Limestone crusher for smelting waste slag disposal

.jpg)

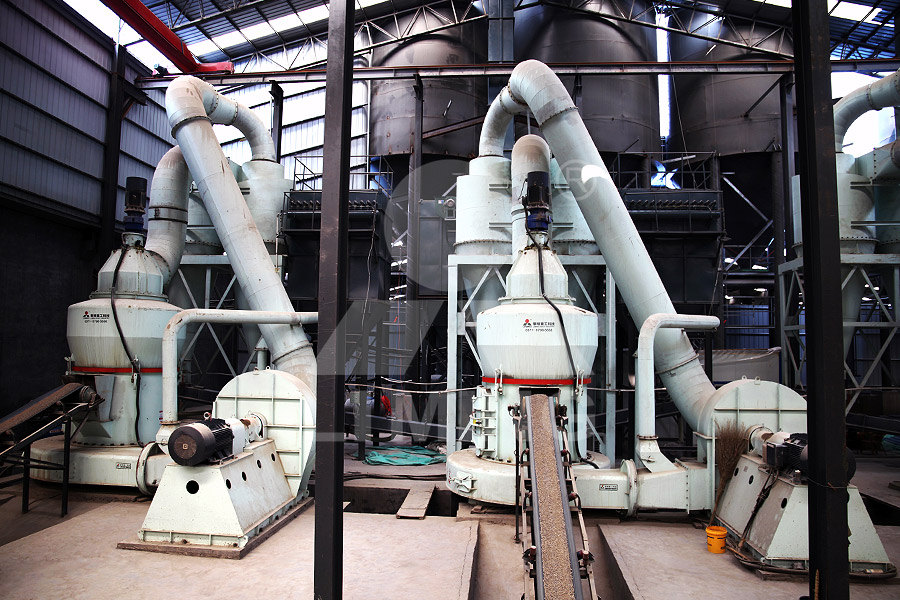

Limestone Mills Williams Crusher

Williams Crusher’s limestone mills and Pulverizers offer solutions for various sizereduction applications We design manufacture the most durable efficient limestone crushing machines on the market2024年10月9日 Stationary recycling crusher plants for slag are an essential part of the Stationary Recycling Crusher Plants for SlagThe proven Sanme impact crusher is a new type of impact crusher with high efficiency, and is Limestone Aggregates Processing SHANGHAI SANME MINING 2018年12月1日 For example, wool fibers from waste building waste recycling in Europe (OIIi and Timo, 2014), wool fibers from fly ash and bottom slag in Taiwan (Wang et al, 2010), and wool fibers from chromium Applicability of gold tailings, waste limestone, red mud, and

.jpg)

Limestone Mills Limestone Crushers Pulverizers

Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve 2018年12月1日 Increasing concerns about environmental issues have led to more attention being paid to the recycling of mining wastes and smelting byproducts In the present study, the utilization of gold tailings, waste limestone, red mud, and ferronickel slag was investigated for producing continuous glass fibersTo verify the applicability of the downdrawing process, the Applicability of gold tailings, waste limestone, red mud, and 2021年10月1日 Copper slag waste has continued to cause increasing concerns due to the huge volumes being produced annually worldwide This paper presents a review of copper slag as a potential resource for cobalt and copper metals for a circular economy An overview of the chemical and mineralogical characterisation of copper slag from 21 major producing countries The potential for copper slag waste as a resource for a circular 2023年1月1日 Although considerable effort has been done over a long period of time in the exploitation of industrial waste, ferrochrome slag has received surprisingly less investigationUtilization of steel slag waste as construction material: A review

.jpg)

Utilization and detoxification of gypsum sludge by replacing limestone

reductions smelting of high lead slag Herein, toxicity leaching experiment of sulfuric acid and nitric acid method was used to evaluate the safety of the cosmelting slag to provide a basis for the cosmelting of high lead slag with gypsum sludge 2 Experimental 21 Materials and reagents In this study, high lead slag as the experimentalJapanese and Korean companies are also found patenting in the area of steel slag [9] Disposal of slag is the major issue for the steel industries as huge space is required for its dumping Dumping of slag on the agricultural land often creates protest by farmers for the disposal of the slag waste by the industry [10](PDF) Review on the innovative uses of steel slag for waste Gypsum sludge refers to a hazardous solid waste produced by the nonferrous smelting industry, and its disposal and utilization are environmentally challenging To investigate the feasibility of replacing limestone with gypsum sludge for smelting slagging, the effect of gypsum sludge and smelting conditions on high lead slag reduction smelting was studied through thermodynamic Utilization and detoxification of gypsum sludge by replacing limestone 2016年5月16日 In this study, aqueous mineral carbonation of Linz–Donawitz (LD) slag waste from Rourkela, Bokaro, and Tata steel industries was undertaken at a room temperature of 30°C and elevated CO2 (PDF) Sustainable Approaches for LD Slag Waste

Life cycle assessment for waste acid treatment in zinc smelting

2022年11月1日 Lift cycle assessment (LCA) methodology was applied to evaluating and comparing two waste acid disposal processes in zinc smelting The results indicate that environmental impacts of gas—liquid vulcanization technologies are human toxicity, abiotic depletion potential, and global warming risk, which are mainly caused in neutralizing— 2021年10月1日 Copper slag waste has continued to cause increasing concerns due to the huge volumes being produced annually worldwide This paper presents a review of copper slag as a potential resource for The potential for copper slag waste as a resource for a circular 2012年5月23日 Gold mine tailing, red mud and waste limestone cause very serious problems to the environment Due to their abundant amount of waste as well as difficulties with disposal, an appropriate recycling (PDF) A new approach to the recycling of gold mine tailings 2023年6月28日 Waste generation Smelting generates a lot of debris, such as slag, which can include heavy metals and other harmful substances Poor slag disposal or containment can cause soil and water pollution, endangering both Smelting Metal: How It Works Metal Supermarkets UK

Utilization and detoxification of gypsum sludge by replacing limestone

2023年5月26日 Gypsum sludge refers to a hazardous solid waste produced by the nonferrous smelting industry, and its disposal and utilization are environmentally challenging To investigate the feasibility of replacing limestone with gypsum sludge for smelting slagging, the effect of gypsum sludge and smelting conditions on high lead slag reduction smelting was studied Slag recovery: Turning a waste disposal problem into a business opportunity; • The slagco product produced from the metallic recovery process fulfills important functions as construction materials for roads, ports, airports, and also as an environmental material for restoring or improving marine, soil, and other environments,Slag Recycling and Metal Recovery MEKAThe limestone crusher is equipment that can crush large limestone gravels about 6001800mm into materials about 25mm or smaller It provides limestone crushed products in the construction industry because limestone is a key ingredient in the production of cement, concrete and other building materialsThe size and type of crushers may vary according to the specific What is Limestone Crusher? AIMIX GROUP2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate Life cycle assessment of melting reduction treatment for iron and

Cotreatment of gypsum sludge and Pb/Zn smelting slag for the PubMed

2016年10月1日 The binder ratio was determined according to the UCS and optimal experiments, and the optimal mass ratio of m (smelting slag): m (cement clinker): m (gypsum sludge): m (limestone) was 70:13:12:5 When the binder was mixed with arsenic sludge using a mass ratio of 1:1 and then maintained at 25 °C for 28 d, the UCS reached 930 MPa2023年12月15日 The pulp production process generates a CaCO 3rich solid waste known as white mud (WM), and its improper disposal is a cause for global concernThe present study investigates the composition, microstructure, and thermal decomposition characteristics of WM and proposes a strategy for replacing limestone with WM for iron ore sinteringA new disposal method for white mud: Replacing limestone in 2018年2月5日 Disposal of slag is the major issue for the steel industries as huge space is required for its dumping Dumping of slag on the agricultural land often creates protest by farmers for the disposal of the slag waste by the industry []Near Jamshedpur in India, where most of the steel industries are established, the people with low to very low income reside near those Review on the innovative uses of steel slag for waste minimizationIndustrial solid waste (ISW) is a collection of waste produced in the process of industrial manufacturing [1], [2]In recent decades, the global production of ISW has continued to increase, in China, for example, by 2020 to reach a staggering 368 billion ton [3], [4]ISW generally has the characteristics of large storage, continuous environmental pollution, rich in valuable metals, Practical experience to theoretical innovation: A model for

.jpg)

Utilization and detoxification of gypsum sludge by replacing limestone

2023年5月26日 Gypsum sludge refers to a hazardous solid waste produced by the nonferrous smelting industry, and its disposal and utilization are environmentally challenging2021年10月1日 The bulk chemical composition of copper slags may vary depending on the pyrometallurgical technique used; the phase composition of the copper slag can be quite diverse (Gbor et al, 2000, Gorai et al, 2003, Lottermoser, 2006, Lottermoser, 2010, Potysz et al, 2015)For example, studies on air cooled and quenched copper slag revealed that the diversity The potential for copper slag waste as a resource for a circular Crusher supplier YIFAN Machine is China's leading supplier of crusher machines It Supply Mobile Crusher, Impact Crusher, Cone Crusher, Jaw Crusher, Sand Making Machine, Mining Crushing Equipment and construction waste disposal equipmentCrusher,Mobile crusher,Crusher Machine YIFAN Mining Shanghai Zenith crusher official website, is professional in providing crusher, jaw crusher, cone crusher, impact crusher, and other series and models of crushers They are widely used in mining, construction, stone crushing, metal ore crushing, solid waste disposal, as well as highway construction, water conservancy, refractories, sand processing and other fieldsCrusher, Crusher Equipment, Crusher Machine, Crushers for Sale

Slag recycling and reuse – GREENY approach Metso

2021年1月12日 The global demand for raw materials is growing exponentially with the world’s urbanization and technological progress The growing raw materials consumption is an economical threat due to the increasing scarcity of critical materials, but also an environmental threat with increased amounts of production waste such as slag2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel 2022年4月1日 This work proposes an environmentally safe and economically feasible method of waste coppernickel production slag utilization (Kola MiningMetallurgical Company, Nornickel, Kola Peninsula, Russia)The potential for copper slag waste as a resource for a circular 2021年3月16日 By Alton Tabereaux, Contributing Editor Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity The International Aluminium Institute (IAI) asserts that 16 million tons of SPL were generated from primary aluminum production in 2019,1 making it the The SPL Waste Management Challenge in Primary Aluminum

Limestone Crusher: What Is It How Does It Work?

In this article, we've discussed what is limestone crusher, its uses, working and tips on choosing the right one In this article, we've discussed what is limestone crusher, Additionally, the machine is designed to be as efficient as possible, meaning that it will not waste any of the limestones that it processes 32018年12月1日 For example, wool fibers from waste building waste recycling in Europe (OIIi and Timo, 2014), wool fibers from fly ash and bottom slag in Taiwan (Wang et al, 2010), and wool fibers from chromium Applicability of gold tailings, waste limestone, red mud, and Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve Limestone Mills Limestone Crushers Pulverizers2018年12月1日 Increasing concerns about environmental issues have led to more attention being paid to the recycling of mining wastes and smelting byproducts In the present study, the utilization of gold tailings, waste limestone, red mud, and ferronickel slag was investigated for producing continuous glass fibersTo verify the applicability of the downdrawing process, the Applicability of gold tailings, waste limestone, red mud, and

The potential for copper slag waste as a resource for a circular

2021年10月1日 Copper slag waste has continued to cause increasing concerns due to the huge volumes being produced annually worldwide This paper presents a review of copper slag as a potential resource for cobalt and copper metals for a circular economy An overview of the chemical and mineralogical characterisation of copper slag from 21 major producing countries 2023年1月1日 Although considerable effort has been done over a long period of time in the exploitation of industrial waste, ferrochrome slag has received surprisingly less investigationUtilization of steel slag waste as construction material: A reviewreductions smelting of high lead slag Herein, toxicity leaching experiment of sulfuric acid and nitric acid method was used to evaluate the safety of the cosmelting slag to provide a basis for the cosmelting of high lead slag with gypsum sludge 2 Experimental 21 Materials and reagents In this study, high lead slag as the experimentalUtilization and detoxification of gypsum sludge by replacing limestone Japanese and Korean companies are also found patenting in the area of steel slag [9] Disposal of slag is the major issue for the steel industries as huge space is required for its dumping Dumping of slag on the agricultural land often creates protest by farmers for the disposal of the slag waste by the industry [10](PDF) Review on the innovative uses of steel slag for waste

Utilization and detoxification of gypsum sludge by replacing limestone

Gypsum sludge refers to a hazardous solid waste produced by the nonferrous smelting industry, and its disposal and utilization are environmentally challenging To investigate the feasibility of replacing limestone with gypsum sludge for smelting slagging, the effect of gypsum sludge and smelting conditions on high lead slag reduction smelting was studied through thermodynamic 2016年5月16日 In this study, aqueous mineral carbonation of Linz–Donawitz (LD) slag waste from Rourkela, Bokaro, and Tata steel industries was undertaken at a room temperature of 30°C and elevated CO2 (PDF) Sustainable Approaches for LD Slag Waste2022年11月1日 Lift cycle assessment (LCA) methodology was applied to evaluating and comparing two waste acid disposal processes in zinc smelting The results indicate that environmental impacts of gas—liquid vulcanization technologies are human toxicity, abiotic depletion potential, and global warming risk, which are mainly caused in neutralizing— Life cycle assessment for waste acid treatment in zinc smelting