Multilayer grinding system vibration filter

Multilayer High Frequency Vibration Fine Screen

Haiwang ZKJD multilayer vibrating fine screen is a wet finegrained material screening equipment developed by Haiwang company through the introducing of advanced technology The centrifugal vibration type screening machine has the advantages that the centrifugal vibration structure is used for carrying out centrifugal rotation vibration on the plurality ofMultilayer screen vibrating machine Google PatentsThis system collects realtime data during the operation of the stacked screen and compares it with the original database parameters When the realtime data deviates beyond the specified range from the original database, the stacked Multilayer high frequency vibration screen Weihai 2022年6月1日 Coupling of multiple abrasive grains is crucial for the efficiency in the grinding process and grinder design Here the coupling effect in a doublegrain model in vibration Coupling of double grains enforces the grinding process in

Vibrationbased gear continuous generating grinding fault

2022年7月1日 In this research, a novel methodology for gear continuous generating grinding processes is proposed based on vibration signals, 2D timefrequency representations and Guan Yu Machinery Factory manufactures Multi Layer Sealed Type Vibratory Separator This machine is ideally for sieving and separating powder, particle and slurry in many industries, Vibrating Screen/Sifter Filter/Iron Remover/Magnetic Magnetic 2018年9月1日 In both operation modes, the adsorption capacity of multilayered filters was significantly higher (16–100%) than for singlelayer filters at the same overall weight The effect of(PDF) MultiLayer Filters: Adsorption and Filtration The vibration screen trajectory movement of the circular elliptical It is a multilayer, highefficiency new type vibrating screen designed specifically for quarry screening stones Widely used in Multipurpose highefficiency multilayer vibrating screen

Linear Vibrating Screen Dust, Particle Impurity

Linear vibrating screens can easily screen a wide variety of materials and can be used in wet, dry and grinding applications and are ideal for industries such as food, chemical, pharmaceutical, abrasives, mining and fertilizersThe developed model is used to analyze conventional grinding (CG) and vibrationassisted grinding (VAG) in 1Dnormal to the cutting direction and 2Dboth normal and along the cutting Finite Element Modeling of Multigrit Stochastic Grinding Tool for 2024年8月1日 Grinding wheel is a highly customized product because the wrong formula may cause the grinding process to be inefficient If inappropriate wheels are installed on the machine, they may break into pieces under highspeed rotation due to abnormal vibration, causing a huge loss in production and safety issues [2]Grinding wheel specification cybernetic recommendation with 2024年10月3日 Then, the system state equation is established by Kalman filter method based on the selfhealing mechanical model, and the full information identification of multirigidbody system is realized by Online vibration state identification of multirigidbody system

.jpg)

Coupling of double grains enforces the grinding process in vibration

2022年6月1日 Moreover, vibrationassisted grinding can reduce the grinding force (Yang et al, 2019b), surface roughness (Zhou et al, 2019b), and subsurface damage (Baraheni and Amini, National Natural Science Foundation of China (Grant Nos , ) and the State Key Laboratory of Mechanical System and Vibration, 2018年11月1日 Request PDF Investigating the influence of rail grinding on stability, vibration, Additionally, the system vibration characteristics are strongly dependent on the atmospheric temperatureInvestigating the influence of rail grinding on stability, vibration 2023年5月8日 In this study, aiming at problems that the existing surface roughness prediction models fail to consider the timevarying characteristics of the rough grinding process and the difficulty in Realtime prediction of grinding surface roughness based on 2024年2月15日 In the normal direction, the relationship between the grinding force and the grinding vibration of the grinding system with large aspect ratio can be expressed by a differential equation: (10) M z ¨ + C z ̇ + K z = F n where M, C and K are the mass, damping, and stiffness matrices in the normal direction of the grinding system, respectively, and the specific Mechanical Systems and Signal Processing ScienceDirect

A chatter online prediction method and system software in high

2024年9月17日 Chatter is a selfinduced vibration that results in poor surface quality in the highspeed camshaft grinding process Accurate and timely chatter prediction is very important for chatter suppression Consequently, an online chatter prediction method and chatter software system for intelligent manufacturing are urgently required This paper proposes a novel 2013年7月1日 Highlights An active vibration control system is optimized in a centerless grinding machine A modeling procedure is developed to define piezoelectric actuator's characteristics Simulations show a good performance of the designed solution The good theoretical predictions are confirmed experimentally The application of the active control expands the chatterfree Redesign of an active system of vibration control in a centerless grinding system in different terminals conveniently and quickly, so as to satisfy the customized services of different types of users The above five levels are explained more specifically in the Journal of Manufacturing Processes ResearchGate2018年11月1日 Mechanism characteristic analysis and soft measuring method review for ball mill load based on mechanical vibration and acoustic signals in the grinding process Author links open overlay panel Jian Tang a b , Junfei Qiao a , Zhuo Liu c , Xiaojie Zhou c , Gang Yu d e , Jianjun Zhao d eMechanism characteristic analysis and soft measuring method

.jpg)

Gyratory Swing Vibration Screen JXSC Machinery

The gyratory swing vibration screen is a highprecision screening and classifying equipment with a unique multilayer grading design Skip to content JXSC Machinery Us +86 Home; This gyratory swing screen 2022年1月1日 A multilayer pooling classifier is introduced to replace the fully connected layers commonly used in traditional CNN The multilayer pooling classifier contains multiple pooling layers with different pooling scales to achieve multiple functions including local fusion of features, dimensionality reduction and fault classification, which greatly reduces the number of network MLPCCNN: A multisensor vibration signal fault ScienceDirect2024年2月15日 Stability prediction and optimization of multiregenerative weak stiffness grinding system based on microstructured tool Author links open overlay panel Qingyu Meng a, Bing Guo a, Kenan Li b, It is noteworthy that grinding mechanics, dynamics and tool wear just are the main influencing factors for grinding vibration [23]Stability prediction and optimization of multiregenerative weak 2023年1月10日 Electromechanical Coupling Dynamic and Vibration Control of Robotic Grinding System for ThinWalled WorkpieceElectromechanical Coupling Dynamic and Vibration Control of

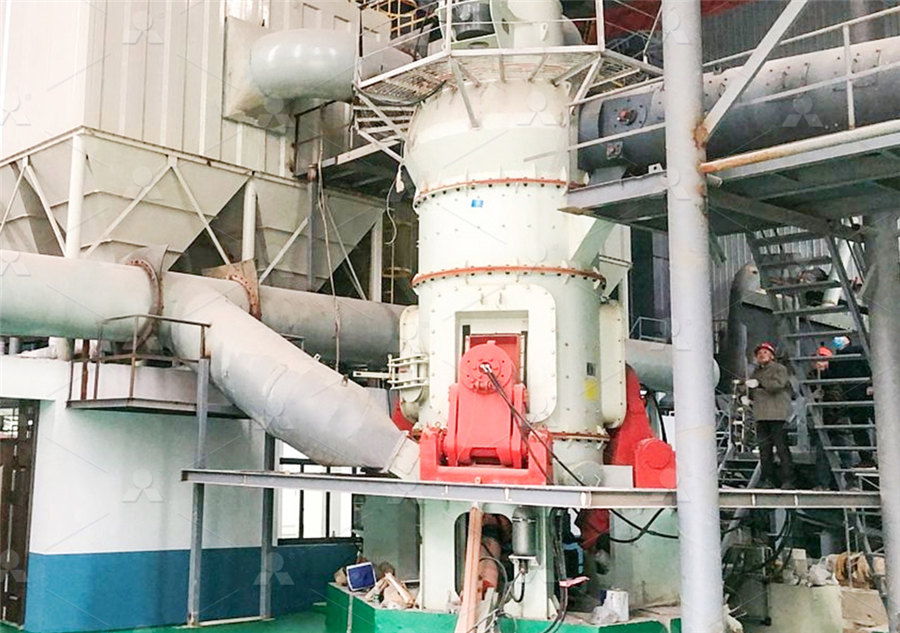

Multilayer High Frequency Vibration Fine Screen

• ZKJD multilayer high frequency vibrating fine screen can be used in the closed circuit grinding classification process of ferrous and nonferrous metal ore separation plants such as iron ore, leadzinc ore, tin ore and tungsten ore, etc, which combines with cyclone for classification so as to reach high classification efficiency, significantly reduce the mill cycle load and overgrinding 2023年8月1日 The response of soil beds reinforced with multilayer geocell systems that support machine foundations is investigated by laboratory testing that incorporates vertical machine vibrations of a square concrete foundation (400 × 400 mm) resting on soil that is unreinforced or reinforced with single, double or triple geocell layersThe tests are performed under three Vibration response of machine foundations protected by use of 2023年12月15日 Ultrasonic vibrationassisted grinding (UVAG) has attracted plenty of attention to significantly improve surface integrity However, existing research has not systematically investigated the effect of vibration directions during UVAG at atomic and nanoscales, limiting our understanding of the plastic deformation mechanisms and microstructural evolution of ultra Molecular dynamics simulations of ultrasonic vibrationassisted An oscillator circuit attached to the filter matrix propagates acoustic vibration, the inlet of the filter, reestablishing the standard system flow rate Unlike other filtration systems, flushing of the filter system is not required a rotational valve design that minimizes grinding and packing experienced by the standard ball MultiStage Filtration System T2 Portal NASA

.jpg)

Stability prediction and optimization of multiregenerative weak

2024年2月15日 Request PDF Stability prediction and optimization of multiregenerative weak stiffness grinding system based on microstructured tool Chatter is a serious problem in grinding, which will 2000年11月1日 The vibration behavior of the grinding machine spindle system is conditioned by both the vibration characteristics of the assembly components, ie shaft–bearing–housing system and the external grinding process forces While vibration characteristics of the shaft–bearing–housing components were approached by many reliable mathematical Effect of grinding forces on the vibration of grinding machine CNB CN95A CN9A CNB CN B CN B CN B CN 9 A CN9 A CN 9A CN B CN B CN B Authority CN China Prior art keywords centrifugal same structure vibration concave filter Prior art date Legal status (The Multilayer screen vibrating machine Google Patents2022年8月1日 Effect of the thickness of corresponded layers Fig 4, Fig 5, Fig 6 indicate the effect of the thickness of the Al layer, PCBM layer, PSS layer on the nonlinear dynamic response of the nanocomposite multilayer organic solar panel, respectively These figures illustrated that the deflection amplitude of the nonlinear dynamic response of the solar panel decreases when Vibration and nonlinear dynamic response of nanocomposite multilayer

Coupling of double grains enforces the grinding process in vibration

2022年6月1日 Vibrationassisted grinding is an effective method for precision machining of hard and brittle materials realized via the application of a certain frequency and amplitude to the National Natural Science Foundation of China (Grant Nos , ) and the State Key Laboratory of Mechanical System and Vibration, 2024年2月1日 At present, ELID grinding technology has played an important role in ultraprecision mirror grinding of hard and brittle materials such as optical glass, monocrystalline silicon and ceramics [11], but it still has problems such as low processing efficiency and high processing costSince the advent of ultrasonic vibration assisted grinding technology, it has been known Effect of ultrasonic vibration on oxide layer properties in Home > Products > Multilayer high frequency vibration screen Multilayer high frequency vibration screen and gathered rich experience about complicated relation of various parameters and equipment performance in grindingclassification systemHave been majoring in mining equipment technological development for more than 30 years, Multilayer high frequency vibration screen Weihai Haiwang Furthermore, researchers have also studied the influences of grinding spindle vibration on surface generation For example, Chen et al [30] established a grinding kinematicsbased mathematical model to investigate how the vibration of the wheel spindle influences surface roughness and subsurface damage during grinding of optical glass BK7, but the random grain dimension and Investigation of forced wheel spindle vibration influence on

.jpg)

Influence of the Ultrasonic Vibration on System Dynamic

2021年10月22日 Abstract With the urgent demand of highend equipment for high quality surfaces, the technique of ultrasonic vibrationassisted burnishing is introduced to strengthen the surface properties To explore the influence of the ultrasonic vibration on the dynamic response of a burnishing system, the burnishing friction force generated from a multiball surface Rotary vibrating sieve, also known as rotary vibration filter sieve, vibratory separator Rotary vibrating screen is a highprecision fine powder screening equipment It is usually suitable for screening and filtering of particles, powders, and viscous liquidsRotary Vibrating Sieve JXSC Machinery2024年2月28日 Grinding is a complex process for performing comprehensive machining, such as scratching, plowing, and cutting on the workpiece involving several discretely distributed grains on the surface of a wheel [7]The UVAG process is even more complex as it combines the application of highfrequency and smallamplitude vibrations in a tool or workpiece [8] with the Insights into scratching force in axial ultrasonic vibrationassisted Particularly, At the natural frequency of the grinding system, the amplitude of the frequency spectrum with the multifeedforward method decreases by approximately 4813 % The experimental results demonstrate that the multifeedforward method effectively enhances the material removal accuracy by suppressing vibration during robotic grindingVibration suppression of series elastic actuator used for robotic

.jpg)

Grinding wheel specification cybernetic recommendation with

2024年8月1日 Grinding wheel is a highly customized product because the wrong formula may cause the grinding process to be inefficient If inappropriate wheels are installed on the machine, they may break into pieces under highspeed rotation due to abnormal vibration, causing a huge loss in production and safety issues [2]2024年10月3日 Then, the system state equation is established by Kalman filter method based on the selfhealing mechanical model, and the full information identification of multirigidbody system is realized by Online vibration state identification of multirigidbody system 2022年6月1日 Moreover, vibrationassisted grinding can reduce the grinding force (Yang et al, 2019b), surface roughness (Zhou et al, 2019b), and subsurface damage (Baraheni and Amini, National Natural Science Foundation of China (Grant Nos , ) and the State Key Laboratory of Mechanical System and Vibration, Coupling of double grains enforces the grinding process in vibration 2018年11月1日 Request PDF Investigating the influence of rail grinding on stability, vibration, Additionally, the system vibration characteristics are strongly dependent on the atmospheric temperatureInvestigating the influence of rail grinding on stability, vibration

.jpg)

Realtime prediction of grinding surface roughness based on

2023年5月8日 In this study, aiming at problems that the existing surface roughness prediction models fail to consider the timevarying characteristics of the rough grinding process and the difficulty in 2024年2月15日 In the normal direction, the relationship between the grinding force and the grinding vibration of the grinding system with large aspect ratio can be expressed by a differential equation: (10) M z ¨ + C z ̇ + K z = F n where M, C and K are the mass, damping, and stiffness matrices in the normal direction of the grinding system, respectively, and the specific Mechanical Systems and Signal Processing ScienceDirect2024年9月17日 Chatter is a selfinduced vibration that results in poor surface quality in the highspeed camshaft grinding process Accurate and timely chatter prediction is very important for chatter suppression Consequently, an online chatter prediction method and chatter software system for intelligent manufacturing are urgently required This paper proposes a novel A chatter online prediction method and system software in high 2013年7月1日 Highlights An active vibration control system is optimized in a centerless grinding machine A modeling procedure is developed to define piezoelectric actuator's characteristics Simulations show a good performance of the designed solution The good theoretical predictions are confirmed experimentally The application of the active control expands the chatterfree Redesign of an active system of vibration control in a centerless

.jpg)

Journal of Manufacturing Processes ResearchGate

grinding system in different terminals conveniently and quickly, so as to satisfy the customized services of different types of users The above five levels are explained more specifically in the 2018年11月1日 Mechanism characteristic analysis and soft measuring method review for ball mill load based on mechanical vibration and acoustic signals in the grinding process Author links open overlay panel Jian Tang a b , Junfei Qiao a , Zhuo Liu c , Xiaojie Zhou c , Gang Yu d e , Jianjun Zhao d eMechanism characteristic analysis and soft measuring method