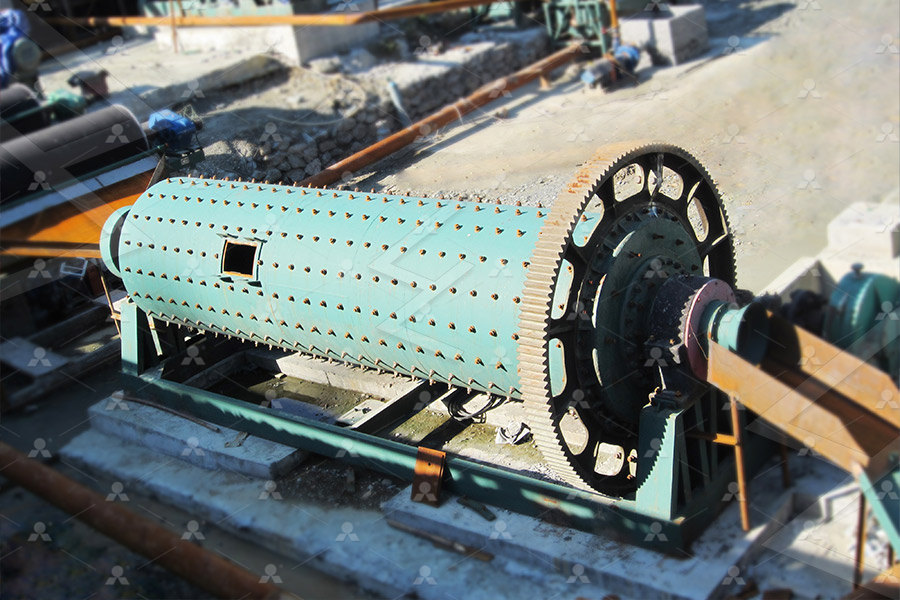

Openpit coal mine ore mill operation

.jpg)

(PDF) Open Pit Coal Mines ResearchGate

2019年4月23日 The mininginduced ecological issues are studied and sufficiently effectively treated in oil shale development, as well in largescale 2021年2月17日 Open pit mining is defined as the method of extracting any near surface ore deposit using one or more horizontal benches to extract the ore while dumping overburden and(PDF) Open Pit Mining ResearchGate2018年11月1日 In this paper, a hypothetical open pit copper mine is considered, which needs to produce 30 million tonnes of waste and 25 million tonnes of ore based on its annual planning Optimized design of drilling and blasting operations in open pit Iron ore production of LTV steel mining, and 10% increase in the production of the Quintette Coal mine Furthermore,Hashemi and Sattarvand (2015) in a simulation study of the Sungun OpenPit Mine Production Optimization: A Review of Models and

.jpg)

(PDF) OpenPit Mine Production Optimization: A

2015年9月1日 Open pit mines operation costs highly depends on material handling 50 to 60 percent of operating costs in an open pit mine is spent on digging and transporting the material So, reducingopen pit mines to have powerful desktop computers that can solve complex optimization problems on site Western Goldfield Group Nigeria has implemented an optimization and scheduling of Open Pit Optimization Processes Of Okobo Coal Mine IJSTRThese applications include orebody modelling and orereserve estimation; the design of optimum pits; the determination of optimal production schedules; the determination of optimal operating Application of Optimisation Techniques in Open Pit MiningFigure 1 illustrates two labour indices ‘mine and mill operation labour’ and ‘mill construction labour’ Both labour indices move together throughout the periodsEstimating Average Total Cost of Open Pit Coal Mines in Australia

Openpit mining Wikipedia

Openpit mines are typically worked until either the mineral resource is exhausted, or an increasing ratio of overburden to ore makes further mining uneconomic [citation needed] After openpit mines are closed, they are 2018年1月1日 Otherwise, the NPV calculation and generated mining sequence could be suboptimal Samavati et al (2018) explored the fact that there is almost no study for optimising the operations with IPCC in OpenPit Mine Production Planning and 2010年4月7日 Applications of operations research to mine planning date back to the 1960s Stochastic strategic planning of openpit mines with ore selectivity recourse 30 June 2016 Openpit coal mine production sequencing incorporating grade blending and stockpiling options: A Review of Operations Research in Mine Planning Interfacesopen pit mines to have powerful desktop computers that can solve complex optimization problems on site Western Goldfield Group Nigeria has implemented an optimization and scheduling of its coal mine using Minex Open Pit Optimizer Programme (MOPOP) to schedule their entire mine and production, resulting in significant process cost savingsOpen Pit Optimization Processes Of Okobo Coal Mine IJSTR

Midlong term boundary dynamic optimization of openpit coal mine

2024年2月23日 The delineation of the openpit mining boundary, particularly in the context of medium to longterm planning, forms the foundation of mining design However, due to the nonlinear and dynamic nature of the economic and technical parameters influencing boundary delineation, determining the optimal mining boundary can be exceedingly challenging is to discuss the general features of open pit mining, ore body characteristics and configurations, stripping ratios and stripping overburden methods, mine elements and parameters, open pit operation cycle, pit slope angle, stability of mine slopes, types of highwall failures, mine closure, and reclamation The chapter will alsoChapter Open Pit Mining2024年7月25日 In an openpit mine, a variety of equipment options are available for transporting ore, with shovels and dump trucks being the most commonly used Depending on the mine’s current conditions, other equipment such as draglines, bucket wheel excavators, inpit crushing plants, and conveyors might also be utilizedEquipment Selection and Sizing for Optimum Planning and2017年6月1日 The aim of the study is to reduce idle times of mining trucks and shovels in an openpit coal mine A heuristic algorithm for making dispatching decisions in conditions of dynamic allocation of Improving the organization of the shovelTruck systems in openpit coal

.jpg)

Cerrejon Openpit Coal Mine, La Guajira, Colombia NS Energy

2020年11月9日 Cerrejon Coal Mine The Cerrejon coal mine in Colombia is the biggest opencast coal mine in Latin America and one of the largest surface coal mining operations in the world It is a highquality thermal coal mining operation jointly owned by Anglo American, BHP, and Glencore each holding onethird of the shares2024年10月23日 We'll talk about how we can control ore dilution using HighPrecision GPS and Geology Ore Solutions to make mining more efficient, safer, and more sustainable In this first part, we'll give a general overview of the Unlocking Efficiency: Ore Dilution and Quality Control Welcome to the first part of our series about Ore Dilution and Quality Control in OpenPit Mines In this series, One of the main consequences of dilution is the reduction of mill feed grade Lower feed grade means less Lower bench height for steeply dipping ore body Mine Scheduling: Operation Sequencing based on Grade and Tonnage Unlocking Efficiency: Ore Dilution and Quality Control in OpenPit 2022年4月28日 Openpit mining plans include implementing operations throughout the entire life of the mine In addition to geometric and geotechnical constraints, it is important to ensure an uninterrupted ore feed by optimizing production plan In order to achieve this and at the same time maximize the net present value, the most wellknown method is “Parametric Analysis Method” Optimization of openpit mine design and production planning

Open Pit Mining IntechOpen

2021年2月17日 Open pit mining method is one of the surface mining methods that has a traditional coneshaped excavation and is usually employed to exploit a nearsurface, nonselective and lowgrade zones deposits It often results in high productivity and requires large capital investments, low operating costs, and good safety conditions The main topics that will coal mining in the open pit, the surface of the rock and soil is stripped, and the original ecosystem is damaged, therefore, the open pit is the main objective of the coal mine repair [1213] 22 Subsided land When coal is mined, the original stress equilibrium state of the rock mass around the mining area is damaged AfterConcept and Practice of Openpit Mining Area Restoration and 2022年9月1日 In underground mines or open pit mines having ore passes, some small particles might be also produced in the ore passes due to movement of ore/rock fragments, especially when they are very deep For example, the ore passes were up to 660 m long in the Grasberg openpit mine (PT Freeport Indonesia, 2022)Towards waterless operations from mine to mill ScienceDirect2015年6月24日 Hustrulid W, Kuchta M, Martin R: Open Pit Mine Planning and Design, Volume 1Fundamentals (3 rd edition), published by Taylor and Fracis Group, Boca Rathon London New York Lelden, 2013 Cost COST ESTIMATION FOR OPEN PIT MINES: TACKLING COST UNCERTAINTIES

Open Pit Mine an overview ScienceDirect Topics

2004年7月24日 An open pit mine is a type of mining operation where valuable minerals are extracted from the Earth's surface through the excavation of a large, open pit This method involves the use of heavy equipment to remove overlying material and access the mineral deposits below AI generated definition based on: Treatise on Geomorphology (Second Edition 2018年5月21日 Operational dilution in openpit mining can influence shortterm mine planning and affect the adherence between designed and executed plans, impacting the reconciliation resultsControlling operational dilution in openpit miningOre from both operations is transported by conveyor to centralized mine facilities, feeding a combined daily average total of some 225,000t of ore to the mill and 135,000t to the stockpiles Production equipment includes 30m3–42m3 buckets, a 170strong fleet of 70t–330t haul trucks, together with 65 dozers and graders, with radar, GPS and robotics used in the mine’s stateof Grasberg Open Pit, Indonesia Mining Frontier2013年8月1日 Thereafter, the ODM procedure is applied to the blasting operation at an Iranian iron ore open pit mine (Chador Malu), with nine blast blocks In summary, this approach could help design engineers ODM: A new approach for open pit mine blasting

Mining MethodsPart II: Surface MiningPlanning and Design of Open Pit

2010年3月1日 The typical large open pit mining operation that has been in production for 10 years and more is operating under conditions When speaking of an open pit mine, (Ex ample iron ore, coal)1 Introduction Openpit mining is a method of extracting mineral deposits by excavating from the Earth’s surface It works by starting at the surface and removing noneconomic overlays to access profitable parts []Compared with the underground mining method, openpit mining has the advantages of high resource recovery, good safety conditions, high labor efficiency and large Midlong term boundary dynamic optimization of openpit coal mine 2022年5月1日 Over the history of DES, two major paradigms have emerged for the expression of models The first is eventscheduling [1], which might be called the “programmer’s view”; a set of possible events which may be scheduled to occur and the appropriate responses to them, shown in Fig 2The second, processinteraction, would then be the “simulant’s view”; a set of Efficient simulation for an openpit mine ScienceDirect2024年5月2日 The Chenbaerhuqi coal field in Hulunbuir City, Inner Mongolia Autonomous Region of China, is where the Baorixile openpit coal mine is situated 31, 32 The mine's external perimeter spans a 5072 km 2 region, measuring 586 km in width from north to south and 1098 km in length from east to westResearch on the method of determining the block size for an openpit

Grasberg Open Pit Copper Mine, Tembagapura, Irian Jaya,

2020年6月24日 Mining at Grasberg Open Pit The workings comprise an openpit mine, an underground mine and four concentrators The openpit mine, which forms a milewide crater at the surface, is a highvolume lowcost operation, producing more than 67 million tonnes of ore and providing more than 75% of the mill feed in 2006Mining and milling Markus HA Piro, Ksenia Lipkina, in Advances in Nuclear Fuel Chemistry, 2020 8231 Open pit mining Open pit mining refers to mining directly on the ground surface, thereby producing an open pit This method is practical and costeffective when the uranium ore is located near the surface (eg, within 100 m) Underground mining and ISL methods may be Open Pit Mining an overview ScienceDirect Topics2023年1月3日 The optimization of open pit mine production scheduling is not only a multistage decisionmaking problem but also involves space–time dynamic action among multiple factors, which makes it Enumeration optimization of open pit production scheduling 2024年11月14日 Mining Strip, OpenPit, Quarrying: It has been estimated that more than twothirds of the world’s yearly mineral production is extracted by surface mining There are several types of surface mining, but the three most common are openpit mining, strip mining, and quarrying These differ from one another in the mine geometries created, the techniques used, Mining Strip, OpenPit, Quarrying Britannica

.jpg)

Estimating Average Total Cost of Open Pit Coal Mines in Australia

Figure 1 illustrates two labour indices ‘mine and mill operation labour’ and ‘mill construction labour’ Both labour indices move together throughout the periodsOpenpit mines are typically worked until either the mineral resource is exhausted, or an increasing ratio of overburden to ore makes further mining uneconomic [citation needed] After openpit mines are closed, they are Openpit mining Wikipedia2018年1月1日 Otherwise, the NPV calculation and generated mining sequence could be suboptimal Samavati et al (2018) explored the fact that there is almost no study for optimising the operations with IPCC in OpenPit Mine Production Planning and 2010年4月7日 Applications of operations research to mine planning date back to the 1960s Stochastic strategic planning of openpit mines with ore selectivity recourse 30 June 2016 Openpit coal mine production sequencing incorporating grade blending and stockpiling options: A Review of Operations Research in Mine Planning Interfaces

.jpg)

Open Pit Optimization Processes Of Okobo Coal Mine IJSTR

open pit mines to have powerful desktop computers that can solve complex optimization problems on site Western Goldfield Group Nigeria has implemented an optimization and scheduling of its coal mine using Minex Open Pit Optimizer Programme (MOPOP) to schedule their entire mine and production, resulting in significant process cost savings2024年2月23日 The delineation of the openpit mining boundary, particularly in the context of medium to longterm planning, forms the foundation of mining design However, due to the nonlinear and dynamic nature of the economic and technical parameters influencing boundary delineation, determining the optimal mining boundary can be exceedingly challenging Midlong term boundary dynamic optimization of openpit coal mine is to discuss the general features of open pit mining, ore body characteristics and configurations, stripping ratios and stripping overburden methods, mine elements and parameters, open pit operation cycle, pit slope angle, stability of mine slopes, types of highwall failures, mine closure, and reclamation The chapter will alsoChapter Open Pit Mining2024年7月25日 In an openpit mine, a variety of equipment options are available for transporting ore, with shovels and dump trucks being the most commonly used Depending on the mine’s current conditions, other equipment such as draglines, bucket wheel excavators, inpit crushing plants, and conveyors might also be utilizedEquipment Selection and Sizing for Optimum Planning and

.jpg)

Improving the organization of the shovelTruck systems in openpit coal

2017年6月1日 The aim of the study is to reduce idle times of mining trucks and shovels in an openpit coal mine A heuristic algorithm for making dispatching decisions in conditions of dynamic allocation of 2020年11月9日 Cerrejon Coal Mine The Cerrejon coal mine in Colombia is the biggest opencast coal mine in Latin America and one of the largest surface coal mining operations in the world It is a highquality thermal coal mining operation jointly owned by Anglo American, BHP, and Glencore each holding onethird of the sharesCerrejon Openpit Coal Mine, La Guajira, Colombia NS Energy