Kaolin processing technology and methods

Kaolin: processing, properties and applications ScienceDirect

1991年9月1日 This review outlines the geology and occurrence of kaolins in the world and the state of the art in processing highquality kaolins The physical and chemical characteristics of 2024年10月8日 Advanced catalytic approaches are crucial for efficient asphaltene removal and the conversion of heavy feedstocks into valuable light fractions Kaolin, an aluminosilicate mineral, has emerged as a key precursor Transforming Petrochemical Processes: CuttingEdge 2014年6月1日 Ore processing consists of removing impurities, engineering particle size and shape, and enhancing certain properties through thermal and chemical treatment In addition Mining and Processing Kaolin Elements GeoScienceWorld1980年10月1日 Innovative and efficient process developments enabled the kaolin industry to wet process over 5,000,000 tons in 1978 in Georgia and over 3,000,000 tons in the Cornwall Major kaolin processing developments ScienceDirect

How is Kaolin Clay Mined and Processed?

2024年8月8日 Discover advanced methods in kaolin mining and processing Learn how modern techniques ensure highquality kaolin with minimal environmental impactKaolin processing technology 1 Dry process The dry process of kaolin generally includes several steps: crushing, drying, fine grinding, and air flotation This process can remove most of the Kaolin Dry And Wet Processing Technologythe kaolin processing technology is evaluated by comparing the processed kaolin with the kaolin ore (from granite and pegmatite) and ROM Samples were analyzed for major elements, The influence of parent rock, mining and processing technologies Technology development for the processing of kaolin is essentially the development for sequentilised flow sheet for its beneficiation so that all unwanted impurities are removed and Technology development for kaolin processing eprints@NML

Kaolin to HPA processing technologies InterGroup Mining

Kaolin to HPA processing technologies are achieving 9999% purity Besides lower production costs, these disruptive processing technologies have a big advantage in using lowcost low 2015年1月1日 The new technology was introduced in Vetovo processing plant decreasing the losses of kaolin in final tailings Two stages granulometric separation flowsheet Hydrocyclone test Ø45 mm(PDF) KAOLIN RECOVERY FROM PROCESSING TAILS 2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, Kaolinite Processing Equipment, Process Flow, Cases 2019年12月7日 Methods: To address this challenge, this study was conducted to assess the effect of wet processing and oxalic acid treatment in the removal of iron oxide bearing impurities from Alkaleri and Refinement of Nigerian Kaolin by Wet Processing and

The influence of parent rock, mining and processing technologies

processed kaolin show the wet processing method brought substantial improvement in the quality of the kaolin (Al 2 O 3 increased by nearly 98% and SiO 2 decreased by 36% with respect to the RunOfMine) Had the feed kaolin ore not been diluted, the kaolin concentrate would have been better than what is achieved through the adopted processing 1991年9月1日 This review outlines the geology and occurrence of kaolins in the world and the state of the art in processing highquality kaolins The physical and chemical characteristics of kaolin are also reviewed with respect to their use for specific applications in paper, ceramics and refractories, plastics, rubber, adhesives and paint industriesKaolin: processing, properties and applications ScienceDirect(DOI: 101016/03017516(80)900228) This article is published in International Journal of Mineral Processing The article was published on 01 Oct 1980 The article focuses on the topics: Slurry DewateringMajor kaolin processing developments (1980) Haydn H Murray2023年6月4日 Kaolin clay, also called China clay, is mined using opencast methods and blended with water to create a slurry Processing begins with physical separation, using wet ball milling or vibratory milling to isolate ceramic particles and remove unwanted byproducts During this step, bleaching may be applied to improve qualitykaolinite processing and nano particle characteristics

.jpg)

All Steps in Kaolin Production Mining and Processing Explained

2021年8月27日 Kaolin is the deposit of naturally occurring minerals containing hydrated aluminum silicates Widely known as white clay or china clay, these minerals have desirable properties crucial for industrial and commercial applicationsFor that reason, the kaolin mining and processing steps thoroughly put the nature of the crude deposits and the enduse of the 2024年5月24日 The main methods include acid leaching, chlorination, alkali treatment, reduction, oxidation and redox combined methods 2 Kaolin ultrafine processing The main methods for ultrafine processing of kaolin are: mechanical crushing method, classification method, intercalationpeeling method and chemical synthesis method The mechanical crushing Kaolin purification and modification processing technology2012年3月1日 Ravishankar, SA, 2008, "Magnetic Enhancer Technology for impurities separation in kaolin processing," Cytec Solutions, Volume 14, March 2008, pp 14 Emerging Technologies Mining Chemical Chemically enhanced magnetic separation technologies for kaolin processing2023年4月12日 Kaolin processing technologyseveral methods of removing iron from kaolin Xinhai (203) 24hour service hotline +85 If you have any questions, please contact us through the following ways, we will give you more and better assistance Kaolin processing technologyseveral methods of removing iron from kaolin

.jpg)

Kaolin trade technology project information PPT

2020年11月16日 There are two main processes for processing kaolin ore dry and wet processes The dry process produces hard kaolin while the wet process produces soft kaolin The wet process involves several stages including ore 2024年5月29日 Nigeria's mining industry is experiencing a surge, and kaolin processing is emerging as a golden opportunity for investors Kaolin, a versatile industrial mineral, finds applications in various products, from ceramics and paints to plastics and pharmaceuticals Here's why investing in kaolin processing in Nigeria is a strategic move: Thriving Domestic Market: Kaolin Processing: A Golden Opportunity in Nigeria’s Booming The production process features the separation of kaolin from quartz and feldspar by dry and wet processing The plant equipment consists mainly of: Mining equipment, crusher, roller with classifier, attritioning cells, hydrocyclones, thickener, bleaching equipment, filter press, dryerpulverizer, baggingKaolinProcessing, Technology, Applications, Equipment This is a complete kaolin processing plant, including a feeder, belt conveyor, spiral washer, attrition scrubber, trommel screen, wheel washer, dewatering screen, hydrocyclone, thickener, and filter press Flowchart Explanation Of Kaolinite clay processing plant Use a forklift or excavator to feed the raw materials to the hopper, through an electromagnetic vibrating feeder Kaolinite Clay Beneficiation Process: Kaolin Processing

.jpg)

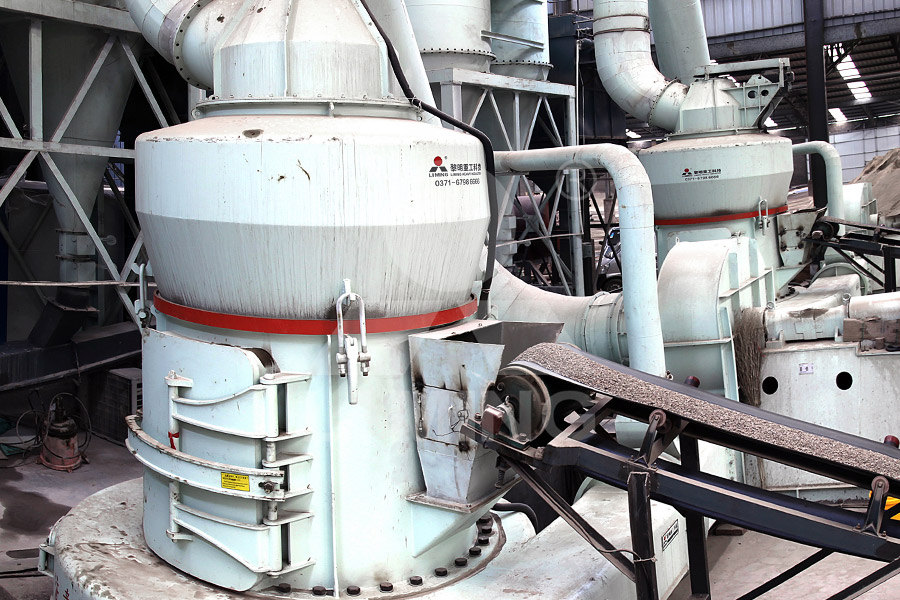

Brief introduction of kaolin deep processing equipment and technology

In the deep processing industry of kaolin, Contact; Get A Quote Brief introduction of kaolin deep processing equipment and technology Home / News K3 Series Portable Crushing Plant VU the dry method is to preliminarily crush the extracted raw ore to about 25 mm by selecting jaw crusher with 2001200 mm feeding particle size or impact 2018年7月9日 The kaolin deposits are located on lowrelief plateaux with a lateritic cap The kaolin strata are in the Ipixuna Formation of Upper Cretaceous Age There are two distinct kaolin layers, a 4–5 m thick soft kaolin which is overlain in the southern portion of the basin by a 4–5 m thick hard kaolinMining, processing and applications of the Capim Basin kaolin, bentonite processing, SCC 305045 for fuller’s earth processing, and SCC 305046 for common clay and shale processing Clays are categorized into six groups by the U S Bureau Of Mines The categories are kaolin, ball clay, fire clay, bentonite, fuller’s earth, and common clay and shale Kaolin, or china clay,1125 Clay Processing US EPA3 Coalbearing kaolin wet process Coalbased (hard) kaolin is a unique kaolin resource in my country Currently, the production basically adopts the processing technology of first ultrafine and then calcination or first calcination and then ultrafine processingKaolin Dry And Wet Processing Technology

.jpg)

Analysis of 8 Whitening Methods for Kaolin MC

The flotation whitening technology is suitable for processing kaolin raw materials with high impurities and low whiteness, and can significantly improve the whiteness and purity of kaolin 4 Coloring Bleaching Color bleaching is the process of adding a white agent to kaolin to cover its surface, thereby increasing its whitenessSo, we need kaolin processing plant machinery Kaolin Processing Plant The beneficiation processing of kaolin can be divided into dry processing and wet processing Dry processing method Generally, the dry processing method is to crush the mined raw kaolin ore to about 25mm through the crusher and feed it into the cage crusher to reduce the Kaolin Processing Plant MachineryAn article to understand the kaolin beneficiation, purification and fine processing methods漳州仲揆新材料科技有限公司At present, kaolin beneficiation An article to understand the kaolin beneficiation, purification and This paper reviews production trends, reserves of crude kaolin and technological chang es in the mining and processing of kaolin in the Czech Republic for the past 17 years 1 Methods Essential data and information were provided by the Mineral nformation System of iDevelopment of kaolin production, reserves and processing in

.jpg)

Research on Processing Technology of Calcined Kaolin Powder

The prepared kaolin was obtained from mechanical method The prepared kaolin has the characteristics of fine size and high specific area [1112] The Chinese processing technic for grinding kaolin has a distance to the national level [13] However, the grinding method has obtained a notable progress in China2024年6月19日 However, throughout the years, the kaolin mining industry has improved its understanding of mining and processing methods It leads to innovative approaches that can be beneficial for business Kaolin products In Conclusion It’s important to note that kaolin processing methods differ based on the quality and its intended useKaolin: The Comprehensive Guide To Mining And Processingm51608C; and processing temperature 200–2208C) To prepare the polymer nanocomposites highly crystalline kaolin supplied by Sigma Aldrich (K7375) was used as filler (chemical composition: 4654% SiOEffect of kaolin nanofiller and processing conditions on the 2020年4月14日 The first demonstration production line with suspension calcining technology has been completed in China The design, construction process and the first trial calcining kaolin clay production results show: (1) The suspension calcining technology can meet the processing requirements of raw materials with different moisture contents (2)Research and Design of Suspension Calcining Technology and

Scalable automation solution optimises process at kaolin processing

Combined with the high quality of the ore reserve, the K99 process delivers highquality, ultrabright kaolin at a lower cost than conventional chemical bleaching and magnetic separation processing WA Kaolin has constructed a Stage 1 commercial processing plant on a threehectare site in Wickepin, about 200 km southeast of Perth, Western 2005年1月21日 Conceptually, dry processing is the simplest processing route, by which the clay, feldspar, and quartz are mixed di rectly with tap water3539,40 The amount of water varies with(PDF) Porcelain—Raw Materials, Processing, Phase Evolution, and The processing technology of kaolin varies depending on the nature of the raw ore, product use and product quality kaolin The main methods include acid leaching, chlorination, alkali treatment, reduction, oxidation and redox combined methods 2 Kaolin ultrafine processing The main methods for ultrafine processing of kaolin are: Kaolin processing technology2015年1月1日 The new technology was introduced in Vetovo processing plant decreasing the losses of kaolin in final tailings Two stages granulometric separation flowsheet Hydrocyclone test Ø45 mm(PDF) KAOLIN RECOVERY FROM PROCESSING TAILS

.jpg)

Kaolinite Processing Equipment, Process Flow, Cases

2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, 2019年12月7日 Methods: To address this challenge, this study was conducted to assess the effect of wet processing and oxalic acid treatment in the removal of iron oxide bearing impurities from Alkaleri and Refinement of Nigerian Kaolin by Wet Processing and processed kaolin show the wet processing method brought substantial improvement in the quality of the kaolin (Al 2 O 3 increased by nearly 98% and SiO 2 decreased by 36% with respect to the RunOfMine) Had the feed kaolin ore not been diluted, the kaolin concentrate would have been better than what is achieved through the adopted processing The influence of parent rock, mining and processing technologies 1991年9月1日 This review outlines the geology and occurrence of kaolins in the world and the state of the art in processing highquality kaolins The physical and chemical characteristics of kaolin are also reviewed with respect to their use for specific applications in paper, ceramics and refractories, plastics, rubber, adhesives and paint industriesKaolin: processing, properties and applications ScienceDirect

Major kaolin processing developments (1980) Haydn H Murray

(DOI: 101016/03017516(80)900228) This article is published in International Journal of Mineral Processing The article was published on 01 Oct 1980 The article focuses on the topics: Slurry Dewatering2023年6月4日 Kaolin clay, also called China clay, is mined using opencast methods and blended with water to create a slurry Processing begins with physical separation, using wet ball milling or vibratory milling to isolate ceramic particles and remove unwanted byproducts During this step, bleaching may be applied to improve qualitykaolinite processing and nano particle characteristics 2021年8月27日 Kaolin is the deposit of naturally occurring minerals containing hydrated aluminum silicates Widely known as white clay or china clay, these minerals have desirable properties crucial for industrial and commercial applicationsFor that reason, the kaolin mining and processing steps thoroughly put the nature of the crude deposits and the enduse of the All Steps in Kaolin Production Mining and Processing Explained2024年5月24日 The main methods include acid leaching, chlorination, alkali treatment, reduction, oxidation and redox combined methods 2 Kaolin ultrafine processing The main methods for ultrafine processing of kaolin are: mechanical crushing method, classification method, intercalationpeeling method and chemical synthesis method The mechanical crushing Kaolin purification and modification processing technology

Chemically enhanced magnetic separation technologies for kaolin processing

2012年3月1日 Ravishankar, SA, 2008, "Magnetic Enhancer Technology for impurities separation in kaolin processing," Cytec Solutions, Volume 14, March 2008, pp 14 Emerging Technologies Mining Chemical