Gypsum powder production process

Gypsum Powder Manufacturing Gypsum Powder

Gypsum powdermaking process According to the process requirements, the construction gypsum production line is usually divided into five parts, including crushing system, storage conveying system, grinding system, calcining The document provides details on each step of the mining, processing, and packaging of gypsum powder This document describes the production process and technology selection for gypsum Gypsum Powder Technical PDF Scribd2024年11月5日 Gypsum powder manufacturing is a comprehensive process that harmonizes mining, processing, and quality assurance By understanding each stage of production and Essential Guide to Gypsum Powder Manufacturing ProcessThe different types of gypsum powder production methods include various processes to create gypsum powder with different properties One method involves heating the dihydrate gypsum Gypsum Powder Production Methods Al Ahli Trading Co

.jpg)

Gypsum Manufacturing Process Gypsum Processing Equipment

2023年11月13日 The gypsum manufacturing process can be tailored to produce various types of gypsum products with specific properties For instance, different additives and production 2024年9月28日 The HGM micro powder grinding mill is an ideal choice for gypsum powder manufacturing, offering efficient, highquality production while addressing modern industrial Gypsum Powder Manufacturing Process Using HGM Micro Powder The invention mainly comprises the following steps: heating the dihydrate gypsum raw material to 110500 ℃ by microwave irradiation, and stirfrying for 5240 minutes to obtain a product A; CNB Production process method of gypsum powder Production processes Gypsum processing plants vary widely in scale and level of technology They range from plants producing one or two tonnes per day using lowcost manual Gypsum processing and use Humanitarian Library

Gypsum Products Springer

Gypsum plaster manufacturing process as well as the main properties of gypsum and gypsum products (fire, acoustic, thermal, and other properties) are described Gypsum products and 2020年4月22日 in this video we visit in the gypsum factory and showing process of gypsum powderHow to make Gypsum powder YouTubeGypsum Board production flow "Tiger Board" is produced in the factory automated production line Let's see the manufacturing process Molding process Calcined “gypsum” is mixed with water to make a slurry (muddy Gypsum Board production flow2024年9月19日 Lastly, the demand for gypsum in construction, agriculture, and other industries has driven the establishment of mining operations and production facilities in many countries It further enhances the availability of gypsum as Gypsum: Building Uses, Attributes, Price and Design

Five Stages of Gypsum Production Process PermuTrade

Gypsum is an extremely useful mineral that occurs naturally in nature Formed between layers of sedimentary rocks, it is a soft (so easy to scratch), chalky rock that appears almost white The impurities embedded in gypsum may give it gray to a yellowish color The post Five Stages of Gypsum Production Process appeared first on PermuTradeprocess, product quality control is ensured through computerized process control systems, visual inspection and frequent lab testing throughout the day Capacity: 2 to 30 Million Sq Mtr / Annum Size: Length – 2400 to 3600mm / Width – 900 toTypical Process of Manufacturing Gypsum Board2024年9月26日 2 Ultrafine mill Get the Latest Price As an advanced grinding mill combining crushing, grading, and static pressure, the ultrafine mill excels in both fineness and environmental performance It is mainly used to produce ultrafine gypsum powder or micronlevel particles, and is widely used in industries requiring highfineness powders, such as chemicals, coatings, and Upgrade Your Process: 3 Best Gypsum Powder Mills2019年5月21日 After the calcining progress, the qualified powder will flow out to the No3 bucket elevator By the lifting, the powder is transported into the final powder silo After the temperature decrease down, the calcined gypsum powder is packed into 25kg or 1 tons jumbo bagsThe boiling furnace for gypsum industry, gypsum powder production

How To Set Up a Gypsum Powder Production Line From Scratch

2023年11月2日 Setting up a gypsum powder production line requires careful planning and a good understanding of the overall process How To Set Up a Gypsum Powder Production Line From Scratch Gypsum powder is widely used in the construction industry for making drywall, plaster, and other building materials2015年4月28日 1 Gypsum Powder Production Line 1)Advanced technology 2)Lower cost 3)According customer request design Gypsum Powder Production Line process Materials: : Content of CaSO42H2O in gypsum mine >80% The grade of mine and the crystal configuration will influence the quality of semihydrated gypsum Fuel for Production: Natural Gas, Oil or Gypsum powder production line,Gypsum powder process line 2024年6月21日 Industrial byproduct gypsum is a solid waste produced in industrial production process Hansen et al [14] studied the effect of using 0–20 % recycled gypsum powder, derived from waste dry wall, as a cementitious material activator in Recycling, reusing and environmental safety of industrial byproduct 2024年11月5日 Gypsum powder, known for its versatile applications in construction and agriculture, is derived from gypsum, a naturally occurring mineral The manufacturing process of gypsum powder is a meticulous operation that requires an understanding of various stages, from the initial extraction to the final productionEssential Guide to Gypsum Powder Manufacturing Process

Gypsum processing and use Humanitarian Library

More recently byproduct gypsum is also available from flue gas desulphurisation; a process for cleaning up emissions from chimneys to reduce the quantity of sulphurous gases flowing into the atmosphere Dehydration: Rock into plaster Gypsum rock is converted into gypsum plaster by driving off some of the chemically combined waterASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fedMaking Gypsum Board Gypsum Association2021年6月15日 The main technology used in this process is the use of a fluid bed furnace to provide a heat source, which can greatly reduce coal consumption and make the most of the heat The daily output is 1001000 tons, which is the ideal equipment today industrial gypsum calcination process Production Process of Gypsum Powder Production LineHow Does The Gypsum Powder Production Line work?CLIRIKGypsum FGD PROCESS SELECTION Individual utilities are selecting FGD processes based on a number of criteria including: •SO2 removal efficiencies—generally 9295% plus •Availability of resources/reagents—ie water, limestone, lime •Byproduct handling requirements—storage/disposal availability •Marketability of byproduct •Cost •Cost •Cost!What is FGD Gypsum US EPA

.jpg)

500 Tons Per Day Gypsum Powder Production Machine

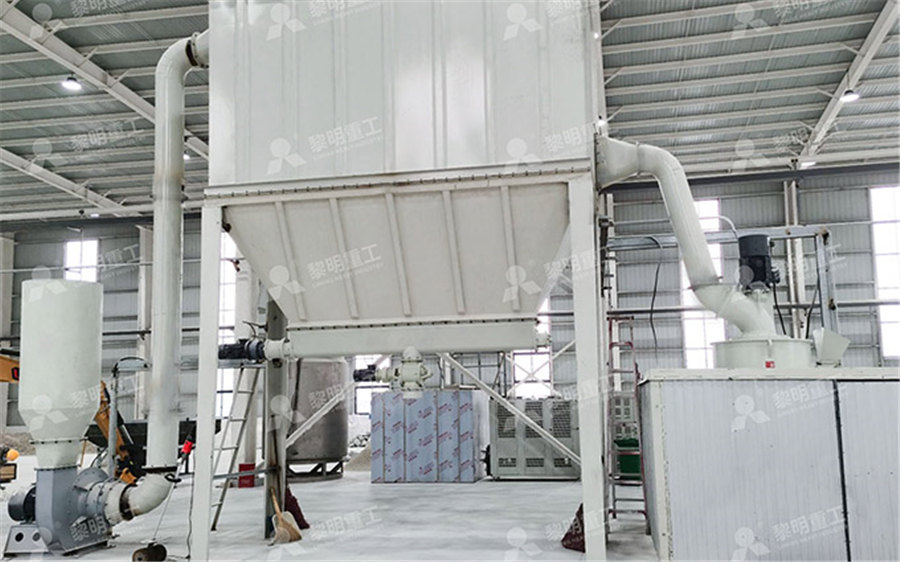

Production Process of gypsum powder Crushing System The crushing system can crush large ore from mine mining to an average granularity of 25 mm by one time, is an ideal version of traditional ways of two and three stage crushing Milling System2024年9月17日 Gypsum powder, a versatile and widely used material, is derived from the mineral gypsum, which is primarily composed of calcium sulfate dihydrate (CaSO₄2H₂O) This naturally occurring mineral has been utilized for various applications throughout history, particularly in construction, agriculture, and industry This article explores the properties of What is Gypsum powder? TechoffersBDThis stone is translucent in nature It consists of around 30% of bounded water in natural state This water is taken out from it through continuous heating till its white powder form is obtained Figure: Gypsum Production Layout Process of Gypsum Production The production of gypsum can be mentioned in following stages: Excavation; Crushing Gypsum Products and Properties as a Building Material for Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery

.jpg)

AAC Blocks Manufacturing Process – An Ultimate Guide

The process involves mixing the raw materials, including sand or fly ash, cement, lime, gypsum, aluminum powder, and water, in the correct proportions to produce a slurry that will form the basis of the AAC blocks Now we will discuss the mixing process of AAC block manufacturing 1) Measuring the Raw MaterialsOur test and process development centre in the Netherlands offers unique possibilities for testing your product to determine the most efficient process, system or plant prior to final design We can provide laboratorylevel as well as productionsized trials Whether you wish to test a single machine or a complete powder processing system, the same skilled and experienced staff are Process Systems for Gypsum Powder Hosokawa MicronGypsum Powder Machinery Gypsum Powder Production Line, Production Process: Multiple processes are taken in production of the plant First, gypsum ores are being crushed, conveyed and stored into raw material bin, and then Gypsum Powder Machinery Gypsum Powder The invention discloses a production process method of gypsum powder with various strength properties The invention mainly comprises the following steps: heating the dihydrate gypsum raw material to 110500 ℃ by microwave irradiation, and stirfrying for 5240 minutes to obtain a product A; mixing the product A with an additive, feeding the mixture into a closed reactor, CNB Production process method of gypsum powder

.jpg)

Gypsum Powder Production in Ethiopia

Gypsum, a mineral widely used in various industries, is processed into powder form for applications such as construction materials, cement production, agriculture, and more Gypsum Powder Manufacturing Process The process of gypsum production in Ethiopia involves several stages: 1 Mining: Gypsum deposits are identified through geological Finally, qualified gypsum powder is collected through a dust collector to complete the entire production process The gypsum powder production line can not only process gypsum but also process ultrafine powder of nonflammable and explosive brittle materials with medium and low hardness, Mohs hardness ≤ 6, such as calcite, dolomite, carbon Gypsum powder production line Baichy Heavy IndustryGypsum Products Contents 81 Introduction – 196 82 Denitions – 198 83 Raw Materials – 199 831 Natural Gypsum – 199 832 Synthetic Gypsum – 201 84 Calcined Gypsum Manufacturing Process – 203 85 Properties of Gypsum – 205 851 Fire Properties – 206 852 Acoustic Properties – 207 853 Thermal Properties – 208Gypsum Products SpringerGYPSUM POWDER PRODUCTION LINE Processing capacity: 50,000300,000 tons/year Processing materials: phosphogypsum, desulfurized gypsum, industrial byproduct gypsum Process method: onestep method, twostep method We have complete set of process technology and core equipment R D and manufacturing technology, Gypsum Disposal Gypsum Grinding Gypsum Calcination Gypsum Powder

.jpg)

The Most Valuable Things You Need to Know about Gypsum

2023年4月23日 The production process of gypsum powder The gypsum powder production line is usually divided into gypsum mining, crushing, grinding, and calcination processes according to technical requirementsThis is an onsite video of a gypsum production line and shows the entire process of gypsum powder 1 Gypsum mining process The gypsum is typically extracted Overall, the production process involves crushing, grinding, classifying, and calcining the raw gypsum to produce the final gypsum powder Different Types of Methods The different types of gypsum powder production methods include various processes to create gypsum powder with different propertiesGypsum Powder Production Methods Al Ahli Trading CoGypsum powder is one of the five major gel materials and occupies an important position in the national economy The gypsum powder production line is to calcinate natural dihydrate gypsum ore (raw gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) at a certain temperatureGypsum Plaster Manufacturing Process Gongyi Jingying 2020年4月22日 in this video we visit in the gypsum factory and showing process of gypsum powderHow to make Gypsum powder YouTube

.jpg)

Gypsum Board production flow

Gypsum Board production flow "Tiger Board" is produced in the factory automated production line Let's see the manufacturing process Molding process Calcined “gypsum” is mixed with water to make a slurry (muddy 2024年9月19日 Lastly, the demand for gypsum in construction, agriculture, and other industries has driven the establishment of mining operations and production facilities in many countries It further enhances the availability of gypsum as Gypsum: Building Uses, Attributes, Price and Design Gypsum is an extremely useful mineral that occurs naturally in nature Formed between layers of sedimentary rocks, it is a soft (so easy to scratch), chalky rock that appears almost white The impurities embedded in gypsum may give it gray to a yellowish color The post Five Stages of Gypsum Production Process appeared first on PermuTradeFive Stages of Gypsum Production Process PermuTradeprocess, product quality control is ensured through computerized process control systems, visual inspection and frequent lab testing throughout the day Capacity: 2 to 30 Million Sq Mtr / Annum Size: Length – 2400 to 3600mm / Width – 900 toTypical Process of Manufacturing Gypsum Board

Upgrade Your Process: 3 Best Gypsum Powder Mills

2024年9月26日 2 Ultrafine mill Get the Latest Price As an advanced grinding mill combining crushing, grading, and static pressure, the ultrafine mill excels in both fineness and environmental performance It is mainly used to produce ultrafine gypsum powder or micronlevel particles, and is widely used in industries requiring highfineness powders, such as chemicals, coatings, and 2019年5月21日 After the calcining progress, the qualified powder will flow out to the No3 bucket elevator By the lifting, the powder is transported into the final powder silo After the temperature decrease down, the calcined gypsum powder is packed into 25kg or 1 tons jumbo bagsThe boiling furnace for gypsum industry, gypsum powder production 2023年11月2日 Setting up a gypsum powder production line requires careful planning and a good understanding of the overall process How To Set Up a Gypsum Powder Production Line From Scratch Gypsum powder is widely used in the construction industry for making drywall, plaster, and other building materialsHow To Set Up a Gypsum Powder Production Line From Scratch2015年4月28日 1 Gypsum Powder Production Line 1)Advanced technology 2)Lower cost 3)According customer request design Gypsum Powder Production Line process Materials: : Content of CaSO42H2O in gypsum mine >80% The grade of mine and the crystal configuration will influence the quality of semihydrated gypsum Fuel for Production: Natural Gas, Oil or Gypsum powder production line,Gypsum powder process line

.jpg)

Recycling, reusing and environmental safety of industrial byproduct

2024年6月21日 Industrial byproduct gypsum is a solid waste produced in industrial production process Hansen et al [14] studied the effect of using 0–20 % recycled gypsum powder, derived from waste dry wall, as a cementitious material activator in