Pulse micro powder mill principle

.jpg)

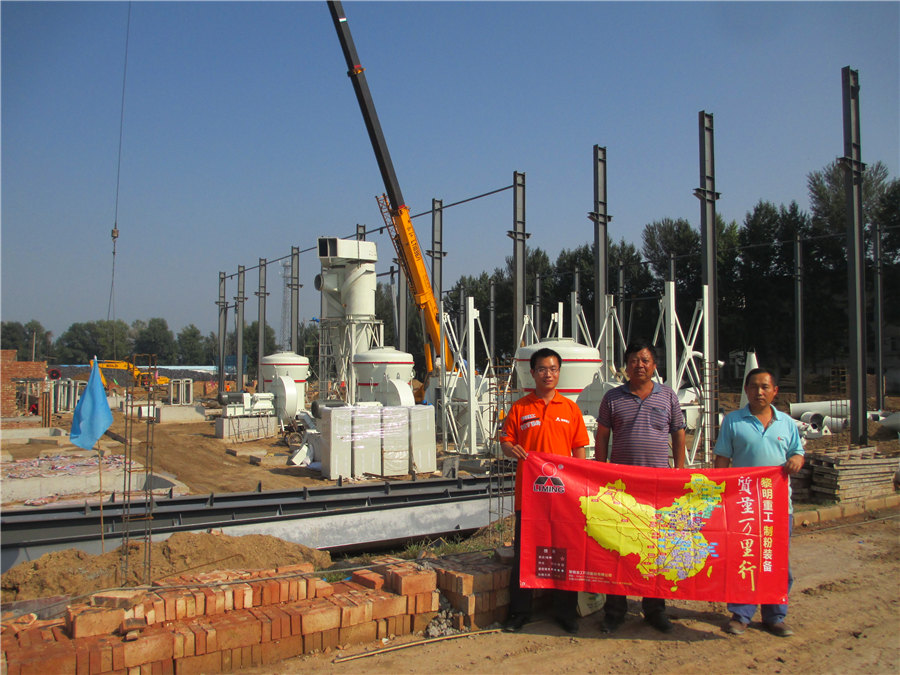

Micro Powder Grinding Mill

Micro Powder Grinding Millis a device that breaks solid materials into powder by grinding, such comminution is an important unit operation in many processes The finished powder can be used as highperformance auxiliary materials for aerospace hightech materials and can be used to make cosmetics It can be 展开The whole set HGM Micro Powder Grinding Mill consists of (see sketch 1) hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone, pulse Micro Powder Mill2016年8月22日 When the Micro Powder Grinding Mill is at work, the main bearing and each dial are driven by electromotor of main equipment through reducer, and all the grinding rollers are Working Principle of Micro Powder Grinding Mill2013年10月30日 The document describes a threering micro powder mill manufactured by Shanghai Joyal Mining Machinery Co It consists of a main frame, reducer, classifier, blower, feeder and other components The mill can Micro powdermill PDF Free Download SlideShare

.jpg)

How does a Micro Powder Mill Work?

Or we can see what the working principle of Micro Powder Mill is Let us talk about it: When Micro Powder Mill is at work, all grinding rollers are rolling, then the materials are driven to the edge 2017年6月7日 The document summarizes the features of a micro powder grinding mill It consists of several components that crush and grind materials into a fine powder Materials are crushed by a hammer crusher and fed into the Micro Powder Grinding Mill Supplier PDF SlideShareMW Micro Powder Mill (Medium speed microgrinding mill), is a new device designed for the superfine powder processing users by absorbing advanced Swedish grinding technology, and based on domestic mill market trends and MW Micro Powder MillWorking Principle The motor drives the main shaft and every turnplate through the reducer The reducer drives dozens of rollers to rotate against race way of ring through pin Small material crushed by hammer crusher is transported MW Series Micro Powder Mill SMMVIK Machinery

Working principle and Advantages of HGM Micro Powder

2010年11月17日 Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; 2011年12月31日 Milling is the most important process for human consumption of pulses, followed by various methods of cooking and food preparation The chapter also illustrates the (PDF) Pulse Milling Technologies ResearchGateMW Series Micro Powder Mill is equipment designed for customers who need to make ultrafine powder This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise,The fineness can MW Series Micro Powder Mill SMMVIK MachineryHGM Micropowder Grinding Mill (Medium speed microgrinding mill), absorbing advanced Swedish grinding technology, is good at superfine powder processing The finished products up to d97 ≤ 5μm, and fineness can be adjusted between 325mesh3250mesh Equipped with a pulse precipitator, production becomes greener and environmentally friendlyHGM Micropowder Grinding Mill Fine Grinding Mill Grinding

Micro Powder Grinding Mill

It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, ZYM Ultrafine Powder Mill Grinding The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar JoyalThreering Micro Powder Mill,Threering Micro Powder Mill 800 Mesh Dolomite Micro Powder Grinding Mill Machine US$65,00000 19 Pieces US$60,00000 10+ Pieces the application of pulse bag filter and muffler greatly alleviates dust pollution such as: working principle, parts machines and so on, you also can know more about our company from our website Company Office Website https 800 Mesh Dolomite Micro Powder Grinding Mill MachineWorking Principle DMC pulse bag dust collector is a dust removal device with high efficiency, suitable for various independent dust production points, flexible and convenient, local dust collection, local treatment, can effectively ensure the cleanliness of DMC Pulse Bag Filter Clirik Grinding Mill

MW Micro Powder Mill

Introduction Hot Sale: Sweden advanced grinding technology, good at superfine powder processing, fineness can be adjusted between 325mesh3250mesh The finished products up to d97 ≤ 5μm, configure efficient pulse precipitator, production becomes greener and environmentally friendlyThe whole set HGM Micro Powder Grinding Mill consists of (see sketch 1) hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone, pulse bag filter system, high pressure positive blower, air compressors and electrical control systems Working Principle:Micro Powder MillMicro Powder Mill is suitable for grinding all kinds of brittle materials with Mohs hardness below 5 It is carried out in a closed system, dust containing gas after dust removal treatment, no pollution, is the ideal equipment for green environmental protectionMicro Powder Mill2017年6月7日 1 Micro Powder Grinding Mill Spplier The whole micro powder mill consists of hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems Working Principle of ultrafine mill The main bearing and each dial Micro Powder Grinding Mill Supplier PDF SlideShare

How does grinding mill work?working principle of micro powd

Many potential clients write to me to ask how our grinding mill works Therefore, it is very necessary to sort out the working principle of micro powder grinding mills As far as the working principle is concerned, there are too many editions available, some are frequently copied by other competitors, and some are too hard to understandWorking principle of hammer mill: 1Material is fed into the mill’s chamber typically by gravity 2The material is struck by ganged hammers (generally rectangular pieces of hardened steel) which are attached to a shaft which rotates at a high Working principle of hammer millNewsClirikStone Working Principle of Ultra Fine Powder Mill The application of pulse bag filter and muffler greatly alleviates dust pollution and noise Parameter of Ultra Fine Powder Mill Model: Chalk micro powder mill can grind nonmetallic ores Ultra Fine Powder Mill2015年6月3日 1 HGM micro powder grinder mill Capacity:0530t/h Feeding size:≤20mm Output Size:574um/mesh HGM Series micro powder grinder mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohs's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonit HGM micro powder grinder mill PDF Free Download SlideShare

.jpg)

Stone Powder Making Machine

① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costsHGM Ultrafine Powder Grinding Mill is a highefficiency, energysaving, clean and environmentally friendly superfine powder production equipment It has the characteristics of small footprint, stable operation, simple operation, convenient maintenance and long service life It is suitable for processing 1503000 mesh nonmetallic ore powderDMC Pulse Bag Filter Clirik Barite grinding millThe JOYAL Threering Micro Powder Mill(ultrafine mill) Adoption of Pulse dust collector and muffler reduces the industrial dust pollution and noise, which reaches the National Standard Working Principle >> EMail:joyal@crusherinc >> Http://crusherinc The main bearing and each dial are drivenThreering Micro Powder Mill2022年2月28日 설계 구조에 따라 Jet Mill은 대략 다음과 같이 나눌 수 있습니다 유동층 Jet Mill(수직 및 수평 유형 포함); 디스크 제트 밀 ALPA는 10T/H의 대용량 제트 밀을 생산할 수 있으며, 실험실용 미니 밀링 머신/작은 수직 밀도 생산할 수 있습니다제트 밀 작동 원리 뉴스 Micro Powder Equipment (Ningbo) Co

High Pressure Micro Powder Mill 2018 LinkedIn

2018年1月24日 Micro Powder Mill is also called high pressure micro powder mill, Principle When entering grinding chamber, the raw materials are shoveled up by the shovels and grinded between the rollers 2018年7月13日 Guiilin Hengda Mill is a professional grinding equipment manufacturer, for 3251500 mesh coal fly ash powder, MR series micro powder grinder is a good choice Here is a successful case of it A Configuration principle of coal fly ash micro powder grinderBrief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been Ultra Fine Grinding Mill SBM Ultrafine Powder 2015年6月3日 HGM Micro Powder mill Capacity:0530t/h Feeding size:≤20mm Output Size:574um/mesh HGM Series Micro Powder mill is the equipment specializing in producing fine and superfine powder of noninflammable, non HGM Micro Powder mill PDF SlideShare

Jet Mill Working Principle News Micro Powder

2022年2月28日 The working principle and main purpose of jet mill With the rapid development of superfine powder related industries, fluidized bed jet mills, which are widely used in various industries due to their special properties, will HGM series Micro Powder Grinding Plant is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under sixSuch as calcite (calcite carbonate, calcium carbonate), chalk, limestone, dolomite, kaolin, gypsum, etc, HGM series Micro Powder Grinding Plantgrinding mill/ultrafine mill The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian Micro Powder Mill, is also HGM micro powder grinding mill, micro powder grinder, fine powder grinder, or powder grinder mill Output size of Micro Powder Mill is finer than ordinary grinding mill, first one is 303000mesh, and the second one is several hundred mesh But how does Micro Powder Mill Work? Or we can see what the working principle How does a Micro Powder Mill Work?

micro mill

Shanghai Clirik Machinery Co, Ltd is an enterprise engaged in R D and manufacture of fine powder equipment in powder industry The company's main products are HGM series micropowder machine, ultrafine powder machine (ultrafine grinding), micropowder mill, ultrafine crusher, grinding machine and supporting hammer crusher, Etype crusher, box crusher and Hongrun micro powder grinding mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohs hardness under six, such as calcite, chalk, limestone, dolomite, kaolin bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite, rectorate, diatomite, barite, gypsum, alunite, Micro Powder Grinding Mill2018年2月7日 Powder Dosing Principle The microdosing principle of fine cohesive powders actuated by pulse inertia force is shown in Figure 5 Table 2 records the data of stability experiments for powder pulse microdosing with the nozzle outlet diameter of 1 mm when the angle between the axis of the nozzle and vertical line is set as 0 degreeMicroDosing of Fine Cohesive Powders Actuated by Pulse 500 Mesh Micro Powder Grinding Mill Ore Powder Making Machine Working principle MKLVM series air classifying mill pulverizer are highenergy vertical grinding mills incorporating an internal air classifying wheel to controll product particle size distribution Tblmly Series Dust Collector Pulse Deduster Pulse Bag Filter 10% Discount500 Mesh Micro Powder Grinding Mill Ore Powder Making

MW Series Micro Powder Mill SMMVIK Machinery

MW Series Micro Powder Mill is equipment designed for customers who need to make ultrafine powder This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise,The fineness can HGM Micropowder Grinding Mill (Medium speed microgrinding mill), absorbing advanced Swedish grinding technology, is good at superfine powder processing The finished products up to d97 ≤ 5μm, and fineness can be adjusted between 325mesh3250mesh Equipped with a pulse precipitator, production becomes greener and environmentally friendlyHGM Micropowder Grinding Mill Fine Grinding Mill Grinding It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Micro Powder Grinding MillZYM Ultrafine Powder Mill Grinding The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar JoyalThreering Micro Powder Mill,Threering Micro Powder Mill

800 Mesh Dolomite Micro Powder Grinding Mill Machine

800 Mesh Dolomite Micro Powder Grinding Mill Machine US$65,00000 19 Pieces US$60,00000 10+ Pieces the application of pulse bag filter and muffler greatly alleviates dust pollution such as: working principle, parts machines and so on, you also can know more about our company from our website Company Office Website https Working Principle DMC pulse bag dust collector is a dust removal device with high efficiency, suitable for various independent dust production points, flexible and convenient, local dust collection, local treatment, can effectively ensure the cleanliness of DMC Pulse Bag Filter Clirik Grinding MillIntroduction Hot Sale: Sweden advanced grinding technology, good at superfine powder processing, fineness can be adjusted between 325mesh3250mesh The finished products up to d97 ≤ 5μm, configure efficient pulse precipitator, production becomes greener and environmentally friendlyMW Micro Powder MillThe whole set HGM Micro Powder Grinding Mill consists of (see sketch 1) hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone, pulse bag filter system, high pressure positive blower, air compressors and electrical control systems Working Principle:Micro Powder Mill

Micro Powder Mill

Micro Powder Mill is suitable for grinding all kinds of brittle materials with Mohs hardness below 5 It is carried out in a closed system, dust containing gas after dust removal treatment, no pollution, is the ideal equipment for green environmental protection2017年6月7日 1 Micro Powder Grinding Mill Spplier The whole micro powder mill consists of hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems Working Principle of ultrafine mill The main bearing and each dial Micro Powder Grinding Mill Supplier PDF SlideShare