Ore grinding mill related processing technology

.jpg)

Grinding Mill an overview ScienceDirect Topics

Grinding within a tumbling mill is influenced by the size, quantity, the type of motion, and the spaces between the individual pieces of the medium in the mill As opposed to crushing, which takes place between relatively rigid surfaces, grinding is a random process2022年4月1日 There are a range of innovative technologies that can be used to liberate and separate critical metals from mining and processing waste Mineral liberation can be achieved Review on advances in mineral processing technologies suitable 2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Ore Grinding SpringerLink2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are VRM's are state(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

Enhancing Iron Ore Grindability through Hybrid

2024年10月14日 Grinding is an important process of ore beneficiation that consumes a significant amount of energy Pretreating ore before grinding has been proposed to improve ore grindability, reduce comminution energy, and Ore grinding process falls into opencircuit and closedcircuit grinding The grinding products of the former are directly processed in the next processing procedure without returning to the Ore Grinding Methods and Process of Ore GrindingIn pit blasting, primary crushing, secondary crushing, SAG and ball milling are all able to exploit natural fracture planes in the ore allowing breakage along these featuresUltra Fine Grinding A Practical Alternative to Glencore 2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the Ultrafine Grinding in Contemporary Flow Diagrams for Mineral

Ore Grinding SpringerLink

2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Processing of Magnetite Iron Ores – Comparing Grinding Options B McNab1, A Jankovic2, D David3 and P Payne4 ABSTRACT Although the majority of current steel production is supported by iron ore sourced from high0grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to Processing of Magnetite Iron Ores–Comparing Grinding OptionsPursuing the Zenith Technology and Quality Shanghai Zenith Mining and Construction Machinery Co, Ltd is a hitech, engineering group We are specialized in the research, development, and production of industrial Grinding Mill, Grinder, Mills for Sale Shanghai Zenith The common first stage grinding machines are AG mill, SAG mill, rod mill or ball mill and so on The second and third stage grinding machines often use ball mill and others The common equipment which combine with grinding system to be closed circuit aretrommel, vibrating screen, spiral classifier or hydrocycloneMineral Processing Wet Ore Grinding and Classifying Plant

.jpg)

Optimization of stirred mill parameters for fine grinding of PGE

Optimization of stirred mill parameters for fine grinding of PGE bearing chromite ore, Particulate Science and Technology, DOI: 101080/2020 To link to this article: https://doi 2018年8月8日 The paper presents a study on the effectiveness of the grinding process in an electromagnetic mill devoted to ultrafine grinding, and the influence of processing parameters on the mill’s (PDF) Grinding Kinetics Adjustment of Copper Ore Grinding in 2018年6月18日 Grinding additives are used commercially successful technology while microwave pretreatment also has been successfully piloted Newly developed techniques such as ultrasonics and electric disintegration have shown potential for success but the cost economics of these processes is still not as attractive as desiredOre Pretreatment Methods for Grinding: Journey and Prospects2024年11月13日 In the processing of freemilling gold ores two most preferred processes Include gravity separation and flotation This process a vibrating feeder can put crushed gold ore in a ball mill for Comparing Mineral Processing Equipment for Different Ore Types

Mineral processing Metallurgy, Crushing Grinding Britannica

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other Find your ore mill easily amongst the 42 products from the the largest grinding jar has a volume of 2,000 ml The closed grinding system guarantees complete processing of the sample The Compare this product Remove chemical industry, etc, it has two ore grinding Compare this product Remove from comparison tool ball grinding millOre mill, Ore grinding mill All industrial manufacturersapparent for fine products Though it is ore dependant, as a general guide sub 10 micron applications will be limited to about 4550% feed solids Power and Energy Efficiency Grinding energy is one of the major costs of mineral processing Choosing the right grinding machine and the best media are certainly importantFine Grinding as Enabling Technology – The IsaMillIt is performed in cylindrical steel vessels that contain a charge of loose crushing bodies—the grinding medium—which is free to move inside the mill, thus comminuting the ore particles According to the ways by which motion is imparted to the charge, grinding mills are generally classified into two types: tumbling mills and stirred mills Chapter 7 Grinding Mills Wills' Mineral Processing Technology,

.jpg)

PGM Ore Processing at Impala's UG2 Concentrator SGS

UG2 Ore PrOcessinG PrObleMs and sOlUtiOns Historically UG2 ore could not be processed due to the high chrome content in the feed and subsequently in the final concentrate Very little of the chrome itself exhibits any degree of positive floatability, but when excessive grinding takes place it reports to the final2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?Review A Review of the Grinding Media in Ball Mills for Mineral Processing Nyasha Matsanga 1,*, Willie Nheta 1 and Ngonidzashe Chimwani 2 Mineral Processing and Technology Research Centre, Department of Metallurgy, University of Johannesburg, PO Box 17011, Johannesburg 2028, South Africa; 2 Department of Mining Engineering, Florida Campus, A Review of the Grinding Media in Ball Mills for Mineral Processing2014年5月15日 119 SEMI AUTOGENOUS GRINDING MILL SAG SAG mills utilize grinding balls to aid in grinding like in a ball mill It is generally used as a primary or first stage grinding solution SAG mills use a ball charge of 8 to 21% Attrition between grinding balls and ore particles causes grinding of finer particlesMineral Processing PPT SlideShare

.jpg)

Processing Materials SBM Ultrafine Powder Technology

SBM has been focusing on the field of mining ore crushing and grinding machinery for many years Our grinding equipment can grind 100+ kinds of nonmetallic +年7月23日 Optimization of stirred mill parameters for fine grinding of PGE bearing chromite ore, Particulate Science and Technology, DOI: 101080/2020 To link to this article: https://doi Optimization of stirred mill parameters for fine grinding of PGE 2020年10月1日 Grinding is a key technology of highadded value sectors including aerospace, automotive, and energy generation [6], which has a direct impact on the accuracy, performance and the surface integrity of the workpiece [7]However, in addition to many factors such as the size precision requirements of the parts, parameter selection, blank type, processing method, Intelligent technology in grinding process driven by data: A Mt Baker Mining and Metals is focused on providing a costeffective and durable ore processing plant that includes a jaw crusher, hammer mill, size classification equipment, and sluice/shaker table This is the most efficient combination of cost, productivity, longevity, and recovery when the job calls for processing bulk samples, performing test runs, or an initial setup to generate Ore Milling Mt Baker Mining and Metals

New Grinding Floating Technology in Graphite Ore Dressing

2024年5月9日 01 Grinding and flotation process of graphite ore The important basis for measuring the value of flake graphite ore is the size of graphite flakes and the fixed carbon content The concentrate measurement index produced in the beneficiation process depends on the dissociation mode, dissociation degree and subsequent beneficiation process of the minerals2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral ProcessingSuccessful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, This new processing route utilizes LOESCHE grinding technology and is considered 100 % sustainable and unprecedent in the MOBILE GRINDING MILL FOR ORE Download METAL RECOVERY AND FILLER PRODUCTION STEEL SLAG Download Mills for minerals and ores Loesche

.jpg)

The Gold Ball Mill: A Crucial Tool in Gold Ore Processing

2024年12月4日 A gold ball mill is a type of grinding mill used in the mining industry to crush and grind gold ore into finer particles It is an essential component of the gold extraction process, as it helps to liberate gold from the surrounding rock matrix, making it easier to extract using various methods such as cyanidation, amalgamation, or gravity separation2022年4月25日 “A well designed and manufactured mill liner is crucial to overall performance of the mill,” says Zane Thomas, Trelleborg manager, mill liners “A grinding mill is the heart of any mining and mineral processing operation, and a mill breakdown or unplanned shutdown causes downtime losses for the operations”Mill liners: grinding out a legacy Mining TechnologyOre pretreatment methods for grinding: journey and prospects Veerendra Singh a, Prashant Dixit , R Venugopalb, and K Bhanu Venkatesha aResearch and Development Department, Tata Steel, Jamshedpur Ore pretreatment methods for grinding: journey and prospectsWills' Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery has been the definitive reference for the mineral processing industry for over thirty yearsWills' Mineral Processing Technology ScienceDirect

.jpg)

Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill

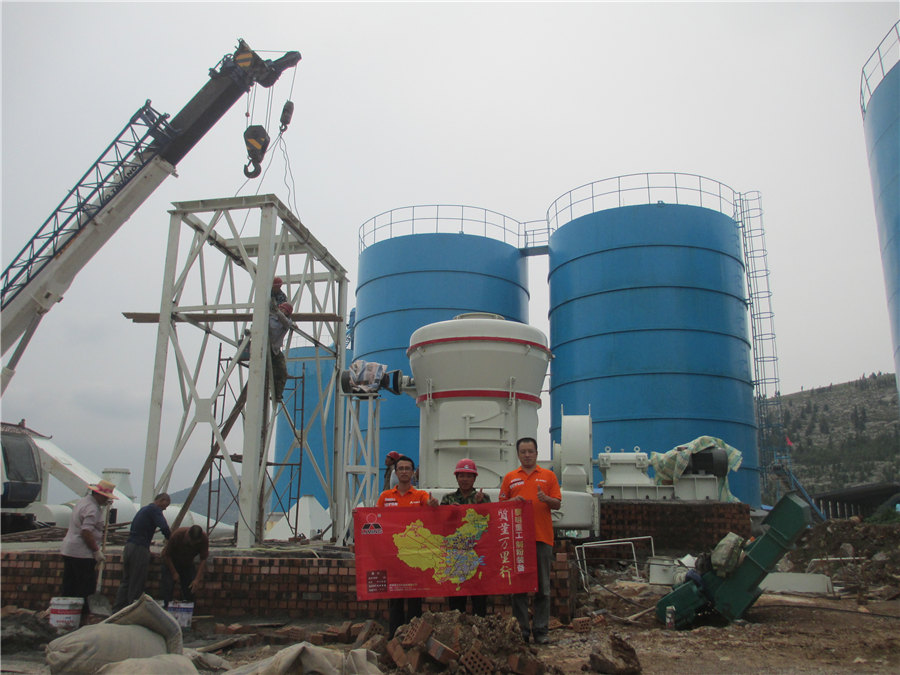

Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreThe core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials, and to separate the tailings, which is 2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLinkProcessing of Magnetite Iron Ores – Comparing Grinding Options B McNab1, A Jankovic2, D David3 and P Payne4 ABSTRACT Although the majority of current steel production is supported by iron ore sourced from high0grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to Processing of Magnetite Iron Ores–Comparing Grinding OptionsPursuing the Zenith Technology and Quality Shanghai Zenith Mining and Construction Machinery Co, Ltd is a hitech, engineering group We are specialized in the research, development, and production of industrial Grinding Mill, Grinder, Mills for Sale Shanghai Zenith

Mineral Processing Wet Ore Grinding and Classifying Plant

The common first stage grinding machines are AG mill, SAG mill, rod mill or ball mill and so on The second and third stage grinding machines often use ball mill and others The common equipment which combine with grinding system to be closed circuit aretrommel, vibrating screen, spiral classifier or hydrocycloneOptimization of stirred mill parameters for fine grinding of PGE bearing chromite ore, Particulate Science and Technology, DOI: 101080/2020 To link to this article: https://doi Optimization of stirred mill parameters for fine grinding of PGE 2018年8月8日 The paper presents a study on the effectiveness of the grinding process in an electromagnetic mill devoted to ultrafine grinding, and the influence of processing parameters on the mill’s (PDF) Grinding Kinetics Adjustment of Copper Ore Grinding in 2018年6月18日 Grinding additives are used commercially successful technology while microwave pretreatment also has been successfully piloted Newly developed techniques such as ultrasonics and electric disintegration have shown potential for success but the cost economics of these processes is still not as attractive as desiredOre Pretreatment Methods for Grinding: Journey and Prospects

.jpg)

Comparing Mineral Processing Equipment for Different Ore Types

2024年11月13日 In the processing of freemilling gold ores two most preferred processes Include gravity separation and flotation This process a vibrating feeder can put crushed gold ore in a ball mill for mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other Mineral processing Metallurgy, Crushing Grinding Britannica