Lithium ore powder processing spodumene ore grinding equipment and process, dehydration

Lithium processing technology Complete solutions that FLSmidth

Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate 2023年11月7日 Spodumene processing and production equipment are used in various stages Spodumene Processing And Production Equipment2023年12月27日 Saltworks’ modular concentrating, refining, and converting (CRC) technologies provide a costefficient and rapid pathway to produce highyield, batterygrade lithium carbonate or lithium hydroxide Both process flows, Hard Rock Spodumene Lithium Processing Saltworks 2019年5月29日 This literature review gives an overview of the lithium industry, including the lithium market, global resources, and processes of lithium compounds production It focuses on the production of lithium compounds Spodumene: The Lithium Market, Resources and

Processing Spodumene by Froth Flotation for

2016年5月9日 Extracting Lithium from its Ore The problems of spodumene mineral dressing depend on the amount of ore deposit, weathering and presence of associated gangue minerals Weathered mineral surfaces must be Spodumene has a theoretical Li2O content of 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentratesHard Rock Lithium Processing SGS2019年8月23日 Lithium batteries are proving to be an effective and affordable alternative to traditional batteries, and also in new battery applications More than 50% of lithium mined is used in batteries This use has recently increased rapidly spurring an increase in lithium mining to provide the lithium for batteriesLithium Processing Equipment, Process Flow, Cases JXSC 2024年7月9日 Lithium ore grinding mills are the devices used to grind lithium ore into fine powder SBM's lithium ore grinding machines are Lithium Ore Processing The process of processing Ore mining 2 Crushing and screening 3 Grinding 4 Ore dressing 5 Calcination 6 Leaching 7 Purification Lithium Ore Processing Equipment Lithium Ore Grinding Mills SBM Ultrafine Powder Technology

Lithium Extraction from Spodumene Ore Process

This SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost 2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?2023年2月1日 The present scenario has urged the necessity to beneficiate and extract lithium from the available resources judiciously Pegmatites constitute the second major economic resource of lithium, after brines, accounting for about 25% of global production [14]The lithiumbearing minerals, hosted by the pegmatite rocks, include spodumene, lepidolite, petalite, Recovery of lithium from spodumenebearing pegmatites: A Key benefits More than 20 years of experience in providing marketleading lithium processing solutions Broad equipment offering and customisable solutions Full lifecycle partnership Cuttingedge technology Additional technologies not offered by other providers Bench and pilot testing facilities Superior pyro processing test facilities worldwideLithium processing technology Complete solutions that

Dry deep screening of spodumene and its mineral processing

2022年3月30日 At the same time, this part of the raw ore is often discarded in the form of tailings or slime, which also results in the waste of resources, to a certain degree, and environmental pollution (Tanhua et al, 2020, Wang et al, 2021a, Wang et al, 2021b, Wang et al, 2021c)By reducing the amount of material entering wet grinding and hydraulic classification, the 2023年4月7日 With the rapid rise of new energy sources, lithium resources have been pushed to a boom in development As a green energy mineral, the most common type of lithium ore is spodumene This blog will focus on spodumene, Green Battery Minerals How to Get Lithium from 2022年10月24日 The Lithium Ore Process Fatty acid or soap flotation of spodumene is one well established recovery method, but pulverized or ground particle surface conditions generally necessitate preflotation Processing Spodumene by Froth Flotation for Lithium Processing The Spodumene concentrate ore is converted into either Lithium Carbonate or Lithium Hydroxide for use as an essential component to make LithiumIon Batteries The process for making Lithium Carbonate is illustrated in Figure 2 A similar flow schematic with different chemical reagents can be used to make Lithium Hydroxide Lithium Processing Spodumene filtration solution

Spodumene Flotation Flowsheet: A Guide to Lithium Ore Processing

To extract lithium from spodumene, a process known as spodumene flotation is used 01 Spodumene Flotation Process The spodumene flotation process starts with the crushing of the spodumene ore into smaller pieces This makes it easier to extract the lithium mineral The crushed ore is then ground into a fine powder and mixed with water to form 2020年4月12日 This SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost (PDF) Lithium Extraction from Spodumene Ore ResearchGate2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, Complete Spodumene Lithium Ore Crushing Grinding Equipment Concentration Plant Lithium Ore Small Scale Mobile Mining Cip Processing Machinery Miner Separator Cil Gold Ore Process Plant $10,00000 $20,00000 Min order Barite Powder Processing Equipment Dolomite Micro Pulverizer Calcium Carbonate Powder Production Line $ Complete Spodumene Lithium Ore Crushing Grinding Equipment

Selection Of Lithium Ore Processing Plant Equipment

2024年4月8日 Suggestion for selecting lithium ore grinding equipment We suggest using a ball mill or vertical mill for grinding lithium ore By crushing the lithium ore in the previous step, the lithium ore and gangue minerals will separate to obtain particles that match the following beneficiation process Suggestion for selecting lithium ore sorting equipmentEquipment and process development services for primary and secondary lithium production While we do not provide equipment for processing lithium brines, FEECO is a leader in advanced thermal processing and agglomeration equipment and supporting services for the processing of lithiumbearing ores, most notably spodumene MATERIAL PROCESSINGLithium Processing Equipment FEECO International Inc2017年10月1日 The carbothermal reduction process of spodumene ore effectively separates Al and Si components from spodumene ore while also extracting lithium (Li) The high valueadded sputum heat reduction A novel approach for flotation recovery of spodumene, mica and 2023年2月27日 In the grinding and classifying stage of lithium ore, in order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and grading process can be adopted, and the first A Comprehensive Guide to Lithium Processing

.jpg)

Processing of lithium ores: Industrial technologies and case studies

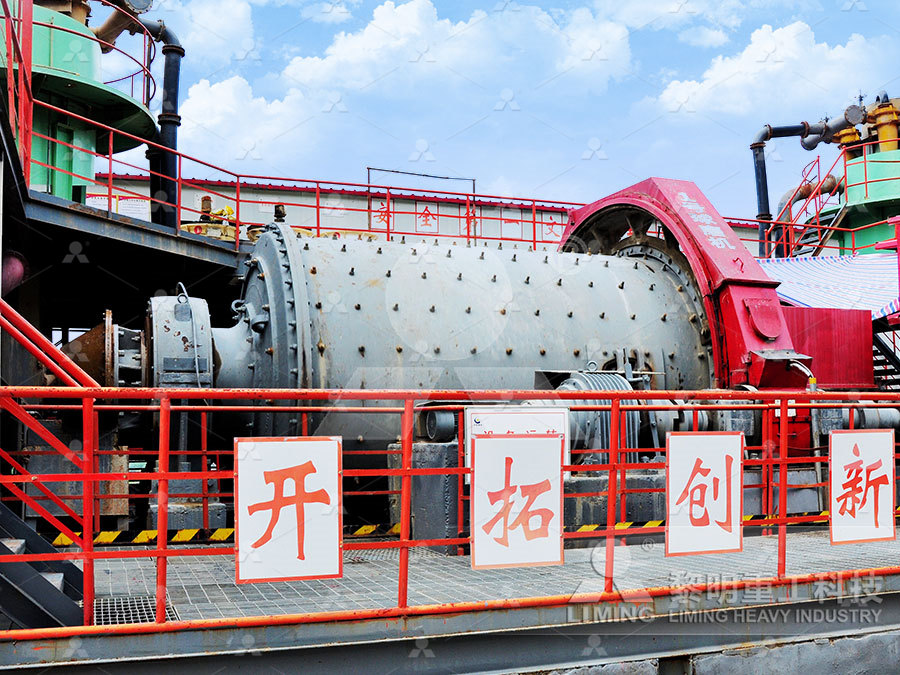

2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007) World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020) Nevertheless, excluding the USA, worldwide lithium production in Request PDF On Mar 1, 2023, Wang Guo and others published Study on the unequalprobability comminution of spodumene and feldspar during the grinding process of lithium ore Find, read and cite Study on the unequalprobability comminution of spodumene 2023年7月18日 01 Spodumene flotation process steps: 1 Crushing and screening: The mined spodumene raw ore is broken into smaller particles for subsequent processing The crushed spodumene ore needs to be further screened, the oversize material enters the grinding equipment, and the undersize material returns to the crushing system for recrushingSpodumene Flotation Process and Successful Case Xinhai2023年5月27日 The role of ball milling in lithium ore processing is to break down the lithiumcontaining minerals and release the lithium ions into the solution This is achieved through the mechanical grinding of the ore, which helps to increase the surface area of the material, making it easier for the leaching solution to penetrate and dissolve the lithium ionsBall Milling in Lithium Ore Processing: A Comprehensive Guide

.jpg)

Lithium ore Beneficiation Jinpeng Mining

Lithium ore processing equipment commonly use: crusher, ball mill, classifier, jig, flotation machine, magnetic separator and so on beneficiation method The beneficiation methods of lithium ore includes hand separation, flotation, gravity separation, hot pressure flotation, magnetic separa tion, chemical beneficiation, magnetic gravity separation flotation, particle flotationLithium Ore Processing Plant Machine, Lithium Ore Processing Plant Machine, Spodumene Beneficiation Mining Plant Design US$10,00000 12 Pieces customers can customize the most effective and scientific beneficiation process and equipment based on the ore properties and investment budget to avoid waste of resources 2Lithium Ore Processing Plant Machine, Spodumene 2023年7月7日 Spodumene, as an important lithium ore resource, has various methods adopted by the concentrator in actual separation Depending on the type of ore, the concentrator will choose different beneficiation methods This article will introduce you to the gravity separation and flotation separation methods of lithium ore spodumene and the equipment used in these two Lithium Ore Spodumene Gravity and Flotation Separation2022年12月13日 After the mining of lithium ore, the bulk material is first crushed by electromagnetic dressing equipment; Then under the action of belt conveyor, it is evenly sent to the grinding machine for deep grinding treatment; After grinding, lithium ore powder should be reasonably screened by spiral classifierHow to mine lithium ore, mineral processing, crushing, grinding

.jpg)

Extraction of Lithium, Lithium Extraction Process, Lithium Ore

For spodumene with a relatively coarse crystal size, the heavymedia beneficiation method can be applied to make lithium ore a heavy mineral productMix the lithium ore after washing and desliming with heavymedia (there are two types of heavy medium: heavy liquid and heavy suspension, here mainly refer to heavy suspension), and feed it into the heavy medium 2019年5月29日 This literature review gives an overview of the lithium industry, including the lithium market, global resources, and processes of lithium compounds production It focuses on the production of lithium compounds Spodumene: The Lithium Market, Resources and 2016年5月9日 Extracting Lithium from its Ore The problems of spodumene mineral dressing depend on the amount of ore deposit, weathering and presence of associated gangue minerals Weathered mineral surfaces must be Processing Spodumene by Froth Flotation for Spodumene has a theoretical Li2O content of 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentratesHard Rock Lithium Processing SGS

Lithium Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 Lithium batteries are proving to be an effective and affordable alternative to traditional batteries, and also in new battery applications More than 50% of lithium mined is used in batteries This use has recently increased rapidly spurring an increase in lithium mining to provide the lithium for batteries2024年7月9日 Lithium ore grinding mills are the devices used to grind lithium ore into fine powder SBM's lithium ore grinding machines are Lithium Ore Processing The process of processing Ore mining 2 Crushing and screening 3 Grinding 4 Ore dressing 5 Calcination 6 Leaching 7 Purification Lithium Ore Processing Equipment Lithium Ore Grinding Mills SBM Ultrafine Powder TechnologyThis SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost Lithium Extraction from Spodumene Ore Process2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?

Recovery of lithium from spodumenebearing pegmatites: A

2023年2月1日 The present scenario has urged the necessity to beneficiate and extract lithium from the available resources judiciously Pegmatites constitute the second major economic resource of lithium, after brines, accounting for about 25% of global production [14]The lithiumbearing minerals, hosted by the pegmatite rocks, include spodumene, lepidolite, petalite, Key benefits More than 20 years of experience in providing marketleading lithium processing solutions Broad equipment offering and customisable solutions Full lifecycle partnership Cuttingedge technology Additional technologies not offered by other providers Bench and pilot testing facilities Superior pyro processing test facilities worldwideLithium processing technology Complete solutions that2022年3月30日 At the same time, this part of the raw ore is often discarded in the form of tailings or slime, which also results in the waste of resources, to a certain degree, and environmental pollution (Tanhua et al, 2020, Wang et al, 2021a, Wang et al, 2021b, Wang et al, 2021c)By reducing the amount of material entering wet grinding and hydraulic classification, the Dry deep screening of spodumene and its mineral processing