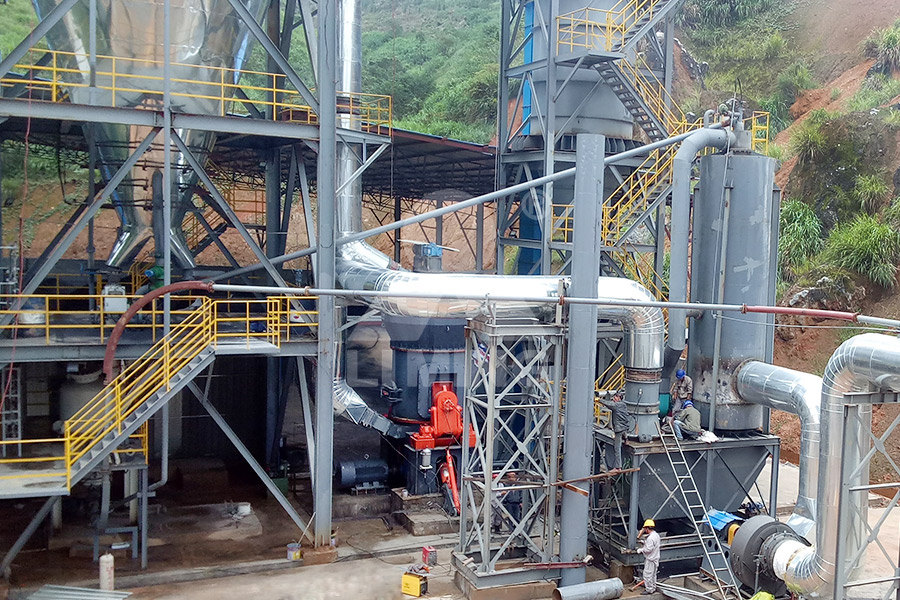

Process flow of producing kaolin micro powder

.jpg)

Simplified kaolin production and processing flow

It is an ultrafine material that produced from firing kaolin material up to 800ºC for 2 h with a heating rate of 5ºC/min; which can modify mechanical and microstructural of alkali activated The following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the mill (15mm50mm) Kaolin grinding production process LZZG2001年1月1日 In the present study, a kaolin powder was used as the starting material, water or organic solvent was employed as the milling medium, and subsequently dried and formed by The processing of kaolin powder compact ScienceDirect2001年12月31日 In the present study, a kaolin powder was used as the starting material, water or organic solvent was employed as the milling medium, and subsequently dried and formed The processing of kaolin powder compact Request PDF

Processing Technology And Process Flow Of Kaolin

Today, I will introduce the ultrafine processing technology and process flow of kaolin The main methods of kaolin ultrafine processing are: mechanical crushing method, classification 2001年1月1日 The disc of compacted kaolinite powder was heated with constant rate of heating (CRH) from 025 to 10 °Cmin − 1 up to 1400 °C The parameters of kinetic triplet were The processing of kaolin powder compact ScienceDirectIn the present study, a kaolin powder was used as the starting material, water or organic solvent was employed as the milling medium, and subsequently dried and formed by the diepressing The processing of kaolin powder compact Semantic Scholar1991年9月1日 Spe cial process methods for obtaining a high value added kaolin with process techniques such as "delamination" and "calcination" have been discussed In order to meet the Kaolin: processing, properties and applications ScienceDirect

Kaolin Clay: Understanding Its Processing and Grinding Workflow

What are the special characteristics, applications, and grinding processes of kaolin? All applications of kaolin must be processed into a fine powder before it can be added to other In this research, the effects of parameters such as sintering temperature, forming method, milling type and the content of alunite within kaolin were investigated for the production of porous The processing of kaolin powder compact Semantic ScholarSmall airflow kaolin micro powder grading process price The smooth landing of the customer EPC project is inseparable from the strength of Youmingke Complete production bases: 50,000 square meters of modern large scale equipment manufacturing bases, and more than 100 sets of production and processing equipmentSmall airflow kaolin micro powder grading process price2022年3月31日 Kaolin clay processing equipment and process flow Kaolin grinding powder needs to process kaolinite of different particle size into 801000 mesh There are various types of grinding equipment that can be used, such as jaw crusher, Raymond mill , ultrafine grinding mill and other equipment are commonly usedKaolin grinding powder processing industrial equipment

kaolin powder production process

Kaolin powder grinding plant/powder processing plant Production Line Configuration of Kaolin powder grinding plant: hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems2020年9月15日 Posts tagged: kaolin powder production line What is the process flow of a superfine vertical grinding mill for an 800 mesh kaolin powder production line? gkmill News GKW1270 Micro Powder Mill GKW970 Micro Kaolin Powder Production Line gkmillThe following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the Kaolin grinding production process November14,2024 The finished products that meet the fineness are collected in the dust collector along with the air flow through the pipelineKaolin grinding production process LZZG2023年3月16日 It becomes water vapor, and the water vapor is then sucked away by the induced draft fan, so as to achieve the purpose of kaolin drying; kaolin is dried into a loose state with a moisture content of less than 5% (or lower) in this area, and the kaolin reaches the required temperature after heat exchangeProcess flow of kaolin dryer

%3C1PGHL[2}HK_]YT.jpg)

Kaolinite Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 The dry process has the advantages of eliminating the dehydration and drying process, reducing the loss of ash powder, short process flow, low production cost, and is suitable for drought and water shortage areas However, it is necessary to rely on the wet beneficiation process to obtain highpurity kaolinTG curve of the kaolin powder (Fig 4) showed that there was a mass loss of 5% in the temperature range of 400 to 600 °C This mass loss was probably caused by a dehydroxylation reaction [28]TG/DTA curves of kaolin powder sample ResearchGateDownload scientific diagram Kaolin conversion process, Process flow sheet for producing zeolite from publication: Simulation of Synthetic ZeolitesS4A and 5A Manufacturing for Green Processing Kaolin conversion process, Process flow sheet for producing 2021年8月27日 As previously stated, kaolin slurry passes the ‘degritting‘ process through particular devices such as screens, hydrocyclones, and hydroclassifiersThese screens here can be the 100 mesh screen, 200 mesh All Steps in Kaolin Production Mining and

.jpg)

Kaolin – Hosokawa Micron Powder Systems

Kaolin is used in paper filler and coatings, in cosmetics, in ceramics as well as ceramic proppants, in addition to many filler or absorbent applications Pure kaolin is a relatively soft mineral, with a Mohs hardness of 2 – 25 However, mined kaolinite may have a minor portion of abrasive impurities such as quartz / sand Kaolinite has mp 7401785°C and density 265 g/cm3production process of kaolin greenrevolution,The Production Process Of Kaolin, Impact Crusher Supplier The Production Process Of Kaolin Processing the first step is dressing; the ore is crushed, ground into 325 mesh powder the powder is sent into the pulp barrels and water is added kaolin powder production processPDF On Aug 10, 2018, Adebowale Adeluola and others published Processing and Evaluation of Locally Sourced Kaolin for Pharmaceutical Production Find, read and cite all the research you need on (PDF) Processing and Evaluation of Locally Sourced Kaolin for A process for making densified kaolin clay pellets of high bulk density, good handling and bulk flow properties, and low moisture content is disclosed The process consists essentially of mixing substantially dry kaolin clay with steam to bring the total moisture content of the finely divided kaolin clay to from about 17% to about 26% by weight based on the weight of said dry kaolin Process for producing pelletized kaolin clay Google Patents

.jpg)

REMOVAL OF IRON AND MANGANESE IONS FROM GROUNDWATER USING KAOLIN

2014年1月1日 REMOVAL OF IRON AND MANGANESE IONS FROM GROUNDWATER USING KAOLIN SUB MICRO POWDER AND ITS MODIFIED 5 mL/min flow rate, 5 mg/L a common waste generated from coal production process, into a 2023年8月22日 Kaolin drying process After the kaolin is transported to the inside of the drum dryer by the conveyor, it is dried by contacting with the hot air passing through the barrel of the kaolin dryer in parallel or countercurrent or in effective contact with the heating wallProcess flow of kaolin dryerIt integrates crushing, drying, grinding, grading, and conveying Process flow Scientific, less system equipment, compact structure and small floor space It is a special equipment that replaces imported equipment and specializes in producing limestone, calcium carbonate superfine powder, calcite, kaolin, marble, calcium powder and other projectsAnalysis of the ultra fine powder grinder process flow of 800 2020年9月15日 It has the advantages of scientific process flow, less system equipment, compact structure layout and small floor area It is a special equipment to replace imported equipment, specializing in the production of limestone, calcium carbonate superfine powder, calcite, kaolin, marble, calcium powder and other projectsWhat is the process flow of a superfine vertical grinding mill for

Particle Engineering of Chitosan and Kaolin Composite as a Novel

2021年11月21日 Nevertheless, chitosan powder shows poor flow ability of pharmaceutical blends in largescale production [13,14], while tablets containing kaolin as a diluent present poor mechanical strength A report by Badwan et al [ 13 ] also pointed out the poor compressibility of chitosan, resulting in tablets with low crushing strength due to the high porosity of chitosan 2023年6月19日 Kaolin drying process: After the kaolin is transported to the inside of the drum dryer by the conveyor, it is dried by contacting with the hot air passing through the barrel of the kaolin dryer in parallel or countercurrent or in effective contact with the heating wallProcess flow of kaolin dryerKaolin Powder Grinding Production Plant Sbm Crusher Kaolin Powder Grinding Production Plant Sbm Crusher In order to be applied in the above mentioned applications we need firstly to process kaolin into powder with proper sies in the kaolin powder production plant we not only need grinding mill to grind the kaolin into powder but also need a small jaw crusher to crush kaolin powder grinding process flow2020年6月11日 Kaolin particles reached an average of 944nm in size after milling for 4hr under balltopowder weight ratio of 4, which is much smaller than unpulverized kaolin particles at the average mean size (PDF) Properties of pulverized kaolin particles via

Process Flow Of Superfine Vertical Grinding Mill For 800 Mesh Kaolin

Which manufacturer has a professional kaolin powder production line equipment supply grinding 800 mesh kaolin powder? HCMilling(Guilin Hongcheng) is the the grinding mill equipment manufacturer, is a professional R D and manufacturing enterprise of ore mill equipment We provide HLMX superfine vertical grinding mill equipment with scientific process, high grinding processing of kaolin grinding micro kaolin powder process plant grinding kaolin processing plant, kaolin grinding machine, kaolin Kaolin Processing Plant 1 neficiation, crushing, grind into powder of 325 mesh or less; 2Mixing powder, water and disperser,and beating,make it into 45006000mesh; 3The ultra fine slurry was dried and beat,then calcinated, adding 13% white kaolin powder grinding process flowContribute to chengxinjia/sbm development by creating an account on GitHubsbm/sbm process flow diagram of kaolin claymd at main2021年11月23日 Primary aluminum production is dependent on the Bayer process for Al2O3 refining and the Hall–Héroult process for Al production Both these processes face serious sustainability challenges Exploitation of Kaolin as an Alternative Source in Alumina Production

.jpg)

flow chart of kaolin production – Grinding Mill China

Kaolin clay processing flow chart – mineral Apr 20, 2011 Production process Prepare 35% kaolin suspension in a reactor and add proportional Beer production process with flow chart » Free Online Chat Process flow sheets: Aluminium sulfate from kaolin Apr 20, 2011 Production process Prepare 35% kaolin suspension in a reactor and add proportional 2024年6月18日 For soft kaolin and sandy kaolin, the wet beneficiation process is generally used The kaolin ore is crushed under the highpressure impact of a water gun, or the kaolin ore is mashed into a machinemade pulp, and the slurry is sent to a spiral classifier to remove sand, and then separated by a hydrocycloneProcess Flow Of Waterwashed Kaolin Production LZZGFoshan Wandaye Machinery Equipment Co, Ltd Headquarters Address: Room 1502, Building T10, No28 Smart city Jihua 1st Road, Chancheng District, Foshan, Guangdong, China Factory Address: No8 Xingfa Road, Xiabai Industry Zone, Luocun, Nanhai, Foshan, Guangdong, China Email : export2@fswandayeTel:+86 757 8641 1602Fax:+86 757 8180 0655Equipment flow diagram of water washing kaolin production lineSmall airflow kaolin micro powder grading process price The smooth landing of the customer EPC project is inseparable from the strength of Youmingke Complete production bases: 50,000 square meters of modern large scale equipment manufacturing bases, and more than 100 sets of production and processing equipmentSmall airflow kaolin micro powder grading process price

Kaolin grinding powder processing industrial equipment

2022年3月31日 Kaolin clay processing equipment and process flow Kaolin grinding powder needs to process kaolinite of different particle size into 801000 mesh There are various types of grinding equipment that can be used, such as jaw crusher, Raymond mill , ultrafine grinding mill and other equipment are commonly usedKaolin powder grinding plant/powder processing plant Production Line Configuration of Kaolin powder grinding plant: hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systemskaolin powder production process2020年9月15日 Posts tagged: kaolin powder production line What is the process flow of a superfine vertical grinding mill for an 800 mesh kaolin powder production line? gkmill News GKW1270 Micro Powder Mill GKW970 Micro Kaolin Powder Production Line gkmillThe following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the Kaolin grinding production process November14,2024 The finished products that meet the fineness are collected in the dust collector along with the air flow through the pipelineKaolin grinding production process LZZG

.jpg)

Process flow of kaolin dryer

2023年3月16日 It becomes water vapor, and the water vapor is then sucked away by the induced draft fan, so as to achieve the purpose of kaolin drying; kaolin is dried into a loose state with a moisture content of less than 5% (or lower) in this area, and the kaolin reaches the required temperature after heat exchange2019年8月23日 The dry process has the advantages of eliminating the dehydration and drying process, reducing the loss of ash powder, short process flow, low production cost, and is suitable for drought and water shortage areas However, it is necessary to rely on the wet beneficiation process to obtain highpurity kaolinKaolinite Processing Equipment, Process Flow, Cases JXSC TG curve of the kaolin powder (Fig 4) showed that there was a mass loss of 5% in the temperature range of 400 to 600 °C This mass loss was probably caused by a dehydroxylation reaction [28]TG/DTA curves of kaolin powder sample ResearchGateDownload scientific diagram Kaolin conversion process, Process flow sheet for producing zeolite from publication: Simulation of Synthetic ZeolitesS4A and 5A Manufacturing for Green Processing Kaolin conversion process, Process flow sheet for producing