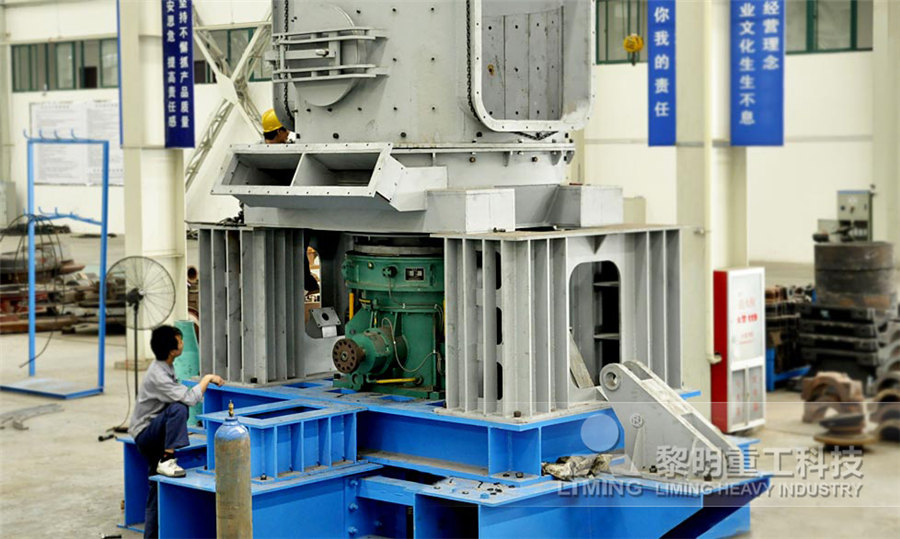

New dry process cement vertical mill

Dry Process Of Cement Manufacturing Dry Cement

The new dryprocess of cement manufacturing technology makes good use of the limestone resources discarded in the traditional mining method and applies the pre decomposition technology, suspension preheating technology, and multi Great Wall Machinery can provide general contracting of new dry process cement production Cement Production LineCement Kilns Manufactured By AGICO Cement kiln: the dry method cement kiln manufactured by AGICO has the characteristic of stable performance, low energy consumption, high yield, and easy operation We equip our cement kiln with a Dry Process Of Cement Manufacturing Dry Cement GRMK3041 Vertical Cement Mill : 1000 t/d : GRMR2231 Vertical Raw Mill : GRMC1231 Vertical Coal Mill : Φ33×52m Rotary Kiln : Φ26×13m Cement Mill 1500 t/d Cement Production Line The new dry process cement production line with a capacity of 1500t/d built by Xinxiang Great Wall Machinery Co, Cement Production Line

Cement Production Process Cement Manufacturing

2020年8月25日 A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement cement ball mill and cement vertical mill are generally used in the raw and it tends to be Using new dry process of Portland cement manufacture, AGICO cement plant achieves high output capacities Ask now for a free quote! Skip to content Home; About Menu Toggle Cement Ball Mill; Vertical Roller Mill; Cement Mill Separator; Cement Mill; Others Menu Toggle Conveying System; Overland Conveyor; Vibrating Grizzly Feeder;Portland Cement Plant for Sale New Dry Process of Portland Cement As a professional cement equipment manufacturer, AGICO has rich experience in the designing and manufacturing of cement ball mills and vertical roller mills Our cement mills have extraordinary performance in the cement grinding process of the new dry process cement plants Cement Ball MillCement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMA

.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 The wet process requires 028 tons of coal and 110 kWh to produce one ton of cement, while the dry process requires only 018 tons With the grinding capacity of a vertical roller mill and the ability to dry, Volume I, Part I, ABI Books Private Ltd, First Edition, New Delhi: 1991 Google Scholar [4] Confederation of Indian 2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10] A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a trueReview on vertical roller mill in cement industry its The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainabilityVertical roller mill vs ball mill for cement grinding: Comparison Providing Consistent Results With Advanced Vertical Cement Mill Technology Magotteaux’s advanced vertical cement mill technology ensures consistent results by providing precise control over the grinding process, enabling the production of highquality cement with minimal variations in finenessMoreover, our use of advanced materials and innovative designs ensures that our Vertical Cement Mill Magotteaux

.jpg)

Performance Evaluation of Vertical Roller Mill in

2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the The 2500t / d cement clinker production line adopts a new dry process, with an annual output of 775,000 tons of cement clinker and a total cement output of 105 million tons / year Tel: which are crushed, proportioned and grinded into 2500TPD new type dry process cement clinker At present, cement production mainly uses a new dry cement production method, which is mainly reflected in the raw material has been preheated by the high temperature of the preheater and the high temperature of the exhaust gas before entering the kiln, and nearly 90% of the calcium carbonate in the raw material is decomposed into calcium oxide in the decomposition furnaceDry Process Of Cement Production 3005000TPD AGICO CEMENTChina leading provider of Vertical Cement Mill and Cement Ball Mill, High Temperature Dry Process 6000T/D Cement Rotary Kiln; Huaqiang New Times, Xian'ge Avenue, HiTech Industry Development Zone, Anyang, Henan, China +86372: @ Find Quality Vertical Cement Mill Cement Ball Mill factory from China

Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%The new dry process cement production line, Pervomaysky, was erected next to Novorossiysk in the southern region of z A marl crusher plant, designed for 800 tph z A raw material grinding system with a vertical roller mill (VRM), designed for 550 tph z A pyroprocessing line, with a daily production rate of 6000 tpd, consisting of the From Virtual to Reality KHD Humboldt Wedag2015年1月1日 Vertical cement mill (vertical mill) is a machine that plays an important role in the raw meal production process of the newtype dry cement, and it is a set breakage, drying, grinding, transport in one []Raw material grinding process is a vital and energy consumption link in the cement productionModeling Based on the Extreme Learning Machine for Raw Cement Mill In 1999 the Polysius roller mill Quadropol was introduced onto the market with the target to offer a vertical roller mill (VRM) of highest reliability which allows feeding of a 10 000 tpd clinker line by a single mill 1 Introduction The vertical roller mill is one of the large host units of the new dry cement production process, Operating experience with the new PolysiusQuadropol2 raw mill Cement

Difference Between Cement Vertical Mill and Ball Mill

Ball mill is a kind of equipment with high energy consumption During operation, all parts of the ball mill are in motion, with large vibration and high energy consumption; Compared with the ball mill, the vertical mill can save 30% 40% of energy consumption, and has low vibration, which is a low energy consumption Energy Saving and Noise Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball mills2020年11月25日 Cement equipment list This is a dry process cement plant customized by a client from Shenyang, Liaoning province To meet the cement production requirement, the cement production line is equipped with raw mill, 5000tpd Dry Process Cement Plant Project In LiaoningAt present, it has completed over 60 new dryprocess cement clinker production lines of various sizes (3008000 tons/d), more than 10 pure low temperature waste heat power generation projects for cement clinker production lines and Leading Supplier of Cement Plant Equipments Rotary

New Type Dry Process Cement Production Line

2016年9月28日 As a professional manufacturer and supplier of new type dry process cement production line in China, CHAENG can also provide you with various other machines, such as 1500 tons/day cement processing line, CHAENG have advanced technology production equipment and a professional technical team The 1000 t d new dry process cement production carries out the overall design concept which combines raw material preparation and clinker calcining together Raw material preparation uses vertical mill, while the waste gas from kiln can be reused by the vertical mill for drying raw 1000 t/d Cement Plant Great Wall2022年1月10日 Vertical Cement Mill is the main tool used in the final process of making cement at PT Semen Baturaja (Persero) Tbk Vertical Cement Mill is used to mix and grind clinker and corrective materialsAnalisa Kinerja Alat Vertical Cement Mill di Pabrik II PT Semen Cyclone preheater is one of the core equipment in the new dry cement production process, which is responsible for many functions such as gassolid dispersion, material heating, gassolid separation, material transportation and some physical and chemical reactions Separation efficiency and resistance loss are two main performance indexes to be considered in the Cyclone Preheater Design for 5500 Ton Cement Production Line

1500 t/d Cement Production Line

The new dry process cement production line with capacity of 1500t/d, (300330) as the drying heat source Cement vertical roller mill has the characteristics of simple technological process, safe and reliable operation, high grinding efficiency, low power consumption, less maintenance, and short debugging cycle, etc2014年4月16日 The company is capable of offering complete dry process cement production line construction service, including engineering We are using 9000 quality management system for production of vertical mill and roller press Along with the rapid development of modern new type dry process cement manufacturing technology and Dry Process Cement Production LineIn order to improve the efficiency and environmental friendliness of cement production, a company in Zambia has introduced a new type of dry production technology They constructed a daily output of 1,200 tons per day new dry cement production line The annual production capacity will be 372,000 tons of cement clinker and 558,000 tons of cementNew Dry Process Cement Production Line Zambia YingYong 2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production Line

Dry Process Of Cement Manufacturing Dry Cement

Cement Kilns Manufactured By AGICO Cement kiln: the dry method cement kiln manufactured by AGICO has the characteristic of stable performance, low energy consumption, high yield, and easy operation We equip our cement kiln with a GRMK3041 Vertical Cement Mill : 1000 t/d : GRMR2231 Vertical Raw Mill : GRMC1231 Vertical Coal Mill : Φ33×52m Rotary Kiln : Φ26×13m Cement Mill 1500 t/d Cement Production Line The new dry process cement production line with a capacity of 1500t/d built by Xinxiang Great Wall Machinery Co, Cement Production Line2020年8月25日 A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement cement ball mill and cement vertical mill are generally used in the raw and it tends to be Cement Production Process Cement Manufacturing Using new dry process of Portland cement manufacture, AGICO cement plant achieves high output capacities Ask now for a free quote! Skip to content Home; About Menu Toggle Cement Ball Mill; Vertical Roller Mill; Cement Mill Separator; Cement Mill; Others Menu Toggle Conveying System; Overland Conveyor; Vibrating Grizzly Feeder;Portland Cement Plant for Sale New Dry Process of Portland Cement

.jpg)

Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill

As a professional cement equipment manufacturer, AGICO has rich experience in the designing and manufacturing of cement ball mills and vertical roller mills Our cement mills have extraordinary performance in the cement grinding process of the new dry process cement plants Cement Ball MillVertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMA2021年1月1日 The wet process requires 028 tons of coal and 110 kWh to produce one ton of cement, while the dry process requires only 018 tons With the grinding capacity of a vertical roller mill and the ability to dry, Volume I, Part I, ABI Books Private Ltd, First Edition, New Delhi: 1991 Google Scholar [4] Confederation of Indian Review on vertical roller mill in cement industry its 2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10] A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a trueReview on vertical roller mill in cement industry its

Vertical roller mill vs ball mill for cement grinding: Comparison

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainabilityProviding Consistent Results With Advanced Vertical Cement Mill Technology Magotteaux’s advanced vertical cement mill technology ensures consistent results by providing precise control over the grinding process, enabling the production of highquality cement with minimal variations in finenessMoreover, our use of advanced materials and innovative designs ensures that our Vertical Cement Mill Magotteaux