High phosphorus powder grinding calcite ore powder processing process

Phosphate rock grinding process

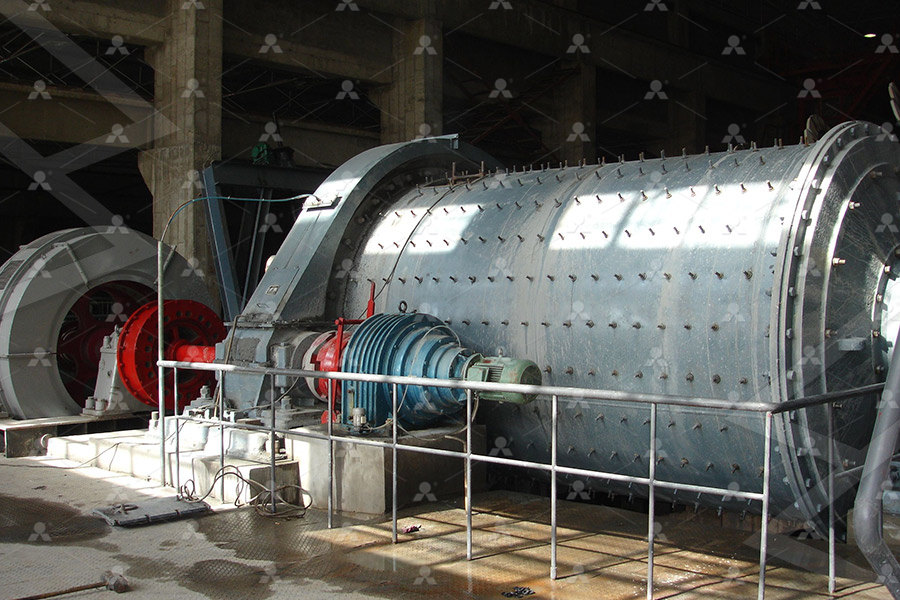

2022年5月16日 In the crushing process, the threestage closedcircuit crushing is a more modern method suitable for the crushing of highhardness phosphate ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding 2021年11月3日 Phosphate ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable Phosphate Mineral Powder Grinding Mill SBM 2024年8月3日 Calcite ultrafine powder preparation process flow The preparation of calcite Calcite ultrafine powder preparation process flow2008年1月31日 Phosphate ores containing high content of organic material as the main Physical and thermal treatment of phosphate ores — An overview

.jpg)

Phosphate rock application and grinding process

2023年2月16日 Crushing and Grinding: The extracted rock is then crushed and ground into a fine powder to prepare it for further processing Beneficiation: The next step in phosphate rock processing is to remove impurities and increase the2019年8月28日 Based on the mineralogical, chemical, material composition, as well as technological research on the possibility of processing phosphate ores, it was concluded that the optimal scheme for the extraction of apatite is a Mineralogical and Technological Aspects of Phosphate 2021年7月31日 In this study, milled ground calcium carbonate (GCC) consisting of calcite is Noninvasive Removal of Phosphorus from Lakes Using Processed Calcite processing mainly includes three steps: crushing, sand making and grinding It has a Calcite Mastery: From Hardness to Powder Processing Techniques

.jpg)

Mineralogical and Technological Aspects of Phosphate Ore

As a result of the grinding process study, it was found that with an increase in the grinding time, 2016年12月1日 In this study, the beneficiation of highphosphorus siderite ore by acid leaching dephosphorization, alkaline oxide reinforced carbothermic reduction and magnetic separation is investigatedBeneficiation of HighPhosphorus Siderite Ore by them, highphosphorus oolitic hematite (HPOH) is a competitive choice since it has a relatively high iron content (average 52%) and a large reserve of 372 9 109 t, accounting for about 7% of the total iron ore resources in China [3, 4] However, HPOH has high phosphorus content and a unique smallparticle oolitic structure, which makesIron recovery and dephosphorization behaviors from highphosphorus Çukurova Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 33(3), ss 225236, Eylül 2018 Çukurova University Journal of the Faculty of Engineering and Architecture, 33(3), pp 225236, September 2018 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 225 Optimization of Wet Grinding Parameters of Calcite Ore in StirredOptimization of Wet Grinding Parameters of Calcite Ore in

Calcite Processing SBM Mill Crusher

2023年4月21日 Calcite processing involves various steps such as crushing, grinding, and classification The process is used to produce highquality calcite powder that is used in various industries such as construction, agriculture, and pharmaceuticals The process also involves the removal of impurities to ensure that the final product is of high purityMechanical activation can improve the effective phosphorus content in phosphate ore powder and increase the practicality of phosphorus in phosphate ore powder (Fang et al, 2019; Shan et al, 2020) The mechanism of mechanical activation of phosphate ore Study on phosphorus release from medium and lowgrade phosphate ore 2022年5月16日 Calcite Grinding Mill; Calcite Powder Production Line; Calcite Vertical Roller Mill +86 Except for some cases, phosphorus in minerals always exists in the form of orthophosphate, Phosphate ore processing and production processPhosphate rock grinding process2 High efficient: Dolomite micro powder grinding mill is equipped with highperformance grinding equipment and classifier This ensures high efficiency in the grinding process, resulting in higher productivity and lower energy consumption than conventional grinders 3Dolomite Micro Powder Grinding Mill

Calcite Ore Crushing Solutions DSMAC

Calcite powder is a natural form of calcium carbonate with extremely high whiteness, purity and free flowing in nature Calcite powder and coated calcite powder has a pivotal role in the modern industrial like plastic, paint, cosmetic, paper, PVC pipe etc Performance characteristics of calcite powder grinder machine The complete configuration of calcite powder grinder machine includes hammer crusher, bucket elevator, storage bin, vibrating feeder, microgrinding host, frequency conversion classifier, double cyclone dust collector, pulse dust removal system, high pressure fan, air compression Machine and electrical control systemcalcite powder grinder machinePowder GrinderCLIRIK ultrafine grinding Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ highquality ore grinding equipment, and perfect service system The main products HGM80 ultrafine mill is used to process 1250 mesh iron oxide powder, with an hourly output of 1 SBM Ultrafine Powder Technology Industrial Grinding Mill, 2022年7月6日 Grinding: The crushed calcite (≤30mm) is lifted to the silo by the elevator and sent to the grinding chamber of the mill for grinding Under the action of the grinding roller and ring, the Calcite Processing: 3 Incredible Technologies You Should Try

.jpg)

Phosphate rock application and grinding process

2023年2月16日 Phosphate rock that has been ground into a fine powder can be used for several purposes, including: Fertilizers: The most common use for phosphate rock is as a source of phosphorus for fertilizers The ground rock is 2023年8月8日 To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration Phosphate Rock Processing: 6 Useful Ways and 4 Stages2023年5月8日 Understanding Dolomite Processing Dolomite processing is a complex process that involves the usage of different techniques and machines The process begins with the extraction of dolomite ore from the ground The ore is then crushed and passed through a separator This is to separate the ore from any unwanted substances or impuritiesProcessing Dolomite: An Overview of Dolomite PowderUltrafine powder deep processing of ore Stable process, high fineness of finished products, low investment cost, high powder yield, low loss of parts, and environmental protection are the six performance advantages of HGM micropowder mill, helping aerospace stealth materials, technical application ceramics, wave absorbing materials Nonmetallic Ore Ultrafine Powder Grinding Plant

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 What are the ore materials that the stone powder making machine is suitable for? Stone powder making machine is suitable for the super fine grinding of all kinds of crisp materials whose Moh’s hardness is below 7, such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory HGM Series Stone Powder Making MachineThis led to a high phosphorus content of DRI This research could provide support to the idea concept for recycling of carboncontaining solid waste and to assist the effective recovery of refractory iron ore by direct reduction–magnetic separation Keywords: dephosphorization; blast furnace dust; coal slime; highphosphorus oolitic hematite Dephosphorization Behavior of HighPhosphorus Oolitic For any questions, please contact with our servicers online You will be most welcome SBM has built calcite processing plant in South Africa and Algeria SBM has offered stone crushers, grinding mills and other calcite powder machinery for grinding calcite into powder SBM had designed calcite mining, crushing, grinding process for quarryingCalcite processing plant design for powder manufacturing by SBM

Grinding plant,Powder processing plant,Powder Grinding

Grinding plant,Powder processing plant,Powder Grinding plant,Stone Grinding plant We are a hightech enterprise and A professional manufacturer of stone powder machine ,stone grinding mill,Located in Pudong New Area, Calcite Powder Manufacturing Process Calcite powder manufacturing process typically involves several stages, 2023年11月26日 The feasibility of dephosphorization using the flotation process and its mechanism of highphosphorus oolitic hematite were discussed in this paper The results showed that phosphorus minerals mainly exist in the form Flotation Dephosphorization of HighPhosphorus Advantages of powder grinding line The grinding technology is very advanced, the machines equipped have high quality, reliable performance, highcost performance, and durable service life The grinding process is simple, the ore Powder Grinding Plant with High Capacity and 2022年4月28日 Solid kalium ore is divided into watersoluble kalium ore and waterinsoluble kalium ore according to its processing properties Waterinsoluble potassium minerals include alumite ore, potassium feldspar ore, potassium Kalium ore powder grinding mill machine

.jpg)

Calcite Grinding Mill/ Calcite Crusher/ Calcite Processing Plant

Calcite powder making plant also suitable for grinding process of other minerals, such as barite, calcite, potassium, feldspar, marble, granite, limestone, basalt Our Customer FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern AsiaIt is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Barite, gypsum, graphite, fluorite, phosphate rock, potassium ore, etc Micro powder grinding mill is double in capacity compare with Energy Micro Powder Grinding Mill2024年8月3日 Calcite ultrafine powder preparation process flow The preparation of calcite ultrafine powder mainly involves the grinding process The following is the general process flow: 1 Raw material selection Selecting highquality calcite ore as raw material is the first step in preparing ultrafine powderCalcite ultrafine powder preparation process flow2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation The optimal process parameters of high pressure grinding roll and magnetic separation were High Pressure Grinding Roll and Magnetic Separation for Energy

The generalized process flowsheet for Pyhäsalmi sulphide ore

Download scientific diagram The generalized process flowsheet for Pyhäsalmi sulphide ore processing from publication: Mineralogical and surface chemical characterization of flotation feed and 2021年1月2日 Phosphorus in high phosphorus oolitic hematite is mainly present in the fluoroapatite, and the temperature of coalbased reduction is generally above 1200 °C, in which case, the fluoroapatite is likely to be reduced together with the iron oxide, causing a large amount of P to beabsorbed into the metallic iron phase [27]In order to reduce the P content in metallic A novel direct reductionflash smelting separation process of 1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing But the degree of largescale is relatively lower compared to vertical grinding mill 2, HLM vertical mill: largescale equipment, high capacity, to meet the largescale production Iron ore grinding mill Grinding plants for Iron Ore2016年12月1日 In this study, the beneficiation of highphosphorus siderite ore by acid leaching dephosphorization, alkaline oxide reinforced carbothermic reduction and magnetic separation is investigatedBeneficiation of HighPhosphorus Siderite Ore by

Iron recovery and dephosphorization behaviors from highphosphorus

them, highphosphorus oolitic hematite (HPOH) is a competitive choice since it has a relatively high iron content (average 52%) and a large reserve of 372 9 109 t, accounting for about 7% of the total iron ore resources in China [3, 4] However, HPOH has high phosphorus content and a unique smallparticle oolitic structure, which makesÇukurova Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 33(3), ss 225236, Eylül 2018 Çukurova University Journal of the Faculty of Engineering and Architecture, 33(3), pp 225236, September 2018 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 225 Optimization of Wet Grinding Parameters of Calcite Ore in StirredOptimization of Wet Grinding Parameters of Calcite Ore in 2023年4月21日 Calcite processing involves various steps such as crushing, grinding, and classification The process is used to produce highquality calcite powder that is used in various industries such as construction, agriculture, and pharmaceuticals The process also involves the removal of impurities to ensure that the final product is of high purityCalcite Processing SBM Mill CrusherMechanical activation can improve the effective phosphorus content in phosphate ore powder and increase the practicality of phosphorus in phosphate ore powder (Fang et al, 2019; Shan et al, 2020) The mechanism of mechanical activation of phosphate ore Study on phosphorus release from medium and lowgrade phosphate ore

Phosphate rock grinding process

2022年5月16日 Calcite Grinding Mill; Calcite Powder Production Line; Calcite Vertical Roller Mill +86 Except for some cases, phosphorus in minerals always exists in the form of orthophosphate, Phosphate ore processing and production process2 High efficient: Dolomite micro powder grinding mill is equipped with highperformance grinding equipment and classifier This ensures high efficiency in the grinding process, resulting in higher productivity and lower energy consumption than conventional grinders 3Dolomite Micro Powder Grinding MillCalcite powder is a natural form of calcium carbonate with extremely high whiteness, purity and free flowing in nature Calcite powder and coated calcite powder has a pivotal role in the modern industrial like plastic, paint, cosmetic, paper, PVC pipe etc Calcite Ore Crushing Solutions DSMACPerformance characteristics of calcite powder grinder machine The complete configuration of calcite powder grinder machine includes hammer crusher, bucket elevator, storage bin, vibrating feeder, microgrinding host, frequency conversion classifier, double cyclone dust collector, pulse dust removal system, high pressure fan, air compression Machine and electrical control systemcalcite powder grinder machinePowder GrinderCLIRIK ultrafine grinding

SBM Ultrafine Powder Technology Industrial Grinding Mill,

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ highquality ore grinding equipment, and perfect service system The main products HGM80 ultrafine mill is used to process 1250 mesh iron oxide powder, with an hourly output of 1