissions, and enhances drying and heatingHow Is Coal Pulverized in a Ball Mill?1The raw coal magnetically separated after coarse crushing; 2Coal going to coal supply machine from hopper; 3Coal going to grinding chamber with hot dry air; 4Broken coal going to a swirl wind separator through the primary wind generated by mill itself 5Fine coal combusting in burner after transmitted through a pipelineHigh Efficient Fan Pulverized Coal Mill Coal Mill and Fan Coal MillThe resulting product, COKE, consists principally of Carbon with sizes ranging from basketballs (foundry coke) to fine powder (coke Hematite Powder Cementing Grade Hematite Powder Fly Ash GRANULATED BLAST FURNACE SLAG Laterite Iron Ore Imported Coal Quartz Mill Scale Dolochar Coal bentonite Gypsum LOW ASH METALLURGICAL COKE 2018 Nilkanth LOW ASH METALLURGICAL COKE Nilkanth Exports

A unified thermomechanical model for coal mill operation

2015年11月1日 The coal mill grinds the raw coal into fine powder and hot air entering the mill dries and carries the pulverized coal to the burners of the furnace Maffezzoni (1986) emphasized that coal mills are the primary cause of slow load following capability and regular plant shutdownsCoal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thBest Practices and Precautions Coal Mill Safety, Explosion and Decision Support System for Coal Mill Fault Diagnosis in CoalFired Steam Power Plant Joga Dharma Setiawan1, *, Ronny Cahyadi Utomo1, 2, equipment that processes coal raw materials into fine coal powder to perfect combustion in the furnace In the operation of 4 coal mill units, delay and selfcombustion often occurred due to using LowRankDecision Support System for Coal Mill Fault Diagnosis in Coal 2020年8月12日 Batubara yang siap digunakan ini dinamakan fine coal yang digunakan menjadi bahan bakar burner dan calciner yang terdapat pada rotary kiln, dan udara bersih akan dihisap oleh fan coal mill dan An investigation of performance characteristics and

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 With a ball mill 1 To pulverize crushed coals in a ball mill, you start by feeding the mill with crushed coal Then the grinding media crushes and grinds the coal in the rotating chamber 2 Airflow carries the pulverized coal out of the ball mill 3 Next, you'll need to use the mill classifier to separate the fine coal particles from the airflow2022年9月13日 Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill Coal gangue powder is widely used in the construction field +17 [ protected] language the vibrating feeder evenly sends small pieces of coal gangue into the ultrafine grinding millCoal gangue ultrafine powder millThe introduction of hot air helps to improve the drying effect of coal powder and carries coal powder into the coal mill shell during the coal grinding process Coal Powder Conveying System The pulverized coal conveying system is used to transport pulverized coal from the pulverizer to the target location, such as a combustion furnace or a pulverized coal storage binAir Swept Coal Mill Cement Plant Equipment Coal Grinding MillCoal Mill: The heart of the system, where raw coal is pulverized into a fine powder Various types of mills, such as ball mills, vertical roller mills, and hammer mills, can be used depending on the specific requirements of the application Storage Bin/Silo: Pulverized coal is temporarily stored in a bin or silo before being fed into the furnaceIndirect Firing Coal Grinding Systems: Enhancing Efficiency and

.jpg)

Coal Dust Explosion Protection: Ensuring Safety in industries using

Coal dust explosions are among the severe hazards in industries using coal, posing significant risks to personnel and infrastructure These explosions occur when fine coal particles become airborne and come into contact with a heat source in an enclosed environment, leading to a rapid combustion event Given the catastrophic potential of such incidents, robust measures for coal Raw Coal Inlet: Raw coal from the coal storage area is fed into the coal mill through a conveyor system Grinding: The raw coal is crushed by rollers or balls against a rotating horizontal grinding table The grinding process reduces the coal to a fine powder, which is necessary for efficient combustion in the furnaceHow does a coal mill work?1 Coal Grinding for Combustion: Ball mills are commonly used in the coal industry for the grinding of coal prior to combustion in power plants and other industrial applications The fine grinding process increases the surface area of coal, enhancing its reactivity and burn rateApplication of ball mills in the coal industry