Grinding mill operation guide

Ball Mill Grinding Process Handbook

This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, 2023年10月20日 Operating a ball mill requires a deep understanding of its components, principles, and operational procedures By following the guidelines provided in this comprehensive guide, operators can optimize the Comprehensive Guide on Operating a Ball MillGrinding systems with tube mills have been operated throughout the world for many decades Many practical ways to operate these mills in an easy way have been developed and many Operation of Tube Mills ArchiveThe document provides standard operating procedures for grinding mills It discusses four mill operation conditions based on relationships between mill power, pressure loss, and process parameters For each condition, it identifies VRM Operation SOPs PDF Mill (Grinding) Pressure

Operation Manual: HRM1700M Vertical Roller Coal Mill

Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that efficiently separates fine and coarse material The document instructs on installation, The Fine Grinder is always supplied with the mill pulley (Figure 68, 5) mounted and the motor pulley and Vbelts supplied loose (except when motor and base are factory supplied) The FINE GRINDER INSTALLATION, OPERATION, AND MAINTENANCE Ball mills can encounter several problems during operation, such as low grinding efficiency, excessive noise, and worn liners The manual provides a detailed guide on how to identify A Comprehensive Guide to Ball Mill ManualThis is a guide to handheld grinding The information is mainly of a practical nature, intended for operators and others professionally involved with these tools The emphasis is on grinding Pocket Guide to Grinding Technique Atlas Copco

.jpg)

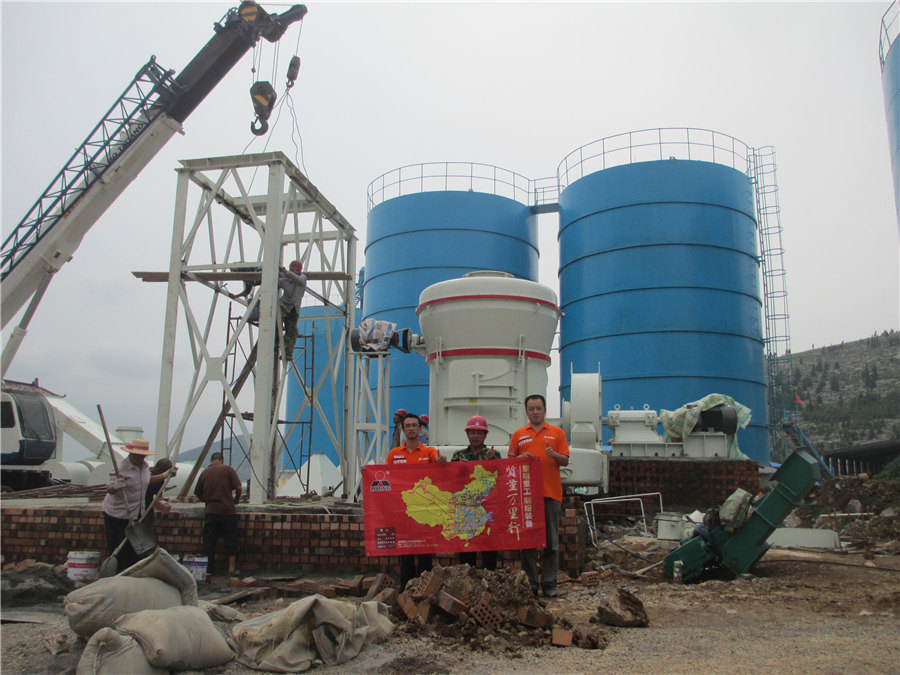

A guide to grinding mill installation: Ensuring efficient and trouble

By following the steps outlined in this guide and seeking guidance from the manufacturer or professionals when needed, you can ensure a successful installation that will lead to efficient Grinding ball mills are indispensable in numerous industries, enabling the fine grinding, mixing, and blending of materials Understanding the principles behind these mills and their The ultimate guide to grinding ball mills: Principles, applications Commissioning Guide Lines Free download as PDF File (pdf), Text File (txt) or read online for free The document provides instructions for commissioning various components of a cement plant, including the raw mill, limestone Commissioning Guide Lines PDF Mill (Grinding)USIM PAC 31 Unit Operation Model Guide Free ebook download as PDF File (pdf), Text File (txt) or read book online for free USIM PAC enables to model and simulate in a single tool the whole industrial transformation raw materials USIM PAC 31 Unit Operation Model Guide

.jpg)

Complete Guide to Lily Extract Grinding Process: Step by Step

10 小时之前 1 Introduction The Lily extract has been widely used in various industries such as food, cosmetics, and pharmaceuticals due to its unique properties The grinding process is a crucial step in obtaining high quality Lily extractThis article will provide a comprehensive guide on the Lily extract grinding process, covering key aspects from equipment selection to quality Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are Ball Mill Grinding Process HandbookBall Mill Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document summarizes different types of mills and their linings used for grinding materials It describes pebble mills which use flint or porcelain balls and can be lined with materials like porcelain, burrstone or rubber It also describes ball mills which use steel or iron balls and have Ball Mill Handbook PDF Mill (Grinding) Natural Rubbergrinding mill clutches However, this control can be effectively applied to other clutch applications Contact your Eaton sales representative for further information 20 GENERAL OPERATION 21 Start Up Monitoring 211 During a mill start, the control monitors the time required to engage the clutch and bring the mill to full RPM (clutch lockup)CP3110 Grinding Mill Slip Detection Control Installation, Operation

.jpg)

Semiautogenous grinding (SAG) mill liner design and development

in variable speed mills, this may be achieved by reducing mill speed; and in both cases this may be achieved by design by increasing the lifter face angle Traditionally, the number of shell lifters used in a SAG mill is equal to twice the number of the feet in the mill shell diameter (eg, a 34ftdiameter mill shell would have 68 shell lifters)Solids Milling Engineering Guide Milling / Grinding / Comminution / Size reduction What is the principle of operation of a jet mill ? Lump Breakers How to deal with lumps in powders ? How to crush lumps ? How is designed a lump breaker ? Top 5 Most Popular 1 Powder Milling and Grinding An Engineering Guide2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill management2024年5月15日 Datadriven operations now Grinding circuits are often equipped with appropriate process sensors to operate, guided by data such as fresh feed tonnage, water addition, specific gravity, mill Empowering grinding mill operation: the impact of datadriven

Cement Plant Operation Handbook PDF Mill (Grinding) Scribd

Cement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for free Cement Plant Operation HandbookThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement Vertical Roller Mill Operation in Cement PlantUnderstanding the operational principles and factors that influence mill performance is crucial for optimizing mill operations and achieving the desired particle size for downstream processes By considering these factors, mining companies can enhance the productivity and costeffectiveness of their grinding mill operationsUnderstanding the operation of grinding mills in the mining and 32 Optimizing Raw Mill Operations Adjusting operational parameters in the raw mill can help control moisture levels and enhance grinding efficiency Key adjustments include: Mill air flow: Increasing the air flow rate through the mill can enhance drying efficiency by carrying moisture away from the materialRaw Mill Moisture Content Management: A Comprehensive Guide

Ball Mill Operation, Inspection Optimization PDF Mill (Grinding

Ball MillOperation, Inspection Optimization Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document discusses parameters for quality finish milling including cement strength, Blaine surface area, and residue percentages It also covers inspection of ball mills including measuring filling degrees, conducting longitudinal testing of material The selection of the appropriate ball mill is critical to ensuring efficient and effective operation or manganese steel to protect the mill walls from wear The grinding media, which are typically made of steel or ceramic materials, are used to crush and grind the materials being processed 2 Selection Guide: When selecting a ball mill, Technical specifications and selection guide for ball millsGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Grinding Mills 911Metallurgist2024年8月22日 Thrufeed grinding excels in highvolume production, infeed grinding offers versatility for complex shapes, and endfeed grinding is ideal for finishing operations and parts with specific end requirements Applications of Centerless Grinding Centerless Grinding can be used on a variety of applications across all industriesCenterless Grinding: A Complete Guide Ripley Machine

.jpg)

Grinding Operations Design Overview PDF Mill (Grinding)

Grinding Operations Design Overview Free download as PDF File (pdf), Text File (txt) or read online for free on empirical data and do not explain the This document provides an overview of grinding concepts and mill operation and design It discusses grinding mechanisms such as impact, chipping, and abrasion It also covers grinding laws proposed by Rittinger, Kick, and VRM operation SOPs Free download as PDF File (pdf), Text File (txt) or read online for free The document provides standard operating procedures for grinding mills It discusses four mill operation conditions based on relationships between mill power, pressure loss, and process parameters For each condition, it identifies potential causes and recommends corrective VRM Operation SOPs PDF Mill (Grinding) PressureThe document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include Operation Manual: HRM1700M Vertical Roller Coal MillVertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary PDF Mill (Grinding) Scribd

.jpg)

Derisk your mill: A practical guide to avoiding catastrophic mill

2024年10月2日 About this event Join our next webinar with Oscar Harrison, Director Product Technical Support, Grinding, as he explores the practical aspects of derisking your millGrinding costs are driven by energy and steel (media, liners, etc) consumption; grinding is the most energyintensive operation in mineral processing On a survey of the energy consumed in a number of Canadian copper concentrators it was shown that the average energy consumption in kWh t −1 was 22 for crushing, 116 for grinding, and 26 for flotation ( Joe, 1979 )Grinding Mill an overview ScienceDirect TopicsThe wet ball mill is usually preferred when the material to be ground is wet, such as in the case of ore processing On the other hand, the dry ball mill is suitable for grinding dry materials, such as cement, limestone, and coal The ball mill diagram is essential for The Ultimate Guide to Understanding Ball Mill Diagrams10 小时之前 1 Introduction The Lily extract has been widely used in various industries such as food, cosmetics, and pharmaceuticals due to its unique properties The grinding process is a crucial step in obtaining high quality Lily extractThis article will provide a comprehensive guide on the Lily extract grinding process, covering key aspects from equipment selection to quality Complete Guide to Lily Extract Grinding Process: Step by Step

The Ultimate Guide to Using a Grain Mill Discover Real Food in

2024年4月1日 Safe Operation and Handling Instructions To ensure safe operation of a grain mill, always read and follow the manufacturer's instructions Keep hands clear of moving parts while the mill is in operation Do not introduce wet grains into the mill, as this can damage the mechanism If milling beans, ensure they are completely dried to avoid Vipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Grinding Mill, Ball Mill // Vipeak Heavy IndustryUser Guide Manuals Brands Chefman Manuals Coffee Grinders Chefman Coffee Grinder Electric Burr Mill Freshly 8oz Beans Large Hopper 17 Grinding Options for 212 Cups, Easy One Touch Operation, Cleaning Brush Included BlackChefman Coffee Grinder Electric Burr Mill Freshly 8ozseparator operationpdf Free download as PDF File (pdf), Text File (txt) or read online for free Separation itself has an essential influence on the grinding performance in the mill Proper functioning is mainly influenced by: 3 3 3 separator adjustment and technical condition, eg Distributor plate speed, number and position of spin rotor blades, wear on fan and spin blades, Separator Operation PDF PDF Mill (Grinding) Particle Size

Commissioning Guide Lines PDF Mill (Grinding)

Commissioning Guide Lines Free download as PDF File (pdf), Text File (txt) or read online for free The document provides instructions for commissioning various components of a cement plant, including the raw mill, limestone USIM PAC 31 Unit Operation Model Guide Free ebook download as PDF File (pdf), Text File (txt) or read book online for free USIM PAC enables to model and simulate in a single tool the whole industrial transformation raw materials USIM PAC 31 Unit Operation Model Guide10 小时之前 1 Introduction The Lily extract has been widely used in various industries such as food, cosmetics, and pharmaceuticals due to its unique properties The grinding process is a crucial step in obtaining high quality Lily extractThis article will provide a comprehensive guide on the Lily extract grinding process, covering key aspects from equipment selection to quality Complete Guide to Lily Extract Grinding Process: Step by Step Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are Ball Mill Grinding Process Handbook

.jpg)

Ball Mill Handbook PDF Mill (Grinding) Natural Rubber

Ball Mill Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document summarizes different types of mills and their linings used for grinding materials It describes pebble mills which use flint or porcelain balls and can be lined with materials like porcelain, burrstone or rubber It also describes ball mills which use steel or iron balls and have grinding mill clutches However, this control can be effectively applied to other clutch applications Contact your Eaton sales representative for further information 20 GENERAL OPERATION 21 Start Up Monitoring 211 During a mill start, the control monitors the time required to engage the clutch and bring the mill to full RPM (clutch lockup)CP3110 Grinding Mill Slip Detection Control Installation, Operation in variable speed mills, this may be achieved by reducing mill speed; and in both cases this may be achieved by design by increasing the lifter face angle Traditionally, the number of shell lifters used in a SAG mill is equal to twice the number of the feet in the mill shell diameter (eg, a 34ftdiameter mill shell would have 68 shell lifters)Semiautogenous grinding (SAG) mill liner design and developmentSolids Milling Engineering Guide Milling / Grinding / Comminution / Size reduction What is the principle of operation of a jet mill ? Lump Breakers How to deal with lumps in powders ? How to crush lumps ? How is designed a lump breaker ? Top 5 Most Popular 1 Powder Milling and Grinding An Engineering Guide

A guide to SAG Mill management

2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given time2024年5月15日 Datadriven operations now Grinding circuits are often equipped with appropriate process sensors to operate, guided by data such as fresh feed tonnage, water addition, specific gravity, mill Empowering grinding mill operation: the impact of datadriven