Concrete mixing station batching process flow

.jpg)

The Flowchart of stationary batching plant

This article aimed to review the ability of the Palestinian construction companies to apply the basic tools of statistical process control (SPC) in their concrete production systems for2016年10月24日 As the core of the concrete mixing station, you must keep your eyes open and choose the right product when you choose a batching plant The control system in a batching Understanding the Working Flow of Concrete Batching Plants2024年8月5日 The flow chart of a concrete batching plant shows the complete process from raw material preparation to finished product delivery, which includes several key steps, such as raw material preparation, proportioning design, pre Batching Plant Process Flow Chart ZOOMJOA typical UHPC mix consists of cement, fine aggregate, supplementary cementitious materials (ie, silicafume, fly ash, or slag), significantly low watertobinder ratio (018022), chemical4 Flow charts of the batching and mixing procedures

How Does a Concrete Batch Plant Work Production

A Concrete batch plant, also named concrete batching plant, batching plant, concrete mixing plant and concrete mixing station, is an assembly device used for the mass production of fresh concrete So how does a concrete batch plant 2024年6月6日 The process flow of this station covers the whole process of measuring, conveying, mixing and discharging of raw materials, which strictly guarantees the quality and Concrete Batching Plant ProcessProcess flow of concrete batching plant 1 Aggregate weighing: the required aggregate includes sand and gravel, which are transported to the plant by truck (the aggregate required for concrete shall meet the use standard, or the Process flow of concrete batching plantBatching is the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer To produce concrete of uniform quality, the ingredients must Batching, Mixing, Transporting, and Handling Concrete

CONCRETE BATCHING PLANT OPERATING

This paper presents an advanced and practical control system for the automated filling of aggregate in concrete batching process The aggregate mixture which account for 60 to 75 percent of the total volume of concrete must be filled 05 m3 concrete batching plant refers to a kind of equipment or facility that can mix 05 cubic meters of concrete at one time The Mixing Time of Concrete In Batching Concrete Batching Plant Process Flow DiagramConcrete Mixing Plants Batching, Stationary, Mobile, Portable A stationary concrete batching station can be customized by our technical engineer to establish the perfect plant solution based on your vision, Process Flow Of A Stationary Concrete Batching Plant Stationary concrete plant What is stationary concrete batching plant? LTG 2024年6月3日 When you think about construction, concrete mixing and batching mightn’t be the first things that come to mind, but they’re essential to building strong structures In this article, you’ll get a clear picture of the concrete Concrete Mixing and Batching: Mastering the

Numerical flow simulation of fresh concrete in mixing truck

2022年9月1日 The flow of fresh concrete in the mixing drum is a complex process [5] Due to the differences in the size, shape and density between mortar and coarse aggregate, they are easy to separate and lead to segregation [6], which seriously affects the strength and durability of concrete structure [7]This document provides operating procedures for a concrete batching plant that supplies concrete for construction projects in the oil and gas field It outlines the procedures for ordering, producing, controlling quality, and delivering concrete The key steps include developing 3month, weekly and daily demand schedules, ensuring quality of raw materials like cement and aggregates Concrete Batching Plant Operations Procedure PDF Concrete 2020年5月30日 #civilengineering #civilengineer #engineer #concretePROCESS OF A CONCRETE BATCHING PLANT Animation video Civil EngineeringThis video contains the processPROCESS OF A CONCRETE BATCHING PLANT Animation video Civil 2011年8月1日 On the basis of analyzing technology processes and control demands of concrete mixing station, a design of control system for this construction machinery based on SIEMENS S7300 PLC and eView Design of Control System for Concrete Mixing Station

Concrete: Batching and Mixing Concrete Technology

In this article we will discuss about the process of batching and mixing of concrete Batching of Concrete: The correct measurement of the various materials used in the concrete mix is called batching It has been observed that batching errors are partly responsible for the variation in the quality of concrete This operation can be properly and better controlled than other factors Each type of concrete batching plant has its advantages and is suitable for different construction applications Factors such as project size, location, and specific requirements will determine the most suitable type to use Importance of Concrete Batching Plants Concrete batching plants offer several advantages in construction projects:What Is Concrete Batching Plant? Work Procedure, Types, Download scientific diagram The Flowchart of stationary batching plant from publication: Quality Management to continuous improvements in process of Ready Mix Concrete production The key The Flowchart of stationary batching plant ResearchGateChina Concrete Mixing Stations wholesale Machining Process: Concrete Mixing Plant Certification: ISO9001: 2000, CE Condition: New Matched Concrete Mixer: Js1000 60m3/H Small Concrete Mixing Plant Batching Station with Higher Output and Lower Price US$ 60000 / PieceConcrete Mixing Stations MadeinChina

Concrete Mixing Plants Batching, Stationary, Mobile, Portable

Concrete Batching Plant Process Flow Diagram what should be paid attention to when buying concrete mixing station? A: 1 Performance label of the concrete 2 The quantity and duration of the concrete 3 Construction environment and construction objects 42021年1月18日 Mostly it is used in Ready mix concrete plants This type of batching is mostly used for large construction 2 Mixing of concrete: Mixing is necessary to make homogeneous concrete To obtain a good quality of Concrete Production, Placement, Curing ProcessThe document discusses batching, mixing, transporting, and handling concrete It covers three main topics: 1 Batching is the process of measuring concrete mix ingredients by mass or volume and introducing them into the mixer Most specifications require batching by mass within certain tolerances 2 Mixing can be done stationary on site or using ready mixed concrete transported Chap10 Batching, Mixing, Transporting and Handling Concrete2024年12月2日 The control panel is the brain of the concrete batch plant It manages and monitors the entire operation, from weighing materials to mixing and discharging the concrete Modern control panels are computerized for improved accuracy and efficiency How to Operate a Concrete Batching Plant Operating a concrete mixing plant involves several stepsConcrete Batching Plants: Ultimate Guide for Efficient Operations

.jpg)

Concrete production process flow chart ResearchGate

Download scientific diagram Concrete production process flow chart from publication: Assessment tools for the environmental evaluation of concrete, plaster and brick elements production The process of mixing concrete is affected by a number of elements, including, Location of the building site with enough space for the activities involved in construction, such as densely populated urban regions; Space available for batching, mixing of concrete, and storing materials required for the production of concrete Required concrete volumeMixing of Concrete – Methods And ProcedureBatching Of ConcreteConcrete mixing plant is a largescale construction machinery and equipment, is built by a large number of mechanical equipment, so the correct operation of the concrete mixing station is very important, led by moving the whole body is also the case, every mechanical equipment After the shutdown and shutdown of these two processes, although the two simple operation, but it is The operation flow of concrete mixing plantCement concrete batching plant, concrete mixing plant is currently the most popular central mixed concrete joint device +86371 Skype: The twostage process of cement concrete mixing station is as follows: sand, stone, cement and other materials subpromoted twice, Concrete Batching Plant Production Process

.jpg)

1112 CONCRETE BATCHING US EPA

Concrete masonry, another type of manufactured concrete, may be best known for its conventional 8 x 8 x 16inch block In a few cases, concrete is dry batched or prepared at a building construction site Figure 11121 is a generalized process diagram for concrete batching The raw materials can be delivered to a plant by rail, truck or bargeDry Mix Concrete Batching Plant Process Flow Concrete Batching Plant Layout Drawing, Find Details and Price about Dry Concrete Batching Plant Dry Mixing Plant Ready from Dry Mix Concrete Batching Plant Process Flow Concrete Batching Plant Layout Drawing Shandong Cad Industry Machinery Equipment Co, LtdDry Mix Concrete Batching Plant Process Flow Concrete Batching A concrete batching plant is equipment designed to combine specific ingredients to form concrete These ingredients include water, sand, aggregates (such as rocks and gravel), cement, and additional elements like fly ash, silica fume, and slag The plant typically houses several key components, including mixers, batchers, conveyors, silos, and control systems For detailed What Is a Concrete Batching Plant? Rethinking The Future2021年2月1日 Wet Mix Batching Plants Process Flow of Wet Mix Plant The process flow of the entire modular wet mix plant operation is as illustrated below: Cycle Time per Load = Batching + Delivery + Discharging + Return + Queuing Concrete Batching Plant PPT SlideShare

.jpg)

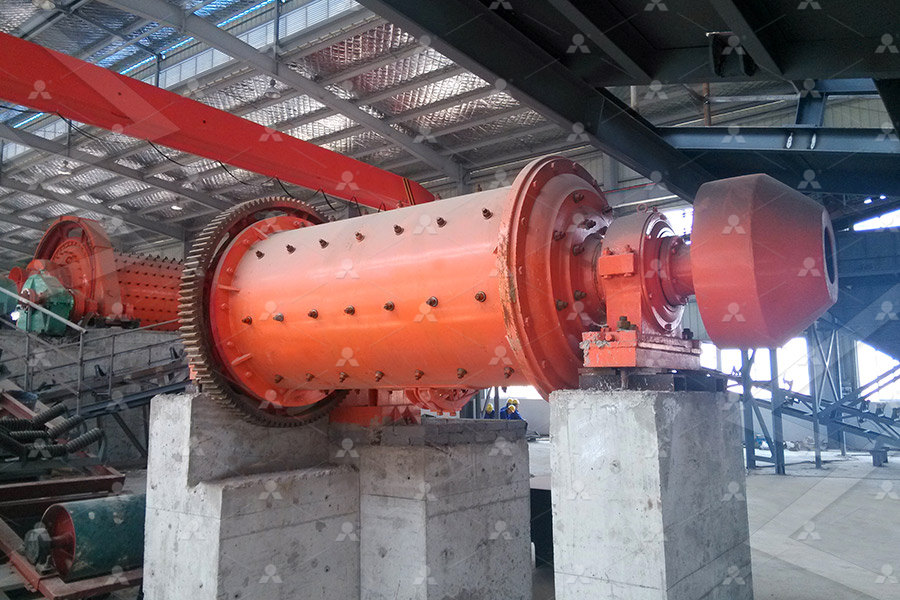

Concrete Mixing Station Get Your Plant Fully Customized

Customizable components with large array of configuration, LUTON Group is dedicated to manufacturing your most suitable and tailormade concrete mixing station with highest quality The capacity (m³/h) of the concrete mixing station we provide is from 25 to 240, if you have any other special needs, you can also tell our expert to adjust your plantChina Concrete Mixing Station wholesale Machining Process: Concrete Wet Mix Structure: Skip Hoist Productivity: 75m²/h Certification: ISO9001: 2000, CE Concrete Batching Mixing Plant Station for Sale US$ 8150081600 / sets 1 sets Concrete Mixing Station MadeinChinaA concrete plant makes concrete through machinery, precisely batching and mixing cement, aggregates (sand and gravel), water and admixtures Visit us at World of Concrete 2025! Booth N355, North Hall Producer Center Las Vegas Convention Center January 2123Overview of Concrete Batch Plants: types, parts applicationsAccidents without size, reasonable and safe switch concrete mixing plant parts of the switch is to reduce the occurrence of accidents and equipment to ensure the useful life of the necessary prerequisite Mix station owners to plan to improve the operator safety switch mixing station work flow Concrete mixing plant boot sequence (Including pellets, cement) open water to open The Mixing Process of Concrete Batching Plant

Concrete Batching Method — Civil Engineering Profile

2023年9月3日 Introduction Concrete batching is an essential step in the production of concrete and is carried out early in the process It involves measuring and mixing the necessary ingredients, including cement, aggregates such as sand, gravel, or crushed stone, water, and admixtures, in the right proportions to create a concrete mixture that meets the desired quality 4, simple concrete batch plant with selffalling cement mixer or coneshaped material out of the mixer is usually stirred for about 2min, until the concrete mixture mixing evenly, you can discharge 5, with the cement mixer on the material out of the chute into the machine within the clinker or reverse the cone mixer out of the material, slippery transport car, sent to the site The process flow of small concrete batch plantOnly the concrete batching plant is prone to dust due to powder batching and vibration of the batching station during production, and the powder flow rate is fast, which is more likely to cause dust pollution Threatening the life and the three main sources of dust in the mixing process of the concrete batching plant will be effectively concrete batch plant dust control, concrete batching plant dust 05 m3 concrete batching plant refers to a kind of equipment or facility that can mix 05 cubic meters of concrete at one time The Mixing Time of Concrete In Batching Concrete Batching Plant Process Flow DiagramConcrete Mixing Plants Batching, Stationary, Mobile, Portable

What is stationary concrete batching plant? LTG

A stationary concrete batching station can be customized by our technical engineer to establish the perfect plant solution based on your vision, Process Flow Of A Stationary Concrete Batching Plant Stationary concrete plant 2024年6月3日 When you think about construction, concrete mixing and batching mightn’t be the first things that come to mind, but they’re essential to building strong structures In this article, you’ll get a clear picture of the concrete Concrete Mixing and Batching: Mastering the 2022年9月1日 The flow of fresh concrete in the mixing drum is a complex process [5] Due to the differences in the size, shape and density between mortar and coarse aggregate, they are easy to separate and lead to segregation [6], which seriously affects the strength and durability of concrete structure [7]Numerical flow simulation of fresh concrete in mixing truckThis document provides operating procedures for a concrete batching plant that supplies concrete for construction projects in the oil and gas field It outlines the procedures for ordering, producing, controlling quality, and delivering concrete The key steps include developing 3month, weekly and daily demand schedules, ensuring quality of raw materials like cement and aggregates Concrete Batching Plant Operations Procedure PDF Concrete

.jpg)

PROCESS OF A CONCRETE BATCHING PLANT Animation video Civil

2020年5月30日 #civilengineering #civilengineer #engineer #concretePROCESS OF A CONCRETE BATCHING PLANT Animation video Civil EngineeringThis video contains the process2011年8月1日 On the basis of analyzing technology processes and control demands of concrete mixing station, a design of control system for this construction machinery based on SIEMENS S7300 PLC and eView Design of Control System for Concrete Mixing StationIn this article we will discuss about the process of batching and mixing of concrete Batching of Concrete: The correct measurement of the various materials used in the concrete mix is called batching It has been observed that batching errors are partly responsible for the variation in the quality of concrete This operation can be properly and better controlled than other factors Concrete: Batching and Mixing Concrete TechnologyEach type of concrete batching plant has its advantages and is suitable for different construction applications Factors such as project size, location, and specific requirements will determine the most suitable type to use Importance of Concrete Batching Plants Concrete batching plants offer several advantages in construction projects:What Is Concrete Batching Plant? Work Procedure, Types,

The Flowchart of stationary batching plant ResearchGate

Download scientific diagram The Flowchart of stationary batching plant from publication: Quality Management to continuous improvements in process of Ready Mix Concrete production The key