Rare earth ore micro powder equipment

Micro Powder Mill Hongxing Mining Machinery

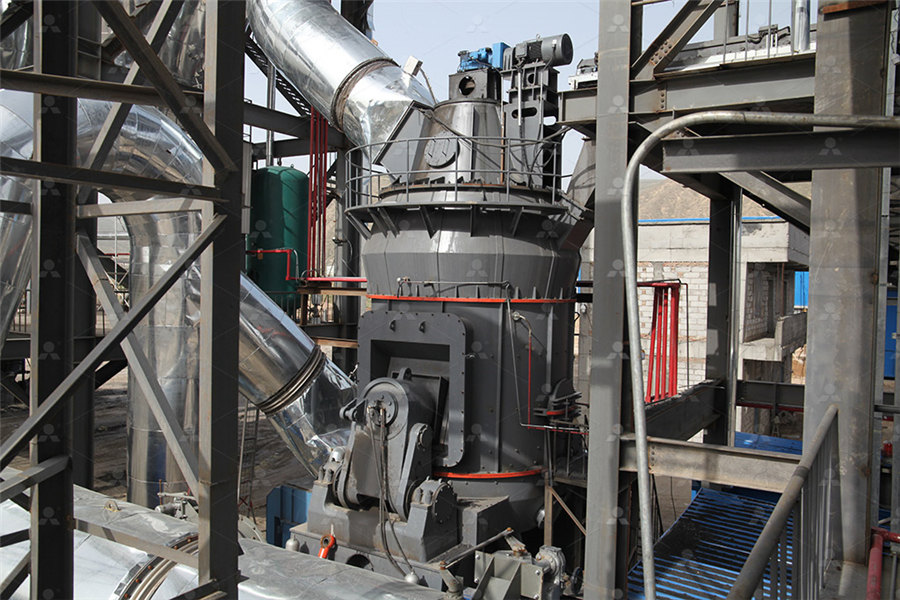

The micro powder mill is mainly composed of the main machine, a blower, an ultrafine analyzer, a cyclone powder collector, a bagtype dust collector, and a connecting pipe According to the needs of users, it can be equipped with some auxiliary equipment, such as the bucket elevator, storage silo, electric control 展开High capacity Niagara XLClass vibrating screens for Rare Earth Elements processing Rare Earths Elements Processing Equipment Haver Boecker Tombarthite Micro powder grinding mill is a new type machine to grind Tombarthite Stone into Tombarthite/ Rare earth Micro powder grinding millThe threerings and medium speed micro powder mill is a new product developed by our Micro Powder MillFote Machinery

.jpg)

Unlocking Potential: Rare Earth Elements Processing Solutions

2023年11月9日 The screened rare earth ore enters a ball mill for dry grinding, improving 2017年9月10日 The purpose of this paper is to comprehensively review and summarize the (PDF) A Review of Rare Earth Mineral Processing TechnologyThe powder mill is suitable for the super fine grinding of all kinds of nonflammable and non Micro Powder Mill – My Blog1997年2月1日 The results demonstrate that magnetic separation separates the powders with Rareearth magnetic separation equipment and ScienceDirect

.jpg)

Rare Earth Elements

ANZAPLAN’s hydrometallurgical facilities can achieve light, medium and heavy rare earth This micro powder mill is suitable for the superfine crushing of all kinds of crisp materials whose Mohs hardness is below 93, such as calcium carbonate, barite, kaolin, rare earth ore, hematite, talc, feldspar, and furnace slagMicro Powder Mill Hongxing Mining Machinery5 天之前 Rare earth ore, also known as rare earth element ore or rare earth metal ore, contains various rare earth elementsIt mainly contains lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, Rare Earth Ore Beneficiation Is Difficult, What Are The 2023年7月28日 Below are the general steps involved in the beneficiation of rare earth ore: Crushing and Grinding The rare earth ore is first crushed into smaller particles to increase the surface area for further processing It is then ground Rare Earth Ore: From Mining to Application JXSC

[GYQ0R)ZQ]ESS4NJ.jpg)

Rare earth oreTuxingsun Mining Equipment mineral Solutions

TuXingSun Mining provides stateoftheart mining and mineral processing equipment for metallic and nonmetallic minerals We offer comprehensive services including ore testing laboratories, global ore trade, and turnkey mining technology solutions Our global expertise ensures efficient and sustainable mining operations for gold, copper, rare earths, and other minerals2021年11月23日 A study recently published in Nature Communications, ‘Generation of a Gluconobacter oxydans knockout collection for improved extraction of rare earth elements’, has described the use of genetically engineered microorganisms to process rare earth elements (REE) in a way which is sustainable, efficient and cost effective The paper was written by Scientists engineer bacteria to extract rare earths2022年5月4日 The demand for highefficiency, lowenergy consumption materials, with high durability and stability, has led to the rapid increase of the demand and prices of Rare Earth Elements (REE)Sustainable Recovery, Recycle of Critical Metals and Rare Earth 2023年11月9日 Utilizing a spiral classifier to purify the ore powder can significantly enhance the quality of rare earths Step 4 Magnetic separation In the beneficiation process of coastal placer mines, weak magnetic separation is commonly employed to separate ilmenite and monaziteUnlocking Potential: Rare Earth Elements Processing Solutions

.jpg)

Review and test on rare earths recovery from polishing powder

Rare earth polishing powder has gained widespread usage in the surface polishing of highprecision materials, exhibiting an annual growth rate exceeding 10 % However, a significant portion of this powder is discarded due to impurities and the need for particle size refinement The waste generated from polishing powder contains 1031 %–8693 % rare earth elements, 2020年12月7日 Therefore, this paper summarizes the research status of microwave heating in the recovery of valuable metals (Cu, Au, V),) from metallurgical waste ore and rare earth elements from rare earth Recovery of Metals and Rare Earth Elements by Microwave heating Rare earth elements (REEs), a group of 17 elements in the periodic table, encompass light, medium, and heavy REEs, which are crucial to numerous modern industries [1], [2]Ionadsorption type rare earth ore (ITREO) is a significant mineral resource abundant in medium and heavy REEs [3]Unlike other rare earth minerals, 80 % of REEs in ITREO exist in an ion Onestep enrichment of rare earth elements from ionic rare earth 2021年7月1日 In this paper, we report an actuator with a magnet made of novel rare earth magnetic powder SmFeN with diameter of 2 µ m to 5 µ m Micro magnets were fabricated by mixing the magnetic powder Temperature stable rare earth magnetic powder SmFeN based micro

.jpg)

Gold and Silver Ore Processing and Recovery Plants for Sales Rare

Savona Equipment is your source for new, used, and reconditioned Ore Mineral Processing Plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling, mining, and treatment facilities Our inventory includes complete gold processing plants, silver processing plants, as well as 2020年9月23日 A Review of RareEarth Elements Extraction with Emphasis on Nonconventional Sources: Coal and Coal Byproducts, Iron Ore Tailings, Apatite, and Phosphate ByproductsA Review of RareEarth Elements Extraction with 2018年6月20日 The use of powderbased technologies for the production of rare earth (RE)doped fibers and preforms is discussed Although these technologies cannot compete with vaporbased technologies such as modified chemical vapor deposition (MCVD) with respect to purity of the silica material obtained, they offer a high degree of versatility with respect to the material Powder Process for Fabrication of Rare EarthDoped Fibers2018年11月19日 Processing recycled micro powder, I recommend to you the Guilin Hengda Mining Machinery HD series raymond mill, which can be applied to 200 kinds of stones, such as feldspar, calcite, limestone Recycled micro powder processing equipment LinkedIn

CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION

ERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sina2023年7月23日 IREO means rare earth content of ionexchangeable phase Considering the rare earth elemental composition, Y 2O 3 content was more than 35% of the total amount of rare earth species, which was significantly higher than that of other rare earth elements Therefore, the sample belonged to a typical high yttrium medium–heavy rare earth oreInfluence of ammonium sulfate leaching agent on engineering 2016年9月11日 For example, at Mountain Pass, California, USA, and Mount Weld mine in Australia, flotation is employed to enrich rare earth oxides (REO) from 3%15% to 40%60% in concentrates [9,17]Rare Earth Flotation Fundamentals: A Review ResearchGate2019年8月15日 The use of powderbased technologies for the production of rare earth (RE)doped fibers and preforms is discussed Although these technologies cannot compete with vaporbased technologies such as modified chemical vapor deposition (MCVD) with respect to purity of the silica material obtained, they offer a high degree of versatility with respect to the material Powder Process for Fabrication of Rare EarthDoped Fibers

Production of mixed rare earth oxide powder from a thorium

2021年2月1日 The rare earth elements (REE) are critical raw materials for manufacturing many emerging electronics and advanced components with widespread fields of applications in the energy, medical, defense, aerospace and automotive industries [6, 11, 24, 32]The global consumption for REE was estimated between 120 and 150 kt in 2016 and the global demand Bastnaesite is a rare earth fluorocarbonate mineral1, RE(CO3)F, which primarily contains light rare earth elements After physical upgrading, bastnaesite ore concentrates contain between 40 to 60% REE2 One of the main concerns in past bastnaesite Leaching of rare earths elements (REE) past and present2022年8月22日 Rareearth Powder Grinding Mill Case Shanghai Clirik had devoted into the field of stone powder making equipment RD and manufacturing more than decade years O +29 [ in a Rareearth powder production line, our HGM micro powder grinding mill also can paly the important roleCustomer Site Rareearth Powder Production LineTuXingSun Mining provides stateoftheart mining and mineral processing equipment for metallic and nonmetallic minerals We offer comprehensive services including ore testing laboratories, global ore trade, and turnkey mining technology solutions Our global expertise ensures efficient and sustainable mining operations for gold, copper, rare earths, and other mineralsheavy rare earthsTuxingsun Mining Equipment mineral

.jpg)

Additive Manufacturing of Rare Earth Permanent Magnetic

2024年4月11日 With the rapid development of intelligent manufacturing, modern components are accelerating toward being light weight, miniaturized, and complex, which provides a broad space for the application of rare earth permanent magnet materials As an emerging nearnetshape manufacturing process, additive manufacturing (AM) has a short process flow and The global Rare Earth Polishing Powder market was valued at 15005 Million USD in 2021 and will grow with a CAGR of 706% from 2021 to 2027Global Rare Earth Polishing Powder Market Research Report 2022 2017年9月10日 p>The recent technological advancement has made the rare earth elements (REEs) more significant and they in turn have facilitated the culmination of more new technological applications owing to (PDF) A Review of Rare Earth Mineral Processing Technology2024年4月1日 Rare earth elements (REEs) are irreplaceable materials supporting lowcarbon technology and equipment acid, sodium oleate and Flotinor SM15 (a commercial phosphoric acid ester) in the flotation of bastnaesite The micro Design and development of novel flotation reagents for the beneficiation of Mountain Pass rareearth oreJournal of Rare Earths ScienceDirect

Temperature stable rare earth magnetic powder SmFeN based micro

2021年5月24日 In this paper, we present the micro magnet made of nitridebased rare earth magnetic powder, SmFeN Compared with NdFeB powder, SmFeN powder is stable in air and can be heated up to 110 °C, which allows monolithically integration with a MEMS structure2021年3月3日 21 Powder consolidation techniques for thermally degradable rareearth magnets Nitride magnets of Sm 2 Fe 17 N 3 and (SmZr)(FeCo) 10 N x undergo thermal decomposition at around 600°C and lose their properties as permanent magnets [5,9,10]Therefore, unlike Nd 2 Fe 14 B magnets, it is impossible simply to apply liquid phase Novel powder processing technologies for production of rareearth 2023年10月1日 Demand for REE grows as the consumption of new electronic equipment increases (Brewer et al, 2019)Estimates suggest that the REE market grows at an annual rate of 37 to 86% (Tan and Li, 2019), contributing to the criticality of these raw materialsDespite their relative abundance on the Earth's crust, REE are considered critical metals due to their poor The recovery of rare earth elements from waste electrical and This micro powder mill is suitable for the superfine crushing of all kinds of crisp materials whose Mohs hardness is below 93, such as calcium carbonate, barite, kaolin, rare earth ore, hematite, talc, feldspar, and furnace slagMicro Powder Mill Hongxing Mining Machinery

.jpg)

Rare Earth Ore Beneficiation Is Difficult, What Are The

5 天之前 Rare earth ore, also known as rare earth element ore or rare earth metal ore, contains various rare earth elementsIt mainly contains lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, 2023年7月28日 Below are the general steps involved in the beneficiation of rare earth ore: Crushing and Grinding The rare earth ore is first crushed into smaller particles to increase the surface area for further processing It is then ground Rare Earth Ore: From Mining to Application JXSC TuXingSun Mining provides stateoftheart mining and mineral processing equipment for metallic and nonmetallic minerals We offer comprehensive services including ore testing laboratories, global ore trade, and turnkey mining technology solutions Our global expertise ensures efficient and sustainable mining operations for gold, copper, rare earths, and other mineralsRare earth oreTuxingsun Mining Equipment mineral Solutions2021年11月23日 A study recently published in Nature Communications, ‘Generation of a Gluconobacter oxydans knockout collection for improved extraction of rare earth elements’, has described the use of genetically engineered microorganisms to process rare earth elements (REE) in a way which is sustainable, efficient and cost effective The paper was written by Scientists engineer bacteria to extract rare earths

.jpg)

Sustainable Recovery, Recycle of Critical Metals and Rare Earth

2022年5月4日 The demand for highefficiency, lowenergy consumption materials, with high durability and stability, has led to the rapid increase of the demand and prices of Rare Earth Elements (REE)2023年11月9日 Utilizing a spiral classifier to purify the ore powder can significantly enhance the quality of rare earths Step 4 Magnetic separation In the beneficiation process of coastal placer mines, weak magnetic separation is commonly employed to separate ilmenite and monaziteUnlocking Potential: Rare Earth Elements Processing SolutionsRare earth polishing powder has gained widespread usage in the surface polishing of highprecision materials, exhibiting an annual growth rate exceeding 10 % However, a significant portion of this powder is discarded due to impurities and the need for particle size refinement The waste generated from polishing powder contains 1031 %–8693 % rare earth elements, Review and test on rare earths recovery from polishing powder 2020年12月7日 Therefore, this paper summarizes the research status of microwave heating in the recovery of valuable metals (Cu, Au, V),) from metallurgical waste ore and rare earth elements from rare earth Recovery of Metals and Rare Earth Elements by Microwave heating

.jpg)

Onestep enrichment of rare earth elements from ionic rare earth

Rare earth elements (REEs), a group of 17 elements in the periodic table, encompass light, medium, and heavy REEs, which are crucial to numerous modern industries [1], [2]Ionadsorption type rare earth ore (ITREO) is a significant mineral resource abundant in medium and heavy REEs [3]Unlike other rare earth minerals, 80 % of REEs in ITREO exist in an ion