Design a kaolin powder preparation process system

Design and implementation of a kaolin feeding system for a tire

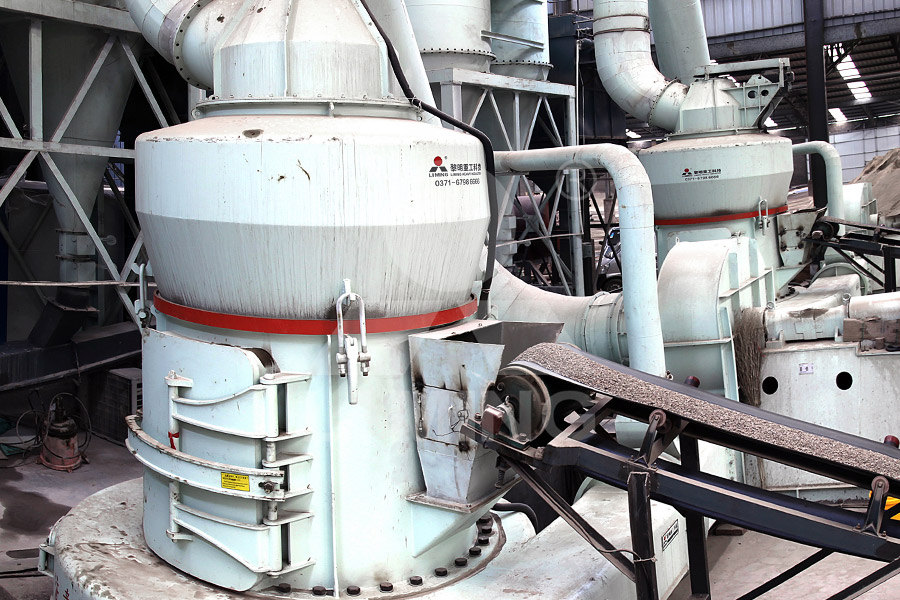

The article presents a research project for tire manufacturing company which is to design an automated kaolin feeding system to disperse 20 grams or less of kaolin powders that can beHosokawa Micron offers excellent processing solutions for drying and mixing kaolin, for example for the production of fillers, pigments, ceramic products, concrete additives or pharmaceutical PROCESS SYSTEMS FOR KAOLIN POWDER Hosokawa Micron BV2024年11月1日 Kaolin membranes are a promising, affordable, and efficient solution for treating oily wastewater Kaolin functions as a supportive substrate, primary separation layer, or Preparation, characterization, and applications of kaolin/kaolin 2016年11月2日 Superfine powder engineering is an important part of the development of modern science and technology, so there are some new materials, new products, effectively Process and Equipment for Deep Processing of Kaolin Ultrafine

The processing of kaolin powder compact Semantic Scholar

In the present study, a kaolin powder was used as the starting material, water or organic solvent was employed as the milling medium, and subsequently dried and formed by the diepressing 2001年1月1日 The disc of compacted kaolinite powder was heated with constant rate of heating (CRH) from 025 to 10 °Cmin − 1 up to 1400 °C The parameters of kinetic triplet were The processing of kaolin powder compact ScienceDirect2001年1月1日 In the present study, a kaolin (Al 2 O 3 2SiO 2 2H 2 O) powder is employed as the starting material The detailed sequence of chemical reactions during the sintering of The processing of kaolin powder compact ScienceDirectIt is an ultrafine material that produced from firing kaolin material up to 800ºC for 2 h with a heating rate of 5ºC/min; which can modify mechanical and microstructural of alkali activated Simplified kaolin production and processing flow

.jpg)

Process Systems for Kaolin Powder Hosokawa Micron

Our test and process development centre in the Netherlands offers unique possibilities for testing your product to determine the most efficient process, system or plant prior to final design We can provide laboratorylevel as well as productionsized trials Whether you wish to test a single machine or a complete powder processing system, the same skilled and experienced staff are 2021年7月31日 PDF Design and Construction of a Parallel Cyclone System for Kaolin Beneficiation Find, read and cite all the research you need on ResearchGateDesign and Construction of a Parallel Cyclone Materials 2023, 16, 3099 2 of 12 mechanical action at 80 C, a modification which can significantly improve the hydropho bicity of the calcined kaolin The optimum process conditions for kaolin Preparation and Characterization of Modified Kaolin by a 2013年12月1日 This paper discussed the relation between composition design and properties of calcined kaolin geopolymeric powder Geopolymeric powder was produced by applying the geopolymerization processCorrelating Composition Design and Properties of Calcined Kaolin

.jpg)

Using Taguchi experimental design to calculate and analyze

grinding process using a ball mill to obtain kaolin powder with finer granular size Magnetic stirrer (600 rpm) at (60 ± 2°C) was used to mix variable amounts of kaolin (0, 02, 05, 0,6, and 08 g) with polyacrylamide in the presence of deionized distilled water to 2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, chemical treatment (bleaching), etc to remove different impurities The prepared slurry pulp is first desanded by the rake type Kaolinite Processing Equipment, Process Flow, Cases JXSC The production process of kaolin/steel slag particle electrode was as follows: First, the steel slag was cleaned by water, and then the steel slag was ground into powder with a ball mill, kaolin Preparation and electrocatalytic properties of kaolin/steel slag 2021年12月1日 Achieving the high early strength of cementbased materials is a necessary condition for the rapid demolding of prefabricated buildings In this study, kaolin treated by wetgrinding process was utilized as an accelerator in Portland cementWetgrinded kaolinPortland cement system was designed, and 1–4% wetgrinded kaolin was addedPreparation of nanokaolin by wetgrinding process and its

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Process Systems for Kaolin Powder Hosokawa Micron

Our test and process development centre in the Netherlands offers unique possibilities for testing your product to determine the most efficient process, system or plant prior to final design We can provide laboratorylevel as well as productionsized trials Whether you wish to test a single machine or a complete powder processing system, the same skilled and experienced staff are 2021年10月1日 In this study, kaolin treated by wetgrinding process was utilized as an accelerator in Portland cement Wetgrinded kaolinPortland cement system was designed, and 1–4% wetgrinded kaolin was Preparation of nanokaolin by wetgrinding process and its Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the Chemical, Pharmaceutical, Food, Mineral, Cosmetic and Plastic industries Call us at 18005264491Kaolin – Hosokawa Micron Powder Systems2017年1月1日 Extraction of alumina from kaolinite is a welldefined process from long decade After preparation, alumina beads were characterized using powder Xray diffractometer (XRD) which shows major phase Synthesis and characterization of nanosized αalumina powder

Preparation of 5A zeolite monolith granular extrudates using kaolin

Preparation of 5A zeolite monolith granular extrudates using kaolin: Investigation of the effect of binder on sieving/adsorption properties using a mixture of linear andDesign and Implementation of a Kaolin Feeding System for a Tire Mixer Machine Dyg Farah Aidha Binti Awg Idrus1, Douglas Tong Kum Tien1, a), Md Suhaimi Md Yusof 2 1School of Engineering, Faculty of Innovation and Technology, Taylor’s University Lakeside Campus, 47500 Subang Jaya, Malaysia 2Engineering, Preventive Maintenance, Mix Prep, Continental Tyre Design and implementation of a kaolin feeding system for a tire Nanokaolin syntheses from kaolin that extracted of gebel gunna, Sinai, Egypt It is an ultrafine material that produced from firing kaolin material up to 800ºC for 2 h with a heating rate of Simplified kaolin production and processing flow diagram Download scientific diagram Sample preparation showing a kaolin prior to drilling; b drilling process and c reinforced sample ready for testing with four sand columns installed from publication Sample preparation showing a kaolin prior to drilling; b drilling

.jpg)

Kaolinite Clay Beneficiation Process: Kaolin Processing

There are two processes used in industrial production: dry and wet process Usually, hard kaolin is produced by dry process and soft kaolin is produced by wet process Specific kaolinite clay beneficiation processes include washing and sand removal, scrubbing, grading, gravity separation, magnetic separation, and flotation 1 Washing and sand 2024年10月11日 In addition to absorption capacity of kaolin, it has adhesive property Zinc steratc and talc are used as covering agent Magnesium carbonate imparts fluffiness to the powder 1 Aim: To prepare and submit 10 gm of face powder REQUIREMENTS Chemicals:Preparation of Face Powder Labmonk1 Introduction Trichoderma is a commonly used microbial resource for the biological control of plant diseases and the promotion of crop growth []In addition, it plays an important role in the promotion of nutrient utilization, yield, and quality in vegetables and food crops [2,3,4,5]In the preparation process of biocontrol or plant growth promotion agents, the important materials for Preparation of High WaterSoluble Trichoderma CoCulture 34 FTIR analysis Fig 6 shows the IR spectra of kaolin, calcined kaolin, cement powder and the resulted cement paste for various mixture proportions and Table 5 summarizes the main FTIR absorption peaks of kaolin, calcined kaolin, cement powder and the resulted cement paste of various mixture proportionsProcessing and characterization of calcined kaolin cement powder

Turbidity Removal from Kaolin Synthetic Wastewater via

of kaolin synthetic wastewater and compare performance of WTSC with commercial alum via coagulation process Therefore, the usage of sludge in a water treatment plant as a coagulant can be viable 2021年11月25日 A mechanochemical preparation, XRD patterns of kaolin–(NH4)2HPO4 sample system milled at speed 600 rpm for 120 min the milling process, the experiments were run for 10minuteA mechanochemical preparation, properties and kinetic study of kaolin 2023年4月14日 1 Introduction The natural clay mineral kaolin has been used for many years []It is a porous substance primarily made up of kaolinite and is a typical silicate mineral, with a crystalchemical formula of 2SiO 2 Al 2 O 3 2H 2 O [2,3]The ratio of silicon–oxygen tetrahedrons to aluminum–oxygen octahedrons is 1:1 and the two are linked by shared oxygen Preparation and Characterization of Modified Kaolin by a This combined design provides optimal process control and makes it the ultimate powder processing solution With this system, porous agglomerates can be made in a range of from 100 to 1,500 microns with a typical D 50 value between 200 and 700 micronsPowder Agglomeration System Hosokawa Micron

.jpg)

Preparation and mechanism of nano mullite powders from kaolin

Nano mullite powders have been synthesized from calcined kaolin via open hydrothermal process The powder product was characterized by Xray diffraction (XRD) analysis, scanning electron microscopy (SEM), transmission electron microscopy (TEM) with selected area electron diffraction (SAED) analysis 2014年7月25日 Continuous use of the pesticide chlorpyrifos has resulted in harmful contaminations in environment and species Based on a chlorpyrifosdegrading fungus Cladosporium cladosporioides strain Hu01 (collection number: CCTCC M 20711), a fungal wettable powder preparation was developed aiming to efficiently remove chlorpyrifos residues Development of a FreezeDried Fungal Wettable Powder Preparation The following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the mill Kaolin grinding production process November14,2024 The structural design of the trommel screen takes full consideration of the diversity and complexity of garbageKaolin grinding production process LZZG2022年12月30日 Kaolin and marble dust (also noted as marble powder) were obtained from Utelka and Arısu Inc in Turkey, respectively The chemical composition of kaolin and marble powder were examined through Xray fluorescence (XRF) analysis and the results are listed in Table 1 Particle size distribution of kaolin and marble powder are exhibited in Figure 1The effect of marble powder on physico Wiley Online Library

Preparation of glassceramic materials using kaolin and oil well

Preparation of glassceramic materials using kaolin and oil well drilling wastes Danielle CS Spínolaa, Auristela De Mirandab,∗, Daniel A Macedoc, Carlos A Paskocimasa,d, Rubens M Nascimentoa,dOur test and process development centre in the Netherlands offers unique possibilities for testing your product to determine the most efficient process, system or plant prior to final design We can provide laboratorylevel as well as productionsized trials Whether you wish to test a single machine or a complete powder processing system, the same skilled and experienced staff are Process Systems for Kaolin Powder Hosokawa Micron2021年7月31日 PDF Design and Construction of a Parallel Cyclone System for Kaolin Beneficiation Find, read and cite all the research you need on ResearchGateDesign and Construction of a Parallel Cyclone Materials 2023, 16, 3099 2 of 12 mechanical action at 80 C, a modification which can significantly improve the hydropho bicity of the calcined kaolin The optimum process conditions for kaolin Preparation and Characterization of Modified Kaolin by a

Correlating Composition Design and Properties of Calcined Kaolin

2013年12月1日 This paper discussed the relation between composition design and properties of calcined kaolin geopolymeric powder Geopolymeric powder was produced by applying the geopolymerization processgrinding process using a ball mill to obtain kaolin powder with finer granular size Magnetic stirrer (600 rpm) at (60 ± 2°C) was used to mix variable amounts of kaolin (0, 02, 05, 0,6, and 08 g) with polyacrylamide in the presence of deionized distilled water to Using Taguchi experimental design to calculate and analyze 2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, chemical treatment (bleaching), etc to remove different impurities The prepared slurry pulp is first desanded by the rake type Kaolinite Processing Equipment, Process Flow, Cases JXSC The production process of kaolin/steel slag particle electrode was as follows: First, the steel slag was cleaned by water, and then the steel slag was ground into powder with a ball mill, kaolin Preparation and electrocatalytic properties of kaolin/steel slag

Preparation of nanokaolin by wetgrinding process and its

2021年12月1日 Achieving the high early strength of cementbased materials is a necessary condition for the rapid demolding of prefabricated buildings In this study, kaolin treated by wetgrinding process was utilized as an accelerator in Portland cementWetgrinded kaolinPortland cement system was designed, and 1–4% wetgrinded kaolin was addedOur test and process development centre in the Netherlands offers unique possibilities for testing your product to determine the most efficient process, system or plant prior to final design We can provide laboratorylevel as well as productionsized trials Whether you wish to test a single machine or a complete powder processing system, the same skilled and experienced staff are Process Systems for Kaolin Powder Hosokawa Micron2021年10月1日 In this study, kaolin treated by wetgrinding process was utilized as an accelerator in Portland cement Wetgrinded kaolinPortland cement system was designed, and 1–4% wetgrinded kaolin was Preparation of nanokaolin by wetgrinding process and its