How to extract titanium powder from vanadium titanium tailings limestone

Powder Technology

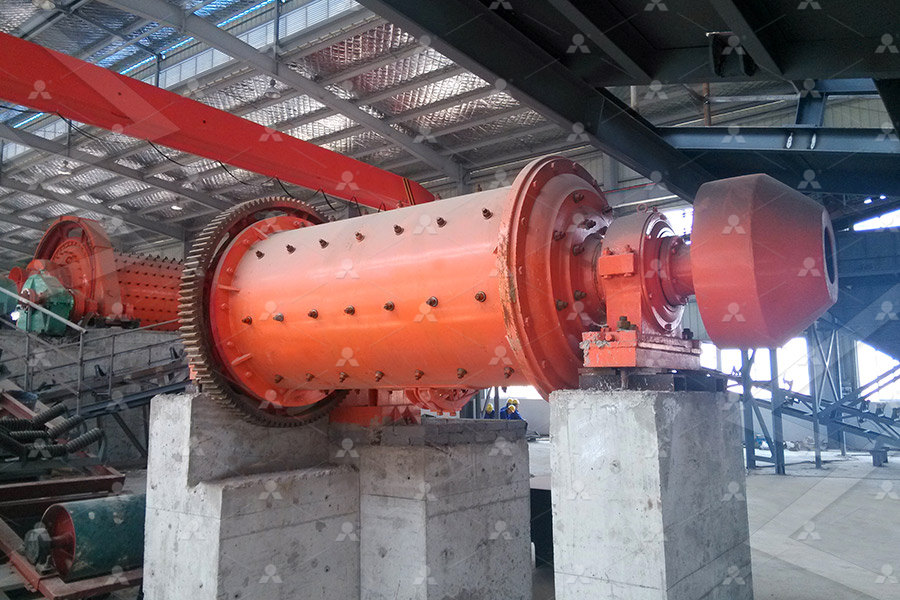

2021年10月1日 We present an optimized magnetic separation process to improve the recovery of highcontent vanadium and titanium concentrates from vanadium‑titanium magnetite (VTM) ore The ore chunks were crushed using jaw crushers and then grinded in a laboratory rod mill for 2021年5月1日 An alkali leachingacid leaching method was proposed to extract vanadium and enrich titanium from modified Tibearing blast furnace slag (MTBBFS) The optimal alkali Extraction of vanadium and enrichment of titanium from modified 2014年10月1日 This process involves several steps: partial reduction of the concentrates, magnetic separation, hydrochloric acid leaching of the titaniumbearing tailing, and alkaline A novel method to extract iron, titanium, vanadium, and 2024年12月4日 Vanadium extraction tailings (VETs), as waste generated from the vanadium smelting process, contain underutilized vanadium (V) metal resources However, improper An Efficient Route for Simultaneous Recovery of Vanadium, Iron

Selective Extraction and Separation of Titanium from Vanadium

2020年12月5日 Xiang et al reported the extraction of titanium from vanadium slag, and the main processes include calcification roasting of vanadium slag to extract vanadium, HCl leaching of In this process, titanomagnetite is first reduced using pulverized coal, followed by the removal of powdery iron from the vanadiumbearing titanium tailing by magnetic separation The A method for recovery of iron, titanium, and vanadium from 2024年8月12日 A new environmentally friendly method of water washing, calcination, and water leaching processes to extract vanadium from titanium tetrachloride tail residue was optimized Parametric Study of Vanadium Extraction Process from Refining 2024年6月18日 PDF The burgeoning accumulation of vanadiumtitanium magnetite tailings (VTMT) presents a dual challenge of environmental hazard and loss of valuable Find, read (PDF) From Waste to Wealth: Current Advances in ResearchGate

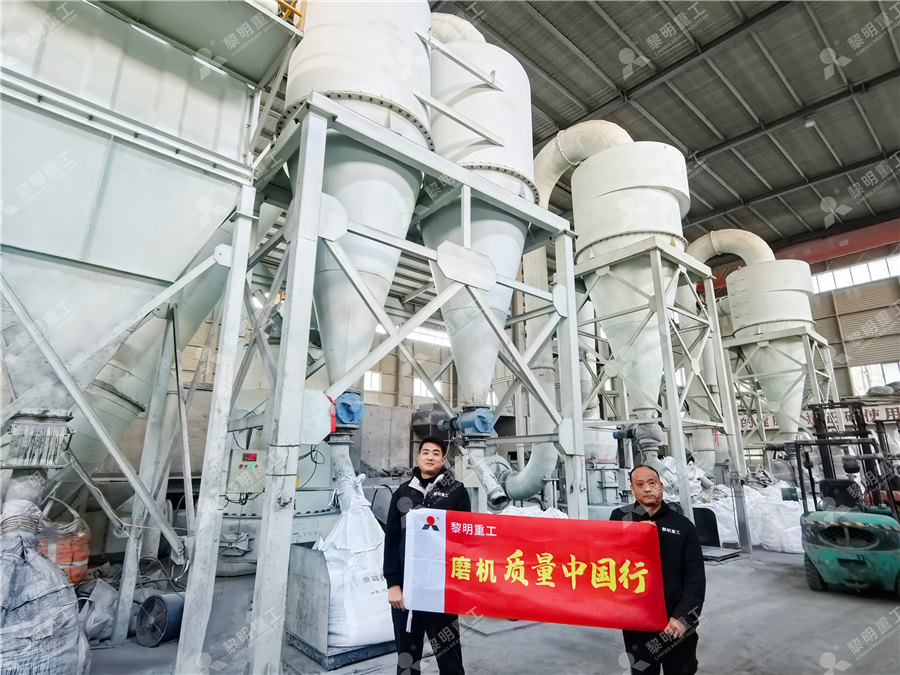

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Efficient separation of vanadium, titanium, and iron from vanadium

2021年1月15日 In order to extract vanadium, titanium, and iron from VBT ore, currently, the most common and mature treatment method in China is the blast furnace smelting [10]The method first sinters the raw ore into a spherical shape or a block shape, and then selectively reduces iron and vanadium through blast furnace roasting to form a vanadiumrich molten iron, 2018年1月6日 The Hongge mineral deposit in the PanzhihuaXichang Area of China is the biggest vanadium bearing titanomagnetite, with titanomagnetite reserves of 355 billion tons []It is also the largest chromium bearing deposit in China []Vanadium , chromium and titanium are all important strategic metals and industrial raw materials, and the comprehensive recovery of Extraction of Vanadium and Chromium from the Material Keywords Vanadiumtitanium magnetite tailings# Metal recovery# Recycling technologies# Environmental protection# Circular economy The contributing editor for this article was Anna KaksonenWealth: Current Advances in Recycling Technologies for Metal sodium roasting–water leaching to extract vanadium from vanadium–titanium magnetite This process had a high vanadium leaching rate, but large amounts of iron also entered the solution, and the tailings were difficult to handle Wen et al [27] titanium magnetite concentrate powder was mixed with Ca(OH)2, MgO, and bentoniteVanadium Titanium Magnetite Concentrate, Calcium Magnesium

Comprehensive Utilization of Vanadium Extraction Tailings: A

2020年1月16日 Vanadium titanium black porcelain was produced after adding a certain proportion of vanadium extraction tailings (25–100%) in traditional ceramic materials The general production process of vanadium titanium black porcelain is shown in Fig 1 Vanadium titanium black porcelain with different formulations has different properties and applicationDownload scientific diagram Powder XRD pattern of vanadium tailings from publication: Corecovery of iron, chromium, and vanadium from vanadium tailings by semimolten reduction–magnetic Powder XRD pattern of vanadium tailings ResearchGateDOI: 101016/JHYDROMET201407014 Corpus ID: ; A novel method to extract iron, titanium, vanadium, and chromium from highchromium vanadiumbearing titanomagnetite concentratesA novel method to extract iron, titanium, vanadium, and vanadium oxychloride and titanium tetrachloride will be extracted and condensed at the same time Because of the close boiling point, aluminum powder or organic substance is used to remove vanadium oxychloride from titanium tetrachloride in order to prepare titanium products such as sponge titanium, titanium dioxide and so on The tailing producedVanadium extraction from vanadium removal tailings of crude titanium

An environmental procedure to extract titanium components and metallic

2015年8月1日 An environmental procedure to extract titanium components and metallic iron from Tibearing blast furnace slag is accomplished via three steps, which are hightemperature modification, gravity separation and hydrometallurgy method The behaviors of metallic iron during the hightemperature modification process are studied The feasibility of separating rutile from 2003年11月1日 Download Citation How to Extract LowCost Titanium The ways to extract lowcost titanium are discussed The Armstrong process is described in detal and it is shown that it can economically How to Extract LowCost Titanium ResearchGate2022年2月18日 1 Introduction Vanadium, titanium and chromium are significant strategic metals which are widely used in aerospace, energy and alloy fields, etc []Vanadium slag (VS) is a byproduct of smelting vanadium titanomagnetite, which is mainly composed of vanadium, titanium, chromium, iron, manganese and silicon [2,3]However, as a highquality raw material Hydrothermal Separation of Titanium Vanadium and Chromium Keywords: Extracted vanadium tailings, reduction and magnetic separation, FeCr alloy, removal 1 Introduction Vanadium and titanium magnetite ores are being smelted in a blast furnace, and the Chromium and iron recovery from hazardous extracted vanadium tailings

Vanadium extraction from vanadium removal tailings of crude titanium

Abstract: In the process of preparing titanium tetrachloride by chlorination technology, vanadium oxychloride and titanium tetrachloride will be extracted and condensed at the same time Because of the close boiling point, aluminum powder or organic substance is used to remove vanadium oxychloride from titanium tetrachloride in order to prepare titanium products such as sponge total recovery ratio of vanadium and titanium and produces Cl 2, SO 2, and HCl, causing serious environmental pollution Therefore, how to use a new environmentfriendly method to extract valuable elements (V, Ti, and Fe) comprehensively and efficiently from vanadium–titanium magnetite has attracted widespread attentionSelective extraction of vanadium from vanadiumtitanium 2023年5月1日 Composite coatings based on nickel have recently become popular in the automotive and aerospace industries owing to their corrosionresistant qualitiesChromium and iron recovery from hazardous extracted vanadium tailings 2024年12月1日 Vanadiumtitanium magnetite (VTM), which is abundant in the Panzhihua region of China, contains not only iron, titanium, and vanadium but also chromium, gallium, scandium, and other useful elements (Li et al, 2017, Silin et al, 2020, Guo et al, 2020)Vanadiumtitanium magnetite tailings (VTMT) were produced in massive quantities during the mining and Preparation of vanadiumtitanium magnetite tailings/quartz

.jpg)

Extraction of vanadium and enrichment of titanium from modified

2021年5月1日 This study aimed to extract vanadium and enrich titanium from the MTBBFS by alkali leachingacid leaching The effects of operating parameters (NaOH/HCl concentration, leaching temperature, and leaching time) on the content of TiO 2, recovery ratio of Ti, and leaching ratio of each element were investigatedFurthermore, the mechanism of vanadium Vanadiumtitanium magnetite tailings (VTMT) were produced in massive quantities during the mining and utilization of the VTM In addition, VTMTs are usually stacked in powder form and direct use of these powders can Photocatalytic activity of K 2 Ti 6 O 13 /TiO 2 nanocomposite prepared using water extract of wood ash from waste for Preparation of vanadiumtitanium magnetite tailings/quartz 2019年10月1日 Zhai et al (2020) worked on early mine tailings derived from the Pangang Group's titanium mining operation in China, and demonstrated how waste from titanium mining operations could serve as an Recycling of iron and titanium resources from early tailings: 2021年3月25日 A new process of extracting titanium from vanadium–titanium magnetite (VTM) in the Panxi area in Sichuan, China is introduced in this work Various experiments, including reduction–magnetic separation, leaching and hydrolyzing experiments, are carried out The results show that the optimum conditions for leaching experiments are an acid/slag ratio of 4:1, A New Process of Extracting Titanium from Vanadium–Titanium

Effective utilization of extracted titanium tailing to prepare

2021年6月15日 Vanadium titanium (V–Ti) magnetite is a family of magnetic composite ore composed of multimetallic elements, mainly iron (Fe), vanadium (V) and titanium (Ti) There is abundant V–Ti magnetite distributed in the Panxi area of southwestern China [ 1 ]2018年4月25日 Sodium and calcification roasting processes are traditional technologies to recover vanadium from vanadium slag However, these processes are associated with many drawbacks, including high energy Simultaneous extraction of vanadium and titanium from vanadium Vanadiumtitanium magnetite, a multimetallic ore rich in iron, titanium, vanadium, and various other metals, plays a pivotal role in highquality steel production and nds applications across diverse sectors, including aerospace, medical devices, and energy storage [–3] While the 1 mineral composition varies regionally, Chinese depositsFrom Waste to Wealth: Current Advances in Recycling Abstract: In the process of preparing titanium tetrachloride by chlorination technology, vanadium oxychloride and titanium tetrachloride will be extracted and condensed at the same time Because of the close boiling point, aluminum powder or organic substance is used to remove vanadium oxychloride from titanium tetrachloride in order to prepare titanium products such as sponge Vanadium extraction from vanadium removal tailings of crude titanium

.jpg)

Overall utilization of vanadium–titanium magnetite tailings to

2020年7月1日 In recent years, the recycling of waste resources and environmental management in industrial companies have attracted people's attention (Ciarapica et al, 2019)In the Panzhihua area of southwestern China, a large number of vanadium–titanium magnetite tailings (VTMT) are generated in the selection process of iron concentrate (Chen et al, 2016; Sun et al, 2019; The invention aims to solve the technical problem of providing a method for extracting vanadium from titanium tetrachloride refined tailings, which comprises the following steps: mixing the titanium tetrachloride refined tailings and hydrochloric acid, adding a reducing agent, uniformly mixing, leaching, and separating to obtain vanadiumcontaining leachate and A Method for extracting vanadium from titanium Vietnam Journal of Chemistry, 2019 Purification of titanium tetrachloride (TiCl4) is an important step in the titanium process After chlorination, impurities in the gained crude TiCl4 such as V, Al, Fe, Si, etc were removed by distillation technique following the chemical pretreatment method(PDF) Production of titanium tetrachloride (TiCl4) from titanium ores The invention discloses a method for separating and extracting iron, vanadium and titanium from vanadiumtitanium magnetite, which comprises the following steps: magnetic separation of raw ore: performing magnetic separation on the vanadiumtitanium magnetite to obtain ironvanadium concentrate and tailings; separating titanium concentrate from tailings: flotation is carried out Method for separating and extracting iron, vanadium and titanium

.jpg)

Selective nitridation–corrosion process to recover vanadium, titanium

2023年1月1日 Although vanadium slag contains various valuable metals, including vanadium, titanium, chromium, iron, etc, it is only used to extract the vanadium due to technical limitations2024年2月15日 The problem of steel slag could be solved by expanding the utilization ways of steel slag At present, steel slag has been used in the production of cement, the construction of urban roads and the production of fertilizer (Fronek et al, 2012; Jiang et al, 2018b; Shi and Qian, 2000; Wang and Cai, 2006)In developed countries, the utilization rate of steel slag is close to Vanadium extraction from steel slag: Generation, recycling and 2021年1月15日 In order to extract vanadium, titanium, and iron from VBT ore, currently, the most common and mature treatment method in China is the blast furnace smelting [10]The method first sinters the raw ore into a spherical shape or a block shape, and then selectively reduces iron and vanadium through blast furnace roasting to form a vanadiumrich molten iron, Efficient separation of vanadium, titanium, and iron from vanadium 2018年1月6日 The Hongge mineral deposit in the PanzhihuaXichang Area of China is the biggest vanadium bearing titanomagnetite, with titanomagnetite reserves of 355 billion tons []It is also the largest chromium bearing deposit in China []Vanadium , chromium and titanium are all important strategic metals and industrial raw materials, and the comprehensive recovery of Extraction of Vanadium and Chromium from the Material

Wealth: Current Advances in Recycling Technologies for Metal

Keywords Vanadiumtitanium magnetite tailings# Metal recovery# Recycling technologies# Environmental protection# Circular economy The contributing editor for this article was Anna Kaksonensodium roasting–water leaching to extract vanadium from vanadium–titanium magnetite This process had a high vanadium leaching rate, but large amounts of iron also entered the solution, and the tailings were difficult to handle Wen et al [27] titanium magnetite concentrate powder was mixed with Ca(OH)2, MgO, and bentoniteVanadium Titanium Magnetite Concentrate, Calcium Magnesium 2020年1月16日 Vanadium titanium black porcelain was produced after adding a certain proportion of vanadium extraction tailings (25–100%) in traditional ceramic materials The general production process of vanadium titanium black porcelain is shown in Fig 1 Vanadium titanium black porcelain with different formulations has different properties and prehensive Utilization of Vanadium Extraction Tailings: A Download scientific diagram Powder XRD pattern of vanadium tailings from publication: Corecovery of iron, chromium, and vanadium from vanadium tailings by semimolten reduction–magnetic Powder XRD pattern of vanadium tailings ResearchGate

A novel method to extract iron, titanium, vanadium, and

DOI: 101016/JHYDROMET201407014 Corpus ID: ; A novel method to extract iron, titanium, vanadium, and chromium from highchromium vanadiumbearing titanomagnetite concentratesvanadium oxychloride and titanium tetrachloride will be extracted and condensed at the same time Because of the close boiling point, aluminum powder or organic substance is used to remove vanadium oxychloride from titanium tetrachloride in order to prepare titanium products such as sponge titanium, titanium dioxide and so on The tailing producedVanadium extraction from vanadium removal tailings of crude titanium 2015年8月1日 An environmental procedure to extract titanium components and metallic iron from Tibearing blast furnace slag is accomplished via three steps, which are hightemperature modification, gravity separation and hydrometallurgy method The behaviors of metallic iron during the hightemperature modification process are studied The feasibility of separating rutile from An environmental procedure to extract titanium components and metallic 2003年11月1日 Download Citation How to Extract LowCost Titanium The ways to extract lowcost titanium are discussed The Armstrong process is described in detal and it is shown that it can economically How to Extract LowCost Titanium ResearchGate