Industrial roller mill power consumption calculation

Ball Mill Design/Power Calculation 911Metallurgist

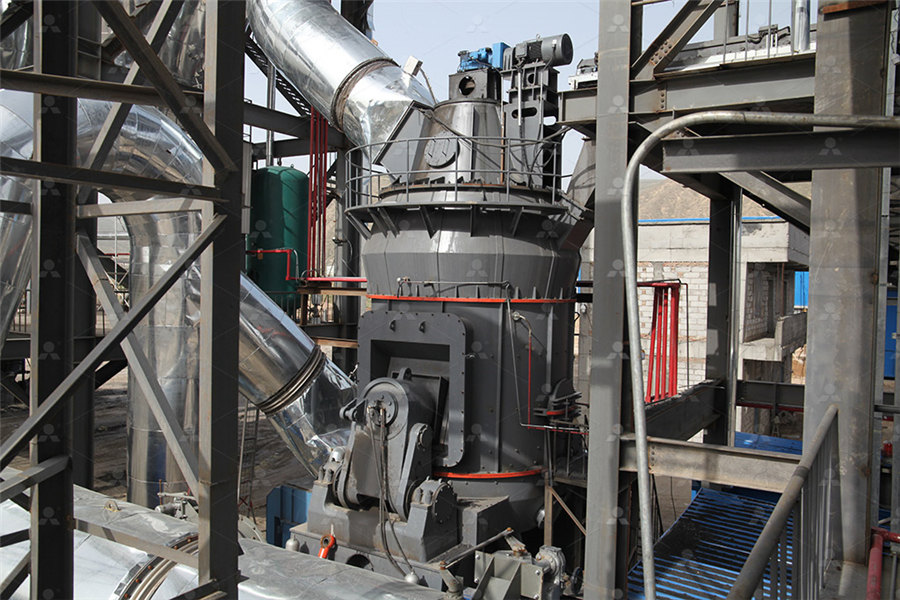

2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Power Distribution: The power in rolling process is expended principally in four ways: 1 The energy required to deform the metal 2 The energy required to over come frictional force in POWER IN ROLLING IDCOnlineThe document discusses the layout, calculations, components, and heat balance of a vertical roller mill (VRM) There are two basic layouts product collection in cyclones or a filter Key Vertical Mill Calculations PDF Mill (Grinding) Nozzle Scribdmill extraction and reducing the power consumption at mills Prepared cane should long fibrous shrades to improve feedability to the millsMILL DESIGN MILL OPERATION

.jpg)

MATHEMATICAL MODEL TO ESTIMATE THE ENERGY

In the milling with the roller mills, the torque of grinding roll shaft can be estimated by calculation if known the forces resultant acting on the roll, the direction of this force and its2021年3月1日 Quick designing of the machines required existence of adequate mathematical models Within the framework of the study’s realization, a mathematical model was developed and we presented the selected results of Selected Aspects of Modelling and Design Calculations The combination of rolling in stands with multiroll gauge and drawing is a promising direction in the production of wire from difficulttoform steels and alloys Digital models for pressure Calculating Power Parameters of Rolling Mill ProQuestCurrent methods of power consumption calculation of a mill drive do not allow determining the power consumption for ball drum mills with a crosslongitudinal motion of the grinding media A The Power Consumption Calculation of a Ball Drum Mill

Power requirements of rolling mills IEEE Xplore

Abstract: The increasing use of electric motors for driving the main rolls in modern steel works, makes the question of the power requirements of rolling mills of considerable importance to The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the mid'90s for grinding clinker and slag by LOESCHE (Schaefer, 2001) Fig 1 illustrates the grinding parts of a Loesche vertical roller millModeling and simulation of vertical roller mill using population (7 ) Making calculations for values of α o, ranged between the limits and 0, results the values of a between 0,75R (for ) și 0 For , is obtained a = 0,64R Also, the angle βMATHEMATICAL MODEL TO ESTIMATE THE ENERGY CONSUMPTION Just plug the 500W in the power consumption calculator above, and we get: We see that the 500W washing machine uses 05 kWh per hour In 3 hours, that is 15 kWh To get the dollar amount, we need to multiply electric consumption Power Consumption Calculator: How To Calculate

A case study on energy and exergy analyses for an industrial

2021年2月1日 Generally, electrical energy is used for a raw mill in the cement plants; hence, the energy intensity of the raw mill (EI RM) is expressed using the following electricity intensity calculation that can be utilized to benchmark [25]: (3) EI RM = Eenergy consumption r m (k W h) Production r m (t o n n e r a w m a t e r i a l s) where EI RM is the energy intensity of the raw 2021年2月1日 Literature showed that using VRM instead of a ball mill could reduce Zinc grinding power consumption from 2011 to 1111 kWh/t of raw materials (kWh/1000 kg) [14] In another research, Gerold et al reported that in copper slag grinding, 229% and 344% of airflow and power were saved by using the VRM, respectively [15]A case study on energy and exergy analyses for an industrial Power consumption calculations are essential in the field of engineering, where understanding and estimating the amount of power consumed by devices, For example, household appliances consume different amounts of power compared to industrial machinery Understanding power consumption is crucial for energyefficient design, Power Consumption CalculatorFind the total daily, monthly and annual power consumption in kWh (Take 30 days = 1 month, and 365 days = 1 year) Solution: 1 Daily Power Consumption Daily Power Consumption = Wattage rating x time in hours 2000 Watts x 3 Hrs = 6000 WattsHour Daily Power Consumption = 6 kWh 2 Monthly Power ConsumptionEnergy and Power Consumption Calculator – kWh Calculator

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 Furthermore, the power consumption of the raw mill grinding process was reduced by 67 percent by using exterior hot gas, as suggested in an energy and exergy analysis of the mill by Atmaca 2 Calculation of the workindex: 3 Estimation of the power consumption of a grinding mill: 4 Example : Step by step estimation of the power required for a grinding mill: 5 Free Excel calculation tool for estimating grinding mill power consumptionGrinding power : step by step calculation PowderProcess2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and Ball Mill Parameter Selection Calculation Power, Critical 2014年5月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the (PDF) Matrix Model Simulation of a Vertical Roller Mill

.jpg)

An energy based comparison of vertical roller mills and

2015年3月10日 The specific power consumption ΔeVRM200 in J/kg could be calculated by the control system according to Eq (3) Details of the VRM600 in the CEMTEC laboratory are published in Gleissenberg and Hofmann (2008) The mill table diameter is around 670 mm forced by three conical grinding rollers of 430 mm mean diameter2009年1月31日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Grinding process within vertical roller mills ResearchGateAbility to produce quality cracks of 1200, 700, 500, and 350 microns, all from one machineVersaMill RMS RollerGrinder438 QianHong Wang et al / Physics Procedia 33 ( 2012 ) 437 – 443 Among the rest, stable operation of the vertical mill vertical means that to ensure the material layer thickness of the disc Design and Realization Of Roller Mill Control System

Indicate Contributions from Several Radial VHYHQ4WRROV

60% of power cost In recent years vertical roller mill (VRM) has proved to be a popular choice for finished cement grinding due to low power consumption but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightly Objective of this research paper is process optimization of Vertical Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer n by Thomas Holzinger, Holzinger Consulting, Switzerland BALL MILLS 1 FEBRUARY 2021 INTERNATIONAL CEMENT BALL MILLS Ball mill optimisation Holzinger ConsultingFind your roller mill easily amongst the 186 products from the leading brands (WAMGROUP, Brabender, MATSUBO, providing users with energysaving, consumptionreducing, qualityenhancing and efficiencyenhancing solutions, realizing maximum Compare this product Remove from comparison tool Motor power: 2,200, 4,000, Roller mill, Roller grinding mill All industrial manufacturersUnits used in the above table: A p, A e, D, W – mm or Inch; V f – m/min or inch/min; V c – m/min or feet/min (SFM); F n – mm/rev or Inch/rev; MRR – Metal Removal Rate CM 3 /min or Inch 3 /min; Step 2 – Obtaining the materials Specific Cutting Force (KC11) Each material has a Specific Cutting Force coefficient that expresses the force in the cutting direction, required to cut a Machining Power Calculator and Formulas

Numerical Investigation of Vertical Roller Mill Operation Using

2023年12月4日 An increase in the dam ring facilitated the higher particle bed and raised the grinding force and power consumption The roller speed is not influenced by the Simulation model of an industrialscale vertical roller mill Braun RL (1986) Viscosity, granulartemperature, and stress calculations for shearing assemblies of 3RollerPressFlSmidthpdf Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses the layout and calculations for a roller press used in comminution processes It describes the 3 Roller Press FL Smidth PDF PDF Mill (Grinding)2022年5月9日 Modeling of energy consumption factors for an industrial cement vertical roller mill by SHAPXGBoost: a "conscious lab" approach May 2022 Scientific Reports 12(1):7543Modeling of energy consumption factors for an industrial Download scientific diagram Idle power consumption of hammer mill with speed from publication: Comminution Properties of Biomass in Hammer Mill and its Particle Size Characterization Biomass Idle power consumption of hammer mill with speed

Power Calculation of BallTube Mill Drives in the Construction

2023年5月12日 Power Calculation of BallTube Mill Drives in the Construction Materials Industry Behind this zone, calculation of power consumption is carried out according to the known methods used for calculation of waterfall and Proceedings of the 5th international conference on industrial engineering, pp 883–893 Springer 2009年1月1日 Powerconsumption Statistics Account for industrial powerconsumption 2003 627 13 757 2004 518 098 616 Possible 074 045 Mill type Ball mills Vertical roller mills Power consumption (kWh/t) 21 12 Main parameters of the vertical roller mill (CKP) Rated power (kW) 950 Measured power (kW) 745 Roller Rotating table Grinding process within vertical roller mills: experiment and The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL Modeling of energy consumption factors for an industrial cement vertical roller mill by SHAPXGBoost: a "conscious lab" approach Rasoul Fatahi Rasoul Fatahi 1 School of Advanced modeling of HPGR power consumption based on operational parameters by BNN: A “ConsciousLab” development Powder Technol 2021;381:280–284 doi: 101016/j Modeling of energy consumption factors for an industrial

.jpg)

S Description Symbol Unit No: FL Smidth's ATOX Vertical Roller Mill

FL Smidth's ATOX Vertical Roller Mill specifications for a raw mill processing limestone including: Mill type, number, grinding pressure, raw material, production rate, table diameter, roller diameter, and power input Calculations for specific roller pressure, maximum material pressure, grinding circulation, and design power consumption based on input parameters 2021年6月10日 Under these conditions, the power consumption of the mill was found to be 422861 kW Also, optimal conditions were established in industrial grinding processesVentilation Prediction for an Industrial Cement Raw Ball Mill by The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the mid'90s for grinding clinker and slag by LOESCHE (Schaefer, 2001) Fig 1 illustrates the grinding parts of a Loesche vertical roller millModeling and simulation of vertical roller mill using population (7 ) Making calculations for values of α o, ranged between the limits and 0, results the values of a between 0,75R (for ) și 0 For , is obtained a = 0,64R Also, the angle βMATHEMATICAL MODEL TO ESTIMATE THE ENERGY CONSUMPTION

Power Consumption Calculator: How To Calculate

Just plug the 500W in the power consumption calculator above, and we get: We see that the 500W washing machine uses 05 kWh per hour In 3 hours, that is 15 kWh To get the dollar amount, we need to multiply electric consumption 2021年2月1日 Generally, electrical energy is used for a raw mill in the cement plants; hence, the energy intensity of the raw mill (EI RM) is expressed using the following electricity intensity calculation that can be utilized to benchmark [25]: (3) EI RM = Eenergy consumption r m (k W h) Production r m (t o n n e r a w m a t e r i a l s) where EI RM is the energy intensity of the raw A case study on energy and exergy analyses for an industrial 2021年2月1日 Literature showed that using VRM instead of a ball mill could reduce Zinc grinding power consumption from 2011 to 1111 kWh/t of raw materials (kWh/1000 kg) [14] In another research, Gerold et al reported that in copper slag grinding, 229% and 344% of airflow and power were saved by using the VRM, respectively [15]A case study on energy and exergy analyses for an industrial Power consumption calculations are essential in the field of engineering, where understanding and estimating the amount of power consumed by devices, For example, household appliances consume different amounts of power compared to industrial machinery Understanding power consumption is crucial for energyefficient design, Power Consumption Calculator

Energy and Power Consumption Calculator – kWh Calculator

Find the total daily, monthly and annual power consumption in kWh (Take 30 days = 1 month, and 365 days = 1 year) Solution: 1 Daily Power Consumption Daily Power Consumption = Wattage rating x time in hours 2000 Watts x 3 Hrs = 6000 WattsHour Daily Power Consumption = 6 kWh 2 Monthly Power Consumption2012年6月1日 Furthermore, the power consumption of the raw mill grinding process was reduced by 67 percent by using exterior hot gas, as suggested in an energy and exergy analysis of the mill by Atmaca Reducing energy consumption of a raw mill in cement industry2 Calculation of the workindex: 3 Estimation of the power consumption of a grinding mill: 4 Example : Step by step estimation of the power required for a grinding mill: 5 Free Excel calculation tool for estimating grinding mill power consumptionGrinding power : step by step calculation PowderProcess2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and Ball Mill Parameter Selection Calculation Power, Critical