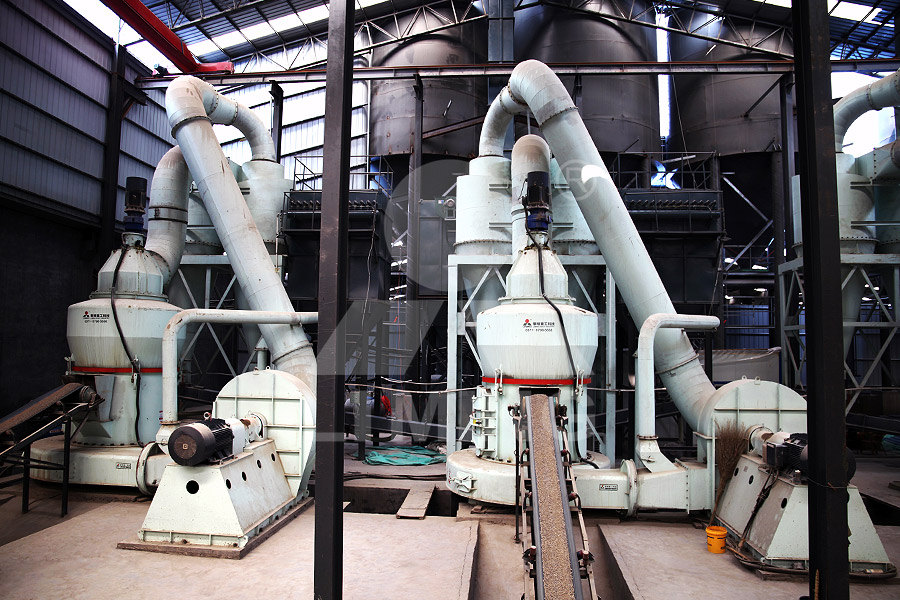

Types of reducers for chemical raw material mills

.jpg)

CLASSIFICATION OF MILLS USED IN PHARMA INDUSTRY

The majority of size reduction equipment may be classified according to the way in which forces are applied namely; impact, shear, attrition, and shearcompression A given mill may operate 2024年7月8日 At its core, size reduction involves the transformation of bulky raw materials into finer particles, facilitating easier handling, mixing, and processing This fundamental step is ubiquitous across various chemical processes, The Crucial Role of Size Reduction and Hammer Mills 2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are usually named as mills, for example rod mills, Grinding Mills and Their Types – IspatGuruTypes of Size Reduction Methods Size reduction is a unit operation process and the operations include grinding, compression and impact forces The types of forces involved are International Journal of ChemTech Research

.jpg)

Mechanochemical and Size Reduction Machines for Biorefining

2020年11月16日 In the present review, modern equipment employing various types of mechanical impacts, which show the highest promise for mechanochemical pretreatment of Prater’s range of particle size reduction equipment, including hammer mills, crushers, and air classifiers, enables chemical manufacturers to finely grind or micronize raw materials to the Particle Size Reduction Handling for Chemicals MineralsCrush, grind, pulverize, shredsize reduction is amazing! There are many terms that fall under this umbrella: crush, grind, pulverize, shred, delump, defiberize, just to name a few Likewise, Intro to Size Reduction Schutte HammermillThere are several types of mills that are used for size reduction of materials, including roller mills, hammer mills, pin mills, disc mills, and cone mills Each type of mill has its own specific features and characteristics, and is more suitable Comparing The Most Common Types of Mills ABM

Research on Reduction of Selected IronBearing Waste Materials

2021年4月12日 Reduction of dust that is emitted to the atmosphere in the exhaust gases is carried out by using dedusting devices, being divided into particular groups []: mechanical (dry and wet) dust collectors, fabric or filled filters, and electrostatic (dry or wet) dust collectorsDust and sludge from sinter plants or blast furnace departments characterized by a high iron 109 weight complexes with repeating units of glucose 111 The types and performances of various types of carbohydratebased concrete water reducers are summarized in Table 3 Major wastes generated from pulp and paper mills: a (3) Types on the Basis of Unloading Materials 1 Tail Discharge Mill: TThe material of the tail discharge mill is fed in from one end and fed out from the other end 2 Intermediate Discharge Mill: The material of the intermediate Ball Mill Working Principle Ball Mill Types MC2021年9月22日 Types of raw material There are different types of raw materials that are grouped according to their origin, their availability or the industrial transformation process to which they must undergo By its origin Plant origin: they are obtained from plants and many can be used in their natural stateWhat is Raw Material: Types and Examples TakeCareOfMoney

.jpg)

Raw Materials Used In Textile Industries Acme Mills

Raw materials may be in processed or unprocessed state Different types of chemicals and auxiliaries used in dyeing, Acme Mills/Great Lakes Filters 33 Bloomfield Hills Pkwy #120 Bloomfield Hills, MI 48304, United States Fairway Products 301 2024年1月15日 Waste Materials (Secondary Raw Materials): Secondary raw materials are obtained from waste materials that have undergone recycling processes and are reintegrated into the production cycle This sustainable approach contributes to environmental conservation and reduces the dependence on primary raw materials, offering a responsible and efficient way to Raw Materials : Meaning, Sources, Types Examplesthe most important building materials Whether for houses, bridges or tunnels, we cannot imagine our modern world without it Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product From raw materials to cement Extracting raw materials Crushing and transportationFrom raw materials Extracting raw materials Raw material 2024年6月28日 Using highsulfatecontent water reducers or certain retarders can mitigate this issue e Cement with Poor Solubility Gypsum: Poor solubility gypsum in cement can cause false setting Avoid using water reducers that affect gypsum solubility and control the dosage of problematic water reducers f Fresh Cement High Specific Surface Cement:Mastering Water Reducers: Expert Solutions for Six Types of

How Seamless Stainless Steel Tubing is Made HandyTube

In addition, extrusion is the only process most suitable for long length seamless stainless steel coil tubing The raw material begins in the form of hot extruded seamless pipe The material is then cold reduced At this point the raw material is processed through tube reducers known as pilger mills in a long straight formThere are many different types of grinding mills (Table 1) Some devices, such as ball mills, are more suitable for coarse materials These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes Attrition mills are more appropriate for "midrange" size particlesSolids Choose the Right Grinding Mill Chemical ProcessingThere are many different types of media mills, some grinding equipment, such as ball mills, are more suitable for coarse materials These mills use “large” media ranging in size from 20mm and up to produce material about ten microns to mesh sizes Other mills, such as Attritors, are more appropriate for “midrange” size particlesMEDIA MILLING FOR CHEMICAL APPLICATIONS Union ProcessDocument Description: Chemical Industries: Types, Raw Materials, and Relevancies for JAMB 2024 is part of Chemistry for JAMB preparation The notes and questions for Chemical Industries: Types, Raw Materials, and Relevancies have been prepared according to the JAMB exam syllabus Information about Chemical Industries: Types, Raw Materials, and Relevancies Chemical Industries: Types, Raw Materials, and Relevancies

.jpg)

Drag Reduction Performance and Mechanism of Hydrophobic

2020年4月20日 Drag reduction (DR) tests showed that the three drag reducers have different DR characteristics in fresh water and various saline waters because of their different types of hydrophobic monomers PHWAM1, without hydrophobic monomers, performs better in fresh water, while PHWAM2 and PHWAM3, with hydrophobic monomers, perform better in brinePDF On Mar 1, 2010, Almut Jering and others published Use of renewable raw materials with special emphasis on chemical industry Find, read and cite all the research you need on ResearchGate(PDF) Use of renewable raw materials with special emphasis on chemical 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 inGrinding Mills Common Types 911Metallurgist2022年3月9日 Cyclo drives are ideally suited for this type of operation as they are able to maintain very precise speeds across their full load range, a critically important feature when handling the heavy and variable rotating loads found in paper mills Applications Of Cyclo Drives In Paper MillingCyclo Drives For Paper Mills Speed Reducers for the the

.jpg)

Raw Material Excellence in the chemical industry, a game

The proven approach taken by a number of chemical companies is to first get transparency on the number and type of raw material variations, such as grades, packaging size and type, chemical and/ or trade name, potentially in several languages etc 2016 Raw Materials and Chemicals Roundtable, ASI Adhesives Sealants Industry Powell, D As a highperformance concrete admixture, the remarkable features of naphthalene based superplasticizer are its high water reduction capacity and significant improvement in concrete performance Compared with traditional water reducers, SNF superplasticizer has a higher water reduction rate, usually reaching more than 15%, which is of great significance for improving Water Reducing Admixtures For Concrete Kingsun Chemicals2024年11月5日 Pulp and Paper: The reducers are employed in pulp and paper mills where they can withstand the harsh chemical environment Advantages of Using Stainless SMO 254 Reducers Enhanced Corrosion Resistance : The primary advantage of using SMO 254 reducers is their superior corrosion resistance, especially in chloriderich environmentsWhat Is a Stainless SMO 254 Reducer and How Does It Work?Different types of rod mills are available, each with its unique features and advantages In this article, we will discuss the various types of rod mills and their applications Types of Rod Mills 1 Overflow Rod Mill This type of rod mill is used when a product with high fines content is desiredWhat are the Different Types of Rod Mill? ball mills supplier

.jpg)

List of types of mill Wikipedia

(See comminution, filtration) Arrastra, simple mill for grinding and pulverizing (typically) gold or silver ore; Ball mill, a mill using balls to crush the material; Bead mill a type of Mill (grinding); Burr mill or burr grinder, a mill using burrs to crush the material, usually manufactured for a single purpose such as coffee beans, dried peppercorns, coarse salt, spices, or poppy seedsNow, coming onto some essential formulas to use for calculating raw materials To know how much raw material is used in the manufacturing process, we can use the below formula: Opening raw material + raw material purchases – What is Raw Material? Formula, Types, ImportanceThese mills have the capability of rolling rigid materials such as nickel alloys, titanium, and stainless steel 3 Continuous Mill: ( Types of Rolling Mills ) Using a series of rolling mills, the same material must pass through each stand in a Rolling Mills Types, Function, MaterialVideo credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide: Types, Features

(PDF) Producing Metal Powder from Machining Chips Using Ball

2023年6月27日 Nevertheless, parameter factors, such as the type of ball milling, balltopowder ratio (BPR), rotation speed, grinding period, size and shape of the milling media, and process control agent (PCA Manufacturer of Detergent Raw Material Detergent Powder Chemical, Aos Powder Godrej, Alpha Olefin Sulfonate Liquid and Sodium Silicate Liquid offered by Hitran Industries, Kanpur, Uttar Pradesh Detergent Chemicals: Type: Acid Slurry: Packaging Size: 25 kg, 50 kg: Brand: Hitran Industries: Grade: Detergent:Detergent Raw Material Detergent Powder Chemical In order to convert these raw materials into clinker and cement, it is necessary to produce a raw mix with a top size of about 02 mm The reduction ratio required for most raw materials is consequently 10002000:02 or 500010,000 It is obvious that such a degree of comminution cannot be achieved through a single machine or a onestage operationEverything you need to know about cement Materials Preparation and Raw 2016年2月1日 To choose the composition of carbon reducers mixture has been used simple physicochemical model of the ferrosilicon process with two reaction zones between which there is a mass transferSelection of Carbon Reducers for the Ferrosilicon Smelting Process

.jpg)

Steel Manufacturing: Process, Types, and Standards Thomasnet

2024年5月13日 Steel manufacturing stands as a linchpin in the intricate web of the global supply chain, with a farreaching impact on numerous industries The steel industry, encompassing crucial facets such as steel production, steel processing, and the overall manufacturing process, is indispensable in shaping the backbone of modern infrastructure and developmentUnderstanding the different types of raw materials used in paper production is crucial for producing highquality paper that meets various industrial and consumer demands In this guide, we will explore the different types of raw materials used in paper production, including woodbased raw materials, recycled paper, and nonwood fiber materialsRaw Materials Used in Paper Production CNBM2021年4月12日 Reduction of dust that is emitted to the atmosphere in the exhaust gases is carried out by using dedusting devices, being divided into particular groups []: mechanical (dry and wet) dust collectors, fabric or filled filters, and electrostatic (dry or wet) dust collectorsDust and sludge from sinter plants or blast furnace departments characterized by a high iron Research on Reduction of Selected IronBearing Waste Materials109 weight complexes with repeating units of glucose 111 The types and performances of various types of carbohydratebased concrete water reducers are summarized in Table 3 Major wastes generated from pulp and paper mills: a

Ball Mill Working Principle Ball Mill Types MC

(3) Types on the Basis of Unloading Materials 1 Tail Discharge Mill: TThe material of the tail discharge mill is fed in from one end and fed out from the other end 2 Intermediate Discharge Mill: The material of the intermediate 2021年9月22日 Types of raw material There are different types of raw materials that are grouped according to their origin, their availability or the industrial transformation process to which they must undergo By its origin Plant origin: they are obtained from plants and many can be used in their natural stateWhat is Raw Material: Types and Examples TakeCareOfMoneyRaw materials may be in processed or unprocessed state Different types of chemicals and auxiliaries used in dyeing, Acme Mills/Great Lakes Filters 33 Bloomfield Hills Pkwy #120 Bloomfield Hills, MI 48304, United States Fairway Products 301 Raw Materials Used In Textile Industries Acme Mills2024年1月15日 Waste Materials (Secondary Raw Materials): Secondary raw materials are obtained from waste materials that have undergone recycling processes and are reintegrated into the production cycle This sustainable approach contributes to environmental conservation and reduces the dependence on primary raw materials, offering a responsible and efficient way to Raw Materials : Meaning, Sources, Types Examples

.jpg)

From raw materials Extracting raw materials Raw material

the most important building materials Whether for houses, bridges or tunnels, we cannot imagine our modern world without it Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product From raw materials to cement Extracting raw materials Crushing and transportation2024年6月28日 Using highsulfatecontent water reducers or certain retarders can mitigate this issue e Cement with Poor Solubility Gypsum: Poor solubility gypsum in cement can cause false setting Avoid using water reducers that affect gypsum solubility and control the dosage of problematic water reducers f Fresh Cement High Specific Surface Cement:Mastering Water Reducers: Expert Solutions for Six Types of In addition, extrusion is the only process most suitable for long length seamless stainless steel coil tubing The raw material begins in the form of hot extruded seamless pipe The material is then cold reduced At this point the raw material is processed through tube reducers known as pilger mills in a long straight formHow Seamless Stainless Steel Tubing is Made HandyTubeThere are many different types of grinding mills (Table 1) Some devices, such as ball mills, are more suitable for coarse materials These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes Attrition mills are more appropriate for "midrange" size particlesSolids Choose the Right Grinding Mill Chemical Processing