How to evaluate the results of the calcium carbonate grinding system

The effects on the grinding parameters of chemical, morphological

2022年1月1日 Firstly, the Bond and Hardgrove grindability tests were performed Secondly, kinetic breakage parameters (Si aT, α, γ, β, and ϕj) were determined from product size The Hosokawa Alpine ATR system in a circuit with a highperformance air classifier is the ultimate energysaving solution for the generation of ultrafine GCC fillers in the fineness range of d 97 CALCIUM CARBONATE (GCC) Hosokawa AlpineThe purpose of this study was to promote the efficiency of the grinding of heavy calcium carbonate in a bead mill by reducing the specific energy and miniaturizing the grinding Evaluation of Grinding Characteristics of Calcium Carbonate by 2015年3月1日 The dependence of the pressure filtration properties of ground calcium carbonate slurries on the grinding results obtained by a stirred media mill was investigated in the study Wet grinding of CaCO3 with a stirred media mill: Influence of

Calcium Carbonate Grinding Union Process

Our technicians excel in determining the correct grinding equipment needed to achieve your desired results For help determining which Attritor grinder is best for your calcium carbonate 2023年6月25日 How to optimize calcium carbonate grinding efficiency? Optimizing your calcium carbonate grinding process improves your product quality, increases production efficiency, and Guide to Calcium Carbonate Grinding: Mills, Tips, and UsesTo develop an enhanced understanding of flow patterns inside stirred media mills and compliment PEPT findings, highspeed imaging was utilised to observe grinding media Although only the Understanding the fine grinding of calcium carbonate2021年12月1日 Results of the grinding experiments revealed logarithmic relations between the weight percentage of fine particles and SEC Power‐low functions were established between (PDF) Effect of the neutralization of the grinding aid in the

(PDF) Effects of Grinding Aids Used in Grinding Calcium Carbonate

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the 2024年3月26日 Calcium carbonate is an important industrial raw material with a wide range of applications With the development of economy, the demand for calcium carbonate will continue to grow Therefore, the establishment of a How to set up a calcium carbonate ultrafine grinding 2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or Effects of Grinding Aids Used in Grinding Calcium 2022年7月1日 In this study, two natural fillers, calcium carbonate (CaCO3) and gypsum (CaSO4H2O), were added to unsaturated polyester resin (UP) to enhance its mechanical and thermal propertiesThe Effects of Calcium Carbonate Filler on HDPE Pipe

How to Choose a Grinding Mill When Grinding Calcium Carbonate

2023年6月19日 Calcium carbonate can be used as a calcium supplement: the absorption rate can reach 39%, second only to calcium fruit acid soluble in stomach acid, has become the most dosage form, the most used calcium supplement For grinding calcium carbonate, we recommend that you choose the HGM series ultrafine grinding mill Capacity: 05~45 t/h2021年11月16日 Microbialinduced calcium carbonate precipitation Urea hydrolysis to carbonic acid takes 18 h to be achieved, while the reaction between carbonic acid and calcium ions occurs instantaneously for Evaluation of the Effectiveness of a Soil Treatment Using Calcium 2015年7月1日 It is shown that calcium carbonate has an accelerating effect on C3S and cement hydration and leads to the precipitation of some calcium carbosilicate hydrate View Show abstract(PDF) Effect of Calcium Carbonate Replacement on Workability and 2022年7月1日 This increase could suggest a decrease in degradation kinetics thus showing a protective effect of calcium carbonate Calcium carbonate nanoparticles, in fact, probably because of their hydrophobic coating, make the polymer surface less susceptible to bacterial degradation This effect is more pronounced in the composite with 5% of calcium Influence of Calcium Carbonate Nanoparticles on the Soil Burial

How to Choose a Calcium Carbonate Grinding Mill DASWELL

2022年8月13日 The grinding mill is the core of the entire production line The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions2011年9月30日 These results have important implications for the bacterial conservation of ornamental stones other than carbonate stones and demonstrate that the chemical/crystallographic affinity between the substrate and the bacterial biomineral (ie, the existence or absence of epitaxy) is important in controlling both calcium carbonate polymorph Influence of Substrate Mineralogy on Bacterial Mineralization of 2021年9月14日 Over a wide range of industries, different functions require different particle size distributions of ground calcium carbonate powders That is the reason why particle sizing is a vital step for (PDF) Measuring the Particle Size Distribution of Calcium Carbonate 2021年2月2日 1 Introduction Ordinary portland cement (OPC) production accounts for about 7% of global CO 2 emission, predominantly by the heat treatments involved (∼1600 °C) and decomposition of limestone and clay 1 Other raw materials are fed into hightemperature kilns for various applications Examples are conventional construction bricks that are manufactured by Cold Sintering of Calcium Carbonate for Construction Material

.jpg)

The efficiency of grinding aids in the production of a biofilling

2023年11月10日 Calcium in eggshells is also regarded as the best natural source of calcium [7] The eggshell composition contains 94% calcite (CaCO 3), 1% magnesium carbonate, 1% calcium phosphate, and 4% organic material [8], [9]Waste eggshells can also be used as a substitute for calcium carbonate (CaCO 3)It is possible to divide waste materials into two groups: industrial 2020年1月1日 While thermogravimetry in air was found to be useful for determing inorganic carbonates (Schnitzer et al, 1959), quantitative results for total carbonates as well as an accurate partitioning into Analyzation of Calcium Carbonate (CaCO3) in Eggshells and The viscosity of calcium carbonate suspension depends on the volume percentage or weight percentage The dispersing agent increases the solid concentration for a given particle fineness Keywords: fillers, calcium carbonate, ultrafine grinding, surface modifications, Mechanochemical activation, polymers 1Influence of polymers on the grinding and rheology of ultrafine 2021年12月1日 The most commonly used additive in wet grinding of calcium carbonate is a low‐PDI sodium polyacrylate with an optimized molecular weight A similar polyacrylate was tested under different Na (PDF) Effect of the neutralization of the grinding aid in the

.jpg)

Biomineralisation by earthworms – an investigation into the

2015年4月28日 Background Approximately 20% of all biominerals are amorphous [] and many of the crystalline ones form through amorphous precursors [24]The most common amorphous phases are silica and amorphous calcium phosphate, but amorphous calcium carbonate (ACC) is increasingly being detected on the basis of its infrared or Raman characteristics, the lack of 2021年2月2日 Recently, new type of papermaking fillers known as the hybrid calcium carbonate (HCC) and the posthybrid calcium carbonate (pHCC) were introduced 10−12 During the preparation of HCC and pHCC, ground calcium carbonate (GCC) was preflocculated with calcium oxide (HCC) and without calcium oxide (pHCC) using ionic polymers to construct soft flocs, Application of In Situ Calcium Carbonate Process for Producing 2020年12月28日 The calcium carbonate (CaCO3) precipitation potential (CCPP) can predict the potential for corrosion and lime scaling in drinking water systems(PDF) Procedure for Calculating the Calcium Carbonate Precipitation calcium carbonate with size of about 15μm, and with the grinding time increased, the size of the particles decreased However, its size remained even reversed when decreased to a certain degreeExperimental Study on Superfine Grind Process for the Preparation

Ultrasonicassisted production of precipitated calcium carbonate

2020年12月30日 This study aimed to investigate the effect of ultrasonic application on the production of precipitated calcium carbonate (PCC) particles from desulfurization gypsum via direct mineral carbonation method using conventional and venturi tube reactors in the presence of different alkali sources (NaOH, KOH and NH 4 OH) The venturi tube was designed to Investigate the factors, which affects how quickly Calcium carbonate reacts with hydrochloric acid Rate of Reactions Aim The aim of this experiment is to find out how different variables affect the rate at which the reaction between Marble chips (CaCO 3) and Hydrochloric acid (HCl) takes placeThere are many variables that affect the rate of this reaction such as the following:Investigate the factors, which affects how quickly Calcium carbonate Calcium carbonate is a solid that turns Hydrochloric acid translucent when reacted together but it is expected to turn cloudy bubble The time taken for a certain amount of calcium carbonate to disappear can indicate the rate of Investigating the rate of reaction between hydrochloric 2022年10月10日 Introduction According to US Energy Information Administration, the pulp and paper is considered to be one of the energyintensive industries, accounting for approximately 5% of the total industrial sector energy consumption 1 Even though energy consumption includes all the paperrelated sectors such as printing industry, energy savings in papermaking still should Effect of Calendering on the Properties of Paper Containing

How to choose a suitable calcium carbonate grinding mill?

2024年9月14日 Understanding Calcium Carbonate Grinding Mills Calcium carbonate grinding mills are vital in many industries These include construction, agriculture, and pharmaceuticals These mills efficiently reduce calcium carbonate particles to meet various application needs Calcium carbonate is a natural mineral2012年1月1日 Download Citation Study on the Performance of Nano Calcium Carbonate Modified Asphalt Concrete AC13 To make nano calcium carbonate as the modifier, firstly the best proportion of nano calcium Study on the Performance of Nano Calcium Carbonate2021年6月1日 In this paper, the wet extractive grinding method for efficient recovery of calcium from steelmaking slags was studied This work supports the Sustainable Development Goal of UN, SDG12 Detailed Performance Analysis of the Wet Extractive Grinding 2020年10月1日 This paper is part of the continued effort to understand calcium carbonate formation and mitigation related to oilfield operations The paper describes the application of a new method, based on laser refraction measurement in transferring the signals to current, to determine the formation of calcium carbonate scale in high calcium brinesInline technique to evaluate the performance of scale inhibitors

Experimental Study on Superfine Grind Process for the Preparation

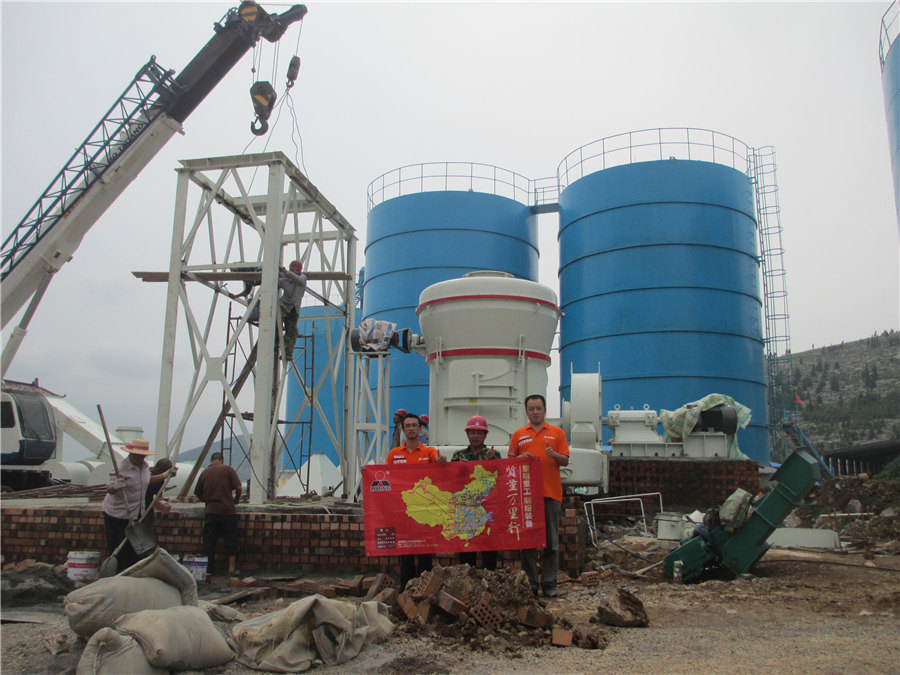

2015年12月31日 The results showed that the vibrated mill could grind analytically pure calcium carbonate with size of about 15 μm, and with the grinding time increased, the size of the particles decreased2021年11月16日 While you are producing calcium carbonate, you should use a properly designed grinding to help you using this process This really is machinery that may be specifically created for the crushing andHow To Use Calcium Carbonate Grinding Mill2019年6月7日 Calcium carbonate scale is formed during oil and gas production Tubeblocking tests (TBTs) are used to define the minimum inhibitory concentration (MIC) in order to prevent scale adhesion in the petroleum production system equipment However, nonadhered crystals may favor heterogeneous nucleation to other deposits such as calcium naphthenates, causing Evaluation of Calcium Carbonate Inhibitors Using Sintered Metal 2024年3月26日 Calcium carbonate is an important industrial raw material with a wide range of applications With the development of economy, the demand for calcium carbonate will continue to grow Therefore, the establishment of a How to set up a calcium carbonate ultrafine grinding

36.jpg)

Effects of Grinding Aids Used in Grinding Calcium

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or 2022年7月1日 In this study, two natural fillers, calcium carbonate (CaCO3) and gypsum (CaSO4H2O), were added to unsaturated polyester resin (UP) to enhance its mechanical and thermal propertiesThe Effects of Calcium Carbonate Filler on HDPE Pipe2023年6月19日 Calcium carbonate can be used as a calcium supplement: the absorption rate can reach 39%, second only to calcium fruit acid soluble in stomach acid, has become the most dosage form, the most used calcium supplement For grinding calcium carbonate, we recommend that you choose the HGM series ultrafine grinding mill Capacity: 05~45 t/hHow to Choose a Grinding Mill When Grinding Calcium Carbonate 2021年11月16日 Microbialinduced calcium carbonate precipitation Urea hydrolysis to carbonic acid takes 18 h to be achieved, while the reaction between carbonic acid and calcium ions occurs instantaneously for Evaluation of the Effectiveness of a Soil Treatment Using Calcium

(PDF) Effect of Calcium Carbonate Replacement on Workability and

2015年7月1日 It is shown that calcium carbonate has an accelerating effect on C3S and cement hydration and leads to the precipitation of some calcium carbosilicate hydrate View Show abstract2022年7月1日 This increase could suggest a decrease in degradation kinetics thus showing a protective effect of calcium carbonate Calcium carbonate nanoparticles, in fact, probably because of their hydrophobic coating, make the polymer surface less susceptible to bacterial degradation This effect is more pronounced in the composite with 5% of calcium Influence of Calcium Carbonate Nanoparticles on the Soil Burial 2022年8月13日 The grinding mill is the core of the entire production line The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestionsHow to Choose a Calcium Carbonate Grinding Mill DASWELL2011年9月30日 These results have important implications for the bacterial conservation of ornamental stones other than carbonate stones and demonstrate that the chemical/crystallographic affinity between the substrate and the bacterial biomineral (ie, the existence or absence of epitaxy) is important in controlling both calcium carbonate polymorph Influence of Substrate Mineralogy on Bacterial Mineralization of

.jpg)

(PDF) Measuring the Particle Size Distribution of Calcium Carbonate

2021年9月14日 Over a wide range of industries, different functions require different particle size distributions of ground calcium carbonate powders That is the reason why particle sizing is a vital step for