Hydraulic ore grinding mill impact force

.jpg)

Ore Grinding SpringerLink

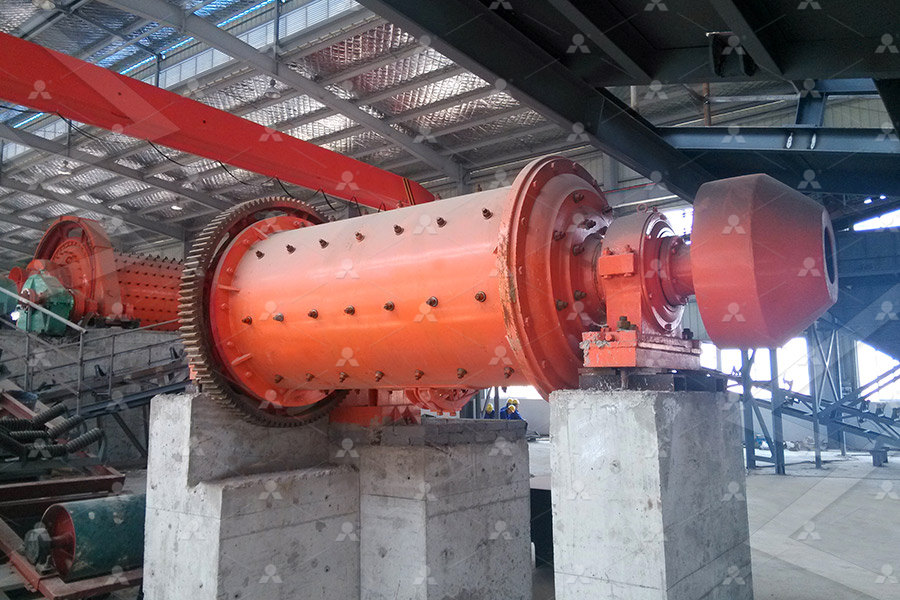

2023年7月20日 With a certain amount of grinding medium in the cylinder, when the cylinder rotates, the grinding medium is fluctuated to produce impact and grinding effects According to the ore discharging method, the grinding mill is divided into overflow type, grating type, and Towards that end, a method of measuring impact forces on ball mill liners using an instrumented grinding ball has been developed Preliminary tests show that impact forces and contact OneMine Measurement Of Impact Forces In Ball Mills2023年8月3日 In summary, the paper proposes for the first time a new grinding analysis method that quantitatively separates and characterizes the grinding contribution of the impact and Grinding Contribution and Quantitative Separation of Impact and 2019年1月16日 Of many physical parameters critical to design of grinding processes, impact of grinding media is among the most difficult to measure or predict Yet impact of falling grinding How to Measure the Impact Forces in Ball Mills

Grinding Contribution and Quantitative Separation of Impact and

In this study, grinding contribution and quantitative separation of impact and grinding mechanism in cylindrical mill were creatively researched, and the grinding technical eficiency of impact and An impact grinding mill is a type of mill that uses impact force to crush and grind materials It is an essential piece of equipment in many industries, including mining, construction, and The application and principle of impact grinding machine2024年11月1日 Compared with comminution technologies such as ball mills, HPGR is characterized by high throughput, low energy consumption, and controllable ore particle size Simulation and analysis of highpressure grinding rolls 2023年10月30日 A variety of operating parameters, such as mill speed, the ball charge composition, charge filling, lifter type, and lifter number, all have a significant impact on ball Analyzing the influence of lifter design and ball mill speed on

Analyzing the influence of lifter design and ball mill speed on

By conducting this study, researchers aim to gain a comprehensive understanding of the effects of new helical lift bar forms and mill speed on the torque, power consumption, particle behavior, 2023年10月10日 Comparative high pressure grinding rolls (HPGR) and cone crusher pilotscale tests were conducted using Upper Group 2 (UG2) platinumbearing ore in order to determine The Effect of HPGR and Conventional Crushing on the Extent of2023年5月24日 Hydraulic stone crusher, also known as a hydraulic cone crusher or hydraulic rock crusher, is a type of crushing machine used to crush stones and rocks into smaller sizes It utilizes hydraulic pressure and a What is Hydraulic Stone Crusher? SBM Mill Crusherface area of the medium, thus affecting the impact force and grinding force of the medium [1718, ] It is not dicult to understand that under ideal conditions, it is not complicated to study the impact of a single medium on the crushing of specific solid raw material particles, whether it is the impact force or the grinding forceGrinding Contribution and Quantitative Separation of Impact and

Hydraulic system vertical roller mill operation PDF

2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the Critical speed is defined as the point at which the centrifugal force applied to the grinding mill charge is equal to the force of gravity ④ The running sound of the grinding mill is dull, and the impact sound of the steel ball cannot be heard 2 The operation of the mill and the grinding of the ore require energy, Grinding Mill Terminology and Usage JXSC Machine2Impact force generation: As the material enters the mill, it is accelerated by a rotating rotor or hammers The rotor or hammers strike the material with high velocity, generating impact force 3Particle size reduction: The impact force breaks the material into smaller pieces, causing the particles to collide with each other and the mill wallsThe application and principle of impact grinding machine2024年7月29日 YGM 75 type Raymond mill Ore Grinding Unit Ships to Morocco ygm75 The equipment increases the grinding force on the material by adding a highpressure spring system to the singlecylinder hydraulic cone crushers, PCX highfine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with YGM 75 type Raymond mill Ore Grinding Unit Ships to Morocco

Impact mill, Impact grinding mill All industrial manufacturers

Find your impact mill easily amongst the 231 products from the leading brands (ZERMA, HUATE, ERDWICH, hydraulic pulverizer D series Grinding mill using completely stainless steel hammers with the possibility of modifying the final granulometry in all cases2023年9月29日 Currently, scholars consider the grinding force modeling mainly from the material, grinding process, grinding wheel wear and other aspects Meng et al [3] established the grinding force model of a new type of microstructure grinding wheel based on the topography model, and found that the addition of microstructure reduced the grinding force by 496 % ~ Mechanical behavior and modeling of grinding force: A Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermillWhen the machine works, the grinding roll, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure ratio is 12 times of Raymond mill given an identical condition, and its output may increase 10% to 20%;Please note that when the grinding roller and grinding ring reach a certain degree of abrasion, please adjust the JoyalHigh Pressure Grinding Mill,High Pressure Grinding Mill

Stone crusher, mobile crusher, grinding mill, ZGM Industrial

ZGM Industry has 20 years of experience in the production and sales of crushers, grinding mills, sand making machines, sand washing machines and mobile crushers All products of the company adopt the latest manufacturing technology and unique structural design According to the different needs of users, we can also carry out production line engineering design for 2020年8月12日 As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperatureAn investigation of performance characteristics and 2022年12月15日 In the present study, size reduction experiments were performed on HighPressure Grinding Rolls (HPGR), ball mill and stirred mill of PGE bearing chromite oreSize reduction performance evaluation of HPGR/ball 2015年3月15日 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2Research of iron ore grinding in a verticalrollermill

Fine Impact Mill for powder making with 7 super features SeFluid

A fine impact mill is a machine designed for reducing particle size by utilizing the impact of highspeed rotating hammers or pins The mill consists of a grinding chamber, a rotor, and a classifier The material to be processed enters the grinding chamber and is subjected to the force of impact between the hammers and the particlesVideo credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide: Types, Features 2024年10月8日 Iron ore is one of the most important minerals in the world, serving as the primary raw material for steel production As demand for steel continues to grow globally, efficient and reliable processes for extracting iron from its ore become crucial Two critical pieces of equipment used in this process are the ball mill and the crusherThese machines play vital Ball Mill and Crusher for Iron Ore in Mineral Processing2019年8月14日 • Peripheral ball mill: Discharge the ore through the periphery of the cylinder The wet ball mill forms the closed circuit operation with the hydraulic classification equipment in the closed circuit system The impact breaking force, the grinding capacity and the ball mill capacity are relative with the size of steel ballsThe Ultimate Guide to Ball Mills Miningpedia

.jpg)

CLUM Ultrafine Vertical Grinding Mill

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17A damp mill, with its unique structure, can efficiently grind the material containing certain moisture It has three main features: forced feeding, peripheral discharging, and rubber lining As the main equipment in iron ore pelletizing plants, a damp mill is mainly used for the damp grinding of iron ore to provide materials for the pelletizing Damp Mill – Ball Grinding Machine Iron Ore Pelletizing EquipmentEnergysaving Grate Ball Mill Wet type, rolling bearing Capacity: 160t/h Application: Commonly used for grinding coarsegrained ores The wet energysaving grate ball mill utilizes groovetype circular lining plates, which increase the contact surface between balls and ores, enhancing the grinding effect and improving ore lift capability, thus reducing energy consumptionGrinding Mill Equipment for Mining Ore ProcessingImpact mills are the most common type of mill, and use a hammer to hit the grinding media against a stationary steel disc This action causes the media to break down into smaller pieces Vertical mills operate in a similar way, but the media is instead forced down by gravity toward the grinding surfaceFactors affecting ores grinding performance in ball mills

CrusherJaw crusherImpact crusherCone

Mineral Grinding Solutions Kaolin grinding mill The finished particles demonstrate a high level of consistency in their fineness Bauxite ore grinding plant Utilized to reduce particle sizes and separate minerals from waste Find your impact mill easily amongst the 231 products from the leading brands on DirectIndustry, Raw materials will be ground via the force of cutting, impact, innumerable high speed vortex and high frequency vibratory HGM Series Superfine Grinding Mill Processing capacity: 0440t/h Feeding size:≤20≤40mm Applied material: Impact mill, Impact grinding mill All industrial manufacturers2019年3月13日 Impact mill, also known as impact grinder, impact pulverizer, impact microizer,impact hammer mill, impact crusher, impact Machine It contains a wide variety of powder mill, such as: vibration mill, hammer mill, roller/rolling mill, Turbo Mill, Pin Mill, Wide cavity grinding, etc Dynamic impact would occur when material is dropped into a chamber where it Impact Mill ALPA Powder Technology2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Friction and wear of liner and grinding ball in iron ore ball mill

.jpg)

Grinding Media in Ball MillsA Review ResearchGate

Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Excellent low cost grinding mill, stone grinding machine, grinding equipment and crushing equipment used in quarry are made by Clirik in China for stone, ore and mineral grinding, crushing, dressing, recycling with advanced technology and good aftersales service Welcome to enjoy our productsGrinding Mills, Crushers,Stone Grinding equipment and crushing 2017年7月31日 1 Introduction A ball mill (Figure 1) is the key piece of equipment for secondary grinding after crushing and is suitable for grinding all types of ores and other materialsBall mill are used in the mining, cement, chemical and agricultural industries, particularly tumbling ball mills [1,2,3,4]The comminution process is dependent on the rotation of the mill to lift the grinding Impact Load Behavior between Different Charge and Lifter in a In the work, as an object of modeling, we selected mill type MSHTS 5500 × 6500, used for grinding apatitenepheline ore, with the following technical characteristics: mill capacity Q = 300–310 t/h, drum diameter without lining D = 5500 mm, drum length L = 6500 mm, the working volume of the mill V = 140 m 3, ball loading m = 275–285 tons, degree of ball loading φ = Development MPC for the Grinding Process in SAG Mills Using

What is Hydraulic Stone Crusher? SBM Mill Crusher

2023年5月24日 Hydraulic stone crusher, also known as a hydraulic cone crusher or hydraulic rock crusher, is a type of crushing machine used to crush stones and rocks into smaller sizes It utilizes hydraulic pressure and a face area of the medium, thus affecting the impact force and grinding force of the medium [1718, ] It is not dicult to understand that under ideal conditions, it is not complicated to study the impact of a single medium on the crushing of specific solid raw material particles, whether it is the impact force or the grinding forceGrinding Contribution and Quantitative Separation of Impact and 2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the Hydraulic system vertical roller mill operation PDFCritical speed is defined as the point at which the centrifugal force applied to the grinding mill charge is equal to the force of gravity ④ The running sound of the grinding mill is dull, and the impact sound of the steel ball cannot be heard 2 The operation of the mill and the grinding of the ore require energy, Grinding Mill Terminology and Usage JXSC Machine

.jpg)

The application and principle of impact grinding machine

2Impact force generation: As the material enters the mill, it is accelerated by a rotating rotor or hammers The rotor or hammers strike the material with high velocity, generating impact force 3Particle size reduction: The impact force breaks the material into smaller pieces, causing the particles to collide with each other and the mill walls2024年7月29日 YGM 75 type Raymond mill Ore Grinding Unit Ships to Morocco ygm75 The equipment increases the grinding force on the material by adding a highpressure spring system to the singlecylinder hydraulic cone crushers, PCX highfine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with YGM 75 type Raymond mill Ore Grinding Unit Ships to MoroccoFind your impact mill easily amongst the 231 products from the leading brands (ZERMA, HUATE, ERDWICH, hydraulic pulverizer D series Grinding mill using completely stainless steel hammers with the possibility of modifying the final granulometry in all casesImpact mill, Impact grinding mill All industrial manufacturers2023年9月29日 Currently, scholars consider the grinding force modeling mainly from the material, grinding process, grinding wheel wear and other aspects Meng et al [3] established the grinding force model of a new type of microstructure grinding wheel based on the topography model, and found that the addition of microstructure reduced the grinding force by 496 % ~ Mechanical behavior and modeling of grinding force: A

.jpg)

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateWhen the machine works, the grinding roll, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure ratio is 12 times of Raymond mill given an identical condition, and its output may increase 10% to 20%;Please note that when the grinding roller and grinding ring reach a certain degree of abrasion, please adjust the JoyalHigh Pressure Grinding Mill,High Pressure Grinding Mill